������

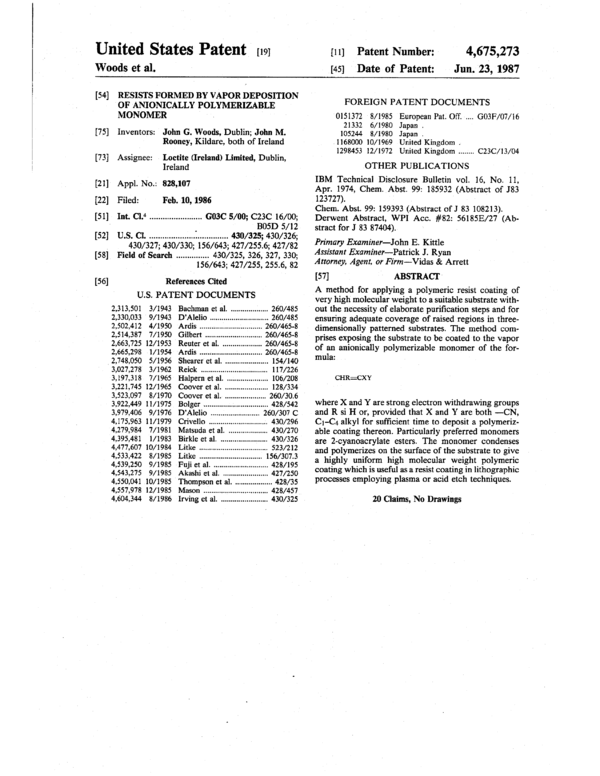

United States Patent [19] [11] Patent Number: 4,675,273

Woods et al. [45] Date of Patent: Jun. 23, 1987

[54] RESISTS FORMED BY VAPOR DEPOSITION

[75]

[73]

[21]

[22]

[51]

[52]

[53]

[56]

OF ANIONICALLY POLYMERIZABLE

MONOMER

Inventors: John G. Woods, Dublin; John M.

Rooney, Kildare, both of Ireland

Assignee: Loctite (Ireland) Limited, Dublin,

Ireland

Appl. No.: 828,107

Filed: Feb. 10, 1986

Int. Cl.‘ ...................... .. G03C 5/00; C23C 16/00;

_ BOSD 5/12

U.S. Cl. .................................. .. 430/325; 430/326;

430/327; 430/330; 156/643; 427/255.6; 427/82

Field of Search ............. .. 430/325, 326, 327, 330;

156/643; 427/255, 255.6, 82

References Cited

U.S. PATENT DOCUMENTS

2,313,501 3/1943 Bachman et al. . . . . . . . . . .. 260/485

2,330,033 9/1943 D’Ale1io . . . . . . . . . . . . . . . . .. 260/485

2,502,412 4/1950 Ardis ....... .. 260/465-8

2,514,387 7/1950 Gilbert . . . . . . . . . . . . . . . .. 260/465-8

2,663,725 12/1953 Reuter et al. . ..... .. 260/465-8

2,665,298 1/1954 Ardis ............... .. 260/465-8

, 2,748,050 5/1956 Shearer et al. .... .. 154/140

3,027,278 3/1962 Reick .................... .. 117/226

3,197,318 7/1965 Halpern et al. . .... .. 106/208

3,221,745 12/1965 Coover etal. . . . . . . . . .. 128/334

3,523,097 8/1970 Coover et al. . . . . . , . .. 260/30.6

3,922,449 11/1975 Bolger . . . . . . . . . . . . . . . .. 428/542

3,979,406 9/1976 D’Ale1io .. 260/307 C

4,175,963 11/1979 Crivello . . . . . . . . . . . . .. 430/296

4,279,984 7/1981 Matsuda et a1. .. .... .. 430/270

4,395,481 1/1983 Birkle et al. . . . . . . . . . . .. 430/326

4,477,607 10/1984 Litke . . . . . . . . . . . . . . . . . .. 523/212

4,533,422 8/1985 Litke ....... .. .. 156/307.3

4,539,250 9/1985 Fuji et al. . . . . . . . . . . . . . . .. 428/195

4,543,275 9/ 1985 Akashi et al. ....... .. 427/250

4,550,041 10/1985 Thompson et al. ...... .. 428/35

4,557,978 12/1985 Mason ....................... .. 428/457

4,604,344 8/1986

Irving et al. ...................... .. 430/325

FOREIGN PATENT DOCUMENTS

0151372 8/1985 European Pat. Off. G03F/07/16

21332 6/1980 Japan .

105244 8/1980 Japan .

1168000 10/1969 United Kingdom .

1298453 12/1972 United Kingdom ...... .. C23C/13/04

OTHER PUBLICATIONS

IBM Technical Disclosure Bulletin vol. 16, No. 11,

Apr. 1974, Chem. Abst. 99: 185932 (Abstract of J83

123727).

Chem. Abst. 99: 159393 (Abstract of J 83 108213).

Derwent Abstract, WPI Acc. #82: 56185E/27 (Ab-

stract for J 83 87404).

Primary Examiner—John E. Kittle

Assistant Examiner———Patrick J . Ryan

Attorney, Agent, or Firm-Vidas & Arrett

[57] ABSTRACT

A method for applying a polymeric resist coating of

very high molecular weight to a suitable substrate with-

out the necessity of elaborate purification steps and for

ensuring adequate coverage of raised regions in three-

dimensionally patterned substrates. The method com-

prises exposing the substrate to be coated to the vapor

of an anionically polymerizable monomer of the for-

mula:

CHR=CXY

where X and Y are strong electron withdrawing groups

and R si H or, provided that X and Y are both ——CN,

C1-C4 alkyl for sufficient time to deposit a polymeriz-

able coating thereon. Particularly preferred monomers

are 2-cyanoacrylate esters. The monomer condenses

and polymerizes on the surface of the substrate to give

a highly uniform high molecular weight polymeric

coating which is useful as a resist coating in lithographic

processes employing plasma or acid etch techniques.

20 Claims, No Drawings

4,675,273

1

RESISTS FORMED BY VAPOR DEPOSITION OF

ANIONICALLY POLYMERIZABLE MONOMER

BACKGROUND OF THE INVENTION

The use of polymeric alkyl cyanoacrylates as resist

materials for microlithography is known in the art. For

example: IBM Technical Disclosure Bulletin, Vol. 16,

No. 11, April 1974, p. 3745, discloses the use of poly

methyl alpha cyanoacrylate homopolymers and copoly-

mers as high-speed positive electron-beam resists; Japan

Pat. No. 80/21,332 discloses the use of poly butyl cya-

noacrylate as a positive-working high sensitivity elec-

tron-beam resist; Japan Pat. No. 80/105,244 discloses

the use of poly ethyl cyanoacrylate as a positive-work-

ing electron-beam resist; U.S. Pat. No. 4,279,984 dis-

closes the use of homopolymers and copolymers of

lower alkyl cyanoacrylates as positive-working high-

energy radiation resists; Eur. Pat. No. 48,899 discloses

the use of copolymers of alkyl cyanoacrylates as posi-

tive-working resists; Japan Pat. No. 82/87,404 discloses

the use of polymeric fluoroalkyl cyanoacrylates as elec-

tron beam resists; Japan Pat. No. 83/113,933 discloses

the use of copolymers of fluoroalkyl acrylates and alkyl

cyanoacrylates as resist materials; Japan Pat. No.

83/108,213 discloses the use of alkyl cyanoacrylate

polymers as positive-working radiation resists; and

Japan Pat. No. 83/123,727 discloses the use of alkyl

cyanoacrylate polymers and azido crosslinking agents

as negative-working radiation resists.

In the prior art, the method of applying the resist

materials to the substrate is by spin-coating a solution of

the cyanoacrylate polymer onto the substrate. This

procedure requires that the polymer is prepared in ad-

vance of the application and then dissolved in a suitable

solvent. The solution must be filtered to remove parti-

cles of dust before application. After application, the

coated substrate must be baked to remove residual sol-

vent. Preparation of cyanoacrylate polymers in large

quantities is complicated by the high reactivity of the

monomers and the strongly exothermic nature of the

polymerization.

After polymerization, the polymeric cyanoacrylate

must then be precipitated to remove impurities such as

initiators and inhibitors, a procedure which consumes

large amounts of solvent. The purified polymer must

then be redissolved in a suitable solvent for spin-coat-

ing. This requirement places a limitation on the types of

solvent and polymer molecular weights which may be

used. For example, poly methyl cyanoacrylate is soluble

in very few solvents, such as nitromethane and dimeth-

ylformamide. In general, it is very difficult to spin-coat

films of cyanoacrylate polymers with molecular

weights in excess of 1,000,000, as stated in U.S. Pat. No.

4,279,984, Col. 2, lines 23-28. However, films formed

from polymers below this molecular weight are easily

removed by common organic solvents necessitating

shortened developing times as stated in U.S. Pat. No.

4,279,984, Col. 3, lines 60-68 and Col. 4, lines 1-9. A

further disadvantage of the spin-coating process is that

attempts to coat a patterned substrate result in uneven

coating thicknesses, i.e., the coating is thicker in de-

pressed regions than in raised regions. One method of

overcoming this problem involves the use of multilayer

resists. However, applying two or three layers and

using two or three image development steps increases

the cost and complexity of the lithographic process.

5

10

15

20

25

30

35

40

45

50

55

60

65

2

Cyanoacrylate monomer vapors have recently been

utilized as a_ fingerprint developer. A detailed discussion

of such techniques is included in U.S. Pat. No.

4,550,041.

SUMMARY OF THE INVENTION

The present invention provides a method for apply-

ing a polymeric resist coating of very high molecular

weight to a suitable substrate without the necessity of

elaborate purification steps and for ensuring adequate

coverage of raised regions in three-dimensionally pat-

terned substrates.

The invention comprises exposing the substrate to be

coated to the vapor of an anionically polymerizable

monomer of the formula:

CHR=CXY I.

where X and Y are strong electron withdrawing groups

and R is H or, provided that X and Y are both —CN,

C1-C4 alkyl for sufficient time to deposit a polymeriz-

able coating thereon. Particularly preferred monomers

are 2-cyanoacrylate esters. The monomer condenses

and polymerizes on the surface of the substrate to give

a highly uniform high molecular weight polymeric

coating which is useful as a resist coating in lithographic

processes employing plasma or acid tech techniques.

The method is especially useful in microlithographic

processes for producing semiconductor devices on sili-

con chips. ’

A further aspect to the invention comprises a process

in which an etchable substrate is coated with polymer as

described above; the coated substrate is subsequently

imaged using high energy radiation; the image is devel-

oped by conventional solvent development processes;

the image is etched using a suitable plasma or acid etch-

ing process, and the resist coating is subsequently re-

moved by heating the coating to a temperature above

the polymer depolymerizatiori temperature.

"A still further aspect of the invention comprises a

substrate etchable by acid or plasma etching processes

which has been coated with a high molecular weight

cyanoacrylate polymer formed by vapor deposition of

cyanoacrylate monomer on the substrate.

The inventive process can be utilized to produce

uniform etch resistant coatings of less than 0.1 micron

thick. -

DETAILED DESCRIPTION OF THE

INVENTION

The preferred monomers for use in the inventive

process are cyanoacrylate ester monomers. The cyano-

acrylate monomers are well known and many are com-

mercially available as “instant” adhesives. The mono-

mers have the formula

CN

CH2=C

COOR1

wherein R1 represents a hydrocarbyl or substituted

hydrocarbyl group such as a straight chain or branched

chain alkyl group having 1 to 12 carbon atoms (which

may be substituted with a substituent such as a halogen

atom or an alkoxy group) a straight chain or branched

chain alkenyl group having 2 to 12 carbon atoms, a

straight chain or branched chain alkynyl group having

4,675,273

3

2 to 12 carbon atoms, a cycloalkyl group, an aralkyl

group or an aryl group. Specific examples of the groups

for R1 are a methyl group, an ethyl group, an n-propyl

group, an isopropyl group, an n-butyl group, an isobutyl

group, a pentyl group, a hexyl group, an allyl group, a

methallyl group, a crotyl group, a propargyl group, a

cyclohexyl group, a benzyl group, a phenyl group, a

cresyl group, a 2-chloroethyl group, a 3-chloropropyl

group, a 2-chlorobutyl group, a triiluoroethyl group, a

2-methoxyethyl group, a 3-methoxybutyl group and a

2-ethoxyethyl group.

Preferred cyanoacrylates are alkyl cyanoacrylates

having 1-6 carbon atoms. Ethyl and isobutyl cyanoac-

rylates are especially preferred.

The monomer vapors are most suitably generated

from the monomers. This may be done at ambient tem-

peratures and pressures but it is generally preferred to

heat the monomers and/or reduce the atmospheric pres-

sure above the monomer generated in the chamber in

order to generate sufficient concentrations of vapor to

accomplish the polymer deposition on the substrate in a

reasonable time.

As an alternative to vapor generation from mono-

mers, cyanoacrylate polymers which are heated above

their depolymerization temperatures, typically about

150° C., may be used as a monomer vapor source. In

particular, vapors generated from thermal removal of

resist coatings may be recirculated, a feature which has

significant environmental advantages.

Concentrated cyanoacrylate monomer vapors may

also be generated by other techniques well known in the

fingerprint development art and summarized in U.S.

Pat. No. 4,550,041.

While the cyanoacrylate ester monomers are pre-

ferred because of their ready availability, better known

handling properties and low depolymerization tempera-

tures, other anionically polymerizable monomers en-

compassed within Formula I above may also be usefully

- employed. As used herein, the term strong electron

withdrawing groups refers to groups which are more

electron withdrawing than halo. Generally, the electron

withdrawing groups X and Y may be independently

selected from —-SO2R; SO3R; —CN; —COOR1 and

——COR2, where R1 is as previously defined and R3 is H

or hydrocarbyl, preferably C1-C1; hydrocarbyl. Vinyli-

dene cyanide, in particular, is known to give especially

insoluble polymeric products, acharacteristic which is

useful where the image development step involves ex-

tensive solvent scrubbing. Vinylidene cyanide and its

lower alkyl homologs may be obtained, for instance, by

processes described in US. Pat. No. 2,313,501;

2,502,412; 2,514,387; 2,663,725, and 2,665,298, the dis-

closures of which are incorporated herein by reference.

Other anionically polymerizable monomers within the

scope» of Formula I include: dialkyl methylene malo-

nates as described in U.S. Pat. No. 2,330,033; 3,197,318;

3,221,745 and 3,523,097; acylacrylonitriles as described

in GB 1,168,000; and vinyl sulfinates and sulfonates of

the formula CH2=CXY where X is -—SO2R2 or

——SO3R2 and Y is —CN, —COOR2, ——COCH3, 60

-—SO2R2 or —SO3R3, as described in U.S. Pat. No.

2,748,050.

The cyanoacrylate or other anionically polymeriz-

able monomer vapors may be applied to any acid or

plasma etchable substrate, particularly substrates used

in microlithography. Suitable substrate materials in-

clude silicon dioxide, including SiO2 coated silicon,

metallic oxides, and glass, all of which may be etched by

10

15

20

25

30

35

40

45

50

55

65

4

plasma or acid etching processes. Metallic substrates

which can be etched by acid processes, such as copper

coated epoxy/ glass boards used in printed circuit board

manufacture and metal printing plates may also be uti-

lized in the inventive process.

The imaging, development and etching processes are

conventional in the art for cyanoacrylate resist materi-

als. Typically a high energy source such as deep UV

(wavelength below 300 nm) and ionizing radiation

sources, is used to produce the image. Ionizing radiation

sources include electron beam, x-ray and gamma ray

sources. Either direct write or photomask techniques

may be employed to imagewise expose the substrate.

After exposure, the image is developed by conventional

solvent development techniques. Following image de-

velopment, the substrate is etched by known acid or

plasma etching techniques. The resist coating may then

be removed by heating the substrate above the depo-

lymerization temperature of the polymer, preferably

under vacuum.

The preferred substrate is SiOz coated silicon, e.g.,

the silicone chips conventionally used in preparation of

semiconductor devices. Most suitably, this substrate is

etched by a plasma etching process. Surprisingly, the

high molecular weight cyanoacrylate polymers pro-

duced by the inventive process have a significantly

greater etch resistance than spin coated cyanoacrylate

polymer resists.

Very high molecular weight polymer is formed by

the inventive process. This is evidenced by the inability

of agressive solvents to dissolve the coating. As noted

above, however, the coating is readily removed by

heating above the depolymerization temperature of the

polymer. For cyanoacrylate polymers, the depolymeri-

zation temperature is only about l50"—200° C. so that

coating removal step will not harm the typical sub-

strate.

If the substrate surface is inherently active for induc-

ing anionic polymerization of cyanoacrylates, or such

other monomer within Formula I as may be employed,

no surface treatment will be necessary to obtain the

desired high molecular weight uniform coatings. In

certain cases, however, where the substrate is slightly

acidic or neutral it is necessary to activate the surface

with a basic liquid or vapor which is substantially re-

moved before exposing the substrate to the monomer

vapor. Suitable activators include the known initiators

for anionic or zwitterionic polymerization of alkyl cya-

noacrylates. Especially suitable activators are organic

amines and phosphines.

The invention is further illustrated by the following

non-limiting examples.

EXAMPLE 1

Polished silicon wafers 3 inches in diameter were

treated with activator as shown in Table 1. The activa-

tor was brushed uniformly across the wafer surface and

allowed to evaporate. The wafer was then polished

with a paper tissue to restore the mirror finish, and

mounted with the treated surface covering the opening

of a 250 ml polyethylene beaker into which 0.2 gram of

ethyl cyanoacrylate monomer had been placed. The

beaker was placed on top of a Tecam DB—3Dri-Block

heating apparatus maintained at a block temperature of

85° C. After the time indicated in Table 1 had elapsed,

the wafer was removed.

Lines were mechanically inscribed on the coated

wafers to expose the wafer surfaces and coating depths

4,675,273

5

were measured with a Nanospec polarized optical sys-

tem. In Table 1, coating thicknesses are reported for the

center of the wafer. The deposited coating was then

carefully removed with a scalpel blade and checked for

solubility. The coatings were found to be substantially 5

insoluble in dichloromethane, indicating the formation

of extremely high molecular weight poly(ethyl cyano-

acrylate).

The amount of polymeric cyanoacrylate deposited

was determined by weighing the wafers on a micro-bal- 10'

ance before and after removal of the coating.

TABLE 1

Expos. Coating Coating

. Amt. Time, Thick- Weight,

Activator: g: Min: ness, p. mg: 15

None — 10 0 0

N,N,N,’N’—Tetramethyl 0.1 3 0.77 3.0

Ethylene Diamine

(TMEDA)

N,N-Diethyl Trimethyl- 6 2.0 7.5

0.1 20

silyl Amine (DTMSA)

Triphenyl Phosphine: 0.3 8 1.7 5.5

Dichloromethane

( 1:3 mixture)

25

EXAMPLE 2

The experiment described in Example 1 was repeated

using 0.1 g TMEDA activator and the cyanoacrylate

monomers specified in Table 2. 30

TABLE 2

Exposure Film

Monomer Time, Min: Thickness, p.

Allyl cyanoacrylate 3 0.3

Methyl cyanoacrylate 8 2.8 35

EXAMPLE 3

The experiment described in Example 1 was repeated 40

using 0.1 g TMEDA activator and ethyl cyanoacrylate.

At specified intervals the wafer was removed from the

vapor and weighed on a microbalance. The amount of

polymer deposited on the wafer after various exposure

times is recorded in Table 3. 45

TABLE 3

Exposure Time, min: Weight Increase, mg:

After Activator Treatment ' 0

2 2.6

4 4.4 50

6 6.3

EXAMPLE 4

A polished silicon wafer 3 inches in diameter was 55

mounted perpendicular to the shaft of a stirring motor

with a variable speed adjustment. The surface of the

wafer was activated with TMED according to the pro-

cedure of Example 1. The wafer was then rotated at a

speed of about 100 revolutions per minute and lowered

into a 1 liter polyethylene beaker containing 0.2 grams

of ethyl cyanoacrylate monomer. The wafer was low-

ered to a depth of about 10 cm above the bottom of the

beaker which has been heated to 85° as described in"

Example 1. After 3 minutes exposure, the wafer was

removed and the thickness of the deposited polymeric

coating was measured at 12 points across the surface of

the wafer. A uniform coating of 0.06 microns had been

60

65

6

deposited with a variation of less than 0.003 microns

across the surface.

EXAMPLE 5

The experiment outlined in Example 4 was repeated

except that the beaker conained 0.4 grams of ethyl cya-

noacrylate, the rotation speed was 35 r.p.m. and the

exposure time was 4 minutes. A uniform coating of 0. 15

microns was deposited with a variation of less than

0.006 microns across the surface.

EXAMPLE 6

The experiment outlined in Example 1 was repeated

using TMEDA and ethyl cyanoacrylate. The substrate

was a silicon wafer on which a pattern of relief images

had been etched. The coated wafer was then sectioned

and examined under a scanning electron microscope.

The coating was found to follow the contours of the

substrate more closely than a comparable coating ap-

plied by spinning from solution.

EXAMPLE 7

Silicon wafers were coated with the polymeric cya-

noacrylate esters listed in Table 4 by each of two meth-

ods: by a conventional spin-coating (SC) technique in

which high molecular weight polycyanoacrylates were

dissolved in nitromethane and applied to the wafer

surface; and by the vapor-coating (VC) technique out-

lined in Example 4. Coated wafers were then placed in

a platen plasma reactor and etched under a CF4: CHF3:

Ar atmosphere. The rate of resist etching was measured

on each sample together with the rate of SiO2 etching

and the results are summarized in Table 4.

TABLE 4

SiO2 Resist

Etch Etch

Resist Polymer Ester Rate Rate Etch

(Coating Method) A/Min A/Min Ratio

Ethyl (SC) 79 134 1.70

Ethyl (VC) 79 53 0.67

i-Butyl (SC) 85 100 1.18

i-Butyl (VC) 73 38 0.52

n-Buty (SC) 88 104 1.18

n-Butyl (VC) 71 51 0.72

Allyl (SC) 71 43 0.61

Allyl (VC) 60 36 0.60

For dry-process compatibility in microcircuit fabrica-

tion, it is desirable that a resist material etch at a lower

rate than SiO2, i.e. that the ratio cited in Table 4 be less

than 1.0. From the data it can be seen that resists depos-

ited by the method of this invention are superior to

those deposited by the conventional technique.

In a related application, the inventors herein disclose

a novel imaging process in which a substrate active or

activated to induce polymerization of an anionically

polymerizable monomer, CHR=CXY, is treated with a

photosensitive compound which releases an acid when

irradiated. The treated substrate is then irradiated im-

agewise after which it is exposed to monomer vapors as

disclosed herein. The resulting polymer coating forms

only on the area not exposed to radiation, thereby pro-

ducing an imaged positive coating on the substrates.

Example 8 illustrates this process on a glass substrate.

EXAMPLE 8

A glass microscope slide (l"X4”) was treated with 2

drops of UVE-1014, which were brushed uniformly

4,675,273

7

across the surface of the slide. The slide was then pol-

ished with a paper tissue, and exposed through a pat-

terned mask to the output of a medium-pressure mer-

cury are (200 watts per linear inch power rating) at a

distance of 10 centimeters for 20 seconds. At the end of

this time, the mask was removed and the slide was

mounted perpendicular to the shaft of a stirring motor

with a variable speed adjustment. The slide was rotated

at a speed of about 35 revolutions per minute and low-

ered into a 1 liter polyethylene beaker containing 0.5

grams of ethyl cyanoacrylate monomer. The slide was

lowered to a depth about 10 cm above the bottom of the

beaker, which was heated to a temperature of about 50°

C. on a hot plate apparatus. After 3 minutes exposure,

the slide was removed from the vapor. A relief image

corresponding to the pattern of the mask had been de-

veloped on the surface of the slide.

What is claimed is:

1. A method of providing a resist coating on an acid

or plasma etchable substrate comprising exposing the

substrate to the vapor of an anionically polymerizable

monomer of the formula

CHR=CXY

where X and Y are strong electron withdrawing groups

and R is H or, provided X and Y are both cyano groups,

C1-C4 alkyl, for sufficient time to deposit a polymerized

coating of the monomer on the substrate.

2. A method as in claim 1 where the monomer is

selected from 2-cyanoacrylate esters, vinylidene cya-

nide and its C1-C4 alkyl homologs, dialkyl methylene

malonates, acylacrylonitriles, and vinyl sulfinates or

sulfonates of the formula CH2=CXY where X is

—-SO2R2 or SO3R2 and Y is selected from —CN,

—COOR2, —COCH3, —SO2R2 or ——SO3R2, and R2 is

H or hydrocarbyl.

3. A method as in claim 2 where the monomer is

cyanoacrylate ester.

4. A method as in claim 3 where the monomer is ethyl

or isobutyl cyanoacrylate.

5. A method as in claim 1 wherein the substrate is

SiO2 coated silicon.

6. A method as in claim 1 wherein the substrate has a

surface activated to induce polymerization of the mono-

mer by treatment with an initiator of anionic or zwitter-

ionic polymerization of alkyl cyanoacrylates.

7. A method as in claim 6 wherein the initiator is an

organic amine or phosphine.

8. A method of providing an imagewise etched sur-

face on a substrate etchable by plasma or acid etching

techniques comprising: .

coating the surface of the substrate with a polymeric

resist coating by exposing the substrate to the

10

15

20

25

30

35

45

50

55

60

65

8

vapor of an anionically polymerizable monomer of

the formula

CHR:CXY

where X and Y are strong electron withdrawing groups

and R is H or, provided that X and Y are both cyano,

C1—C4 alkyl; imagewise exposing the substrate to deep

UV or ionizing radiation;

developing the image;

etching the substrate; and

removing the resist coating by heating the coating to

a temperature above the polymer depolymerization

temperature.

9. A method as in claim 8 wherein the substrate is

silicon coated with $02.

10. A method as in claim 8 where the monomer is a

cyanoacrylate ester.

11. A method as in claim 8 where the monomer is

vinylidene cyanide or a C1-C4 alkyl homolog thereof.

12. A method as in claim 8 where the monomer is a

dialkyl methylenemalonate.

13. A method as in claim 8 wherein the substrate

surface is treated with an initiator of anionic zwitter-

ionic polymerization of alkyl cyanoacrylates prior to

exposing the substrate to the monomer vapor.

14. A method as in claim 13 wherein the anionic

initiator is an organic amine or phosphine.

15. A method as in claim 10 wherein the substrate

surface is selected from acid etchable metals, SiO2, glass

and metalic oxides.

16. A method as in claim 10 wherein the resist coating

removal step comprises heating the coating to a temper-

ature between 150° and 200° C.

17. An article having a surface etchable by acid or

plasma etching techniques and a polymeric resist coat-

ing over said etchable surface, the resist coating com-

prising a polymer formed by vapor deposition onto the

etchable substrate surface of an anionically polymeriz-

able monomer of the formula

CH2=CXY

where X and Y are strong electron withdrawing

groups, for sufficient time to form said polymeric coat-

mg.

18. An article as in claim 17 wherein the monomer is

a cyanoacrylate monomer.

19. An article as in claim 18 wherein the polymeric

coating thickness is less than 0.1 micron thick.

20. An article as in claim 18 wherein the etchable

substrate surface is SiO2.

* It it it it

UNITED STATES PATENT AND TRADEMARK OFFICE

CERTIFICATE OF CORRECTION

PATENT NO. : 4,675,273

DATED : June 23,

lNVENT0m5); John G. Woods et al

HwcmmmdmmmmammmhHmamw4mmmwpmmtmdmmmmLmashmm

are hereby corrected as shown below:

Column 2, line 27, delete "tech" and insert — etch —

Column 5, line 20, delete "0.1" and insert at end of

line 19 -- 0.1 --

Column 7, line 27, insert "that" before'X and Y"

Signed and Sealed this

Twenty-fourth Day of November, 1987

Attest:

DONALD J. QUIGG

Attesting Officer Commissioner of Patents and Trademarks