l%vel

of

8

D, Kotzev and V. Kotzev

(Chemence Ltd, UK)

Cyanoacrylate polymer foams can be obtained by blending cyanoacrylate monomer

with an appropriate solvent and a polymerization initiator. Foaming takes place in

seconds at room temperature. Various monomers, solvents and initiators were tested

and best performance compositions and ratios were determined. The resultant foams

are lightweight and can occupy volume up to 30 times that of the original

cyanoacrylate monomer. The onset time and temperature of foaming can be regulated

in wide ranges. Odourless foaming compositions were obtained. The cyanoacrylate

foam and foaming process can be used for a variety of medical applications such as

broken-limb support, and blood vessel and Fallopian tube sealing. They are especially

suitable for stoppage of fluid flow in industrial pipelines, e.g., gas mains. The foam plug

can be collapsed at a later stage and fluM flow restored.

Key words: polycyanoacrylates; adhesives; foams; foaming optimization; medical

applications; industrial applications

Cyanoacrylates are enjoying increased popularity as

instant-setting speciality adhesives in industrial and

consumer markets I. Commercially known as 'Super

Glue' or 'Crazy Glue', they are one-component,

catalyst-free and cure in seconds at room temperature.

They have exceptionally high adhesion towards most

materials -- metals, rubber, plastics, wood, ceramics,

glass and even live tissue. The reason behind these

unique properties is the chemical structure of the

cyanoacrylate monomer, which is the active ingredient

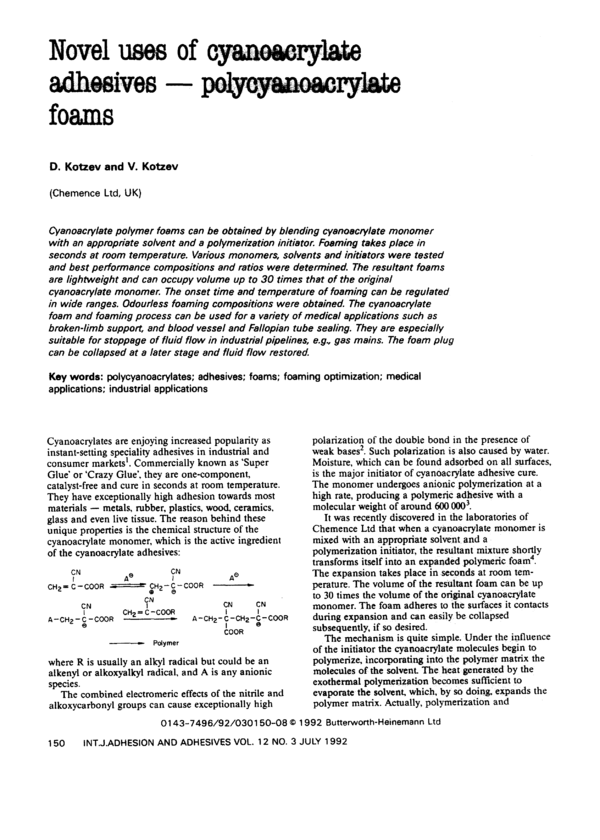

of the cyanoacrylate adhesives:

CN

I

CHz=C-COOR

A-CH2-C

CN

AB

~,

CN

I

-COOR

e

I

_-- C H 2 - C - C O O R

Q

e

CN

I

C H 2 : C -COOR

'

-A-CH2-

A®

:

=

CN

CN

I

I

C - C H 2 - C - COOR

I

e

COOR

Polymer

where R is usually an alkyl radical but could be an

alkenyl or alkoxyalkyl radical, and A is any anionic

species.

The combined electromeric effects of the nitrile and

alkoxycarbonyl groups can cause exceptionally high

polarization of the double bond in the presence of

weak bases 2. Such polarization is also caused by water.

Moisture, which can be found adsorbed on all surfaces,

is the major initiator of cyanoacrylate adhesive cure.

The monomer undergoes anionic polymerization at a

high rate, producing a polymeric adhesive with a

molecular weight of around 600 0003.

It was recently discovered in the laboratories of

Chemence Ltd that when a cyanoacrylate monomer is

mixed with an appropriate solvent and a

polymerization initiator, the resultant mixture shortly

transforms itself into an expanded polymeric foam4.

The expansion takes place in seconds at room temperature. The volume of the resultant foam can be up

to 30 times the volume of the original cyanoacrylate

monomer. The foam adheres to the surfaces it contacts

during expansion and can easily be collapsed

subsequently, if so desired.

The mechanism is quite simple. Under the influence

of the initiator the cyanoacrylate molecules begin to

polymerize, incorporating into the polymer matrix the

molecules of the solvent. The heat generated by the

exothermal polymerization becomes sufficient to

evaporate the solvent, which, by so doing, expands the

polymer matrix. Actually, polymerization and

0 1 4 3 - 7 4 9 6 / 9 2 / 0 3 0 1 5 0 - 0 8 © 1992 Butterworth-Heinemann Ltd

150

INT.J.ADHESION AND ADHESIVES VOL. 12 NO. 3 JULY 1992

�expansion take place simultaneously and when the

expanding foam reaches an obstacle, such as a

containing surface, it contacts the substrate and bonds

to it in the same fashion as does a cyanoacrylate

adhesive,

The present paper reports on work which had the

following objectives: (1) to study and optimize the

foam-forming reaction: (2) to characterize the

cyanoacrylate polymer foam produced: and (3) to make

a preliminary assessment of the suitability, of the

cyanoacrylate foam for various applications.

Materials and m e t h o d s

Cyanoacrylate monomers

Ethyl-2-cyanoacrylate was obtained by distillation of

Anacure 3020 adhesive (Chemence Ltd). All other

cyanoacrylate monomers were prepared following wellknown synthetic procedures 5-7.

Foam expansion

In a polyethylene cylindrical container with diameter

of 50 mm were placed 4 ml of freshly distilled

cyanoacrylate monomer. A specific amount of liquid

foaming agent, containing the polymerization intiator,

was added to the cyanoacrylate monomer. The contents

were manually mixed for 3 seconds so that a clear

solution was produced. The mixture was left static and

the time lapse before the onset of expansion and the

time interval of actual expansion recorded. The volume

of the expanded foam was measured and the

coefficient of expansion calculated as the ratio of the

volume of the polycyanoacrylate foam to the initial

volume of the cyanoacrylate monomer in the

composition.

tube had an internal diameter (ID) of 18 mm and a

wall thickness of 2 ram: a = 40 mm. In the case of

human duct occlusion simulation the polyethylene

tube had an ID of 2 mm, a wall thickness of 0.5 mm

a n d a = 12mm.

Foam strength measurement

Cyanoacrylate monomer and l,l,2-trichlorotrifluoroethane (TCTFE) in volume ratio of 4:1 and containing

0.01% by weight of N,N-dimethyl-p-toluidine (DMPT)

were mixed and injected into a polyethylene tube with

an ID of 12.5 ram. Seconds after the injection the

composition expanded into polycyanoacrylate foam,

plugging the tube. The wall of the tube was carefully

cut and the foamed material removed. Test-pieces were

cut from it and tested. In order to measure the tensile

strength, the foam specimens, which were cylindrical

and had a diameter corresponding to the diameter of

the pipe into which they were expanded, were bonded

with cyanoacrylate adhesive to standard steel

specimens for adhesive tensile strength measurements.

The steel specimens were placed in the testing machine

and were pulled at a cross-head speed of 1 mm min -l.

Failure occurred in the volume of the cyanoacrylate

foam, rather than at the adhesive bond. Compression

testing was carried out using the same cross-head

speed. Tensile shear strength data were obtained by

expanding the same compositions in the gap between

two coaxially inserted stainless steel pipes (Fig. 2).

When the plugged assembly was tested in tensile mode

(1 mm min -I) the foam was subjected to tensile shear

Foaming temperature measurement

The experimental set-up is shown in Fig. 1. The

thermocouple was placed in the volume of the initial

liquid composition where the largest build-up of heat

occurs. In the case of expansions simulating

preparation of broken-limb support the polyethylene

I%t

Polyethylene tube

= ~I

\.=

\\1

\\=

1

-~--12 mm---

W

Foam

Failure line

" * - - - - - 2 0 rnm

[

~"~

Volume before expansion

Volume after expansion

Fig. 1 Experimental set-up for temperature measurement during

foaming

Fig. 2 Tensile shear strength test of foam expanded between two

coaxially placed tubes

INT.J.ADHESION AND ADHESIVES JULY 1992

1 51

�force. Failure occurred in the volume of the foam. The

adhesive strength of the foam towards the surface of

the tubes was higher than the strength of the material

itself.

Results and discussion

Evaluation of different foaming agents end

optimization of their foaming compositions

In the first series of experiments the objective was to

evaluate numerous solvents as potential foaming agents

and to find the most suitable ones. Ethyl-2cyanoacrylate was used as the cyanoacrylate monomer

and DMPT as the polymerization initiator. In the same

set of experiments the ratio of cyanoacrylate to

foaming agent and the amount of initiator were varied

so that the optimum composition for each tested

foaming agent was determined.

Pentane, hexane, TCTFE, heptane, diethyl ether,

cyclohexane, 2-butanone, acetone, ethanol, acetonitrile

and methanol were studied. They are ordered in

respect of their solubility parameters. Petroleum ether

was also tested as a typical example of mixed alkanes.

The results are summarized in Table 1.

The data for the volume ratio of cyanoacrylate to

foaming agent and the concentration of initiator are

the optimum values found in preceding experiments.

In general, excess of foaming agent over the optimum

ratio found either produces soft foams with large pores

or the foaming agent splashes out, and part of it

remains in liquid form during and after foaming. On

the other hand, when its quantity is below the

optimum ratio the expansion coefficient is reduced due

to shrinkage of the foam after its expansion.

DMPT concentration has a major influence only on

the onset of the reaction, relatively less pronounced is

the influence on the expansion coefficient. Generally,

higher expansion ratios are obtained when the

concentration of DMPT is higher. It creates more sites

for initiation of polymerization and the associated

exotherm is sufficient for fast simultaneous evaporation

of the solvent, which expands the forming polymer.

The experimental data show that the foaming ability

of the tested compounds depends on a variety of

factors. One of these is the boiling point. As a rule. the

lower the boiling point, the better the foams produced.

A striking example is the pentane/hexane/heptane

series of solvents with similar solubility parameters,

polarity and structure. Pentane with 35°C boiling point

creates foams with 23 times expansion; hexane with

69°C boiling point creates foams with 13 times

expansion; while heptane with 98°C boiling point

produces foams with only four times expansion.

The solubility parameter and foaming agent's

polarity also have a major influence on the foams

produced. These two factors determine the degree of

solubility of the monomer and polymer in the liquid

and vapour of the foaming agent. They also determine

the degree of permeability of the trapped vapour

through the walls of the foam cells. The best results are

obtained with non-polar solvents with solubility

parameters in the lower end of the scale, i.e., pentane

and TCTFE. Solvents with solubility parameters at the

other end of the scale, such as methanol, are most

unsuitable as foaming agents, producing exceptionally

brittle foams. Solvents such as acetone and acetonitrile,

which have similar solubility parameters to poty(ethyl2-cyanoacrylate) (8 = 11.2s), are polar and thus are good

solvents for the polymer, proved also to be poor foamforming agents. Their vapours or liquid left after the

expansion tended to swell and dissolve the polymer,

thus shrinking the foam. Furthermore, upon their

evaporation, the resultant foams are very. brittle. In

most ratios these solvents usually produce gel-like

material rather than foam. Solvents in the mid-range of

the solubility parameter scale and with boiling point

around 80°C, such as cyclohexane, give good resilient

Comparison of foaming compositions based on different foaming agents (FA)

Table 1.

Volume

ratio of

cyano-

Foaming

agent

Cone. of

initiator

(wt%)

Solubility Polarity

parameter of FA

of FA

Boiling

point of

FA (°C)

Onset

time (s)

Time of

expansion

(s)

Expansion

coefficient

acrylate

to FA

Grading

of FA

suitability

(! -- best,

11 --worst)

Pentane

1:1

0.025

7.0

non

35

20

5

23

2

Hexane

2:1

0.017

7.3

non

69

25

5

13

3

TCTFE

4:1

0.010

7.3

non

48

6

6

25

!

Heptane

4:1

0.020

7.4

non

98

10

10

4

8

Diethyl ether

4:1

0.010

7.4

mod

35

19

5

18

4

Cyclohexane

2:1

0.017

8.2

non

81

34

5

10

5

2-Butanone

2:1

0.017

9.3

mot

80

10

15

17

7

Acetone

2:1

0.017

9.9

mod

56

5

10

22*

9

Ethanol

2:1

0.017

10.0

high

78

5

10

10

6

Acetonitrile

2:1

0.017

11.9

high

82

10

10

3

10

Methanol

4:1

0.020

14.5

high

65

5

25

8

11

*Foam collapses after expansion

152

INT.J.ADHESION AND ADHESIVES JULY 1992

�foams displaying high adhesion towards the contacted

surfaces.

Good results are obtained when petroleum ether is

used as a foaming agent. The foam formation is better

controlled, temperature- and time-wise, and resilient

homogeneous foams are produced. This is a result of

its wide boiling range, which indicates that blends of

different solvents will produce the best required

foaming agent for every specific need or application.

Evaluation of different polymerization initiators and

optimization of their foaming compositions

In the second series of experiments, several initiators of

the anionic polymerization of cyanoacrylate

monomers were evaluated as potential foaming

initiators with the objective of finding the most suitable

ones. Ethyl-2-cyanoacrylate was used as the

cyanoacrylate monomer and TCTFE was used as the

foaming agent.

The results summarized in Table 2 clearly indicate

that N-(oxydiethylene)benzothiazole-2-sulphenamide

(ODEBTSA)and DMPT are by far the best initiators for

foaming cyanoacrylate compositions. They dissolve

well in the volume of the cyanoacrylate/foaming agent

mixture and, shortly after, initiate polymerization,

which has the necessary exothermal effect to evaporate

the foaming liquid. ODEBTSA has the added

advantage of no smell and presents no health hazard.

Next in order comes piperidine, which gives slightly

longer onset times and produces less expanded foams.

A further disadvantage is its noxious smell and

toxicity.

Triphenyl- and triethylphosphines can be used as

initiators when a very long onset time is required. They

may prove valuable in expansions of large quantities of

foaming compositions, where otherwise a large buildup of heat might be expected.

Pyridine may be considered as an unacceptable

compound for initiation of cyanoacrylate foaming. The

very high reactivity of pyridine (an initiator level of

only 1 ppm causes polymerization) prevents the even

distribution of the initiator in the bulk of the foaming

composition.

Table 2.

Evaluation of different cyanoacrylate monomers and

optimization of their foaming compositions

In the next series of experiments the suitability of

different cyanoacrylate monomers for producing

expanded foams was tested and compared (Table 3).

Isobutyl-2-cyanoacrylate produces the highest foam

expansion. Further advantages of its foam are the

elasticity and homogeneity. Foams based on butyl-2cyanoacrylate are very similar to those based on the

isobutyl monomer. Ethyl-2-cyanoacrylate is also an

excellent foam-forming monomer, producing high

expansion ratios and hard and resilient foams. The

alkoxyalkyl monomers produce mid-range expansion

foams and are very compatible with diethyl ether, as a

result of the common ether bond in their molecules.

Their foams are very elastic. Least suitable of the

studied monomers is methyl-2-cyanoacrylate. Its foams

are very brittle, as a result of the relative stiffness of its

corresponding polymer molecule.

Regulating the onset time of foaming

In an attempt to control the onset time, i.e.. the time

interval between mixing of the composition and its

expansion into foam, two acids commonly used to

stabilize cyanoacrylate monomers against spontaneous

anionic polymerization during storage were tested. The

results are presented in Table 4. The ethyl-2cyanoacrylate/TCTFE composition of 4:1 ratio, containing 0.01% by weight of DMPT, was used.

The results clearly indicate that the onset time of

foaming can be successfully regulated by introducing

different amounts of p-toluenesulphonic or trifluoromethanesulphonic acid into the cyanoacrylate

monomer, or into the composition itself. The minute

quantities used do not affect the properties of the

foams and do not alter the actual time of foam

expansion.

When similar experiments were made with

hydroquinone, which is most often used as a stabilizer

for cyanoacrylate monomers against radical

polymerization, it was found, as expected, that it did

not have any effect on the onset time of foam

Comparison of foaming compositions based on different foaming initiators

Initiator

Health and

safety

hazard

Optimum

concentration

of initiator

Optimum

volume

ratio of

E-2-CA*

to TCTFE

Onset

time (s)

DMPT

Irritant

0.01

4:1

6

Pyridine

Irritant

Flammable

1.7 x 10 -4

4:3

Piperidine

Highly toxic

Flammable

0.01

Triethylphosphine

Pyrophoric

Stench

Triphenylphosphine

ODEBTSA

Time of

expansion

(s)

Expansion

coefficient

Grading of

initiator

suitability

(1 - - best,

6 - - worst)

6

25

2

450

20

7

6

2:1

30

10

18

3

0.003

2:1

73

40

17

4

Irritant

4.8 x 10-4

4:3

298

68

13

5

--

0.017

2:1

25

5

25

1

* E-2-CA = ethyl-2-cyanoacrylate

INT.J.ADHESION AND ADHESIVES JULY 1992

153

�Table 3.

Foaming compositions based on different cyanoacrylate monomers

Cyanoacrylate monomer

Foaming agent

Volume ratio of

cyanoacrylate to

foaming agent

Expansion coefficient

M ethyl-2-cyanoacrylate

Diethyl ether

4:1

12

Ethyl-2-cyanoacrylate

TCTFE

4:1

25

Butyl-2-cyanoacrylate

TCTFE

1: 1

24

Isobutyl-2-cyanoacrylate

TCTFE

1: 1

33

Allyl-2-cyanoacrylate

Diethyl ether

1: 1

17

2-Methoxyethyl-2-cyanoacrylate

TCTFE

4:3

12

2-Ethoxyethyl-2-cyanoacrylate

TCTFE

2:1

14

2-M ethoxyisopropyl-2-cyanoacrylate

TCTFE

2:1

15

Table 4.

Stabilized foaming compositions

Acid

Concentration

of acid in

cyanoacrylate

expansion in such a large interval as 0.01-1.0% by

weight of the cyanoacrytate monomer.

Onset time

(s)

Monitoring and regulating the temperature during

foam formation

(wt%)

Control

0

p-Toluenesulphonic

0,0003

0.0006

0,0012

0.002

0,005

0.01

14

16

20

37

66

195

Trifluoromethanesulphonic

0.001

0.002

0.005

0.01

In the envisioned medical applications of the foam.

such as broken-limb support and Fallopian tube

sealing, the heat evolved during foaming, if excessive.

may render the methods unacceptable.

Temperature measurements (Fig. 1) of expansions

likely to be encountered in broken-limb support

formation are summarized in Table 5. The following

conclusions can be drawn. The temperature of foaming

depends on the nature of the cyanoacrylate monomer

and decreases with increasing length of the radical R

in the molecule, the order being: methyl, ethyl, allyl;

isobutyl, butyl, methoxyethyl, ethoxyethyl and

methoxyisopropyl. It also depends on the nature of the

foaming agent, i.e.. the lower the boiling point of the

agent, the lower the temperature of expansion. The

11

24

43

117

Table 5.

10

Temperature of foaming for different compositions

Maximum

temperature

reached (°C)

Volume ratio of

cyanoacrylate to

foaming agent

2-Cyanoacrylate

monomer

Foaming

agant

I nitiator

Content of

initiator in

composition

(wt%)

4:1

2:1

2:1

Ethyl

TCTFE

TCTFE

TCTF E

0.01

0.017

0.003

95

84

85

Pentane

Pentane

DM PT

ODEBTSA

Triethylphosphine

DM PT

DMPT

0.017

0.025

80

65

2:1

1: 1

2:1

Allyl

TCTF E

DM PT

0.025

75

2:1

Butyl

Pentane

DM PT

0.017

66

2:1

1: 1

Isobutyl

Pentane

Pentane

DM PT

DMPT

0.017

0.025

67

41

4:1

M ethyl

TCTF E

DM PT

0.01

106

4:3

Methoxyethyl

TCTF E

DM PT

0.01

63

1:1

Ethoxyethyl

TCTF E

DM PT

0.025

58

1: 1

M ethoxyisopropyl

TCTF E

DM PT

0.025

58

154

INT.J.ADHESION AND ADHESIVES JULY 1992

�temperature of foaming depends also on the ratio of

monomer/foaming agent and is lowered by increasing

the quantity of the foaming agent. The type and

quantity of initiator do not have a major effect on the

temperature of foaming.

These results are very promising in that the recorded

temperature values are only the maxima and the

generated heat dissipates very rapidly. Considering that

the limb would be covered and protected by

stockinette, with considerable heat insulating

properties, it can be expected that unbearable heat

during foaming will not be experienced.

A similar set-up (Fig. 1), simulating a human duct

occlusion, was used to monitor the temperature of

foaming. The time interval during which the temperature stays above 37°C was also recorded. The

results presented in Table 6 show that when foamed

plugs are used instead of pure cyanoacrylate polymers

the temperature that the tissues of the tube, duct or

vessel will experience is greatly reduced, which will

eliminate any heat-associated necrosis. Furthermore, by

choosing the right monomer, foaming agent and

composition, very low temperatures of foam expansion

can be achieved, even as low as below body

temperature. Almost all of the monomers, except

methyl-2-cyanoacrylate, can produce acceptable

compositions.

Monitoring and regulating the odour emitted during

foaming

During the formation of polycyanoacrylate foams the

foaming agent evaporates and can be the main source

of odour. Along with it, small amounts of

cyanoacrylate monomer and initiator can also be

carried away and be a further source of odour. In the

Table 6.

case of tubular vessel blocking, whether it is industrial

pipelines or human ducts, any odour associated with

the foaming is unimportant. Only in the case of opentop expansions, such as broken-limb support formation

or adhesive bonding or sealing, will the odour emitted

be a factor of consideration.

Each cyanoacrylate monomer had its own odour,

the methyl, allyl and ethyl being the most offensive

and with lacrymatory action. Butyl and isobutyl

cyanoacrylates had a sweet scent and were less

offensive. Methoxyethyl and methoxyisopropyl cyanoacrylates had almost no smell with a faint mouldy

scent, while ethoxyethyl cyanoacrylate was completely

odourless.

A completely odourless foaming process is achieved

when TCTFE is used as the foaming agent, alkoxyalkyl

cyanoacrylate is used as the monomer and ODEBTSAis

used as foaming initiator.

Characterization of the foams produced

Table 7 summarizes some of the properties of foams

based on different cyanoacrylate monomers. The foam

based on ethyl-2-cyanoacrylate shows the best strength

characteristics. Next come the foams based on butyl-,

isobutyl- and allyl-2-cyanoacrylates. Methyl-2cyanoacrylate foams have markedly the poorest

properties.

It should be noted that the results presented must be

treated for comparison purposes only. The structure of

the foam (specific gravity, pore size) varies greatly not

only with the variation of the components of the

composition, but also with the volume available for

expansion. When that volume is restricted the foam is

denser with smaller pores, harder and tougher.

Therefore the physical characteristics of the foam will

Temperature of foaming in 2 mm tube for different compositions

2-Cyanoacrylate

monomer

Foaming

agent

Volume ratio of

cyanoacrylate to

foaming agent

Maximum temperature

reached during

foaming (°C)

Time interval

above 37°C

(s)

Methyl

TCTFE

2:1

58.5

60

Ethyl

TCTFE

Diethyl ether

1: 1

1: 1

39.6

43.6

37

48

Allyl

TCTFE

1: 1

41.5

40

Butyl

Diethyl ether

1:1

40.6

35

Isobutyl

TCTFE

TCTFE

Diethyl ether

Diethyl ether

2:1

1: 1

2:1

1: 1

51.2

44.7

41.6

36.2

59

54

53

Methoxyethyl

TCTFE

Diethyl ether

1: 1

1: 1

44.8

45.3

52

32

Ethoxyethyl

TCTFE

Diethyl ether

2:1

1: 1

57.5

41.7

59

35

Methoxyisopropyl

TCTFE

Diethyl ether

1: 1

1: 1

40.1

37

36.0

Methyl

70.4

Ethyl

67.3

INT.J.ADHESION AND ADHESIVES JULY 1992

155

�Table 7.

Physical characteristics of polycyanoacrylate foams

2-Cyanoacrylate

monomer

Specific

gravity

(gcm -3)

Tensile

strength

at break

(kg cm -2)

Elongation

at break (%)

Tensile shear

strength at

break

(kg cm -2)

Compression

strength at 10%

deformation

(kg cm -2)

Methyl

Ethyl

Butyl

Isobutyl

Allyl

2-M ethoxyethyl

2-Ethoxyethyl

2-Methoxyisopropyl

0.28

O. 13

0.25

0.24

0.18

0.41

0.22

0.28

0.8

10.6

5.7

3.2

5.0

1.6

1,6

1.8

2.5

3.7

6,7

3,7

3.0

2,0

1.7

2.0

0,5

5.2

1 o8

3.0

3.0

1.9

1.5

1.7

5,7

4.9

4.9

5.7

7.3

6.5

5.5

4.0

be dependent on the components, composition and

available volume for expansion.

It was determined (for the 4:1 ethyl-2-cyanoacrylate/

TCTFE composition) that approximately 50% of the

foaming agent escapes during foaming and the rest is

trapped into the foam. Approximately 95% of that is in

closed-pore cells.

The diameter of the pores varies mainly with the

volume available for expansion. If that volume is

unlimited it is between 0.06 mm and 0.2 mm. When the

volume for expansion is restricted the cell size can be

below 0.002 mm.

The molecular weight of the poly(ethyl-2cyanoacrylate) foam was determined to be in the

region of 500 000, which corresponds very well with the

molecular weight of this cyanoacrylate's bondline 3.

Evaluation of the suitability of the cyanoacrylate

polymer foam for orthopaedic casts

The results obtained during the course of this work

strongly indicate that the cyanoacrylate polymer foam

will be suitable for immobilization of broken limbs.

The foaming composition can be based on alkoxyalkyl

cyanoacrylate monomer, which will have the advantage

of no odour and bearable heat build-up during the

expansion. As a foaming agent TCTFE can be used,

which has the advantage of being odourless, non-toxic,

non-irritant and non-flammable; while as an initiator

ODEBTSA can be used, which has the advantage of

being odourless, non-toxic and non-irritant. The

broken limb will be covered with a suitable stockinette,

preferably of non-woven polypropylene fabric, and

placed in a polymer mould. The foaming composition

will be injected into the mould from a cartridge

dispenser. It will expand into a foam, thus

immobilizing the broken limb. The shell of the mould

can stay in place if desired, in which case it can be

made from any polymer but polyolefin. If it is

desirable to remove the mould it has to be made of

polyethylene or polypropylene. When the lightweight

and rigid polycyanoacrylate foam support is no longer

needed (the fracture has healed), it can easily be

removed by soaking with adequate polycyanoacrylate

solvent. The actual collapse and removal of the cast

will be painless, simple and again accomplished in

matter of seconds or minutes. The shell of the polymer

mould can be reused.

156

INT.J.ADHESION AND ADHESIVES JULY 1992

Evaluation of the suitability of the cyanoacrylate

polymer foam for Fallopian tube sealing and blood

vessel occlusion

Currently methyl-2-cyanoacrylate is being applied as

an agent to occlude the oviducts as a means of

permanent, non-reversible sterilization of consenting

women9. It is instilled in the fundal region of the

uterus, and then is forced into the proximal portion of

the oviducts, where it polymerizes, by the action of an

expanding balloon. The poly(methyl-2-cyanoacrylate)

plug then degrades, releasing degradation products

which incite a local inflammatory response, resulting

in bilateral occlusion of the Fallopian tubes by fibrous

tissue. In two to three months the polymer completely

disappears and is replaced by collageneous scar

tissue1°. A systemized report N on 652 sterilization cases

points out that bilateral tubal closure is obtained in

70.2% of the women after a single application, and in

90.3% after two cyanoacrylate applications.

Experiments on blood vessel treatment with

cyanoacrylates were performed as early as 196412.

Isobutyl cyanoacrylate has been injected by selectively

positioned catheters to close off arteriovenous fistula13

The procedure proved generally successful. In-growth

of fibrous tissue into the sponge-like mass of adhesive

was noted. A life-saving procedure in cases of acute

stomach ulcer haemorrhage is the injection of

cyanoacrylate into the blood vessel responsible for the

haemorrhage 14.

The results obtained in the present study without

any doubt show that any cyanoacrylate foam will be

better than the cyanoacrylate monomer alone. Firstly, it

will ensure better plugging and the plug itself will be

flexible and elastic, rather than a glassy material;

secondly, the heat developed during foaming will be

less than that evolved during the block polymerization

of pure cyanoacrylate, which will eliminate the

associated tissue necrosis; and thirdly, the amount of

cyanoacrylate introduced into the vessel or tube will be

reduced tenfold, which will ease the burden of

eliminating the toxic bio-degradation products. The

best foaming composition will be based on isobutyl-2cyanoacrylate, a monomer which has been tested and

evaluated extensively and has proven to be amongst

the most suitable as surgical adhesives, As most

suitable foaming agent diethyl ether is envisioned. An

advantage in its favour is the expectation that, along

with its excellent foaming ability and wide acceptance

�as a medical aid, diethyl ether will exercise a local

anaesthetic effect and will render the procedure

painless. In the case of Fallopian tube blocking, it is

our belief that, due to its porosity, the

polycyanoacrylate foam plug will degrade faster than a

solid polycyanoacrylate plug. Also, because of its

structure, it will be very easily intertwined during that

process with fibrous tissue, which will take the foam's

place in the formation of a permanent plug of body

tissue. It might be expected that when a foaming

cyanoacrylate composition is used instead of pure

cyanoacrylate monomer the success rate of female

sterilization will improve from the current 90% to 100%

due to its better plugging capacity, and this without the

need of second or third applications.

creating an efficient plug whose adhesion to the pipe

wall was higher than the strength of the foam material

itself. The pipes were hermetically sealed by the foam

plug and easily withstood pressure of 10 atmospheres.

In a following operation acetone was injected with a

syringe through the same opening, subsequently

plugged with foam. In 5 seconds to 2 minutes,

depending on the size of the pipe, the foam collapsed

and flow through the pipe was restored.

The compositions and foaming method discussed

can also be used as instant, foaming adhesives and

sealants as well as in numerous, not so obvious,

applications.

Evaluation of the suitability of the cyanoacrylate

polymer foam for permanent or temporary blockage

of fluid flow in pipelines

Lightweight polycyanoacrylate foams can be obtained

instantly by combining cyanoacrylate monomer with

foaming agent and polymerization initiator. The foams

have high adhesion and instantly bond to the surfaces

they contact during expansion. This new property of

cyanoacrylates opens new vistas of potential

applications as adhesives and sealants in medicine and

industry.

Currently polyurethane-based foam is used to stop gas

flow in gas mains. The foam is produced by mixing

polyether or polyester diol, containing tertiary amine as

catalyst with diphenylmethane-4,4-diisocyanate. By

drilling a hole in the gas main and using special

membranes and cartridges, the foam is injected into

the pipe 15. Very often, however, the foam or pre-foam

material flows along the pipe and/or its expansion

(only four times) is insufficient to block and seal the

pipe. In an improvement of the method 16 a special bag

has been devised which is inserted into the pipe and

has the purpose of holding the material 'in place'. It is

porous, thereby permitting some of the foam to 'ooze'

through the bag, contact the wall of the pipe and

provide a seal. A special device is needed in turn to

hold the bag in the correct position during this

procedure.

It is obvious that the current foam and methods of

blocking gas mains are in no way ideal. The ideal case

would require: (1) a simple method of foam injection

without the use of special bags and devices; (2) the

foam to adhesively bond itself to the walls of the pipe,

so that complete sealing and blockage are ensured; and

(3) the foam to be easily removed at a later stage if

desired, so that fluid flow through the pipe can be

reinstated.

All of these conditions are met by the foaming

compositions and method described in this work. The

foams with best physical properties are based on ethyl2-cyanoacrylate. A variety of foaming agents can be

used, but TCTFE has the advantage of being nonflammable. As initiator both DMPT and ODEBTSAare

adequate.

Tubes and pipes made of cast iron, stainless steel,

copper, polycarbonate, polystyrene, polyvinylchloride,

polypropylene and polyethylene having inside diameter

from 1 mm to 100 mm were plugged with foam by

injecting through a specially drilled opening a foaming

composition consisting of ethyl-2-cyanoacrylate and

TCTFE in volume ratio 4:1 and containing 0.01% by

weight DMPT. The composition expanded into a foam,

Conclusions

Acknowledgement

This work was supported by Feasibility Award FA-90285 in the BRITE/EURAM Programme of the

Commission of the European Communities, 1990.

References

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

"JapanAdhesives Industry Annual Book" (Tokyo, Ja!3an, 1985) p 57

Coover, Jr, H.W. in "Handbook of Adhesives" edited by I. Skeist

(Van Nostrand-Reinhold, New York, NY, USA, 1977) p 569

Guthrie, J., Ottenburn, M.S., Rooney, J.M. and Tsang, C.N. J

Appl Polyrn Sci 30 (1985) pp 2863-2867

International Patent Application WO 92/09651 (1992)

Joyner, F.B. and Sheerer, N.H. US Pat 2 721 858 (1955)

Hawkins, G.F. and McCurry, H.F. US Pat 325 411 (1966)

Danchav, Z., Kotzev, D. and Serafimov, B. J Adhesion Sci Technol

2 No 3 (1988) pp 157-165

Donnelly, E.F. end Pepper, D.C. Makrornol Chem, Rapid Commun

2 (1981) pp 439-442

Nauwirth, R.S. ArnJObstet Gynecol 136 (1968) p 951

Nightingale, J.A., Hoffman, A.S. and Harbert, S.A. Polyrn

Preprints (Am Chem Soc, Div Polym Chern) 24 No 1 (1983) pp

28-29

Neuwirth, R.S. and Richart, R.M. Contraception 31 No 3 (1985)

pp 243-252

Weissberg, D. and Goetz, R.H. Surgery, Gynecol Obstetr 119

(1964) pp 1248-1252

Zanetti, P.H. and Sherman, F.E. J Neurosurg 36 (1972)

pp 72-79

Akimova, A. (VNIIMT, Moscow) private communication

Vick, S.M. UKPet 2 123919 (1986)

~ck, S.M. UKPat2157390{1987)

Authors

The authors are with Chemence Ltd, Princewood

Road, Corby, Northants NN17 2XD, UK.

Correspondence should be directed to D. Kotzev.

INT.J.ADHESION AND ADHESIVES JULY 1992

157

�