Filled Cyanoacrylate Adhesive Compositon

Filled Cyanoacrylate Adhesive Compositon

Folder:

Journal:

Year:

Abstract:

Filled cyanoacrylate adhesive compositions possessing electro- and heat-conducting properties have been developed. These compositions are recommended for panel wiring of electro- and radioelements and hermetic sealing of aluminum casting.

DOI:

10.1134/S1811238207010110

Type of document:

Language:

ISSN 1811-2382, Polymer Science, Ser. C, 2007, Vol. 49, No. 1, pp. 50–51. © Pleiades Publishing, Ltd., 2007.

Original Russian Text © O.N. Klenovich, A.M. Vetrova, 2006, published in Klei. Germetiki. Tekhnologii, 2006, No. 1, pp. 21–22.

Filled Cyanoacrylate Adhesive Compositions

O. N. Klenovich and A. M. Vetrova

Federal State Unitary Enterprise, Kargin Polymer Chemistry and Technology Research Institute,

Dzerzhinsk, Nizhni Novgorod oblast, 606000 Russia

e-mail: niip@kis.ru

Abstract—Filled cyanoacrylate adhesive compositions possessing electro- and heat-conducting properties

have been developed. These compositions are recommended for panel wiring of electro- and radioelements and

hermetic sealing of aluminum casting.

DOI: 10.1134/S1811238207010110

A wide application of cyanoacrylate adhesives in

industry, medicine, and private life is due to the high

rate of bonding (from several seconds to minutes) of

diverse materials, such as metals, glass, ceramics, plastics, wood, rubber, and living tissues, giving rise to

strong adhesive joints [1]. These adhesives are solventfree, low-toxicity, and are handled rather easily.

In this study, cyanoacrylate compositions were

tested as binding agents for the manufacture of filled

adhesives with functional properties.

As is known, filled adhesives are two-phase systems

in which particles of one phase (filler) are joined by a

thin layer of the binding agent phase. The thickness of

the binding layer in such a system should be minimum

so that the whole polymer could transform into the ultimately structured state [2]. The mechanical characteristics of such systems take the highest values since the

three-dimensional matrix appears in these systems in

the course of hardening in which filler particles are

strongly held [3].

Some metal fillers render polymers conductive and

reduce their gas and vapor permeability. Formulations

filled with boron nitrides and aluminum oxides offer

promise as heat-conducting dielectric materials.

Conducting adhesives. Conducting materials, such

as metals and their alloys, are usually joined by soldering or welding methods. This process related to the

heating of materials to high temperatures cannot be

used in some electronic units, in assembly of microminiature radio components, and for conductive joining

of ceramics [4]. In this case, it is advisable to bond

items via adhesion with the use of conductive adhesives.

The conducting behavior of adhesive formulations

is provided by metal fillers, such as silver, copper, iron,

and nickel carbonyl, which are characterized by good

conductivity.

In the development of conductive adhesives, we

tested powders of silver as the most conducting metal

and nickel carbonyl of the PNK-1L5 grade as less prone

to form passivating films on the surface of particles.

As binding agents, we used cyanoacrylate adhesives

TK-200 and TK-300 developed at our institute. These

adhesives were chosen since the TK-200 adhesive

forms the strongest joints, while the TK-300 adhesive is

thermally stable and can withstand short-term heating

to 250–300°C. Cyanoacrylate adhesives were additionally modified so that the pot life of filled formulations

was no less than 30–60 min. These times are sufficient

for practical applications and maintenance of the optimal combination of properties (Table 1).

Heat-conducting adhesives. Adhesive heat-conducting formulations have found wide use for mounting

of semiconductors, transistors, and thermistors.

Unfilled adhesives are characterized by low heat conductivity. A difference in the heat conductivities of an

adhesive and a material to be bonded leads to a temperature jump at the bonding boundary and causes an additional increase in the temperature of the working area of

a construction during heat flux passage.

The heat conductivity of adhesives may be governed

via incorporation of fillers that impart high dielectric

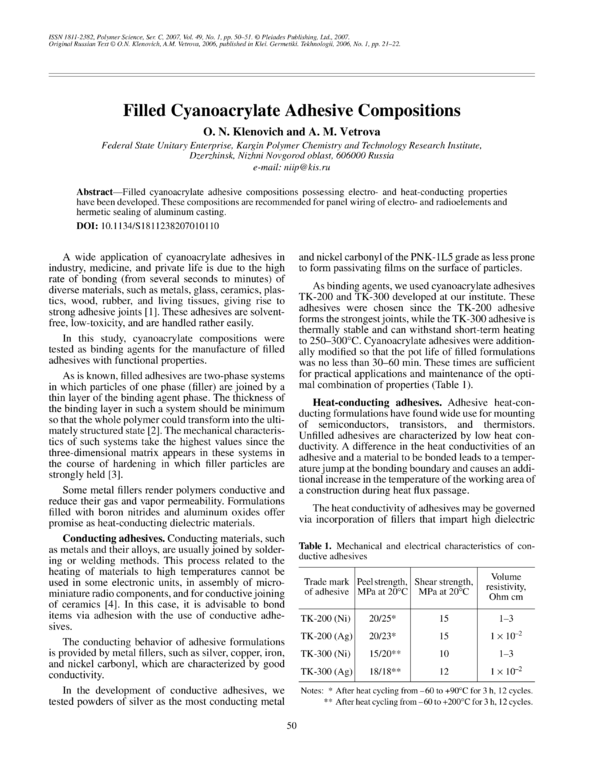

Table 1. Mechanical and electrical characteristics of conductive adhesives

Trade mark Peel strength, Shear strength,

of adhesive MPa at 20°C MPa at 20°C

Volume

resistivity,

Ohm cm

TK-200 (Ni)

20/25*

15

1–3

TK-200 (Ag)

20/23*

15

1 × 10–2

TK-300 (Ni)

15/20**

10

1–3

TK-300 (Ag)

18/18**

12

1 × 10–2

Notes: * After heat cycling from –60 to +90°C for 3 h, 12 cycles.

** After heat cycling from –60 to +200°C for 3 h, 12 cycles.

50

FILLED CYANOACRYLATE ADHESIVE COMPOSITIONS

51

Table 2. Mechanical characteristics of heat-conductive adhesives

Trade mark

of adhesive

Peel strength,

MPa at 20°C

Shear strength,

MPa at 20°C

Heat conductivity

coefficient, V/(m K)

Volume resistivity,

Ohm cm

TK-200 (NB)

25/28*

15

1.4

1 × 1013

TK-300 (NB)

20/25**

12

1.5

1 × 1013

Notes: * After heat cycling from –60 to +90°C for 3 h, 12 cycles.

** After heat cycling from –60 to +200°C for 3 h, 12 cycles.

characteristics to the adhesives. Boron nitride was

employed as such filler.

The distinctive feature of hexagonal boron nitride is

a flaky structure of its dispersed particles. This fact

explains high heat conductivity of the boron nitridefilled systems. It was shown that, at a filling degree of

25–30 wt %, boron nitride particles form a continuous

three-dimensional framework in the polymer matrix

that also serves as a heat bridge [5].

On the basis of modified cyanoacrylate adhesives

TK-200 and TK-300, we developed two-component

heat-conducting adhesives TK-200 (NB) and TK-300

(NB) with high dielectric parameters (Table 2).

Sealing of aluminum casting. Articles manufactured by various casting methods contain inevitable

defects as pores or blisters that sometimes occupy up to

40% of the surface. The development of a method for

improvement of casting defects with the use of highly

filled polymer materials is an urgent problem.

A filled cyanoacrylate formulation based on the TK201 adhesive with a viscosity of 1000–2000 cSt and an

aluminum powder was prepared. The TK-201 adhesive

shows sufficient elasticity and heat resistance to 160°C

in combination with high strength (Table 3).

The TK-201-based formulation filled with the aluminum powder is characterized by a set of excellent

Table 3. Mechanical characteristics of the TK-201 adhesive

filled with the aluminum powder

Trade mark Shear strength,

of adhesive MPa at 20°C

TK-201

TK-201 +

aluminum

powder

Compressive

Compressive

yield stress,

yield strain, %

MPa at 20°C

10

38

60

10/12*

30/45*

50/70*

* After heat cycling from –50 to +90°C for 3 h, 12 cycles.

POLYMER SCIENCE

Series C

Vol. 49

No. 1

2007

mechanical properties, including heat cycling stability,

indicating its elasticity.

All the above-described cyanoacrylate formulations

exhibit good moisture resistance, which was estimated

from the peel strength after 1-month storage of bonded

specimens at 40°C at a humidity of 98%. This parameter was found to be 70–80% of the initial value. A

reduction in the peel strength of unfilled adhesives

TK-200, TK-201, and TK-300 under these conditions

was as high as 50%.

Techniques of adhesive preparation and bonding. Filled adhesive formulations were prepared

directly before use via mixing of a binding agent (modified TK-200, TK-201, and TK-300) and fillers. The

mixture was stirred for 5–10 min in a clean dry container until a homogeneous paste was obtained. Before

use, fillers were dried to the content of the moisture

weight fraction not higher than 0.01%.

The treatment and bonding of the surface of articles

are similar to those of traditional employment of

unfilled cyanoacrylate adhesives.

Thus, on the basis of modified cyanoacrylate adhesives, formulations with electro- and heat-conductive

properties have been developed. These formulations

show promise for wide use in the instrument-making

industry, electronics, radio engineering, engineering

industry, and other branches of industry.

REFERENCES

1. L. M. Pritykin, D. A. Kardashov, and V. L. Vakula,

Monomer Adhesives (Khimiya, Moscow, 1988) [in Russian].

2. Metallopolymer Materials and Products: A Handbook,

Ed. by V. A. Belyi (Khimiya, Moscow, 1979).

3. Yu. S. Lipatov, Plast. Massy, No. 11, 6 (1976).

4. F. F. Bazarova and L. S. Kolesova, Adhesives in Electronics Production (Energiya, Moscow, 1975) [in Russian].

5. Ya. A. Abeliov, Klei Germet. Tekhnol., No. 8, 26 (2005).

Coments go here:

- Log in to post comments