Adhesive

Folder:

Year:

Abstract:

An adhesive compostion, of the 'instant adhesive' type, comprising:

(a) from 77 to 95% by wight of monomeris 2'-ethoxyethyl 2 cyanoacrylate;

(b) from 3 to 15% by wight of a poly-(C1-5) alkyl acrylate of methacrylate having an average molecular wight within the range from 400,000 to 600,000;

(c) from 2 to 8% by wights of hydrophobic fumed silica; and

(d) from 100 to 1000 ppm by wight of a polymerization stabilizer;

overcomes a number of disadvantages associated with currently available 'instant adhesives' (such as high volatilit, breittle adhesive bond, poor resistance to heat and unpleasant smell) and it has the advantages that it cures rapidly and can be on porous substrates.

Type of document:

Language:

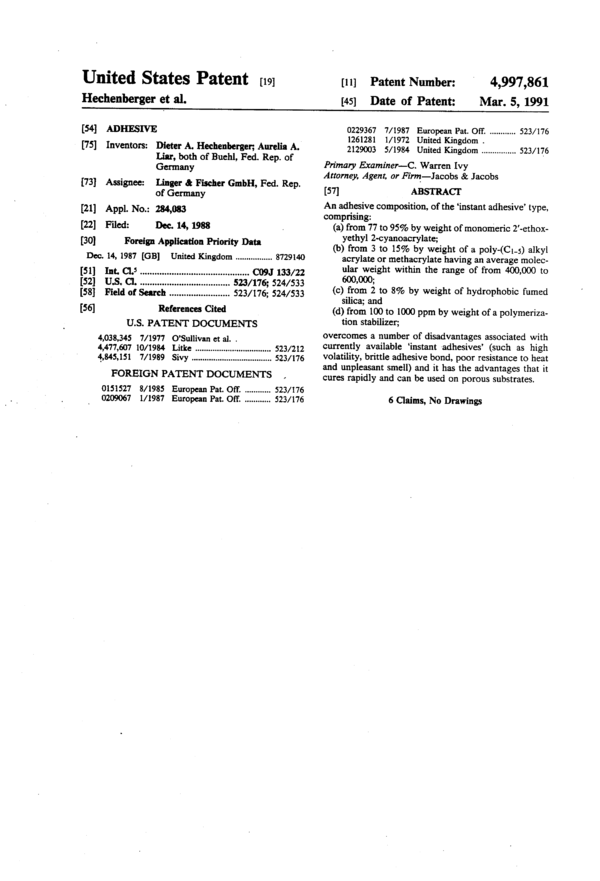

United States Patent [191

Hechenberger et al.

[11] Patent Number:

[45] Date of Patent:

4,997,861

Mar. 5, 1991

[54] ADHESIVE

[75] Inventors: Dieter A. Heclienberger; Aurelia A.

Liar, both of Buehl, Fed. Rep. of

Germany

[73] Assignee: Linger & Fischer Gmbl-I, Fed. Rep.

of Germany

[21] Appl. No.: 284,083

[22] Filed: Dec. 14, 1988

[30] Foreign Application Priority Data

Dec. 14, 1987 [GB] United Kingdom ............... .. 3729140

[51] Int. Cl.’ ........................................... .. C09J 133/22

[52] US. Cl. ............................ .. 523/176; 524/533

[58] Field of Search ....................... .. 523/176; 524/533

[56] References Cited

U.S. PATENT DOCUMENTS

4,038,345 7/1977 O’Sul1ivan et al. .

4,477,607 10/1984 Litke ................................. .. 523/212

4,845,151 7/1989 Sivy ........................ .. 523/176

FOREIGN PATENT DOCUMENTS

0151527 8/1985 European Pat. Off. .......... .. 523/176

0209067 1/ 1987 European Pat. Off. .......... .. 523/ 176

0229367 7/1987 European Pat. Off. .......... .. 523/ 176

1261281 1/1972 United Kingdom .

2129003 5/1984 United Kingdom .............. .. 523/176

Primary Examiner—C. Warren Ivy

Attorney, Agent. or Fimt—Jacobs & Jacobs

[57] ABSTRACT

An adhesive composition, of the ‘instant adhesive’ type,

comprising:

(a) from 77 to 95% by weight of monomeric 2'-ethox-

yethyl 2-cyanoacrylate;

(b) from 3 to 15% by weight of a poly-(C1_5) alkyl

acrylate or methacrylate having an average molec-

ular weight within the range of from 400,000 to

600,000;

(c) from 2 to 8% by weight of hydrophobic fumed

silica; and

(d) from 100 to 1000 ppm by weight of a polymeriza-

tion stabilizer;

overcomes a number of disadvantages associated with

currently available ‘instant adhesives’ (such as high

volatility, brittle adhesive bond, poor resistance to heat

and unpleasant smell) and it has the advantages that it

cures rapidly and can be used on porous substrates.

6 Claims, No Drawings

4,997,861

1

ADHESIVE

The present invention relates to a novel adhesive

composition, and more particularly to an adhesive com- 5

position of the so-called ‘instant adhesive’ type. .

‘Instant adhesives’ based on monomeric (C1_5)alkyl

2-cyanoacrylates (such as ethyl 2-cyanoacrylate) as the

adhesive component have long been commercially

available. Curing of such adhesives occurs very rapidly 10

through the action of atmospheric moisture under an-

aerobic conditions. There are a number of disadvan-

tages associated with such adhesives, one of which is

that they are not suitable for use with porous substrates,

such as paper, cardboard, leather and wood, which is

thought to result from the porous substrates being un-

able to provide the necessary anaerobic environment,

and also from the adhesive being absorbed by the sub-

strate.

Another disadvantage is that the adhesive bond itself 20

15

_ exhibits a low tensile strength or impact resistance be-

cause of the brittleness of the polymer formed on curing

of the adhesive. Additionally, the adhesive bond tends

to soften at about 70'—80' C., which temperatures are

commonly encountered, for example, in domestic dish-

washing machines, thus imparting another limitation to

the use of the adhesives.

A further disadvantage is that the monomeric ester

has a high degree of volatilization, which causes frothy

exudation from the bottle or tube as soon as it is opened.

As the monomer is exuded it is deposited as a whitish

layer of polymer. The monomeric ester also has a sting-

ing, unpleasant smell, which is upsetting in both indus-

trial and domestic use.

Attempts have previously been made to overcome

the difficulties with porous substrates, especially wood,

by adding an adhesion accelerator (such as a crown

ether or a polyglycol ether) to a cyanoacrylate adhesive

composition. One problem with this is that the presence

of the adhesion accelerator and also stabilisers in the

same composition gives a very precarious equilibrium,

such that the adhesives have a poor storage stability.

The present invention now provides an adhesive

composition comprising:

(a) from 77 to 95% by weight of monomeric 2'-ethox-

yethyl 2-cyanoacrylate;

(b) from 3 to 15% by weight of a poly—(C1_5)alkyl

acrylate or methacrylate having a weight average

molecular weight within the range of from 400,000

to 600,000;

(c) from 2 to 8% by weight of hydrophobic fumed

silica; and

(d) from 100 to 1000 ppm by weight of a polymerisa-

tion stabiliser;

all proportions being based on the total weight of com-

ponents (a) to (c).

The adhesive composition of the invention over-

comes a number of the disadvantages of the currently

available ‘instant adhesives’. The present adhesive com-

position cures rapidly and can be used on porous sub-

strates. Moreover it does not exhibit the above-men-

tioned disadvantages of high volatility, brittle adhesive

bond, poor resistance to heat and unpleasant smell.

In the adhesive composition according to the present

invention, 2'-ethoxyethyl 2-cyanoacrylate is used as

(C1_5)alkyl 2-cyanoacrylate conventionally used. The

cyanoacrylate ester is present in an amount of from 77

to 95% by weight, preferably from 85 to 90% by

25

30

35

45

50

55

65

2

weight, based on the total weight of components (a) to

(c). The cyanoacrylate ester should advantageously be

of high purity, preferably about 99.5% by weight pure.

The cyanoacrylate ester is used in combination with

two selected thickeners, namely a poly-(C1_5)alkyl ac-

rylate or methacrylate having an average molecular

weight within the range of from 400,000 to 600,000, and

hydrophobic fumed silica.

The poly-(C1_5)alkyl (meth)acrylate is used in an

amount of from 3 to 15% by weight, preferably from 6

to 10% by weight, based on the total weight of compo-

nents (a) to (c). It may suitably be, for example, a po-

lyethyl (meth)acrylate or a polymethyl (meth)acrylate.

Preferably, a polymethyl methacrylate is used, and

suitable polymethyl methacrylates are commercially

available under the trade name ‘Plexidon’ M449, M489

or M527 from Roehm AG,, Darmstadt, Germany.

The hydrophobic fumed silica (also referred to as

pyrogenic silica) is used in an amount of from 2 to 8%

by weight, preferably from 2.5 to 5% by weight, based

on the total weight of components (a) to (c). Suitable

hydrophobic fumed silicas for use in the present adhe-

sive compositions are commercially available under the

trade names ‘Aerosil’ R802, R812, or R972 from

Degussa, Frankfurt, Germany, ‘HDK’ H15 or H20

from Waker-Chemie GmbH, Munich, Germany, and

‘Cabosil’ M5 from Cabot Co., U.S.A.

For example, ‘Aerosil’ R972 is a pyrogenic silicic acid

having the following typical properties:

specific surface area 110 m2/ g

primary particle size 16 mm

pH value (DN 53200) 3.6-4.3

The adhesive composition according to the present

invention also comprises one or more polymerisation

stabilisers, as is conventional in ‘instant adhesive’ com-

positions, to prevent premature polymerisation of the

cyanoacrylate. Advantageously, the adhesive composi-

tion according to the present invention includes both a

stabiliser against radical polymerisation and a stabiliser

against anionic polymerisation, each of which may suit-

ably be present in an amount of from 100 to 500 ppm by

weight, all amounts (ppm=parts per million) being

based on the total weight of components (a) to (c).

Stabilisers suitable for use in the present compositions

are those currently used or suitable for use in commer-

cially available instant adhesives based on cyanoacry-

lates. Such stabilisers include, for example, hydroqui-

none (which stabilises against radical polymerisation of

the cyanoacrylate), and acidic stabilisers, for example

phosphorus pentoxide (or phosphoric acid) and p-tol-

uenesulphonic acid (both of which stabilise against ani-

onic polymerisation of the cyanoacrylate). A suitable

stabiliser mixture for use in the present adhesive compo-

‘ sitions comprises from 100 to 500 ppm (preferably about

200 ppm) by weight of hydroquinone and from 100 to

500 ppm (preferably about 300 ppm) by weight of phos-

phorus pentoxide. Other acidic stabiliser mixtures may,

however, be used.

The adhesive composition according to the invention

advantageously has a viscosity within the range of from

50 to 800 poise, preferably from 80 to 150 poise. Thus

the composition has a thickish consistency, like a gel.

Surprisingly, the combination of a selected cyanoac-

rylate with two selected thickeners, in the given

amounts, in the adhesive composition according to the

present invention gives good adhesion to porous sub-

- strates. This is achieved without the need to incorporate

an alkaline adhesion accelerator and consequently the

4,997,861

3

present adhesive composition does not have reduced

storage stability. Indeed, the present composition has

good storage stability, combined with the other advan-

tages mentioned previously.

The adhesive composition according to the invention

can be used to advantage for any purpose where at least

one of the substrate surfaces to be adhered together is

porous, such as paper, cardboard, leather, wood, pot-

tery and porcelain. Adhesion of wood substrates is of

particular practical importance. The adhesive composi-

tion can however also be used for smooth and non-por-

ous substrates. .

Because of its viscosity, the adhesive composition

according to the invention can easily be applied to in-

clined or vertical surfaces without risk of rippling or

running. It can also successfully be used to adhere un-

even substrates and to fill small gaps and indentations in

or between the substrates to be joined.

In the preparation of the adhesive composition ac-

cording to the invention, it is advantageous L(-) initially

to ensure that the 2’-ethoxyethyl 2-cyanoacrylate is of

sufficient purity, as discussed above, and also to test its

stability, for example by maintaining it at at least 80° C.

for at least 7 days.

Additionally, the polyalkyl (meth)acrylate should

advantageously be thoroughly dried by heating under

low vacuum. This ensures that all moisture and perox-

ide, either of which could cause premature curing, are

removed. Advantageously, the low vacuum should be

maintained until shortly before (e.g. not more than 5

min before) the polyalkyl (meth)acrylate is mixed with

the other components.

In general, all components should, of course, be used

dry.

The adhesive composition may be prepared by first

adding the acidic stabiliser(s) to the monomeric cyano-

acrylate, with stirring, followed by addition of the

dried, peroxide-free polyalkyl (meth)acrylate, after

which the mixture is heated to not more than 80° C., and

then allowed to cool, with constant stirring, to room

temperature. Thereafter, the hydrophobic fumed silica

is added to the cooled mixture with brief stirring.

The examples summarised in the following table illus-

trate the invention. In each example, the adhesive com-

position was prepared using the procedure outlined

above. The table gives the proportions of the various

components (in % w/w) and the viscosity (in poise) of

the resulting composition. All compositions were stable

for more than 7 days at 80° C.

10

20

25

30

35

40

45

50

55

65

4

TABLE

EXAMPLE 1 Z 3 4 5 6

2'-ethoxyethyl 82.95 88.95 94.95 77.05 88.00 89.50

2.

cyanoacrylate

polymethyl 15.00 3.00 3.00 l5.00 9.00 8.00

methacrylate

(Plexidon

M449)

fumed silica 2.00 3.00 2.00 7.90 3.00 2.50

(Aerosil

R972)

phosphonis 0.03 0.03 0.03 0.03 0.03 0.03

pentoxide

hydroquinone 0.02 0.02 0.02 0.02 0.02 0.02

Viscosity (P) 600 200 50 800 180 I20

We claim:

1. An adhesive composition consisting essentially of:

(a) from 77 to 95% by weight of monomeric 2’-

ethyoxyethyl 2-cyanoacrylate;

(b) from 3 to 15% by weight of a poly-(C1_5)alkyl

A acrylate or methacrylate having a weight average

molecular weight within the range of from 400,000

to 600,000;

(c) from 2 to 8% by weight of hydrophobic fumed

silica; and

(d) from 100 to 1000 ppm by weight of a polymerisa-

tion stabiliser;

all proportions being based on the total weight of com-

ponents (a) to (c).

2. An adhesive composition as claimed in claim 1,

having a viscosity within the range of from 80 to 80

poise.

3. An adhesive composition as claimed in claim 2.

having a viscosity within the range of from 80 to 150

poise.

4. An adhesive composition consisting of:

(a) from 77 to 95% by weight of monomeric 2'-

ethyoxyethyl 2-cyanoacrylate;

(b) from 3 to 15% by weight of a poly-(C1_5)alkyl

acrylate or methacrylate having a weight average

molecular weight within the range of from 400,000

to 600,000;

(C) from 2 to 8% by weight of hydrophobic fumed

silica; and

(d) from 100 to 1000 ppm by weight of a polymerisa-

tion stabiliser;

all proportions being based on the total weight of com-

ponents (a) to (c).

5. An adhesive composition as claimed in claim 4,

having a viscosity within the range of from 50 to 800

poise.

6. An adhesive composition as claimed in claim 5.

having a viscosity within the range of from 80 to 150

poise.

# I it It t

Coments go here:

- Log in to post comments