Sterilization Methods and Apparatus which Employ Additive-Containing Supercritical Carbon Dioxide Sterilant

Sterilization Methods and Apparatus which Employ Additive-Containing Supercritical Carbon Dioxide Sterilant

US7108832

Company:

Year:

Abstract:

Sterilization methods and apparatus are effective to achieve a 6-log reduction in CFUs of industry standard bacteria and bacterial spores, i.e., B. stearothermophilus and B. subtilis spores, by subjecting sterilizable materials to a chemical additive-containing carbon dioxide sterilant fluid at or near its supercritical pressure and temperature conditions. Most preferably, the chemical additive-containing supercritical carbon dioxide sterilant fluid is agitated during sterilization, e.g., via mechanical agitation or via pressure cycling.

Type of document:

Language:

United States Patent

US007l08832B2

(12) (10) Patent No.: US 7,108,832 B2

Christensen et al. (45) Date of Patent: Sep. 19, 2006

(54) STERIALIZATION METHODS AND 5,851,483 A * 12/1998 Nicolle et al. .............. .. 422/28

APPARATUS WHICH EMPLOY 5,996,155 A * 12/1999 Chao et al. .................. .. 8/158

é§3E(§;7E];€(()’§}]T)1EI§ITPl::(l}{ISIJIi1;1E]13CRITICAL 6,149,864 A 11/2000 Dillow et al.

6,518,307 B1* 2/2003 McKenzie et al. ........ .. 514/557

(75) Inventors: Timothy Wayne Christensen, Ithaca, 6’613’278 B1 9/2003 Mills et 31'

NY (US); David Carroll Burns, Ithaca, 6,716,457 B1 * 4/2004 Eagles et al. ............. .. 424/616

NY (US); Angela Lydia White, 2003/0072677 A1 4/2003 Kafesjian et al.

Truxton, NY (US); Bruce Ganem, 2004/0033269 A1* 2/2004 Hei et al. ................. .. 424/616

Ithaca, NY (US);Anth0I1y Rome)’ 2004/0120852 A1 6/2004 Karmo

Eisenhut, Lansing, NY (US)

(73) Assignee: NoVaSterilis Inc., Ithaca, NY (US)

OTHER PUBLICATIONS

( * ) Notice: Subject to any disclaimer, the term of this

patent is extended Or adjusted under 35 Holyoak et al, “Toxic effects of ethylene oxide residuals on bovine

U.S,C, 154(b) by 0 days, embryos in vitro”, TOXICOLOGY, 108, 1996, pp. 33-38.

Cornu et al, “Effect of Freeze-Drying and Gamma Irradiation on the

(21) Appl. No.: 10/869,052 Mechanical Properties of Human Cancellous Bone”, Journal of

Orthopaedic Research, vol. 18, No. 3, 2000, pp. 426-431.

(22) Filed J“n- 17: 2004 Spilimberrgo et al, “Microbial inactivation by high-pressure”, Jour-

nal of Supercritical Fluids, 22, 2002, pp. 55-63.

(65) Prlor Pubhcatlon Data Akkus et al, “Fracture resistance of gamma radiation sterilized

Us 2005/0025667 A1 Feb. 3, 2005 :((;i(t11caIl)pb(;I;e7_gl3l:grafts”, Journal of Orthopaedic Research, 19,

Related U.S. Application Data (Continued)

(60) :’go\éi(s)i0o3nal application No. 60/480,410, filed on Jun. Primary Examl.neriKI_iSanne Jastrzab

’ ' (74) Attorney, Agent, or F irm—Welsh & Flaxman LLC

(51) Int. Cl.

A61L 2/00 (2006.01) (57) ABSTRACT

(52) U.S. Cl. .......................... .. 422/28; 422/28; 422/31;

_ _ 22/33; 422/119; 422/297; 516/9 Sterilization methods and apparatus are effective to achieve

(58) Field of Classification Search .................. .. 134/1; a 6_10g reductionin CFUS Ofindustry Standard bacteria and

204/15715’ 1582; 422/42:2’ bacterial spores, i.e., B. stearothermophilus and B. subtilis

S 1. . fil f 1 h h. ’ spores, by subjecting sterilizable materials to a chemical

ee app lcanon e or Comp ete Seam lstory‘ additive-containing carbon dioxide sterilant fluid at or near

(56) References Cited its supercritical pressure and temperature conditions. Most

U.S. PATENT DOCUMENTS

4,944,837 A * 7/1990 Nishikawa et al. ......... .. 216/41

5,213,619 A * 5/1993 Jackson et al. . . . . . . . . .. 134/1

5,370,740 A * 12/1994 Chao et al. .................. .. 134/1

preferably, the chemical additive-containing supercritical

carbon dioxide sterilant fluid is agitated during sterilization,

e.g., via mechanical agitation or via pressure cycling.

9 Claims, 2 Drawing Sheets

- H

PFESSUFB

VESSEI

US 7,108,832 B2

Page 2

OTHER PUBLICATIONS

Jahan et al, “Long-Term Effects of Gamma-Sterialization on Deg-

radation of Implant Materials”, Appl. Radiat. Isot., Vol. 46, No. 6/7,

1995, pp. 637-638.

Ikarashi et al, “Cytotoxicity of medical materials sterilized with

Vapour-phase hydrogen peroxide”, BIOMATERIALS, Vol. 16, No.

3, 1995, pp. 177-183.

Duffy et al, “An Epidemic of Corneal Destruction Caused by

Plasma Gas Sterilization”, Arch. Ophthalmol., Vol. 118, Sep. 2000,

pp. 1167-1176.

Godette et al, “Biomechanical Effects of Gamma Irradiation on

Fresh Frozen Allografts in Vivo”, ORTHOPEDICS, Vol. 19, No. 8,

Aug. 1996, pp. 649-653.

Schiewe et al, “Toxicity Potential of Absorbed-Retained Ethylene

Oxide Residues in Culture Dishes on Embryo Development in

Vitro”, Journal of Animal Science, Vol. 60, No. 6, 1985, pp.

1610-1618.

Windebar1k et al, “Residual Ethylene Oxide in Hollow Fiber

Hemodialysis Units Is Neurotoxic in Vitro”, Annals of Neurology,

Vol. 26, No. 1, Jul. 1989, pp. 63-68.

* cited by examiner

N ma

E

U.S. Patent Sep. 19,2006 Sheet 1 of2 US 7,108,832 B2

3

_$8>

mm

8 8

o>_m>

R 3

_ wa

smaaeoo

__<

E

_%=__>o

N8

@

S

U.S. Patent Sep. 19,2006 Sheet 2 of2 US 7,108,832 B2

6

U) 5

E

C.)

.5

.5 4

*5’

§

‘E. 3

.4 Regression

2 "" “ 95% CI

20 30 40 50 60

Time; Minutes

Fig. 3

US 7,108,832 B2

1

STERIALIZATION METHODS AND

APPARATUS WHICH EMPLOY

ADDITIVE-CONTAINING SUPERCRITICAL

CARBON DIOXIDE STERILANT

CROSS REFERENCE TO RELATED

APPLICATION

This application is based on, and claims domestic priority

benefits under 35 U.S.C. §119(e) from, Provisional Appli-

cation No. 60/480,410, filed Jun. 23, 2003, the entire content

of which is hereby incorporated by reference.

FIELD OF THE INVENTION

The present invention relates generally to sterilization

methods and apparatus in which supercritical carbon dioxide

is employed as a sterilization fluid. In especially preferred

embodiments, the present invention relates to methods and

apparatus in which the eflicacy of the supercritical carbon

dioxide is enhanced by certain chemical additives.

BACKGROUND OF THE INVENTION

A need has developed in the tissue implantation or trans-

plantation, biomedical polymers, medical equipment, and

drug delivery industries for a gentle and reliable sterilization

method that results in greater than 106 log reductions of

microbial and viral contaminants without impacting the

properties of the material being sterilized. Indeed many new

medical advances carmot be implemented because the ster-

ilization industry is unable to provide a suitable sterilant as

part of the manufacturing process.

In the case of polymers, gamma irradiation has been

shown to compromise the mechanical properties.1 Further-

more, steam sterilization is incompatible with thermally or

hydrolytically labile polymers. Ethylene oxide, a common

and widely used sterilant, is toxic, mutagemc, and a carci-

nogenic substance that can react with some polymers, and

also requires prolonged periods of outgassing.

llahan et al, “Long-term effects of gamma-sterilization on degradation of

implant materials.” Applied Radiation and Isolopes: Including Dala, Inslru-

menzarion and Mezhods For Use in Agricullure, Induslry and Medicine

46(6—7): 637—8 (1995), incorporated expressly hereinto by reference.

Biological tissues, including macromolecular biopoly-

mers, are also incompatible with steam. Gamma radiation

results in a significant decrease in tissue integrity and bone

strength.2 Certain antibacterial washes have been used to

disinfect tissue, but incomplete sterilization is achieved and

the washes leave residual toxic contaminants in the tissues.3

Ethylene oxide also reacts with biological tissue and is thus

an undesirable sterilant for such reason.

2 Comu et al, “Eflect of freeze-drying and gamma irradiation on the

mechanical properties of human caucellous bone”, Joumal of Orthopaedic

Research, 18(3), p. 426-31 (2000); and Akkus et al, “Fracture resistance of

gamma radiation sterilized cortical bone allografts.” Journal of Orlhopaedic

Research: Ofiicial Publicalion of lhe Orlhopaedic Research Sociely 19(5):

927—34 (2001), the entire content of each incorporated expressly hereinto by

reference.

3Holyoak et al, “Toxic effects of ethylene oxide residues on bovine embryos

in vitro”, Toxicology, 108(1—2, p. 33—8 (1996), the entire content of each

incorporated hereinto by reference.

Many medical devices, such as stents, catheters and

endoscopes, are fabricated from, or coated with, sensitive

polymers that cannot tolerate steam, irradiation, or ethylene

oxide. Plasma sterilization has been shown to be incompat-

ible with some medical equipment and leaves toxic residues

(Ikarashi, Tsuchiya et al. 1995; Duffy, Brown et al. 2000).4

4Ikarashi et al, “Cytotoxicity of medical materials sterilized with vapour-

phase hydrogen peroxide.” Biomalerials 16(3): 177—83 (1995) and Duffy et

al, “An epidemic of comeal destruction caused by plasma gas sterilization.

10

15

20

25

30

35

40

45

50

55

60

65

2

The Toxic Cell Destruction Syndrome Investigative Team.” Archives of

Ophzhalmology 118(9): 1167—76 (2000), the entire content of each expressly

incorporated hereinto by reference.

Recently, in U.S. Pat. No. 6,149,864 to Dillow et al (the

entire content of which is expressly incorporated hereinto by

reference), the use of supercritical CO2 was disclosed as an

altemative to existing technologies for sterilizing a wide

range of products for the healthcare industry with little or no

adverse effects on the material treated.

Specifically, the Dillow ’864 patent disclosed the inacti-

vation of a wide range of vegetative microbial cells using

supercritical carbon dioxide with agitation and pressure

cycling. However, only one spore-forming bacterium was

investigated in the Dillow ’864 patent, specifically, B.

cereus. No disclosure appears in Dillow ’864 patent regard-

ing the eflicacy of the therein suggested techniques using

currently accepted bio-indicator standards used to judge

sterilization (i.e., B. slearozhermophilus and B. subtilis).

Subsequently, however, other investigators achieved only a

3.5 log reduction in B. sublilis spores using the method

disclosed in the Dillow et al ’864 patent.5

5Spilimbergo et al, “Microbial inactivation by high-pressure.” J. Supercrirical

Fluids 22: 55—63 (2002), the entire content expressly incorporated hereinto by

reference.

Bacterial spores are more diflicult to sterilize than veg-

etative cells. B. szearothermophilus and B. subtilis spores

represent the greatest challenge to sterilization methods

(FDA 1993) and are the currently accepted standards within

the industry for validating sterilization methods. Steriliza-

tion is defined as greater than or equal to 6-log (106)

reduction in colony forming units (CFUs). Reproducible

inactivation of these resistant microbes is required for com-

mercialization of novel sterilization equipment and pro-

cesses.

It therefore would be highly desirable if sterilization

methods and apparatus could be provided which are effec-

tive to achieve a 6-log reduction in CFUs of industry

standard bacterial spores. It would more specifically be

especially desirable if sterilization methods and apparatus

could be provided that achieve a 6-log reduction in CFUs of

B. slearothermophilus and B. subtilis spores. The present

invention is therefore directed to fulfilling such needs.

SUMMARY OF THE INVENTION

Broadly, sterilization methods and apparatus are provided

by the present invention which are effective to achieve a

6-log reduction in CFUs of industry standard bacterial

spores. More specifically, according to the present invention,

sterilization methods and apparatus are provided which are

effective to achieve a 6-log reduction in CFUs of B. steam-

thermophilus and B. sublilis spores. These 6-log reductions

are achieved by the present invention by subjecting steril-

izable materials under sterilization pres sure and temperature

conditions using a chemical additive-containing supercriti-

cal carbon dioxide as a sterilant fluid. Most preferably, the

chemical additive-containing supercritical carbon dioxide

sterilant fluid is agitated during sterilization.

The apparatus and methods of the present invention are

especially well suited for the sterilization of thermally or

hydrolytically sensitive, medically-important materials,

including biodegradable and other medical polymers, tissue

for implantation or transplantation, medical equipment,

drugs and drug delivery systems. Most preferably, such

materials are sterilized by treatment with a chemical addi

US 7,108,832 B2

3

tive-containing carbon dioxide sterilant at or near its super-

critical pressures and temperatures.

Sterilization is specifically further enhanced by imparting

turbulence or agitation to the sterilant fluid either mechani-

cally or by means of pressure cycling (see, the above-cited

Dillow et al ’864 patent). Process variables depend on the

material being sterilized. The improved method enhances

the mass transfer and sterilization capabilities of supercriti-

cal carbon dioxide. Medically useful log reductions (>106)

in microbial contaminants are realized for a range of resis-

tant bacteria, their Vegetative forms, and spores, especially

bacteria and bacterial spores which are traditionally known

to be the hardest to inactivate, such as B. slearozheromophi—

lus, B. pumilus and/or B. subtilis and spores. Thus, as used

herein the term “sterilization” is meant to refer to at least a

6-log (>106) reduction of industry standard bacteria and

related bacterial spores selected from B. slearozheromophzl

lus, B. pumilus and/ or B. subtilis. Thus, a “sterile” surface or

article is one which has at least a 6-log (>106) reduction of

such bacteria and spores following a sterilization treatment,

as compared to the surface or article prior to such steriliza-

tion treatment.

These and other aspects and advantages will become more

apparent after careful consideration is given to the following

detailed description of the preferred exemplary embodi-

ments thereof.

BRIEF DESCRIPTION OF THE

ACCOMPANYING DRAWINGS

Reference will hereinafter be made to the accompanying

drawings, wherein like reference numerals throughout the

various FIGURES denote like structural elements, and

wherein;

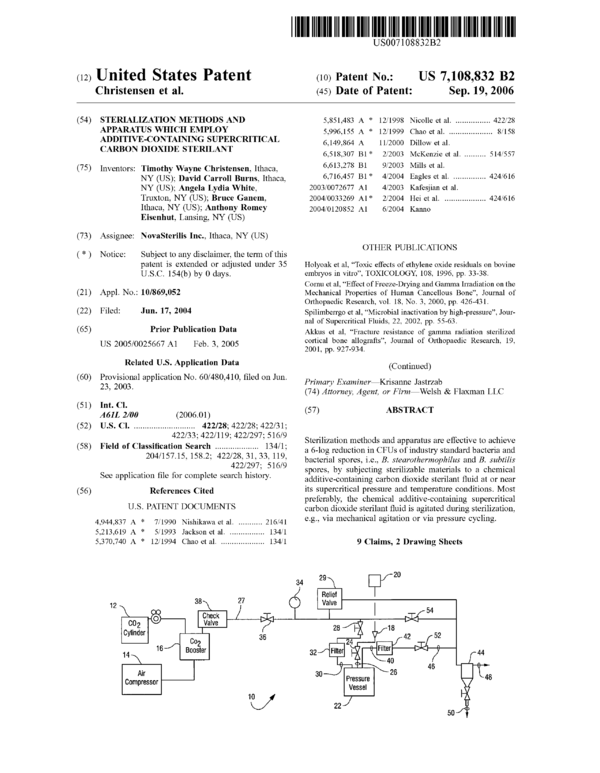

FIG. 1 is a schematic view of a presently preferred

sterilization apparatus in accordance with the present inven-

tion;

FIG. 2 is a detailed schematic view of the pressure vessel

employed in the apparatus of FIG. 1; and

FIG. 3 is a graph of the log reduction in CFU’s of B.

slearothermophilus spores versus time obtained from the

data of Example 8 below and shows the linearity of inacti-

vation achieved by means of the present invention.

DETAILED DESCRIPTION OF THE

INVENTION

The sterilization apparatus and methods of the present

invention are usefully employed to sterilize a variety of

materials, biological tissues, instruments, and devices that

are thermally or hydrolytically unstable, or otherwise

incompatible with conventional sterilization techniques, or

where such techniques are not preferred. Examples of mate-

rials that may be sterilized by the present invention include,

but are not limited to, biodegradable polymers such as

poly(lactic acid) (PLA) or poly(lactic-co-glycolic acid)

(PLGA)-based polymers, which can be used in various

embodiments as implantable drug delivery devices; tissues

for implantation or transplantation, including but not limited

to, bone, cartilage, ligament, or other connective or muscu-

loskeletal tissue for allografts in the treatment of orthopaedic

trauma and joint reconstruction; grafted or artificial skin

tissue for the treatment of bums and other dermal abrasions

or damage; medical devices, such as cardiac or urological

stents and catheters, including drug- or gene-coated stents

and catheters, rigid and flexible endoscopes for orthopaedic,

plastic, and gastroenterological surgery; drug delivery

10

15

20

25

30

35

40

45

50

55

60

65

4

devices, including, but not limited to, implantable polymer

devices, polymer microspheres, or other specifically shaped

drug-releasing devices comprised of PLA, PLGA, or other

biodegradable polymers, and drugs in solid or liquid forms

(i.e., any substance or active agent used in the diagnosis,

treatment or prevention of a disease or illness).

As noted previously, 6-log reductions in CFUs may be

achieved in accordance with the present invention by sub-

jecting materials to be sterilized under sterilization tempera-

ture and pressure conditions using a chemical additive-

containing supercritical carbon dioxide as a sterilant fluid,

and especially where the sterilant fluid is agitated during the

sterilization process.

Most preferably, the sterilant is carbon dioxide at or near

its supercritical pressures and temperature conditions. Thus,

the sterilization process of the present invention is practiced

using carbon dioxide as a sterilant at pressures between

about 1000 to about 3500 psi, at temperatures in the range

between about 25° C. to about 60° C. Most preferably, the

article to be sterilized is subject to carbon dioxide at or near

such pressure and temperature conditions for times ranging

from about 20 minutes to about 12 hours. The carbon

dioxide employed in the practice of the present invention is

most preferably substantially pure. Thus, trace amounts of

other gases may be tolerated provided that the sterilization

properties of the carbon dioxide are not impaired. For ease

of further discussion below, the term “supercritical carbon

dioxide” will be used, but it will be understood that such a

term is non-limiting in that carbon dioxide within the

pressure and temperature ranges as noted immediately above

may be employed satisfactorily in the practice of the present

invention.

The chemical additives employed in the present invention

most preferably include peroxides and/or carboxylic acids.

Preferred carboxylic acids include alkanecarboxylic acids

and/or alkanepercarboxylic acids, each of which may

optionally be substituted at the alpha carbon with one or

more electron-withdrawing substituents, such as halogen,

oxygen and nitrogen groups. Particularly preferred species

of chemical additives employed in the practice of the present

invention include hydrogen peroxide (H202), acetic acid

(AcA), peracetic acid (PAA) and trifluoroacetic acid (TFA),

and mixtures thereof. One particularly preferred liquid addi-

tive that may be employed in the practice of the present

invention is commercially available Sporeclenz® sterilant

which is a mixture of acetic acid with hydrogen peroxide and

peracetic acid.

The chemical sterilization additive is employed in a

sterilization enhancing effective amount of at least about

0.001 vol. % and greater, based on the total volume of the

carbon dioxide. The amount of sterilization additive will be

dependent upon the particular sterilization additive that is

employed. Thus, for example, peracetic acid may be present

in relatively small amounts of about 0.005 vol. % and

greater, while acetic acid may need to be employed in

amount of about 1.0 vol. % and greater. Thus, a range of at

least about 0.001 vol. % and greater, up to about 2.0 vol. %

will typically be needed in order to achieve a sterilization

enhancing effect in combination with carbon dioxide.

One presently preferred embodiment of an apparatus 10

according to the present invention is depicted in accompa-

nying FIGS. 1 and 2. In this regard, it can be seen that the

apparatus includes a standard compressed gas cylinder 12

containing carbon dioxide, and a standard air compressor 14

used in operative association with a carbon dioxide booster

US 7,108,832 B2

5

16 (e.g., Haskel Booster AGT 7/30). Alternatively, the air

compressor 14 and booster 16 can be replaced with a single

carbon dioxide compressor.

An additive cycle is also provided by means of a series of

an inlet port 18 which allows additive contained in reservoir

20 to be added to a pressure vessel 22 through valve 24 and

additive line 26. The carbon dioxide is introduced to the

pressure vessel 22 from header line 27 via valve 28 and CO2

supply line 30. A filter 32 (e.g., a 0.5 micron filter) is

provided in the supply line 30 to prevent escape of material

from the vessel. A pressure gauge 34 is provided down-

stream of CO2 shut-olf valve 36 in supply header 27 to allow

the pressure to be visually monitored. A check valve 38 is

provided in the line 27 upstream of the valve 36 to prevent

reverse fluid flow into the booster 16. In order to prevent an

overpressure condition existing in line 27, a pressure relief

valve 9 may be provided.

An outlet line 40 through valve 52 allows the pressure

vessel 22 to be depressurized. In this regard, the depressur-

ized fluid exits the vessel 22 via line 40, is filtered by filter

unit 42 and then is directed to separator 44 where filtered

CO2 gas may be exhausted via line 48, and liquid additive

collected via line 50 for possible reuse. Valves 52, 54 may

be provided in lines 46 and 27, respectively, to allow fluid

isolation of upstream components.

The reactor vessel 22 is most preferably constructed of

stainless steel (e.g., 316 gauge stainless steel) and has a total

internal volume sufficient to accommodate the materials

being sterilized either on a laboratory or commercial scale.

For example, in laboratory studies, an internal volume of

600 mL (e.g., approximately 8 inches long by about 2.5

inches inside diameter) was deemed adequate As is perhaps

more clearly shown in FIG. 2, the pressure vessel 22

includes a vibrator 60, a temperature control unit 62, and a

mechanical stirring system most preferably comprised of an

impeller 64 and a magnetic driver 66. The reactor vessel 22

contains a conventional basket (not shown) which is also

preferably constructed of 316 gauge stainless steel. The

basket serves to hold the items to be sterilized as well as to

protect the impeller 64 and direct the sterilant fluid in a

predetermined marmer.

The reactor vessel 22 may be operated at a constant

pressure or under continual pressurization and depressuriza-

tion (pressure cycling) conditions without material losses

due to splashing or turbulence, and without contamination of

pressure lines via back diffusion. The valves 24, 28 and 52

allow the vessel 22 to be isolated and removed easily from

the other components of the apparatus 10. The top 68 of the

pressure vessel 22 may be removed when depressurized to

allow access to the vessel’s interior.

In use, the material to be sterilized is introduced into the

interior space of the pressure vessel 22 along with any initial

portion of liquid sterilization additive from reservoir 20. The

temperature control unit 62 is operated so as to set the

desired initial temperature for sterilization. The vessel 22

may then be pre-equilibrated with carbon dioxide from gas

cylinder 12 at atmospheric pressure, following which the

magnetic driver 66 is operated so as to activate the impeller

64. The pressure vessel 22 may thereafter be pressurized to

a desired pressure by introducing additional carbon dioxide

gas from cylinder 12 via the air compressor 14 linked to

booster 16.

In order to effect a pressure cycling of the vessel 22, an

amount of carbon dioxide may be released therefrom via

depressurization line by momentarily opening valve 52

sufficient to partially reduce pressure within the vessel 22.

5

10

15

20

25

45

50

55

60

65

6

Additive may be introduced into the vessel 22 for any given

pressure cycle by opening valve 24 which allows liquid

additive to flow from reservoir 20 into inlet port 18. It will

be understood that the sterilization additives may be intro-

duced prior to pressurization and/ or during pressure cycling.

Prior to pressurization, additives are introduced directly into

the reactor vessel 22 prior to sealing and/or via the additive

port 18. The sterilization additives are most preferably

introduced during the cycling stages by measured addition to

the additive port 18 at ambient pressures. The port 18 is

subsequently sealed and the additive chamber is pressurized

so that the additive may enter the reactor vessel 22 without

altering the internal pressure. The exact mechanism of

addition may be modified such that the process is more

eflicient and/or convenient.

Following additive introduction, the vessel 22 may be

repressurized to a desired pressure following introduction of

the liquid additive therein. Such depressurization/repressur-

ization with introduction of liquid additive may be repeated

for any number of cycles that may be desired. The cycle of

depressurization and repressurization as well as the intro-

duction of the carbon dioxide and liquid additive may be

automatically controlled via a controller (not shown) which

sequences the various valves discussed previously so as to

achieve the desired pressure conditions and cycles.

Most preferably, periodic agitation to the contents of

vessel 22 is effected using vibrator 60 through the entire

process. Intermittent or continuous agitation of the reactor

vessel and its contents is performed by vibrating the reactor

vessel during sterilization. Agitation enhances mass transfer

of the carbon dioxide and additives by eliminating voids in

the fluid such that the material being sterilized comes into

more complete contact with sterilant. The specific means of

agitation may be adjusted to accommodate the particular

apparatus employed and to optimize sterilization times,

temperatures, and pressure cycles. When sterilization is

complete, the vessel 22 is depressurized, the magnetic drive

66 is stopped thereby stopping the stirring impeller 64, and

the thus sterilized material removed by opening top 68 of

vessel 22.

Although the precise mechanism by which the present

invention enhances sterilization is not entirely understood at

this time it is theorized that, in conjunction with near-critical

or supercritical carbon dioxide, the chemical sterilization

additives employed in the present invention likely enhance

sterilization by increasing the acidity of the interior of the

bacterial cell, especially in the presence of water. Moreover,

additives may enhance the permeability of the cell to carbon

dioxide, irreversibly inhibit essential cellular processes, and/

or extract components required for cell viability, all of which

could possibly contribute to enhancements in sterilization

that have been observed.

The present invention will be further understood after

careful consideration is given to the following Examples.

EXAMPLE 1

The effects of using an additive in accordance with the

present invention was compared using the method described

by U.S. Pat. No. 6,149,864 to Dillow et al for inactivating B.

slearothermophilus spores. Specifically, as noted in Table 1

below, the most extreme sterilizations conditions as dis-

closed in the Dillow et al ’864 patent were employed and

resulted in only a 1 log reduction in CFUs/mL for the

experiment in which no additive was employed (Ex. A). In

contrast, a greater than 6 log reduction was achieved using

the method of the present invention (Ex. B). The additive

US 7,108,832 B2

7

was placed on a cotton ball and inserted in the chamber prior

to closure. No further additive was used.

8

remove the additive was performed by pressurizing and

de-pressurizing the reactor vessel using C02. The stirring

Agitation

Pressure # Random/ Temp Time Initial Final Log

Additive range psi cycles Directional ° C. hrs CFU/ml CFU/ml Reduction

Ex. A. Water 1500- 3 +/— 60 2 2.3 x 105 2.1 x 105 1.0

3000

Ex. B Water + 1100- 3 +/+ 60 2 2.3 x 106 0* 6.4

TFA 3000

*confirmed by turbidity test

15

EXAMPLE 2—INVENTION

The apparatus generally depicted in FIGS. 1 and 2 was

employed for this Example. A sample of B. stear0lhermo—

philus spores (1 mL) of greater than 106 CFU/mL was placed

in 16 mm diameter test tubes in a stainless steel basket.

Trifluoroacetic acid (4 mL) was transferred by syringe onto

the surface of a cotton ball placed in the basket and water (6

mL) was placed at bottom of vessel. The basket was then

loaded into the 600 mL reactor vessel. The reactor vessel

was heated to 50° C. and equilibrated with CO2 at atmo-

spheric pressure. The stirring and agitation mechanisms

were activated and the reactor vessel pressurized to 2000 psi

for 40 minutes. The CO2 pressure was then allowed to drop

to 1100 psi at a rate of 300 psi/minute. Agitation by means

of vibration of the vessel was carried out for 1 minute.

The pressurization/stirring/agitation/depres surization pro-

cess was repeated a total of three times. After the third cycle,

a series of three flushing cycles to remove the additive was

performed by pressurizing and partial de-pressurizing the

reactor vessel using C02. The stirring was stopped and the

basket was removed from the reactor vessel. The residual

CFUs were counted after serial dilution and culturing of

both treated and untreated controls.

Complete kill of bioindicators were achieved over mul-

tiple experimental evaluations. These reductions correspond

to a log reduction in CFUs of between 6.2 to 6.9.

EXAMPLE 3A—INVENTION

The apparatus generally depicted in FIGS. 1 and 2 was

employed for this Example. A sample of B. subtilis spore/

vegetative preparations (1 mL) of greater than 106 CFU/mL

was placed in a 16 mm diameter test tube in a stainless steel

basket. Acetic acid (6 mL) was transferred by syringe onto

the surface of a cotton ball placed in the basket, which was

then loaded into the 600 mL reactor vessel. The reactor

vessel was heated to 50° C. and equilibrated with CO2 at

atmospheric pressure. The stirring and agitation mechanisms

were activated and the reactor vessel pressurized to 3000 psi

for 40 minutes. The CO2 pressure was then allowed to drop

to 1500 psi at a rate of 300 psi/minute. Agitation was carried

out for 1 minute.

After depressurizing the reactor vessel, more acetic acid

(4 mL) was introduced at ambient pressure to the additive

loop via port 18 (FIG. 1). The loop was sealed and pressur-

ized to 3000 psi. The reactor vessel was the re-pressurized

through the additive loop to 3000 psi such that acetic acid

was transported into the reactor vessel.

The pressurization/stirring/agitation/depressurization/ad-

ditive addition process was repeated a total of three times.

After the third cycle, a series of three flushing cycles to

20

25

30

35

40

45

50

55

60

65

was stopped and the basket was removed from the reactor

vessel. The residual CFUs were counted after serial dilution

and culturing of both treated and untreated controls.

A log reduction in CFUs of between 6.0 to 6.9 was

observed for multiple experimental evaluations using the

procedure described above.

EXAMPLE 3B—INVENTION

Example 3A was repeated except that samples containing

less than 106 CFU/ml of B. subzilis was used. Sterilization

resulted in total kill of the B. sublilis present. It can therefore

be extrapolated from this Example that, had greater than 106

CFU/ml of B. sublilis been presented, the sterilization pro-

cedure would have resulted in a corresponding 6 log reduc-

tion in CFUs.

EXAMPLE 3C—Comparative

Example 3A was repeated except that the acetic acid was

added only once at the beginning of the procedure. Although

a 6 log reduction in CFUs was not observed, relatively high

log reductions of between 4.5 and 4.7 were observed. This

data suggests that multiple additions of acetic acid would be

needed in order to achieve the desired 6 log reduction in B.

sublilis CFUs.

EXAMPLE 3D—INVENTION

Example 3A was repeated except that pressure was main-

tained at a constant 2000 psi rather than cycling Compete

kill of bioindicators were observed over multiple tests.

These log reductions in CFUs ranged from 6.0 to 7.2.

EXAMPLE 4—INVENTION

Using the equipment and procedure in Example 1,

samples of fresh or freeze-dried bone (1 cm>106 reduction

in bacterial spores), and there was no reduction in compres-

sion strength attributes.

EXAMPLE 5—INVENTION

To evaluate the eflicacy of the improved method for

sterilization of bone tissue for implantation, human bone

tissue was saturated with a solution containing 106 CFUs/

mL of B. subtilis spores and subjected to the presented

method. The treatments were carried using the following

conditions: 4 hours, 60° C., 6 cycles form 3000—1500 psi,

constant stirring of SCD, periodic agitation of vessel, addi-

tion of 6 mL acetic acid to vessel prior to pressurization,

addition of acetic acid (4 mL) per cycle, and ending in two

5 minute flushing cycles.

The sterilized samples and unsterilized controls were

assayed for the presence of B. sublilis spores by two

methods. In the first method, bone was immersed in bacterial

media allowing germination and growth of B. sublilis

spores. Turbidity of media indicated incomplete inactivation

while clear media was complete inactivation. When cultured

for bacterial growth, none of the bone samples treated with

the above method showed detectable turbidity of the culture

medium as compared to controls (Table 2).

A sample of sterilized bone tissue was pulverized by

grinding under aseptic conditions, then cultured in media.

No turbidity was detected, indicating that the sterilization

process had permeated the bone tissue (Table 2).

TABLE 2

Sterilization of bone tissue using supercritical carbon dioxide with the

presented method

Intact Bone Pulverized Bone

Bone Inoculants Culture Culture

Treated 105 CFUs/ml No- growth No- growth

ofB. subrilis spores

Untreated 106 CFUs/ml Growth Growth

ofB. subrilis spores

EXAMPLE 6A—INVENTION

Example 3D was repeated except that peracetic acid was

employed as the sterilization additive. A log reduction in

CFUs of between 6.5 to 7.2 was observed for multiple

experimental evaluations using the procedure described

above.

EXAMPLE 6B—INVENTION

Example 6A was repeated except that pressure was main-

tained at a constant 2000 psi rather than cycling. Complete

kill of bioindicators was observed over multiple tests with

log reductions in CFUs ranging from 6.0 to 7.2.

EXAMPLE 7—Comparative

Example 3A was repeated except that the additives listed

in Table 3 below were employed under the conditions stated.

The results also appear in Table 3.

10

15

20

25

30

35

40

45

50

55

60

65

10

TABLE 3

Quantity Log

Additive Temp C. Time (vol. %) Cycles reduction

HOC1 60 3 hours 1.0 4 0—0.50

Ethanol 60—50 3 hours 1.0 4 1.24.0

Yeast Extract 60 2 hours 1.0 3 0.37—1.1

50% Citric acid 60 2 hours 1.0 3 0.03—0.62

Succinic acid 50 2 hours 1.0 3 0.25—0.29

Phosphoric acid 50 2 hours 1.0 3 0.18—0.25

Fonnic acid 50 2 hours 1.0 3 0

Malonic acid 50 2 hours 1.0 3 0—0.12

None of the additives tested in this Example showed

eflicacy to achieve at least a 6 log reduction in CFUs of B.

slearothermophilus spores.

EXAMPLE 8—Linearity of Inactivation

Example 2B was repeated except that 4.5% peracetic acid

was initially added to the vessel at 0.02 vol. % on a cotton

ball and water was added on a separate cotton ball at 1 vol.

%. B. stearothermophilus spores were inoculated onto glass

fiber filters, allowed to dry and packaged into pouches

formed of nonwoven fine polyethylene fibers (1073B

TYVEK® brand material) and served as bioindicators. Total

CFUs per filter were greater than 106. The bioindicators

were exposed to differing times of treatment with 4 repli-

cates per time point. The total remaining CFUs were then

determined and a plot was generated of log reduction in

CFUs over time (FIG. 3). Results revealed that inactivation

rates are linear and the time for a single log reduction in the

bioindicator packaged in the pouches was 14.24 minutes.

While the invention has been described in connection

with what is presently considered to be the most practical

and preferred embodiment, it is to be understood that the

invention is not to be limited to the disclosed embodiment,

but on the contrary, is intended to cover various modifica-

tions and equivalent arrangements included within the spirit

and scope of the present invention.

What is claimed is:

1. A sterilization method comprising:

(a) bringing a material in need of sterilization into contact

with a sterilant fluid comprised of carbon dioxide at

supercritical pressure and temperature conditions, and

a sterilization enhancing effective amount of between

about 0.001% to about 2.0 % based on the total volume

of a chemical sterilization additive, wherein the addi-

tive is selected from the group consisting of acetic acid,

peracetic acid, trifluoroacetic acid, acetic acid deriva-

tives or mixtures thereof, and

(b) maintaining said contact with the sterilant fluid under

said temperature and pressure conditions while

mechanically agitating for a time suflicient to achieve

a 6-log reduction or greater in colony forming units

(CFUs) of bacterial spores.

2. The sterilization method of claim 1, which comprises

agitating the sterilant fluid by stirring.

3. Apparatus for sterilizing an article in need of steriliza-

tion through the application of a sterilant fluid comprising:

a pressure vessel for containing the article in need of

sterilization

a source of supercritical carbon dioxide connected to the

pressure vessel;

a source of a liquid chemical sterilization additive

selected from the group consisting of acetic acid,

US 7,108,832 B2

11

peracetic acid, trifluoroacetic acid, acetic acid deriva-

tives or mixtures thereof connected operatively to the

pressure vessel;

means for introducing the supercritical carbon dioxide

and sterilization additive to the pressure vessel in an 5

amount of between about 0.001% to about 2.0% of the

additive based on a total volume of the sterilant fluid

introduced;

means for introducing an article in need of sterilization

into the pressure vessel so as to bring the article into

contact with the sterilant fluid at supercritical pressure

and temperature conditions and maintaining the article

in contact with the sterilant fluid under said temperature

and pressure conditions while mechanically agitating

for a time sufficient to achieve a 6-log reduction or

greater in colony forming units (CFUs) of bacterial

spores; and

a depressurization line fluid-connected to the pressure

vessel for evacuating at least some portion of the

carbon dioxide and sterilization additive from the pres-

sure vessel so as to depressurize the same.

10

15

20

12

4. Apparatus as in claim 3, further comprising a liquid-gas

separator in said depressurization line for separating carbon

dioxide gas from the liquid sterilization additive.

5. Apparatus as in claim 3, further comprising a valve in

said depressurization line to allow said at least some portion

of the carbon dioxide and sterilization additive to be evacu-

ated from the pressure vessel through the depressurization

line.

6. The sterilization method of claim 1, wherein materials

treated are selected from the group consisting of thermally

or hydrolytically sensitive, medically-important materials.

7. The sterilization method of claim 6, wherein the

materials treated are selected from the group consisting of

tissue for implantation or transplantation.

8. The sterilization method of claim 6, wherein the

materials treated are selected from the group consisting of

biodegradable and other medical polymers.

9. The sterilization method of claim 6, wherein the

materials treated are selected from the group consisting of

drugs, drug delivery systems and/or medical equipment.

* * * * *

Coments go here:

- Log in to post comments