Cyanoacrylate Adhesive Composition

Folder:

Year:

Abstract:

A cyanoacrylate adhesive composition, which contains esters in which an alcohol residue thereof includes a dipentaerythritol residue and an acid residue thereof is an acrylic or methacrylic acid residue, and which composition is improved in adhesion performance under high temperature and humid conditions, namely moisture and thermal resistance. The cyanoacrylate adhesive composition according to the present invention has excellent moisture and thermal resistance and thus is more widely usable than conventional ones in various industries, medical field, and leisure activity as well as household application and pupils' stationary.

Type of document:

Language:

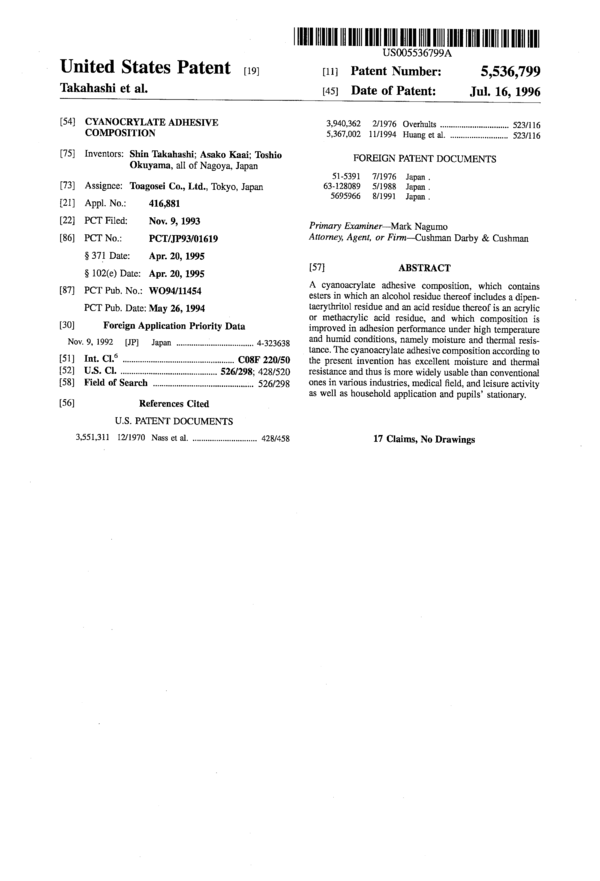

United States Patent [19]

Takahashi et al.

[54]

[75]

[73]

[21]

[22]

[86]

[37]

[30]

Nov. 9, 1992

[51]

[52]

[53]

[56]

CYANOCRYLATE ADHESIVE

COMPOSITION

Inventors: Shin Takahashi; Asako Kaai; Toshio

Okuyama, all of Nagoya, Japan

Assignee: Toagosei Co., Ltd., Tokyo, Japan

Appl. No.: 416,881

PCT Filed: Nov. 9, 1993

PCT No.: PCT/JP93/01619

§ 371 Date: Apr. 20, 1995

§ l02(e) Date: Apr. 20, 1995

PCT Pub. No.: W094/11454

PCT Pub. Date: May 26, 1994

Foreign Application Priority Data

[JP] Japan

Int. Cl.6 ........................... ..

US. Cl. .................... ..

References Cited

U.S. PATENT DOCUMENTS

3,551,311 12/1970 Nass et al. ............................ .. 428/458

...... .. 4-323638

C08F 220/50

526/298; 428/520

Field of Search ............................................. .. 526/298

H|||||||||||||ll|||||||l|||I|||lll|||||||Illlllllll||||||I|||I|||I|||||||l

US005536799A

Patent Number:

[45] Date of Patent:

[11]

5,536,799

Jul. 16, 1996

3,940,362 2/1976 Overhults .............................. .. 523/116

5,367,002 11/1994 Huang et al. ......................... .. 523/116

FOREIGN PATENT DOCUMENTS

51-5391 7/1976 Japan .

63—128089 5/1988 Japan .

5695966 8/1991 Japan .

Primary Examiner——-Mark Nagumo

Attomey, Agent, or Firm—-Cushman Darby & Cushman

[57] ABSTRACT

A cyanoacrylate adhesive composition, which contains

esters in which an alcohol residue thereof includes a dipen-

taerythritol residue and an acid residue thereof is an acrylic

or methacrylic acid residue, and which composition is

improved in adhesion performance under high temperature

and humid conditions, namely moisture and thermal resis-

tance. The cyanoacrylate adhesive composition according to

the present invention has excellent moisture and thermal

resistance and thus is more widely usable than conventional

ones in various industries, medical field, and leisure activity

as well as household application and pupils’ stationary.

17 Claims, No Drawings

5,536,799

1

CYANOCRYLATE ADHESIVE

CONIPOSITION

TECHNICAL FIELD

The present invention relates to a cyanoacrylate adhesive

composition which is improved in adhesion function under

conditions of high temperature and high humidity, namely

resistance to heat and moisture. It is utilized widely in the

adhesive industry and various industries using adhesives.

BACKGROUND ART

Cyanoacrylate adhesives, which contain 2-cyanoacrylate

as a major component, have been favorably used as an

instantaneous adhesive in wide variety of industries, medical

field, leisure activity and household since 2-cyanoacrylate as

the major component has the property of easily polymeriz-

ing anionically in the presence of a trace amount of moisture

and basic substances to quickly cure.

While cyanoacrylate adhesives have excellent moisture

and thermal resistance on adherends of rigid PVC, ABS or

the like, they are poor in moisture and thermal resistance

upon application to materials of nitrogen-containing com-

pounds or sulfur-containing compounds such as chloroprene

rubber, EPDM and other synthetic rubbers and Bakelite.

A reason for the poor moisture and thermal resistance in

adhesion of cyanoacrylate adhesives to chloroprene rubber,

EPDM and other synthetic rubbers and to Bakelite would be

that humidity and/or heat promote the nitrogen-containing

compounds or sulfur-containing compounds to bleed from

these materials and accumulate on the adhesion interface

resulting in reduction of adhesion strength and that the bled

compounds promote decomposition of cyanoacrylate poly-

mers.

The moisture and thermal resistance of the adhesives is

further deteriorated when they are used to bond synthetic

rubbers such as chloroprene rubber and EPDM in a state

where internal residual stress exists.

The reason is understood as follows:

Hardened bodies of cyanoacrylate adhesives are stiff and

are poor in a function of relaxing the intemal stress. Thus,

it is considered that the effect of stress on adhesion interface

and adhesion layer becomes significant, and as a result,

deterioration of adhesion caused by humidity and/or tem-

perature is promoted.

Because of these reasons, urethane adhesives, epoxy

adhesives, acryl adhesives and the like have been used in the

industry for adhesion to sites where durability is required,

while hot melt adhesives, pressure-sensitive adhesives and

the like have been used for adhesion to sites where flexibility

is required.

However, urethane adhesives, epoxy adhesives, acryl

adhesives and the like have disadvantages that they are

“poor in operability due to requirements of blending of two

packages or primer pretreatment of the surfaces to be

adhered” and “poor in productivity due to slow adhesion

rate.” On the other hand, hot melt adhesives and pressure-

sensitive adhesives have a disadvantage that they are “poor

in durability.” In the industry, thus there is a strong demand

for development of an adhesive that is excellent in durability

and brings about improvement in operability and produc-

tivity.

10

20

25

30

35

40

45

50

55

60

65

2

Cyanoacrylate adhesives, which are characterized by

single package instantaneous adhesion, may bring about the

above-mentioned improvement in operability and produc-

tivity, however are poor in durability and flexibility (stress

relaxation) as already explained.

For the purpose of providing flexibility with cyanoacry-

late adhesives, a known technology is to blend a phthalate,

a sebacate, and a saturated copolymer polyester described in

JP-A-63-284279.

However, these softening materials adversely aifect mois-

ture and thermal resistance since they are present in

cyanoacrylate polymers just in dispersed state.

JP-A-58- 1 85 666 is another known technology for provid-

ing flexibility, which discloses blending a C1-C4 alkyl

(meth)acrylate or a C1-C4 alkoxyalkyl (meth)acrylate.

These (meth)acrylates not only exist in cyanoacrylate poly-

mers in dispersed state but also have a possibility of improv-

ing durability by radical polymerization at elevated tem-

perature.

In the adhesion to chloroprene rubber which contains

nitrogen-containing compounds or sulfur-containing com-

pounds, however, the compositions blended with the C1-C4

alkyl (meth)acrylate or the C1-C4 alkoxyalkyl (meth)acry-

late described in JP~A-58-185666 can not still satisfy the

moisture and thermal resistance.

Under such situations, there is a strong need for devel-

oping an instantaneous adhesive-that is excellent in moisture

and thermal resistance even on materials said to be difiicult

to bond, that is, materials that contain nitrogen-containing

compounds or sulfur-containing compounds, for example,

synthetic rubbers like chloroprene rubber and EPDM, and

Bakelite.

The present invention is to provide a cyanoacrylate

instantaneous adhesive that has excellent moisture and ther-

mal resistance when applied for adhesion particularly to

adherends that contain nitrogen-containing compounds or

sulfur-containing compounds, for example, synthetic rub-

bers like chloroprene rubber and EPDM, and Bakelite.

DISCLOSURE OF INVENTION

As a result of intensive studies for solving the above

mentioned problems, the present inventors have found that

a composition obtained by adding a specific acrylate or

methacrylate to 2-cyanoacrylate, can be an adhesive com-

position exhibiting excellent moisture and thermal resis-

tance, and have completed the present invention.

The present invention relates to a cyanoacrylate adhesive

composition characterized in that it comprises an ester the

alcohol residue of which contains a dipentaerythritol residue

and the acid residue of which is an acrylic or methacrylic

acid residue. '

Now, the adhesive composition according to the present

invention is explained.

As 2-cyanoacrylate, which is the main component exhib-

iting adhesion function in the present composition, may be

widely adopted what has been used as a main component of

cyanoacrylate instantaneous adhesives; examples of the

2-cyanoacrylate are listed below:

That is to say, 2-cyanoacrylic acid esters of methyl, ethyl,

n-propyl, i-propyl, propargyl, n-butyl, i-butyl, n-pentyl,

n-hexyl, 2-ethylhexyl , n-octyl, n-nonyl, oxononyl, n-decyl,

n-dodecyl, allyl, ethynyl, 2-butenyl, cyclohexyl, phenyl,

phenethyl, tetrahydrofurfuryl-, chloroethyl, 2,2,2-trifluoroet-

hyl, hexafluoroisopropyl, methoxyethyl, ethoxyethyl, pro-

5,536,799

3

poxyethyl, isopropoxyethyl, butoxyethyl, hexyloxyethyl,

2-ethyl hexyloxyethyl, butoxyethoxyethyl, hexyloxyethoxy-

ethyl, 2-ethyl hexyloxyethoxyethyl, methoxypropyl, meth-

oxypropoxypropyl, methoxypropoxypropoxypropyl, ethox-

ypropyl, ethoxypropoxypropyl, or the like, but not limited

thereto.

Preferable 2-cyanoacrylates for use in the present inven-

tion are ethyl 2-cyarroacrylate, methoxyethyl 2-cyanoacry-

late and ethoxyethyl 2-cyanoacrylate.

The present ester that has a dipentaerythritol residue as an

alcohol residue and has an acrylic acid or mathacrylic acid

residue as an acid residue, includes esters of dipentaeryth-

ritol with acrylic acid or mathacrylic acid, or esters of a

modified alcohol with acrylic acid or mathacrylic acid in

which said modified alcohol is a dipentaerythritol modified

by addition of a lactone such as caprolactone to dipen-

taerythritol. Specific examples of these esters include, but

are not limited to, dipentaerythritoltriacrylate (commercially

available from Nippon Kayaku Co., Ltd. as KAYARAD

D-330), dipentaerythritoltetraacrylate (commercially avail-

able from Nippon Kayaku Co., Ltd. as KAYARAD D-320),

dipentaerythritolpentaacrylate (commercially available from

Nippon Kayaku Co., Ltd. as KAYARAD D-310), dipen—

taerythritolhexaacrylate (commercially available from Nip-

pon Kayaku Co., Ltd. as KAYARAD DPHA), and modified

dipentaerythritolhexaacrylates in which dipentaerythritol is

modified with caprolactone (commercially available from

Nippon Kayaku Co., Ltd. as KAYARAD DPCA-20,

KAYARAD DPCA-30, KAYARAD DPCA-60, and

KAYARAD DPCA—120).

Preferable esters among the ones listed above are dipen-

taerythritoltriacrylate (available from Nippon Kayaku Co.,

Ltd. as KAYARAD D-330), dipentaerythritoltetraacrylate

(available from Nippon Kayaku Co., Ltd. as KAYARAD

D-320), dipentaerythritolpentaacrylate (available from Nip-

pon Kayaku Co., Ltd. as KAYARAD D-310) and dipen-

taerythritolhexaacrylate (available from Nippon Kayaku

Co., Ltd. as KAYARAD DPHA).

The amount of the present ester to be blended with

2-cyanoacrylate is preferably 1 through 50% by weight,

more preferably 10 through 40% by weight, based on the

total of the ester and 2-cyanoacrylate. When the blending

amount of the ester is lower than 1% by weight, sufiicient

durability will not be obtained. When it is more than 50% by

weight, poor hardening and lowering of the adhesive

strength will be caused.

Stabilizers, polymerization accelerators, thickeners and

other additives shown below may be appropriately incorpo-

rated as optional ingredients into the cyanoacrylate adhesive

in ordinary marmer.

STABILIZER

Hydroquinone, sulfurous acid gas or others may be added

as a polymerization inhibitor for improving storage stability.

POLYMERIZA'I‘ION ACCELERATOR AND

INITIATOR

A polyalkylene oxide or its derivative, crown ether or its

derivative, silacrown ether or its derivative, calixarene

derivative, or others may be added as an anionic polymer-

ization accelerator for improving adhesion rate. An organic

peroxide such as a hydroperoxide, peroxy ester, ketone

peroxide, peroxyketal, dialkyl peroxide, diacyl peroxide,

peroxydicarbonate or others may be added as a radical

initiator.

5

10

15

20

25

30

35

40

45

50

55

60

65

4

THICKENER

2-Cyanoacrylate monomer is essentially colorless and

transparent liquid of low viscosity; this liquid can be made

viscous or thixotropic by dissolution or dispersion of a

homopolymer or copolymer of various kinds of (meth)acry-

lates, or acrylic rubber, cellulose derivative, silica or others.

OTHER ADDITIVES

Other additives such as a dye, pigment, plasticizer, diluent

and others may be blended.

BEST MODE FOR CARRYING OUT THE -

INVENTION

Hereinafter, the present invention will be explained in

more details by way of examples and comparative examples.

However, the present invention is not limited to these

examples.

EXAMPLES 1 THROUGH 16

COMPARATIVE EXAMPLES 1 THROUGH 5

Adhesives having the compositions shown in Table 1

were prepared, and their characteristics were evaluated as

follows. Meanwhile, KAYARAD DPCA-20 and

KAYARAD DPCA-30 in Table 1 are modified dipentaeryth-

ritolhexaacrylates made by Nippon Kayaku Co., Ltd.

Moisture and thermal resistance on chloroprene rubber:

Chloroprene rubber was selected as the material to be

adhered. The moisture and thermal resistance of the com-

positions shown in Table 1 upon adhesion to chloroprene

rubber was determined by the following procedures:

Preparation of test pieces

(1) Pieces of chloroprene rubber with the size of 3 mm

(thickness)x25 mm (width)>

Coments go here:

- Log in to post comments