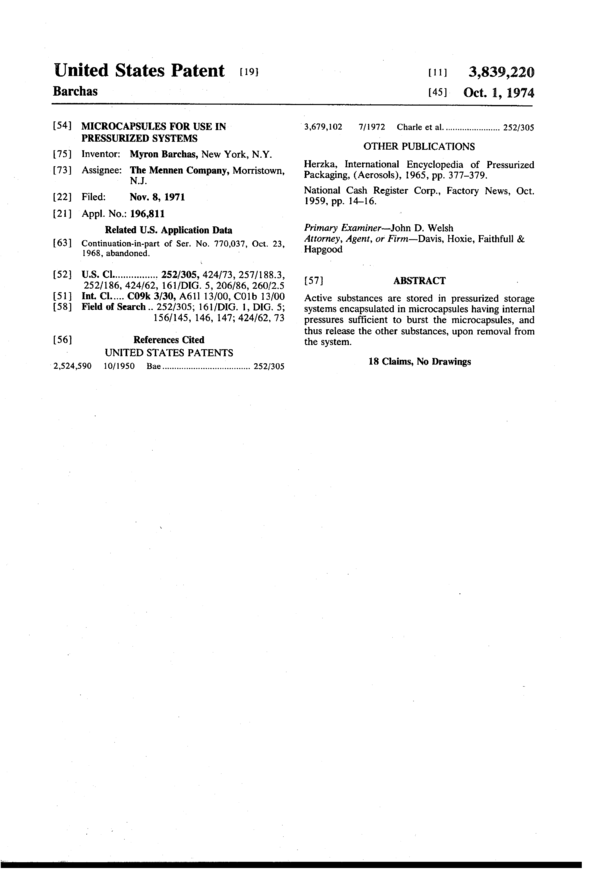

Microcapsules for Use in Pressurized Systems

Folder:

Year:

Abstract:

Active substances are stored in pressurized storage systems encapsulated in microcapsules having internal pressure sucfficient to burst the microcapsules, and thus release the other susbtances, upon removal from the system.

Type of document:

Language:

United States Patent

[19]

Barchas

[54]

[75]

[73]

[22]

[21]

[63]

[52]

[51]

[53]

[56]

2,524,590

MICROCAPSULES FOR USE IN

PRESSURIZED SYSTEMS

Myron Barchas, New York, N.Y.

The Mennen Company, Morristown,

NJ.

Filed: Nov. 8, 1971

Appl. No.: 196,811

Related U.S. Application Data

Continuation—in-part of Ser. No. 770,037, Oct. 23,

1968, abandoned. '

Inventor:

Assignee:

U.S. Cl ............... .. 252/305, 424/73, 257/188.3,

252/186, 424/62, 161/DIG. 5, 206/86, 260/2.5

Int. Cl..... C09k 3/30, A611 13/O0, C01b 13/00

Field of Search .. 252/305; 161/DIG. 1, DIG. 5;

156/145, 146, 147; 424/62, 73

References Cited

UNITED STATES PATENTS

10/1950 Bae ................................... .. 252/305

[111 3,839,220

[45] Oct. 1,1974

3,679,102 7/1972 Charle et al. ..................... .. 252/305

OTl-lER PUBLICATIONS

Herzka, International Encyclopedia of Pressurized

Packaging, (Aerosols), 1965, pp. 377-379.

National Cash Register Corp., Factory News, Oct.

1959, pp. 14-16.

Primary Examiner-—.lohn D. Welsh

Attorney, Agent, or Firm—Davis, Hoxie, Faithfull &

Hapgood

[5 7 ] ABSTRACT

Active substances are stored in pressurized storage

systems encapsulated in microcapsules having internal

pressures sufficient to burst the microcapsules, and

thus release the other substances, upon removal from

the system.

18 Claims, No Drawings

3,839,220

1

MICROCAPSULES FOR USE IN PRESSURIZED

SYSTEMS -

This application is a continuation-in-part of my co-

pending application Ser. No. 770,037, filed Oct. 23,

1968 and now abandoned.

This invention is concerned with systems for storing

active substances under conditions such that their ac-

tivity is suppressed, and in particular with systems for

storing active substances in the presence of other active

substances under conditions such that no reaction will

occur between the two active substances. Further, the

invention is concerned with systems in which an active

substance may be stored in a pressured container, such

as an aerosol container, under conditions such that

upon release or discharge from the container the active

substance can react with another active substance, or

to effect such other physical or chemical change as may

be desired.

In recent years, in a number of areas, it has become

desirable to store active substances in pressurized sys-

tems under conditions such that their activity vis-a-vis

other elements of the system is suppressed or nullified.

Such areas include the fields of shaving preparations,

hair dyes, shampoos, rinses, bleaches and other cos-

metic products, as well as aerosol dispensed polyure-

thane foams, epoxy adhesives, and nylon films. Accord-

ing to present techniques used in these cases, one or

more reactants or catalysts are stored in separate com-

partments and only brought into contact with one an-'

other immediately before use, separate storage of such

active ingredients being necessary to prevent prema-

ture combination or reaction. Many of these proposals

have failed to reach commercial fruition because of the

complexity of available separate storage systems.

One example, which has only recently reached wide-

spread commercial utility, is the so-called hot-shave

aerosol form. Such aerosols are packaged in a two-zone

container, with one‘ zone containing a propellant, a

soap or detergent (with the other ingredients common

to shavecreams), and a reducing agent such as potas-

sium sulfite, potassium theiosulfate or thiourea, as an

active substance; whilethe other zone contains, in ad-

dition to other components and propellant, a second

active substance, viz., an oxidant such as hydrogen per-

oxide. On discharge the oxidant and reducing agent

combine and react exothermically to provide the sensi-

ble heat of the hot shave. See, for example, U.S. Pat.

No. 3,341,418. Such aerosol systems are convention-

ally packaged in containers having separate storage

zones and a complex valve system for discharge. Exam-

ples of these two-zone containers and valves are shown

in numerous U.S. patents, see for example U.S. Pat.

Nos. 2,973,885; 3,045,925.; 3,241,722; and 3,326,416.

Other instances in which multizone storage of active

ingredients is indicated include:

1. permanent hair dyes, where the two separate ac-

tive ingredicnts may be, for example (a) dye intermedi-

ates such as aromatic amines and phenols, and (b) a de-

veloper such as hydrogen peroxide, sodium percarbon-

ate or potassium percarbonate;

2. hair bleaches, where the separate active ingredi-

ents may be. for example. (a) aqueous ammonia and

(b) aqueous hydrogen peroxide, and optionally (c) a

toner dye as an additional component;

l0

15

20

25

30

35

40

45

50

55

60

2

3. epoxy adhesives, where the two separate active in-

gredients may be, for example (a) a polyamide resin

and (b) a bisphenol A epichlorohydrin-based epoxy

resin;

4. polyurethane foams, where the two separate active

ingredients may be, for example, (a) a glycol or poly-

ether, such as hexylene glycol, and (b) a diisocyanate

such as toluene diisocyanate; 9

5. spray-on nylon coatings, where the two separate

active ingredients may be, for example (a) an acylha-

lide, such as adipoyl chloride, and (b) hexamethyl di-

amine;

6. spray-on polyurea coatings, ‘where the two sepa-

rate active ingredients may be, for example, (a) hexa-

methylenediamine and (b) phosgene gas in carbon tet-

rachloride; and ‘ "

7. pressure-dispersed auto body putty formulations,

where the separate active ingredients may be, for ex-

ample, (a) a liquid polyester resin and inhibitor and (b)

an organic peroxide such as benzoyl peroxide.

The present invention provides a means through

which two active substances (including substances mu-

tually reactive with one another as in any of the above

cases) can be stored in a single zone pressurized con-

tainer and maintained isolated from one another until

their release from the container.

In the text which follows, the term “active sub-

stance” includes both substances which will engage in,

promote or retard a chemical reaction, and substances

which, while not actually entering into a chemical reac-

tion, will achieve a physical change in termperature,

color, odor, phase, viscosity, solubility or the like.

Some examples of active substances have been cited

above. .

In the present text, the term “microcapsules” is used

in the sense familiar to the art to mean capsules of min-

ute size, e.g., from less than 200, say from 3 to about

450 microns, comprising a solid wall (which may be of

a single layer or multilayered) enclosing a material dif-

ferent from the wall. See for example NCR “Factory

News” October l959, p. 14. The present invention

finds its greatest application in aerosol containers and

the limit of 450 microns is indicated by the structure of

conventional aerosol valves. However, the invention is

capable of other applications and in some of these,

such as pop-top containers, there is no specific upper

vi!

limit on microcapsule size. _

In accordance with the invention, active substances

are encapsulated in microcapsules along with a burst-

ing fluid component and stored in a container, e.g., an

aerosol container, under pressure. The nature and

quantity of bursting fluid are selected so that the pres-

sure inside the capsules (due in most cases solely to the

vapor pressure of'the bursting fluid), under the condi-

tions of storage, is equal to or less than the pressure in

the container, but substantially greater than the pres-

sure outside the container under use conditions so that

when released from the container the microcapsules

are caused to burst or explode through the agency of

the bursting fluid, releasing the active substance to

react with other active substances or to exert some

other desired physical effect.

Since storage of the microcapsules in their container

is under pressure. there must obviously be some fluid

medium present in the container external to the micro-

capsules to maintain the external pressure. In the case

of aerosol systems, this fluid medium is normally an

3,839,220

3

aerosol propellant, typically one of those listed below,

with, possibly, other materials including materials ca-

pable of reacting with the encapsulated active material

dissolved or dispersed within the propellant. The mi-

crocapsules themselves may be dispersed in the fluid

medium in a stable suspension or they may be concen-

trated in an upper or lower-layer depending on relative

densities of the capsules and the fluid medium.

Obviously, the fluid medium need not be an aerosol

propellant if an aerosol spray is not desired. For exam-

ple, a pop-top container might be pressurized with ni-

trogen or carbon dioxide. The fluid pressuring medium

will normally be present, in part, in the liquid phase.

However, the invention includes the case where pres-

suring liquid is held in a solid adsorbent as in U.S. Pat.

No. 3,088,874.

The invention therefore comprises, in one aspect, a

system for storing active materials comprising a con-

tainer, a fluid pressurizing medium in said container,

and a multiplicity of microcapsules in said container,

each of said microcapsules containing a charge consist-

ing essentially of said active material to be stored and

a bursting fluid, said bursting fluid being present in an

amount, and having a vapor pressure such that, the

pressure inside said microcapsules is not substantially

different from‘ the pressure of said fluid medium in said

container, but is sufficiently greater than the pressure

prevailing outside said container under normal condi-

tions of use, to effect bursting of said capsules upon

their removal from said container.

Numerous techniques are available for microencap-

sulating substances, such as the active ingredients in-

volved here. Seefor example U.S. Pat. Nos. 2,665,228;

2,800,457; 2,800,458 (U.S. Pat. No. Re. 24,899);

2,846,971; 2,969,330; 2,969,331; 3,015,128;

3,041,289; 3,056,728; 3,091,567; 3,121,698;

3,159,585; and 3,172,878; British Pat. No. 1,091,141;

and Microencapsulation, a special report published by

Management Reports, Boston (1963).

Virtually any kind of compound can be encapsulated

in any of a number of encapsulating media, by one or

more encapsulating processes. These processes include

the simple and complex coacervation processes, the in-

terfacial polymerization process, the organic phase sep-

aration method. the exchange process and the meltable

dispersion process, all of which are described in the ref-

erence noted above.

With reference to the encapsulation of some of the

typical active ingredients listed above, for example,

solid potassium percarbonate may be encapsulated by

the method of U.S. Pat. No. 3,121,698; toluene diisocy.-

anate may be encapsulated by the interfacial polycon-

densation,method; hexamethylenediamine may be en-

capsulated by the organic phase separation method;

and perfume may be encapsulated by the simple coac-

ervation process. ‘

In accordance with this invention, an active ingredi-

ent is encapsulated by one of the above procedures or

its equivalent. A volatile bursting fluid may then be in-

corporated into the microcapsules. Preferably this is

accomplished by soaking microcapsules containing an

active ingredient under high pressure in the bursting

fluid while the bursting fluid is in a liquid state until the-

liquid diffuses into the interior of the microcapsules.

The resulting pressurized microcapsules then contain

both an activer ingredient and the bursting compo-

ment. It is of course possible in some instancesto pre-

l0

15

20

25

30

40

45

50

55

60

4

pare similar microcapsules by the reverse procedure,

that is, by first encapsulating the bursting fluid and then

adding the active ingredient, or by simultaneously en-

capsulating both the bursting component and the active

ingredient. ‘ ’

As indicated above, the bursting liquid must be se-

lected, having regard to the other components of the

system, so that its vapor pressure under normal storage

conditions is equivalent to, or not substantially differ-

ent from (and in any case not substantially greater

than) the pressure in the container but is sufficiently

greater than the pressure outside the container under

normal use conditions to burst the capsule walls. Obvi-

ously the numerical values of the pressures will vary

substantially depending on the use /intended, as well as

on the material shape and uniformity of the capsule

walls. The internal microcapsule pressure will roughly

be the same as the container pressure. This internal

pressure is for the most part equal to the vapor pressure

of the bursting fluid, sincefor the most part the active

material will be solid or liquid of low volatility and its

contribution to the internal capsule pressure will be

negligible, and hence the internal capsule pressure will

usually be from 10 psig to 96 psig. Conventional aero-

sol containers have internal pressures of this order, de-

pending on the propellants used, and, of course, the

prevailing temperature. On the other hand, for applica-

tions such as underwater or deep-sea operations, or for

operations in outer space, the pressures in the con-

tainer and hence in the microcapsules may vary very

greatly indeed, from this norm. For example, the sea

water pressure at a depth of 1,000 feet is 443' psig. and

if it was intended to use the invention at such depths,

the container pressure and the microcapsule pressure

should be 10 psig. to 100 pounds above that to secure

propulsion and explosion of the capsule. Conversely, in

a vacuum, e.g., in outer space, the pressure required for

the container and capsules could be on the order of 0~2

psig. Obviously, therefore, hard and fast numerical lim-

its cannot be defined.

For most purposes, the bursting component can be

selected from those materials conventionally used as

aerosol propellants. Such propellants include the fluo-

rocarbons, such as fluorocarbon 1 1 (trichloroflu-

oromethane) fluorocarbon 14 (tetrafluoromethane),

fluorocarbon 21 (dichlorofluoromethane), fluorocar-

bon 22 (chlorodifluoromethane), fluorocarbon 23

(fluoroform), fluorocarbon l 13 (trichlorotri-

fluoroethane), fluorocarbon 1 14 (dichlorotetra-

fluoroethane), fluorocarbon 1 15 (chloropenta-

fluoroethane), and fluorocarbon 116 (hexafluoroe-

thane); and other propellants such as hydrocarbons,

including propane, n-butane and isobutane, and halo-

hydrocarbons such as methylene chloride and vinyl

chloride and other volatile organic materials, such as

dimethyl ether. Preferably the bursting fluid is one that

may be readily encapsulated by diffusion through cap-

sule walls or by the simple coacervation process.

Microcapsules as described, containing one or more

active substances and a bursting fluid may be incorpo-

rated in pressurized systems, such as aerosol systems

with other similar microcapsules containing different

active substances. '

In most instances there will be a plurality of active

substances present in the pressurized system at least

one of which willbe inpressurized microcapsules.

3,839,220

5

The pressurized composition is, of course, main-

tained in a container. As the product is discharged from

the container, or as the container is opened to the at-

mosphere, the pressurized microcapsules upon reach-

ing atmospheric pressure burst or explode due to the

pressure of the encapsulated bursting fluid, and thereby

release the encapsulated active substance to contact

with the other active ingredients in the system. The ac-

tive ingredients in contact with one another are then

capable of reacting, or catalyzing a reaction, or other-

wise combining, depending upon their desired func-

tion. -

As in the examples briefly described above, the en-

capsulated active ingredient employed in this invention

generally engages in a chemical reaction, after release

upon rupture of the microcapsules at atmospheric pres-

sure. However, there are other uses for the exploding

microcapsules wherein the active ingredients are not

chemically reactive.

It may be desirable, for example, to keep separate

two or more mutually soluble components, as in a spat-

ter paint where two or more differently colored, mutu-

ally soluble phases are used. Accordingly, pressurized

microcapsules containing variously colored paints, as

active ingredients, may be dispersed in a base paint, in

a pressurized system. When this produce is sprayed

onto a surface, the pressurized microcapsules explode

to release tiny spots of color, which by dissolving into

the continuous base paint phase form variously colored

areas. A smooth continuous paint film results which is

unique in texture, appearance and stability, when com-

pared with existing multiphase spatter paints. By this

method, it is ‘possible to produce round spots of color

on a background, or to run multicolored droplets down

a surface.

Another area of utility for the invention, also not in-

volving a chemical reaction, is to increase the stability

of pressurized systems, such as aerosols. In such appli-

cations, pressurized microcapsules are employedto en-

capsulate a component, as the active substance, other-

wise unstable in the pressurized system. For example,

in water—based aerosol room deodorants, perfume may

be encapsulated to prevent ‘its deterioration during

storage, as by reaction with other components of the

aerosol system, or with the container and its linings or

the like. The stabilized perfume is released by explo-

sion of the microcapsules as the product is used.

There are numerous additional variations of the pres-

ent concept which are intended to be included within

the scope of the invention. Thus in one embodiment, a

solid active agent, for example, benzoyl peroxide, a

solid oxidant, may be encapsulated simultaneously with

a volatile bursting liquid by the simple coacervation

process. In carrying out tne encapsulation, the volatile

bursting liquid. for example, a 50:50 mixture of fluoro-

carbons 11 and 12, is dispersed in an aqueous disper-

sion of a hydrophilic colloid, such as gelatin or starch.

Then solid benzoyl peroxide is also dispersed into the

aqueous dispersion, and the mixture is agitated to form

an emulsion of the volatile liquid, with the solid oxidant

particles occluded thereon. The colloid is then coacer-

vated to form solid microcapsules containing the vola-

tile liquid and solid oxidant. All of the above steps are

performed under pressure, and the pressurized micro-

capsules are then packaged in a product container.

It is also within the scope of this invention to employ

walled clusters of capsules, such as those described in

I0

15

25

30

35

40

45

50

55

60

6

U.S. Pat. No. 3,041,289. In such an embodiment, the

clusters may include a plurality of different microcap-

sules, for example, one group of capsules might be

pressurized and contain an active substance, while the

other, also containing active substances, is not pressur-

ized. In this case, the first group of capsules will in-

stantly burst upon release, while the second group can

be arranged to release more gradually, for example by

dissolution of the capsule walls, to provide a sustained

reaction. Such an arrangement is particularly appropri-

ate in hot shaves, which now have the drawback of los-

ing heat rapidly, since a sustained reaction such as

above described will permit the shave cream to remain

hot for a longer period. _

The walls of the microcapsules prepared by conven-

tional processes ‘are typically porous to propellants

such as the fluorocarbons listed above. This permits in-

corporation of volatile fluids or active ingredients by

diffusion and displacement. But the wall porosity may

allow as well premature release of the active ingredient,

or diffusion of other active ingredients into the nuclei.

Thus, it may be desirable to coat the microcapsules

with an impermeable layer prior to use. Dual-walled

capsules, as described in U.S. Pat. No. 2,969,331, may

also be used. Such dual-walled capsules may be de-

sired, for example, when the inner wall would be solu-

ble in the aerosol product, with the outer wall in that

case being insoluble or water-repellant. In addition, the

pressurized microcap_sules may be sealed by an inert

outer wall, for example by dipping or vapor coating

with aluminum, or by coating with glass.

The present invention involves the phenomenon by

which pressurized microcapsules burst upon being sub-

jected to atmospheric pressure. In accordance with the

present invention microcapsules are formed containing

a perfume encapsulated in colloidal gelatin hardened

with formaldehyde by the simple coacervation process

described in U.S. Pat. No. 2,800,458. The gelatin cap-

sule walls are porous, and a volatile fluid, such as a flu-

orocarbon propellant, may be added to the microcap-

sules by the exchange process, simply by soaking in the

volatile fluid. In this example, the microcapsules thus

formed were soaked in 50:50 mixture of propellants 1 l

and 12, at about 37.5 psig., for about 24 hours. The

pressurized microcapsules were then removed from the

container and allowed to stand for a very short time at

atmospheric pressure. After about 2 minutes, the mi-

crocapsules burst, releasing to the atmosphere the ac-

tive perfume ingredient in the nuclei.

The following examples will illustrate embodiments

of the present invention for some of the uses discussed

generally above. Ratios and percentages are by weight,

and temperature is about room temperature unless

stated to be otherwise.

EXAMPLE I

In the example a hair dye is prepared by encapsulat-

ing one of the active ingredients in pressurized micro-

capsules, which are then stored in a pressurized aerosol

system containing the remaining components of the

dye. The dyes, in this case a combination of aromatic

amines and phenols are stored in the system separately »

from the developer, potassium percarbonate, encapsu-

lated in pressurized microcapsules.

The solid potassium percarbonate is encapsulated in

a polyolefin in accordance with a method more com-

pletely set forth in U.S. Pat. No. 3,121,698. In this pro-

3,839,220

7

cedure, 5-micron or smaller potassium percarbonate

particles are precoated with a water-soluble cellulose

ether, by dispersing the particles in a solution of Klucel,

a cellulose ether, with Cellosolve solvent, ethylene gly-

col monoethyl ether, and a spray drying the dispersion.

Precoating the particles prevents the poisoning of the

catalyst in the following polymerization step.

A 3,000 ml. reaction flask is flushed with nitrogen,

and then charged under agitation with 1,800 ml. of tol-

uene, 50 grams of the cellulose-coated potassium per-

carbonate particles, and 20 millimols of titanium tetra-

chloride. After 5 minutes 20 millimols of triethylalu-

minum are added. Ethylene gas is passed into the reac-

tion mixture, and the temperature is raised to 65°C. For

3 hours the reaction is continued by the addition of eth-

l0

15

ylene as fast as it is used up. Then the reaction is -

stopped, and the product is filtered, washed with meth-

anol and dried.

The polyolefin coating of the microcapsules at this

point is not continuous, and the encapsulated potas-

sium percarbonate may be leached out with a solvent,

such as water, to provide space for a volatile fluid. The

particles are leached by stirring in water at 60°C. until

about 5 percent of the encapsulated potassium percar-

bonate is extracted. Then the microcapsules are dried

and sintered to render the polyolefin coating continu-

ous. The microcapsules are then slurried under pres-

sure with a 50:50 mixture of liquid propellants 11 and

12, and maintained at 90°—l25°F. under at least 110

psig. for at least 24 hours, whereby the volatile liquid 30

propellant molecularly permeates the capsule walls and

fills the leached voids of the microcapsules. ,

Finally the microcapsules are packaged in a conven-

tional manner in an aerosol container with the dye in-

termediates, the aromatic amines and phenols, and

other ingredients to complete the product, in the re-

quired stoichiometric proportions.

EXAMPLE II

In this example a hot shave cream in an aerosol con- 40

tainer is prepared by encapsulating an oxidant, sodium

percarbonate, as an active ingredient in pressurized mi-

crocapsules, and packaging the aerosol with the micro-

capsules dispersed in the remaining components of the

20

25

35

product, including a reductant as the other active in- 45

gredient. Upon discharge of the product from the aero-

sol container, the microcapsules explode to release the

oxidant, which in turn reacts exothermically with the

reductant to provide sensible heat to the shave cream.

The sodium percarbonate is encapsulated in polyole‘-,

fin microcapsules by substantially the same procedure

used in Example I to encapsulate the potassium percar-

bonate; and the same volatile fluid, an equal mixture of

propellants 1 l and 12, is added to pressurize the micro-

capsules.

The product is packaged in a conventional manner as

a shave cream, except that a reducing agent, a mixture

of potassium sulfite and potassium thiosulfate, is added

directly to the product, and the pressurized microcap-

sules containing the oxidant are dispersed therein, both

active ingredients being in proper stoichiometric ratio

and quantity to heat the shave cream to about l50°F.

shortly after discharge from the aerosol.

EXAMPLE lll

In this example the components of a polyurethane

50

55

60

65

8

foam are packaged in a pressurized container, with one

of the reactants encapsulated in pressurized microcap-

sules to prevent reaction until the discharge of the

product from the container. The two primary reactants

of the system are hexylene glycol and toluene diisocya-

nate. It is advantageous to encapuslate the diisocyanate

because of its highly toxic nature.

The toluene diisocyanate is encapsulated by the in-

terfacial polycondensation method, described in

greater detail in British Pat. No. 1,091,141. A polyam-

ide, a polyurethane or any other suitable wall material

may be used. The procedure may be carried out in the

following manner:

Into a flask containing 300 ml. of polyvinyl alcohol

(Elvanol SO-42, containing 0.5 percent water), there is

added rapidly a solution of 12' g. of sebacoyl chloride,

3 ml. of trimesoyl trichloride and 75 ml. of toluene di-

isocyanate containing 5 percent perfume, under agita-

tion sufficiently strong to form a dispersion of tiny

droplets. The agitation is reduced but maintained while

there is added rapidly 50 ml. of distilled water contain-

ing l2 g. of ethylenediamine, 4.65 g. of 1,3,5-benzene

triamine trihydrochloride, 2.4 g. of sodium hydroxide

and 10 g. of sodium carbonate monohydrate. Slow agi-

tation is continued for two hours. Then the microcap-

sules so formed are filtered, washed with acetone and

dried.

The microcapsules are pressurized by diffusion to

displace the encapsulated perfume with an equal mix-

ture of propellants 1 1 and 12, in a "closed container at

about 100 psig. and 90°—l25°F. for at least 72 hours.

The volatile liquid propellant diffuses through the cap-

sule wall to displace the perfume. The microcapsules

are maintained under pressure until use.

Alternatively the toluene diisocyanate and the vola-

tile propellant may be encapsulated simultaneously, by

substituting the propellant for the perfume in the above

procedure. The conditions of encapsulation remain the

same except that the procedure is carried out under

pressure sufficient to maintain the propellant as a liq-

uid. Direct encapsulation in this manner of course elim-

inates the need for the diffusion step.

The encapsulated toluene diisocyanate is packaged

in proper stoichiometric proportion with the hexylene

glycol, and the remaining components of the polyure-

thane foam: water, catalysts, dispersing agents, fillers,

emulsifiers, and other substances. Upon release of the

product from the pressurized system, the microcap-

sules explode to release the diisocyanate, which in turn

reacts with the glycol and water to form a polyurethane

foam. Other reactants may also be used, and their

choice as well as the choice and proportions of the re-

maining components will depend on the characteristics

desired for the foam product.

'0 EXAMPLE [V

In this example a spray—on nylon coating product is

prepared and packaged in an aerosol container. The

two separated active ingredients are adipoyl chloride

and hexamethylenediamine. The hexamethylene-

diamine being somewhat soluble in water may be en-

capsulated by the organic phase separation method de-

scribed more fully in U.S. Pat. No. 3,173,878.

l-lexamethylenediamine containing 5 percent of a

suitable perfume is dispersed by strong agitation into a

5 percent solution of ethyl cellulose in tetrachloro~

ethylene. A 48 percent ethoxylated cellulose polymer

3,839,220

‘ 9

(Hercules N-100), eventually to form the resin wall

material, is added to the dispersion to provide a weight

ratio of hexamethylenediamine to polymer of 5: 1. One

percent of sorbitain sesquioleate (Arlacel C) is also

added to the dispersion as an emulsifying agent. Petro-

leum ether (65°—l 10°C) is slowly added to the disper-

sion, and the ethoxylated polymer precipitates about

the dispersed amine droplets to form a profusion of tiny

(0.5-5 microns) microcapsules. The resulting slurry is

stirred and cooled to about 15°C. The microcapsules

are then separated from the equilibrium liquid by de-

cantation, and are hardened by gradual and progressive

insolubilization of the ethyl cellulose by washing with

petroleum ether successively until the effluent is sub-

stantially free of tetrachloroethylene. The hardened

capsules are separated from the final wash by filtration,

and dried.

The bursting fluid, an equal mixture of Freons l 1 and

12, is added to pressurize the microcapsules by essen-

tially the same method as employed in the above exam-

ples. The microcapsules are maintained dispersed in

the liquid propellant at about 90°—l25°F. and 100 psig.

for at least 24 hours, while the propellant permeates

the capsule walls to displace the perfume and pressur-

ize the microcapsules. Also, as in the above examples,

the pressurized microcapsules are maintained under

sufficient pressure to prevent explosion until use.

The microcapsules containing as an active ingredient

hexamethylenediamine are charged into a conventional

aerosol container in proper proportion with adipoyl

chloride, propellant and other ingredients to provide a

spray—on nylon aerosol product.

EXAMPLE V

In this example an epoxy adhesive is prepared and

packaged in an aerosol container. An active ingredient,

a polyamide resin (Versamid), is encapsulated by the

simple aqueous coacervation method, described more

fully in U.S. Pat. No. 2,800,458, now U.S. Pat. No. Re.

24,899. . .

One gallon of a polyamide-in-water emulsion is pre-

pared by combining two parts by weight of the polyam-

ide containing 5 percent of a suitable perfume, and 100

parts of a solution of 10 percent pigskin gelatin in water

and emulsifying the mixture until the polyamide drop-

lets are about 2-5 microns in diameter. The emulsifica-

tio__n takes place at 50°C. to prevent gelling of the gela-

tin. Continuing about 50°C ., coacervation is induced by

adding slowly and uniformly 0.4 gallon of a 20 percent

sodium sulfate solution in water. The coacervate is then

gelled, by pouring it with agitation into 10 gallons of 7

percent solution of sodium sulfate in water at 19°C.

The resulting microcapsules are filtered and washed

with water to remove the salt, at a temperature below

the melting point of the gelatin. The microcapsules are

l0

15

20

25

30

35

40

45

50

then hardened by combining the filter cake with 2 gal- _

lons of a 37 percent solution of formaldehyde in water.

The hardened mass of microcapsules is again filtered

and washed to remove the residual formaldehyde. The

resulting microcapsules are finally slurried in water and

spray-dried to yield unagglomerated capsules.

The microcapsules are pressurized in a slurry with an

equal mixture of propellants l l and 12, at about

90°—125°F. and l00 psig., for at least 24 hours. The

60

65

propellants permeate the capsule walls to displace the A

encapsulated perfume.

10-

The encapsulated polyamide resin is combined under

pressure with a bisphenol A epichlorohydrin-based

epoxy resin (Genepoxide) and the remaining ingredi-

ents in an aerosol container to provide the epoxy adhe-

sive product.

It will be noted that in the above examples the micro-

capsules are pressurized by contact with a liquid pro-

pellant at about 90°—l 25°F. This procedure accelerates

the diffusion of the propellant into the microcapsules.

Higher or lower temperatures (and pressures)'may be

employed, however, with a proportional effect on the

rate of diffusion. Indeed, in some cases it may be possi-

ble to eliminate the pressurization step entirely, and to

pressurize the microcapsules in the finished product

containing a propellant. The success of this latter pro-

cedure will depend largelyon the propellant concentra-

tion in the finished product, which will directly affect

the rate of diffusion. It is preferred, nevertheless, to

pressurize the microcapsules, as a separate step, by

contact at elevated temperature with a liquefied vola-

tile fluid.

What is claimed is:

l. A system for storing two active substances which

are reactive with one another comprising an aerosol

container containing said substances, a liquid aerosol

propellant in said container under pressure and a multi-

plicity of_ microcapsules having solid walls in said con-

tainer, at least some‘ of said microcapsules containing

an encapsulate consisting essentially of one of said ac-

tive substances and a bursting fluid selected from the

group consisting of fluorocarbons, hydrocarbons,

methylene chloride, vinylchloride, dimethyl ether and

mixtures thereof, said bursting fluid being present in an

amount and having a vapor pressure such that the pres-

sure inside said microcapsules is not substantially dif-

ferent from the pressure of said propellant in said con-

tainer, but is sufficiently greater than the pressure pre-

vailing outside said container under normal conditions

of use to cause bursting of said capsules upon their dis-

charge from said container, substantially all of said one

substance in said container being in microcapsules.

2. The system claimed in claim 1 wherein the burst-

ing fluid is trichlorofluoromethane, difluorodi-

chloromethane, tetrafluoromethane, dichloroflu-

oromethane, chlorodifluoromethane, fluoroform, tri-

chlorotrifluoroethane, dichlorotetrafluoroethane, chlo-

ropentafluoroethane, hexafluoroethane, or mixtures

thereof.

3. The system claimed in claim 1 wherein the burst-

ing fluid is propane, n-butane, i-butane, or mixtures

thereof.

4. The system claimed in claim 1, wherein the burst-

ing fluid is methylene chloride or dimethyl ether.

5. The pressurized system of claim 1, wherein the sys-

tem contains a shave cream and at least two active sub-

stances which in combination are capable of reacting

exothermically to provide sensible heat to the shave

cream, at least one of said active substances being en-

capsulated in microcapsules.

6. The pressurized self-heating shave cream system of

claim 5, wherein said active substances include an oxi-

dant and a reducing agent.

7. The pressurized self-heating shave cream system of

claim 6, wherein said oxidant is selected from the group

consisting of sodium percarbonate and potassium per-

carbonate and is encapsulated within microcapsules _

3,839,220

11

having polyolefin walls, and wherein said bursting fluid

comprises dichlorodifluoromethane.

8. The pressurized system of claim 1, wherein the sys-

tem contains at least two active substances which in

combination are-capable of reacting to form a hair dye,

at least one of said active substances being encapsu-

lated ‘in microcapsules.

9. The pressurized hair dye system of claim 8,

wherein said active substances include at least one dye

intermediate, selected from the group consisting of aro-

matic amines and aromatic phenols, and a developer

selected from the group consisting of hydrogen perox-

ide, sodium percarbonate and potassium percarbonate,

and wherein said developer is encapsulated in said

pressurized microcapsules. '

10. The pressurized system of claim 1, wherein the

system contains active hair bleach component sub-

stances, comprising aqueous ammonia and hydrogen

peroxide, at least one of said active substances being

encapsulated in microcapsules.

ll. Thepressurized system of claim 1,‘wherein the

system contains at least two active substances which in‘

combination are capable of reacting to form an adhe-

sive, at least one of said active substances being encap-

sulated in microcapsules. '

12. The pressurized system of claim 11 wherein the

bursting fluid is trichlorofluoromethane, difluoro-

10

I5

20

25

-30

35

40

45

50

55

60

65‘

12

chloromethane, tetrafluoromethane, dichloroflu-

oromethane, chlorodifluoromethane, fluoroform, tri-

chlorotrifluoroethane, dichlorofluoroethane, hexa-

fluoroethane or mixtures thereof.

13. The pressurized system of claim 11 wherein the

bursting fluid is propane, i-butane or n-butane or mix-

tures thereof.

14. The pressurized system of claim 11 wherein the

active substances are capable of forming an epoxy ad-

hesive.

15. The pressurized system of claim 1, wherein the

system contains at least two active substances which

are capable of reacting to form a polyurethane foam,

at least one of said active substances being encapsu-

lated in microcapsules.

16. The pressurized system of claim 1, wherein the

system contains at leasttwo active substances capable

of reacting to form a nylon, at least one of said active

substances being encapsulated in microcapsules.

17. The pressurized system of claim 1, wherein the

system contains at least two active substances capable

of reacting to form a polyurea, at least one of said ac-

tive substances being encapsulated in microcapsules.

18. The pressurized system of claim 1, wherein the

system contains a first paintrencapsulated in microcap-

sules, and a second paint of a different color.

=l< * =l< * *

Coments go here:

- Log in to post comments