3D Printing

At AFINITICA we love 3D printing because we have innovation in our DNA. Our products are ideal to assemble and repair your creations and save print time.

AFINITICA has been elected as the best brand and product range for the assembly of 3D printed parts by MADE in Barcelona and by many users around the world. Our product range offers the greatest versatility in terms of materials, surface type, type of bonding (tough or flexible and/or gap-filling), and achieves all of the above in seconds.

BX family is the perfect adhesive for general purpose gluing This series will bond parts rapidly without staining.

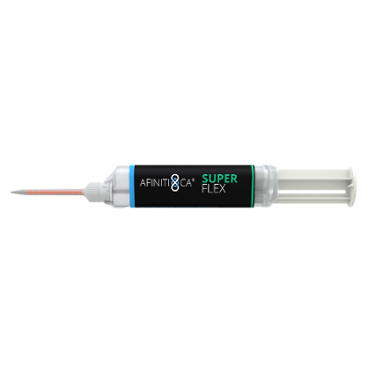

Superflex enables flexible joints and provides impact resistance.

Super Repair is perfect for in-fills, strengthening and bonding, also for healing ABS temperature retraction cracks.