Powder Aerosol

Folder:

Year:

Abstract:

This invention relates to a novel powder aerosol system. More specifically, this invention relates to a novel powder aerosol formulation which enables at least 15 percent by wieght of active powder to be dispensed in a conventional aerosol bomb.

Type of document:

Language:

United States Patent Office

3,088,874

Patented May 7, 1963

1

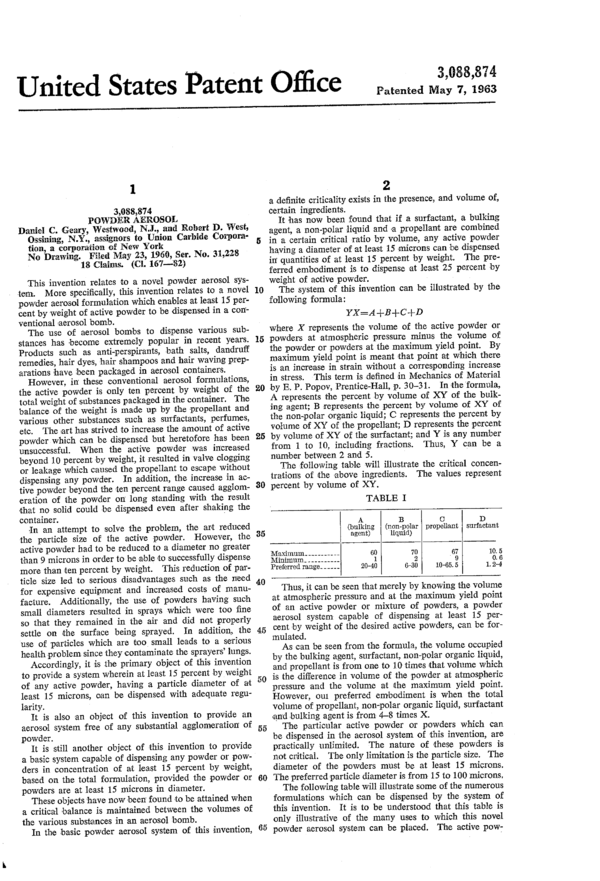

3,088,874

POWDER AEROSOL

Daniel C. Geary, Westwood, N.J., and Robert D. West,

Ossining, N.Y., assignors to Union Carbide Corpora-

tion, a corporation of New York

No Drawing. Filed May 23, 1960, Ser. No. 31,228

18 Claims. (Cl. 167-482)

This invention relates -to a novel powder aerosol sys-

tem. More specifically, this invention relates to a novel

powder aerosol formulation which enables at least 15 per-

cent by weight of active powder to be dispensed in a con‘-

ventional «aerosol bomb.

The use of aerosol bombs to dispense various sub-

stances has -become extremely popular in recent years.

Products such as anti-perspirants, bath salts, dandruff

remedies, hair dyes, hair shampoos and hair waving prep-

arations have been packaged in aerosol containers.

However, in‘ these conventional aerosol formulations,

the active powder is only ten percent by Weight of the

total weight of substances packaged in the container. The

balance of the weight is made up by the propellant and

various other substances such as surfactants, perfumes,

etc. The art has strived to increase the amount of active

powder which can be dispensed but heretofore has been

unsuccessful. When the active powder was increased

beyond 10 percent by weight, it resulted in valve clogging

or leakage which ca-used the propellant to escape without

dispensing any powder. In addition, the increase in ac-

tive powder beyond the ten percent range caused agglom-

eration of the powder on long standing with the result

-that no solid could be dispensed even after shaking the

container.

-In an attempt to solve the problem, the ar-t reduced

the particle size of the active powder. However, the

active powder had to be -reduced to a diameter no greater

than 9 microns in order to be ‘able -to successfully dispense

more than ten percent by weight. This reduction of par-

ticle size led to serious disadvantages such as the need

for expensive equipment and increased costs of manu-

facture. Additionally, the use of powders having such

small diameters resulted in sprays which were too fine

so that they remained in the air and did not properly

settle on the surface being sprayed. In addition, the

use of particles which are too small leads to a serious

health problem since they contaminate the sprayers’ lungs.

Accordingly, it is the primary object of this invention

to provide a system wherein at least 15 percent by weight

of any active powder, having a particle diameter of at

least 15 microns, can be dispensed with adequate regu-

larity.

It is also an object of this invention to provide an

aerosol system free of any substantial agglomeration‘ of

powder.

It is still another object of this invention to provide

a basic system capable of dispensing any powder or pow-

ders in concentration of at least 15 percent by weight,

based on the total formulation, provided the powder or

powders are at least 15 microns in diameter.

These objects have now been found to be attained when

a critical balance is maintained between the volumes of

the various substances in an aerosol bomb.

In the basic powder aerosol system of this invention,

10

15

20

25

30

35

40

45

50

55

60

65

2

a definite criticality exists in the presence, and volume of,

certain ingredients.

It has now been found that if a surfactant, a bulking

agent, a non-polar liquid and «a propellant are combined

in a certain critical -ratio by Volume, any active powder

having a diameter of -at least 15 microns can be dispensed

in‘ quantities of at least 15 percent by weight. The pre-

ferred embodiment is to dispense at least 25 percent by

weight of active powder.

The system of this invention can be illustrated by the

following formula:

YX=A+B+C+D

where X represents the volume of the active powder or

powders at ‘atmospheric pressure minus the volume of

the powder or powders at the maximum yield point. By

maximum yield point is meant that point at which there

is an increase in strain without a corresponding increase

in stress. This term is defined -in Mechanics of Material

by E. P. Popov, Prentice-Hall, p. 30-31. In the "formula,

A represents the percent by volume of XY of the bulk-

ing agent; B represents the percent by volume of XY of

the non-polar organic liquid; C represents the percent by

volume of XY of the propellant; D represents the percent

by volume of XY of the surfactant; and Y is any number

from 1 to 10, including fractions. Thus, Y can be a

number between 2 and 5.

The following table will illustrate the critical concen-

trations of the above ingredients. The values represent

percent by volume of XY.

TABLE I

A B C D

(bulking (non—polar propellant surfactant

agent) liquid)

Maximum ......... .. 60 70 67 10. 5

Minimum _________ __ 1 2 9 0.6

Preferred range ____ ._ 20-40 6-30 10-65. 5 1. 2-4

Thus, it can be seen that merely by knowing the volume

at atmospheric pressure and at the maximum yield point

of an active powder or mixture of powders, a powder

aerosol system capable of dispensing at least 15 per-

cent by weight of the desired active powders, can be for-

mulated.

As can be seen from the formula, the volume occupied

by the bulking agent, surfactant, non-polar organic liqu-id,

and propellant is from one to 10 times that volume which

is the difference in volume of the powder at atmospheric

pressure and the volume at the maximum yield point.

However, oui preferred embodiment is when the total

Volume of propellant, non—polar organic liquid, surfactant

and -bulking agent is from 4-8 times X.

The particular active powder or powders which can

be dispensed in the aerosol system of this invention, are

practically unlimited. The nature of these powders is

not critical. The only limitation is the particle size. The

diameter of the powders must be at least 15 microns.

The preferred particle diameter is from 15 to 100 microns.

The following table will illustrate some of the numerous

formulations which can be dispensed by the system of

this invention. It is to be understood that this table is

only illustrative of the many uses to which this novel

powder aerosol system can be placed. The active pow-

3,088,874

3

ders set forth under the various headings can be used

alone or in combination with each other.

TABLE II

Type of Formulation Active Powder

Tooth Powder ___________________ __ dicalcium phosphate.

anhydrous dicalciuin phosphate.

hydrated dicalcium phosphate.

tricalcium phosphate.

calcium sulfate.

calcium carbonate.

aluminum sulfocarbolate.

zinc sulfocarbolate.

aluminum chlorohydrol.

aluminum sulfate.

aluminum chloride.

zinc sulfate.

zinc chloride.

zirconium chloride.

zirconium sulfate.

Anti-Persplrants _________________ __

Catamenlal napkin powder or hexachlorophcne and talc.

Body Powder. '

Foot Powder ..................... -_ talc and dlehlorophene.

tale‘ and a salt of nndelaeic acid.

Polish ........................... -_ pumice and a detergent. ‘

It is to be understood that the presence of conventional

amounts of other ingredients does not affect the novel

powder aerosol system. Thus, when making a body

-powder, small amounts of perfume can be added as is

customarily done in this type of formualtion. Addition-

ally, small amounts of water can be added when making

autiperspirants, as is also conventional in this type of

formulation.

The nature of the bulking agent is also not critical. It

can be any powder which does not affect the intended use

of the aerosol formulation. The only practical limitation

of the bulking agent is that it must have a particle size

no bigger than that of the active powder being dispensed.

Examples of these bulking agents include silicon dioxide,

powdered mica, clay, flour, etc.

‘As a further illustration that the nature of the bulk-

ing agent is not critical, the following example is given.

Assuming that an aerosol bomb was desired to dispense

a foot powder whose active ingredient was talc. If the

tale employed was composed of particles which had a

diameter of 50 microns, the bulking agent ,c,ou_ld also be

talc having a particle size of 20 microns.

Thus, it can be seen that the nature of the bulking

agent is not critical but its presence is.

The organic liquid which is also necessary in the pres-

ent system can be any non-polar organic liquid which is

miscible in all proportions with the surfactant and pro-

pellant, which reduces the cohesive force of the active

-powder particles and which is an electrical insulator.

The reason why this liquid must be an electrical insulator

to operate in the system of this invention is not under-

.stood.. The fact remains that liquids which act as con-

ductors will not be operable. Examples of operable

substances include any hydrophobic oil or ester having a

specific gravity of 1.6 or less, and liquid hydrocarbons

such as hexane, heptane, octane, etc. The preferred

liquid is a_ mineral oil having a specific gravity of 0.9 or

less. The esters which are operable include the esters of

monocarboxylic acids having from 2-18 carbon atoms

and monohydric alcohols having from 1 to 18 carbon

atoms. Of these esters, the ones which are especially

desirable are those of monocarboxylic acids having from

10 to 1-8 carbon atoms. Specific examples of these esters

include butyl stearate, propyl myristate, pentyl laurate,

ethyl caprate, etc.

The propellant can be any conventional propellant used

in aerosol containers. These propellants include hydro-

carbons, fluorocarbons, and compressed gases. Specific

propellants include compressed air, nitrogen, carbon di-

oxide, C1 to_ C5 hydrocarbons, Cl3FC, Cl3F-2C and any

tetrafluoroethane.

The surfactants employed in the powder aerosol sys-

tem can be any nonionic, anionic, cationic or amphalytic

surfactants include the sorbitan derivatives, Other opera-

10

15

20

25

3.0

3.5

40

45

50

55

60

65

70

76

4

ble surfactants are those surfactants on pages 191 to 194

and 338 to 367 of Emulsions: Theory and Practice by

Becher, published by the Reinhold Publishing Corporation

(1957), which are liquids.

‘It is also to be understood that the shape and size of

the aerosol container as well as the size of the spray

nozzle are not critical. Any conventional package can be

employed.

The following examples illustrate the invention. The

volume is in cubic feet at atmospheric pressure.

EXAMPLE 1

(Tooth Powder)

Formulation 10-53 Percent Volume,

by Wt. cu. ft.

Dicalcium Phosphate (anhydrous) .............. ._ 25.0 0. 286

Santocel 54 ................................ .. _ 1. 5 0. 395

Blandol ........ -. . 10.0 0.187

Spau 85 .................. -.; .................... -- 2. 5 0. 042

“Ucon” Prope11ant12/114 40/60 .................. .. 61.0 0. 690 V

In the above example, the volume of dicalcium phos-

phate at atmospheric pressure is 0.286 cubic foot. The

volume at m_aximun_1 yield point is 0.139 cubic foot.

Thus, X_ is, equal to (0.286——0.139) 0.147 cubic foot.

Substituting X in the general formula gives the following:

0.147y=A+B+C+D

=0.395+0.187+0.69+.0.0_42

=1.3l4

y=_-8.94

Percent by volume of A, B, C and D to XY

0.395

A-T,’-1—4>< 100—14.2

0.69 _

C.~.1—_§1—4>< 100——9.9

0.730

C’--1_T7t;)X100—49.5

0.019

D—-ifia X 100- 1.3

The following defines various terms used in the exam-

ples.

Dicalcium phosphate anhydrous=CaHPO4 dry powder

having a bulk density of 85/90 lbs./cu. ft.

Dicalcium phosphate dihydrate=CaPO4.2H2O—a crys-

talline powder having a bulk density of 46 -lbs./cu. ft.

8,038,374

7

F'lavor=Any flavor which is oil soluble is a potential

agent for -these products.

Santocel 54-=A silica gel made ‘by Monsanto having a

particle size of 0.5—3.0 microns and a bulk density of

3.8 1-bs./cu. ft.

“Ucon” propellant 12:Dichlorodifluoromethane, CCl2F2,

70 p.s.i.g. at 70° F.

“Ucon” propellant 114=Dichlorotetrafluoroethane,

CC1F2——CCl»F2

13 p.s.i.g. at 70° F.

Klearol=Light viscosity white mineral oil. Specific

gravity at 60° F. .828/.838. Pour point 30° F. Say-

bolt viscosity at 100° F. of 55/65. A

Span 8_5==Sorbitan tri-oleate.

Tween 80=P0lyoxyethylenesorbitan mono-oleate.

_Blandolx=Ha-s a specific gravity at 70° F. .850/.860

a Saybolt viscosity at 100° F. of 80/90.

Ca.rnation=Light viscosity mineral oil which has a

specific gravity at 70° F. .835/ .845 and a Saybolt vis-

cosity at 100° F. of 65/75.

45 oil=Light viscosity mineral oil which has a specific

gravity at 70° F. .815/.825 and a Say-bolt viscosity at

100° F. of 40/48.

Aluminum chlorohydrol=Al2 (OH) 5C1.

What is claimed is:

1. A powder dispensing aerosol composition which

comprises ( 1) at least 15 weight percent of an active

powder having a particle diameter of at least 15 microns,

(2) a powder bulking agent having a particle diameter

no larger than the active powder, (3) a non-polar organic

liquid, (4) a liquid surfactant, and (5) a propellant; said

non-polar liquid, surfactant, and propellant being miscible

in all proportions; the combined volume “YX” of said

bulking agent, non-polar organic liquid, surfactant, and

propellant being 1 to .10 times the difference between

the volume of the active powder at atmospheric pressure

and the volume of the active powder at maximum yield

point; the volume percent “A” of “YX” which is bulk-

ing agent, the volume percent “B” of “YX” which is non-

polar organic liquid, the volume percent “C” of “YX”

which is propellant and the volume percent “D” of “YX”

which is surfactant ‘being defined 'by:' V '

Y.XT—i41 +1.9 + C+D

where Y is ca 11urnber.f.r9m 1 to 1.0, X is the difterenqe

between the volume of the active powder at atmospheric

pressure and the volume of the active powder at maxi-

mum yield point, A is 1 to 60 volume percent of YX,'B

is 2 to 70 vol-ume percent -of YX, C is 9 to 67 volume

percent of YX, and D is 0.6 to 10.5 volume percent of

YX. A

2. The composition of claim 1 wherein the active

powder has a particle size of from 15 to 100 microns.

3. The composition of claim 1 wherein A is 20 to 40

volume percent of YX, B is 2 to 30 volume percent of

YX, C is 10 to 65.5 volume percent of YX, and D is 1.2

to 4 volume percent of YX. ‘ V

4. The composition of claim 1 where Y is a number

between 2 and 5.

5. The composition of claim 1 wherein the nonpolar

organic liquid is a hydrophobic oil having a specific

gravity of less than 1.9.

and

6. A powder dispensing aerosol composition which .

comprises ( 1) at least 15 weight percent of an active

powder having a particle diameter of at least 15 microns,

(2) a powder bulking agent having a particle diameter

no. larger than the, active powder, (3), a hydrophobic oil

having a specific ‘gravity of less than 1.9, (4) a liquid

surfactant, and (5) a propellant; said» non-polar hydro-

phobic oil, surfactant, and propellant -being miscible in

all proportions; the combined volume “YX” of said bulk-

ing’ agent, non-polar hydrophobic oil, surfactant, and

10

15

29

25

.30

35

.40

45

69

55

60

65

70

75

8

propellant being 2 to 8 times the difference between the

volume of the active powder at atmospheric pressure and

the volume of the active powder at maximum yield point;

the volume percent “A” of “YX” which is bulking agent,

the volume percent “B” of “YX” which is hydrophobic

oil, the volume percent “C” of “YX” which is propellant

and the volume percent “D” of “YX” which is surfac,tan.t

being defined by:

YX=A +B +C+D

where Y is any number‘ f.r9m 2. to 8.» X13 the difierence

between the volume of the active powder at atmospheric

pressure and the volume of the active powder at maxi-

mum yield point, A is 20 to 40 volume percent of YX,

B is 2 to 30 volume percent of YX, C is .10 to 65.5

volume percent of —_YX, and D is 1.2 to 4 volume percent

of YX.

7. The composition of claim 6 wherein the propellant is

fluorochloroalkane having a vapor pressure of 13 pounds

and greater per square inch gauge at 70° F.

8. The aerosol composition of claim 6 wherein the ac-

tive powder has a particle size of from 15 to 100 microns.

9. The aerosol composition of claim ,6 wherein Y is a

number of 4 to 8.

10. The aerosol composition of claim 6 wherein the

active powder is at least one of the group consisting of

aluminum sulfocarbolate, zinc sulfgcarbolate, aluminum

chlorohydrol, aluminum sulfate, aluminum chloride, zinc

sulfate, zinc chloride, zirconium chloride and zirconium

sulfate.

11. The aerosol composition of claim 6 having talc as

active powder.

12. The aerosol composition of claim 6 having pumice

as active powder.

13. The aerosol composition of claim 6 wherein the ac-

tive powder is at least one of the group consisting of di-

calcium phosphate, anhydrous dicalcium phosphate, hy-

drated dicalcium phosphate, tricalcium phosphate, cal-

cium sulfate and calcium carbonate.

.14. The aerosol compos.itiQn_9f claim 13 wherein the

bulking agent is a silica gel having a particle size of 0.5

to 3.0 microns, the surfactant is a liquid nonionic sorbitan

surfactant, and the propellant is a fluorochloroalkane hav-

ing a vapor pressure of 13 pounds and greater per square

inch gauge at 70° F.

15. A powder dispensing aerosol composition which

comprises‘ ,( 1) at least 15 weight percent of an active

powder having a ,particle d-iameter of 15 to 100 IniCr0.nS,

(2) a powder bulking agent having a particle diameter no

larger than the activepowder, (3) _a Lmi'r1er,a_l oil having

a specific gravity of less than 0.9, (4) a liquid nonionic

_surfactan_t, and (5) a fluorochloroalkane propellant hav-

ing -a vapor pressure of 13 pounds and greater per square

inch gauge at 70° F.; said mineral oil, surfactant, and pro-

pellant being miscible in all proportions; the combined

volume “YX” of said bulking agent, mineral oil, sur-

factant, and propellant being 2 to 8 times the diiference

between the volume of the active powder of atmospheric

pressure and the volume of the active powder at maximum

yield point; the volume percent “A” of “YX” which is

bulking agent, the volume percent “B” of “YX” which is

mineral oil, the volume percent “C” of ‘YX” which is

propellant and the volume percent “D” of “YX” which is

surfactant being defined by

YX=A+B+C+D

where Y is any number from 2 to 8, X is the difference

between the volume of the active powder at atmospheric

pressure and the volume of the active powder at maximum

yield point, A is 20 to 40 volume percent of YX, B is 2

to 30 volume percentpof YX, C is .10 to 65.5 volume per-

cent of YX, and D is 1.2 to 4 volume percent of YX.

16. The aerosol composition of claim 15 having an ac-

tive powder content of at least 25 weight percent.

3,088,874

9

17. The aerosol composition of claim 15 as a tooth

powder dispensing aerosol containing dicalcium phosphate

dihydrate as active powder, a silicia gel having a particle

diameter of 0.5 to 3.0 microns as bulking agent and

liquid nonionic sorbitan surfactant.

18. A novel aerosol tooth powder having -the follow-

ing composition:

Percent by weight

Dicalcium phosphate (anhydrous) ___________ __ 2.50

Dicalcium phosphate (dihydrate) ____________ __ 22.50

Silica gel having density of 17.1 lbs./ gal ______ __ 1.75

Mineral oil _______________________________ __ 10.50

Sorbitan tri-oleate _________________________ __ 0.80

Polyoxyethanesorbitan mono-oleate ___________ __ 0.40

Flavor __________________________________ __ 0.50‘

Dichlorodifluoromethane ___________________ __ 54.95

6.10

CC12F—CClF2 ___________________________ __

10

References Cited in the file of this patent

2,700,011

2,868,691

2,959,325

3,014,844

524,757

10 554,789

UNITED STATES PATENTS

Taylor ______________ __ Jan. 18, 1955

Porush et al. __________ __ Jan. 13, 1959

Beard _______________ __ Nov. 8, 1960

Thiel et al. __________ __ Dec. 26, 19611

FOREIGN PATENTS

Canada ______________ __ May 8, 1956

Canada. _____________ __ Mar. 18, 1958

OTHER REFERENCES

Soap & Chemical Specialties, vol. 31, No. 1, January

1955, pages 139, 141, and 169.

15 Journal of the Society of Cosmetic Chemists, July 1956,

pages 349, 359, 361 and 362.

Cosmetics, Science, & Technology, Interscience Pub-

lishers, Inc., N.Y., 1957, page 323.

Coments go here:

- Log in to post comments