Cyanoacrylate Composite Forming System

Folder:

Year:

Abstract:

This invention relates to a system for forming a composite from a cyanoacrylate composition and a filler within depressions, holes, cracks or spaces in a substrate. The system also allows for the placement of a cantilevered member in the filled depression, hole, crack or space in the substrate to support a load when the cyanoacrylate has cured.

Type of document:

Language:

US008071675B2

(12) Ulllted States Patent (10) Patent No.: US 8,071,675 B2

McDonnell et al. (45) Date of Patent: Dec. 6, 2011

(54) CYANOACRYLATE COMPOSITE FORMING 4,440,910 A 4/ 1984 0’C0I1I10r

4,444,933 A 4/1984 Columbus 61

4,477,607 A 10/1984 Lltke

_ 4,533,422 A 8/1985 Litke

(75) Inventors: Patrick F. McDonnell, Terenure (IE); 4,556,700 A 12/1985 Harris et 31.

Brendan J. Kneafsey, Lucan (IE); 4,560,723 A 12/1985 Millet et al.

Robert J. Lambert, Lucan (IE) 4,582,648 A * 4/1986 Hirakawa ,,,,,,,,,,,,,,,,,,,, ~ 558/442

4,622,414 A 11/1986 McK_ervey

(73) Assignee: Loctite (R&D) Limited, Dublin (IE) Q §f~§:f0j§:1t~a1.

* , , , , , 4,695,615 A 9/1987 Leonard et al.

( ) Notice: Subject to any disclaimer, the term ofthis 4,713,405 A 12/1987 Koga et a1.

patent is extended or adjusted under 35 4,718,966 A 1/1988 Harris et al.

U.s.C. 1540,) by 1453 days, 4,837,260 A 6/1989 Sato etal.

4,855,461 A 8/1989 Harris

, 4,906,317 A 3/1990 Liu

(21) Appl" No" 11/ 305147 4,906,318 A 3/1990 Miyazaki

. 5,246,973 A 9/1993 Nakamura et al.

(22) Flledi Dec-19,2005 5,312,864 A 5/1994 Wenz etal.

5,340,873 A 8/1994 Mitry

(65) Prior Publication Data 5,739,205 A 4/ 1998 NiShiI10

5,994,464 A 11/1999 Ohsawa et al.

US 2007/0137784 A1 Jun. 21, 2007 6,475,331 B1 11/2002 O’C0nn0r

6,607,632 B1 8/2003 McD0nne11eta1.

(51) [nt_ C]_ 6,617,385 B1 9/2003 Klauck et a1.

3290 47/00 (2006.01) FOREIGN PATENT DOCUMENTS

B29C 65/00 (2006.01) CA 715 140 8/1965

C08F 12/28 (2006.01) (C t. d)

C08F 118/02 (2006.01) 0“ “me

(52) US. Cl. ........ .. 524/556; 524/13; 156/293; 526/310; OTHER PUBLICATIONS

526/319

(58) Field of Classification Search .................. .. 524/13, AbS‘“1°‘f°”P 55'1275°9~

524/556; 156/293; 526/310, 319 (Continued)

See application file for complete search history.

Primary Examiner — William Cheung

(56) References Cited

U.S. PATENT DOCUMENTS

2,794,788 A 6/1957 Coover, Jr. et al.

3,223,083 A 12/1965 Cobey

3,254,111 A 5/1966 Hawkins etal.

3,607,542 A 9/1971 Leonardet al.

3,654,340 A 4/1972 Banitt

3,663,501 A * 5/1972 Adams et a1. ............... .. 523/203

3,692,752 A 9/1972 Setsuda et al.

3,836,377 A 9/1974 Delahunty

4,102,945 A 7/1978 Gleave

4,105,715 A 8/1978 Gleave

(74) Attorney, Agent, or Firm — Steven C. Bauman

(57) ABSTRACT

This invention relates to a system for forming a composite

from a cyanoacrylate composition and a filler within depres-

sions, holes, cracks or spaces in a substrate. The system also

allows for the placement of a cantilevered member in the

filled depression, hole, crack or space in the substrate to

support a load when the cyanoacrylate has cured.

36 Claims, 1 Drawing Sheet

US 8,071,675 B2

Page 2

FOREIGN PATENT DOCUMENTS

DE 34 00 577 C2 8/1994

DE 695 03 844 T2 8/1998

EP 197 481 B1 10/1986

EP 0 686 681 B1 8/1998

FR 2 358 454 A1 7/1977

GB 1529105 10/1978

JP 55-129473 A 10/1980

JP 56-127609 A 10/1981

W0 W0 83/02450 A1 7/1983

W0 W0 99/28399 A1 6/1999

OTHER PUBLICATIONS

Abstract for JP 55-129473 (1980).

H. V. Coover et al., “Cyanoacrylate Adhesives”, Handbook of Adhe-

sives, 27, pp. 463-477, Skeist, ed, Van Nostrand Reinhold, NeWYork,

3"’ Edition (1990).

G.H. Millet, “Cyanoacrylate Adhesives” in Structural

Adhesvies.'Chemistry and Technology, S.R. Hartshorn, ed., Plenun

Press, NeWYork, pp. 249-307 (1986).

C. Donker, “The Chemistry of Tackifying Resins—Parts I, II and III”,

Adhesives & Sealants (2002 and 2003) (WWW.

specialchem4adhesives.com).

“Molecular Weight and Solution Viscosity Characterization of

PVC”, D. E. Skillicorn, Journal of Vinyl Technology, Jun. 1993, vol.

15, No. 2, pp. 105-108.

“UCARTM VMCC”, DoW Product Information, Form No. 322-

00119-0306X-Am, pp. 1-3, Mar. 2006.

“UCARTM VMCC”, DoW Product Information, Form No. 322-

00120-0306X-AM, pp. 1-3, Mar. 2006.

“Determination of the Viscosity of Polymers in Dilute Solution using

Capillary Viscometers”, Part 2: Poly(vinyl chloride) resins, Refer-

ence No. ISO 1628-2:1998(E), pp. 1-14.

“Reference: Polymer Properties and Reference: Glossary”, Aldrich

Polymer Products Application And Reference Inforn1ation, pp. 42-45

and 50-51, (2007) at WWW.sigrnaaldrich.com/aldrich/brochure/al_

pp_applications.pdf.

* cited by examiner

U.S. Patent

‘2

’//////A

FIG. 1

//////A

FIG. 2

V/////A

FIG. 3

*2

30

12 gmw/:/::n

US 8,071,675 B2

1

CYANOACRYLATE COMPOSITE FORMING

SYSTEM

BACKGROUND OF THE INVENTION

1. Field of the Invention

This invention relates to a system for forming a composite

from a cyanoacrylate composition and a filler within depres-

sions, holes, cracks or spaces in a substrate. The system also

allows for the placement of a cantilevered member in the

filled depression, hole, crack or space in the substrate to

support a load when the cyanoacrylate has cured.

2. Brief Description of Related Technology

Cyanoacrylate compositions are well known, and widely

used as quick setting, instant adhesives with a wide variety of

uses. See H. V. Coover, D. W. Dreifus and J. T. O’Connor,

“Cyanoacrylate Adhesives” in Handbook of Adhesives, 27,

463-77, I. Skeist, ed., Van Nostrand Reinhold, New York, 3rd

ed. (1990). See also G. H. Millet “Cyanoacrylate Adhesives”

in Structural Adhesives: Chemistry and Technology, S. R.

Hartshom, ed., Plenun Press, New York, p. 249-307 (1986).

A variety of fillers have been incorporated directly into

cyanoacrylate compositions to bring about certain changes in

physical properties in one part compositions. For instance,

U.S. Pat. No. 2,794,788 teaches thickening of cyanoacrylate

adhesives by dissolving therein quantities of polymeric alkyl

cyanoacrylates, as well as other compounds including poly-

acrylates and methacrylates, and cellulose esters such as

acetate, propionate and butyrate. U.S. Pat. No. 3,836,377

notes among the additional known thickeners polyvinyl

ethers such as polyvinylmethyl ether. U.S. Pat. No. 3,692,752

discloses thickened cyanoacrylates containing certain poly-

ether acrylates/methacrylates, acrylic/methacrylic esters of

bis(hydroxyalkyl)phosphonic acid derivatives, and acrylic/

methacrylic esters of tris(hydroxyalkyl)cyanuric acid deriva-

tives. The ’788, ’377 and ’752 patents each relate to one part

thickened cyanoacrylate compositions containing organic

compounds as thickeners.

Various inorganic materials have also been proposed as

fillers, which can thicken the composition. In that regard U.S.

Pat. No. 3,663,501 teaches preparation of a dental cement

containing inert, finely-divided solids such as fused silica,

quartz and alumina. Similarly, U.S. Pat. No. 3,607,542

teaches the preparation of a water-resistant cyanoacrylate

paste containing insoluble, inert fillers such as salts of cal-

cium, titanium, zinc, tin, aluminum, iron and copper, among

others.

U.S. Pat. No. 4,102,945 (Gleave) is directed to and claims

a thickened, curable adhesive composition comprising a

monomeric ester of 2-cyanoacrylic acid, and for each 100

parts by weight of monomeric ester, about 3 to about 30 parts

by weight of an organic material which is an acrylonitrile-

butadiene-styrene terpolymer, where the composition has

improved peel strength over the corresponding unthickened

adhesive.

U.S. Pat. No. 4,105,715 (Gleave) is directed to and claims

a thixotropic, curable adhesive composition comprising a

monomeric ester of 2-cyanoacrylic acid, and for each 100

parts by weight of monomeric ester, about 5 to about 100 parts

by weight of a polyvinylidene fluoride powder. It is also

disclosed therein that polycarbonates, polyethylenes, and

acrylic block copolymer resins containing saturated elas-

tomer segments may be used. The particle size of the filler is

about 2 to 200 microns. These finely-divided organic powders

which are not dissolved or not fully dissolved in the

cyanoacrylate monomer convert the liquid cyanoacrylate to a

non-drip, thixotropic gel or paste.

10

15

20

25

30

35

40

45

50

55

60

65

2

Despite the state-of-the-art it is not believed that

cyanoacrylates have been used as part of a two part system to

form together with a filler a composite within a depression,

hole, crack or space in a substrate or between two substrates,

let alone to anchor placement of a cantilevered member which

is capable of supporting a load.

However, other adhesive systems are known for such appli-

cations in general. For instance, CHEMOFAST ramcord

Befestigungssyteme GmbH has promoted for sale three dif-

ferent “chemical anchoring” systems for heavy load carrying

attachments in concrete, solid stone or hollow brick surfaces.

These systems are based on one of “reaction resin mortar,

epoxy-acrylate-based in cartridges”, “reaction resin mortar,

polyester-based” or “reaction resin mortar, vinyl-ester-based

styrol-free”.

In each of these systems, their usage is described in terms

of drilling a hole in the substrate, cleaning out the drilled hole,

and either filling the cleaned drill hole with the reaction resin

mortar and then placing a reinforcement bar or threaded rod

into the reaction resin mortar filled drill hole or placing a

sleeve collar into the cleaned drill hole and filling the collar

with the reaction resin mortar and then placing an anchoring

element into the reaction resin mortar filled collar within the

drill hole, and thereafter curing the reaction resin mortar, say

for forty five minutes at room temperature (though other

conditions of temperature and time combinations are also

disclosed). Once cured, a component may be installed onto

the reinforcement bar, threaded rod or anchoring element and

torque applied thereto.

While these CHEMOFAST systems have been met with

commercial acceptance, it would be desirable to create adhe-

sive systems for such applications that are faster curing at

room temperature and that do not require a step of cleaning

out the hole, whether the hole was made for the purpose of

“chemical anchoring” or whether the hole previously existed

and is to be used to “chemically anchor” another article or is

simply to be filled. In addition, it would be desirable to create

such an adhesive system where the adhesive is dispensed after

the filler material, so that there is less opportunity for excess

adhesive to be used, thus rendering clean up simpler.

In addition, a system has been offered for sale in Japan,

which is seemingly similar to the CHEMOFAST systems, but

is based on polyurethane chemistry and includes in the pack-

age a series of sponges for placement within the holed prior to

dispensing of the polyurethane.

Thus, notwithstanding the state-of-the-technology it

would be desirable to provide a composite forming system in

which a cyanoacrylate may be applied to a depression, hole or

crack in a substrate, into at least a portion of which has been

placed a filler, and a composite may be formed within the

depression, hole or crack within a period of time of less than

about five minutes at room temperature, and when formed

such composite is capable of anchoring a cantilevered mem-

ber which is capable of supporting a load.

SUMMARY OF THE INVENTION

According to the invention, there is provided in one aspect

a curable system for filling a depression, hole, crack or space

in a substrate or a space between an assembly of two or more

substrates. The curable system includes the combination in a

first part a cyanoacrylate composition and in a second part a

filler material.

US 8,071,675 B2

3

In one way, the second part may be applied or introduced

first to the depression, hole, crack or space in the substrate so

as to fill at least a portion of that depression, hole, crack or

space with the filler material. Thereafter, the first part may be

applied or introduced to the depression, hole, crack or space

in the substrate filled at least partially with the filler material

to fill at least a portion of that depression, hole, crack or space

with the cyanoacrylate composition.

In another way, the first part of the second part may be

mixed together to form a part, which may then be applied or

introducted to the depression, hole, crack or space in the

substrate.

The cyanoacrylate should be allowed to cure at room tem-

perature for a period of time of five minutes or less to form a

substrate or assembly of two or more substrates that contains

a filled cured cyanoacrylate occupying the at least a portion of

the depression, hole, crack or space. Of course, depending

upon the dimensions (e.g., width, depth, etc.) of the depres-

sion, hole, crack or space, the type of cyanoacrylate chosen

and the type of filler chosen, the time required to cure the

composition to form the composite may vary.

In a second aspect of the invention, there is provided a

combination of a cyanoacrylate composition and a filler

material, each of which is to be applied to a depression, hole,

crack or space in an article in a stepwise fashion so that the

filler is initially occupied at least a portion of that depression,

hole, crack or space and the cyanoacrylate composition is

applied thereover and allowed to cure thereafter. An article is

thus created with a depression, hole, crack or space filled with

a cured cyanoacrylate composition.

In a third aspect of the invention, there is provided a room

temperature curing composite forming system. The system

includes two parts. Part A includes a one part adhesive of a

cyanoacrylate component; and Part B includes a filler mate-

rial.

In a fourth aspect of the invention, there is provided a kit for

filling a depression, hole, crack or space in a substrate or a

space between an assembly of two or more substrates. The kit

includes two parts. Part A includes a one part adhesive com-

prising a cyanoacrylate component; and Part B includes a

filler material.

In a fifth aspect of the invention, there is provided a method

of using a cyanoacrylate composition to fill a depression,

hole, crack or space in a substrate. The method includes the

steps of providing an article having a depression, hole, crack

or space; providing a filler material; providing a cyanoacry-

late composition; introducing the filler material into at least a

portion of the depression, hole, crack or space of the article

and thereafter applying the cyanoacrylate composition

thereto; and allowing the cyanoacrylate composition to cure,

thereby forming an article having a depression, hole, crack or

space filled at least partially with a cured cyanoacrylate com-

position.

In a sixth aspect of the invention, there is provided a

method of using a two part cyanoacrylate bonding system to

bond together two or more substrates. The method includes

the steps of providing a first substrate to be bonded; providing

a second substrate to be bonded in at least a partially spaced

apart relationship with said first substrate; providing a filler

material; providing a cyanoacrylate composition; introducing

the filler into the at least partially spaced apart first and second

substrates and thereafter applying the cyanoacrylate compo-

sition into at least a portion of the space between the first and

second substrates; and allowing the cyanoacrylate composi-

tion to cure, thereby forming an article having at least a

partially filled, cured cyanoacrylate composition between the

first and the second substrates.

The composition once placed within the depression, hole,

crack or space of the substrate to be filled is capable to take the

shape thereof and cure into that shape. Once the composition

10

15

20

25

30

35

40

45

50

55

60

65

4

(the cyanoacrylate/ filler combination) cures into that shape, it

is sandable so that a smooth surface may be created. In addi-

tion, the composition is coatable such that a paint, stain or

coating may be applied (the degree to which the coating

adheres to the article will depend in part on the article itself

but also the nature of the filler chosen).

BRIEF DESCRIPTION OF THE FIGURES

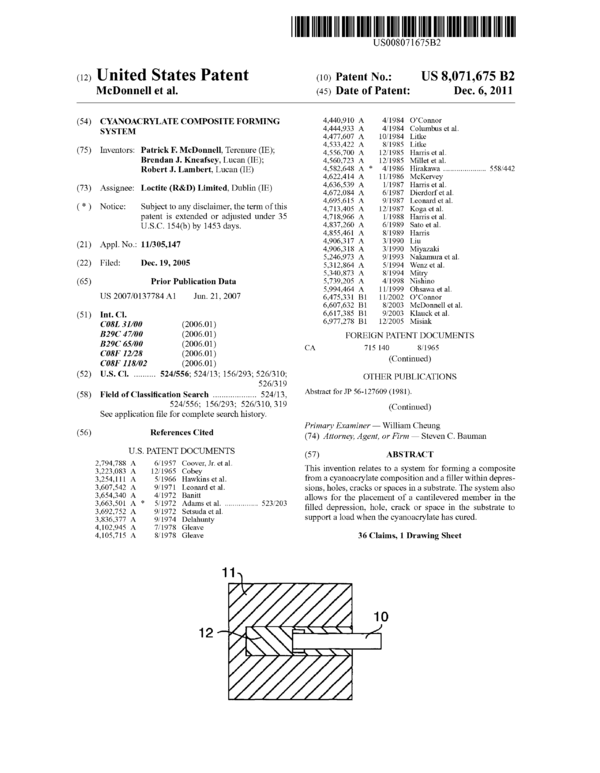

FIG. 1 depicts in cross sectional view of a cantilevered

member (here, a headed bolt) inserted into a cyanoacrylate-

filled hole.

FIG. 2 depicts in cross sectional view of a cantilevered

member (here, a threaded bolt) inserted into a cyanoacrylate-

filled hole.

FIG. 3 depicts in cross sectional view of a cantilevered

member (here, a rod-like member) inserted into a cyanoacry-

late-filled hole.

DETAILED DESCRIPTION OF THE INVENTION

The cyanoacrylate component includes cyanoacrylate

monomers which may be represented by H2C:C(CN)—

COOR, where R is selected from CH5 alkyl, alkoxyalkyl,

cycloalkyl, alkenyl, aralkyl, aryl, allyl and haloalkyl groups.

Desirably, the cyanoacrylate monomer is selected from

methyl cyanoacrylate, ethyl-2-cyanoacrylate, propyl

cyanoacrylates, butyl cyanoacrylates (such as n-butyl-2-cy-

anoacrylate), octyl cyanoacrylates, allyl cyanoacrylate,

[3-methoxyethyl cyanoacrylate and combinations thereof. A

particularly desirable one is ethyl-2-cyanoacrylate.

Additives may be included in the inventive compositions to

confer additional physical properties, such as improved shelf-

life stability, thixotropy, increased viscosity, color, improved

touglmess, flexibility and enhanced resistance to thermal deg-

radation. Such additives therefore may be selected from free

radical stabilizers, anionic stabilizers, gelling agents, thick-

eners, dyes, toughening agents, thermal resistance enhancers,

and combinations thereof.

Anionic stabilizers are ordinarily an acidic substance,

soluble in the ester of 2-cyanoacrylic acids, which inhibits

anionic polymerization, and are conventionally present in

cyanoacrylate compositions. The specific stabilizer chosen is

not critical to this invention, and a number of suitable inhibi-

tors of anionic polymerization are well known in the art, such

as soluble acidic gases such as sulfur dioxide, sulfur trioxide,

nitric oxide, and hydrogen fluoride.

Free radical stabilizers that inhibit polymerization, such as

quinone, hydroquinone, t-butyl catechol, p-methoxyphenol,

and the like are also conventionally present in cyanoacrylate

compositions. The above inhibitors may be used within wide

ranges, which are known in the art and for the sake of brevity

not repeated here. In the case where the composition is des-

tined for outside use, it may be desirable to increase the level

of free radical stabilizer in the cyanoacrylate in order to

inhibit environmental degradation.

Plasticizers when used in cyanoacrylate compositions

serve to make the cured products less brittle and, therefore,

more durable. In the context of the present invention, the

plasticizers can also be used to confer tack onto the filler

materials (see below for additional discussion). Common

plasticizers used in cyanoacrylates are C1_ 10 alkyl esters of

dibasic acids such as sebasic acid and malonic acid. Other

plasticizers, such as diaryl ethers and polyurethanes, also may

be used, and a variety of other plasticizers are also known. For

instance, in the context of providing enhanced and robust

adhesion to glass substrates, U.S. Pat. No. 6,607,632 (Mc-

Donnell) speaks to and claims a composition that includes

beyond the a cyanoacrylate monomer, at least one plasticizer

in the amount of 28 to 60% w/w by weight of the composition

US 8,071,675 B2

5

and at least one silane in the amount of 0.1 to % to 5.0% w/w

by weight of the composition. With this combination, such

enhanced and robust adhesion to glass substrates was

obtained. Representative plasticizers include conventional

materials such as is disclosed in Great Britain Patent Appli-

cation No. GB 1 529 105, for instance alkyl phthalates, aze-

lates, adipates, sebacates, citrates, phosphates, succinates,

benzoates and trimellitates. Desirable plasticizers are dibutyl

phthalate, benzylbutyl phthalate, diheptyl phthalate, dibutyl

sebacate and diethyleneglycol dibenzoate. Blends of two or

more different plasticizers are also beneficial.

In addition, U.S. patent application Ser. No. 10/023,950,

the disclosure of which is hereby incorporated herein by

reference, describes and claims cyanoacrylate compositions

that possess enhanced flexibility that use in addition to a

combination of different cyanoacrylates an ester group con-

taining plasticizer, which is miscible in the cyanoacrylate

combination, is present in the composition in an amount

between about 15 to about 40% by weight of the composition,

and has anAp/ Po ratio in the range of about 1.25 to less than

about 6 and/or the plasticizer component comprising trim-

ethyl trimellithate or an Ap/ Po ratio in the range of about 1 to

less than about 6, provided the plasticizer component does not

include pentaerythritoltetrabenzoate as the sole plasticizer.

Referring back to the ’632 patent, the term “silane” as used

herein includes silane hydrides and substituted silanes. The

silane may contain a cyclic structure. If the Si atom forms part

of a cycle it should not form part of a silacrown cycle (crown

structure). If the Si atom forms part of a cycle, the cycle

desirably should comprise no more than three oxygen atoms.

The cyclic group may be unsubstituted or substituted with

halogen or may be bridged or interrupted by one or more oxo

groups and suitably four to eight atoms form the cycle.

Examples of cyclic silanes of this general formula include:

cyclohexyldimethylchlorosilane, cyclohexyldimethylsilane,

cyclohexylmethyl)trichlorosilanes, cyclohexyltrichlorosi-

lane, (3-cyclopentadienylpropyl)-triethoxysilane, cyclopen-

tamethylenedichlorosilane, cyclopentarnethylenedimethyl-

silane, cyclotetrarnethylenedichlorosilane,

cyclotetramethylenedimethylsilane, cyclotrimethylethylene-

dichlorosilane, cyclotrimethylenedimethylsilane, dihexyldi-

chlorosilane, diisopropenoxydimethylsilane, diisopropyl-

chloro silane, dimesityldichlorosilane, 1,1-dimethyl-1-sila-2-

oxacyclohexane, Si-methyl(4-chloro-3,5 dimethyl)

benzooxasilepin methyl ester, and benzooxasilepin

dimethylester.

The silane constituent can suitably be one or more of a

range of alkoxy silanes such as vinyltriethoxy silane, vinylt-

rimethoxy silane, glycidoxypropyltrimethoxy silane, ethyl-

triethoxy silane, dimethyldiacetoxy silane, propyltriacetoxy

silane and vinylmethyldiacetoxy silane. Silanes giving a par-

ticularly good balance of compatibility and performance

include methyltriacetoxy silane, 3-(methacryloxy)propyltri-

methoxy silane and vinyltriacetoxy silane.

As regards tougheners, U.S. Pat. No. 4,440,910

(O’Connor) speaks to cyanoacrylate compositions toughened

through the use of elastomeric fillers, such as about 0.5% to

about 20% by weight of an elastomeric copolymer of a lower

alkene monomer and (i) acrylic acid esters (ii) methacrylic

acid esters or (iii) vinyl acetate.

The filler material may be selected from a variety of mate-

rials including paper, cardboard, fiber, gauze, cotton, wood,

glass (beads, crushed glass, fragments and the like), rubbers,

sponge, metals, natural materials (such as crushed sea shells,

hemp, nut shells and the like), inorganic fillers and synthetics.

The chosen filler should be readily wettable by the cyanoacry-

late to ensure that the cyanoacrylate has migrated throughout

the filler that occupies the depression, hole, crack or space.

10

15

20

25

30

35

40

45

50

55

60

65

6

The filler once placed within the depression, hole, crack or

space should have some porosity to permit the cyanoacrylate

to penetrate the depth of the depression, hole, crack or space

into which the filler and cyanoacrylate have been disposed.

In order for the filler material to remain in place within the

depression, hole, crack or space, it is desirable for the filler

material to have some tack. Tack may be inherent to the

material used or may be created by combining the filler ini-

tially with an additional material, such as any liquid whose

rheology is greater than that of the cyanoacrylate and/or is

capable of at least partially wetting the filler material so that

the surfaces of the filler material become sticky and thus

capable of forming a paste. In the context of the present

invention, “tack” may be viewed as the ability to maintain the

filler inplace so that the filler does not become dislodged from

the depression, hole, crack or space. For instance, tackifying

resins can be mixed with the fillers to provide the desired tack.

Tackifying resins can be divided into three groups: hydrocar-

bon resins, rosin resins and terpene resins. Hydrocarbon res-

ins are based on a petroleum feedstock, i.e., a synthetic

source, rosin resins are based on a natural feedstock: gained

from pine trees and terpene resins are generated from a natu-

ral source, wood turpentine or from the kraft sulphate pulping

process. See C. Donker, “The Chemistry of Tackifying Res-

ins—Parts I, II and III”, Adhesives & Sealants (2002 and

2003); www.specialchem4adhesives.com.

In that regard, the cyanoacrylate may be mixed initially

with the filler material, with or without a tackifying resin to

form a paste which may then be disposed within the depres-

sion, hole, crack or space. Alternatively, the filler, again with

or without the tackifying resin, may be disposed within the

depression, hole, crack or space and thereafter the cyanoacry-

late dispensed thereover.

Synthetics or plastics may be selected from a host of mate-

rials such as polyhydrocarbons, including polyacrylates and

polymethacrylates, polyurethanes, polyesters, polyethers,

polyphenolics, polystryrenes, and polyolefins. Representa-

tive though not limiting examples of such materials include

cellulose esters such as acetate, propionate and butyrate,

polyethers, such as polyvinyl ethers such as polyvinylmethyl

ether, polyether acrylates/methacrylates, acrylic/methacrylic

esters of bis(hydroxyalkyl)phosphonic acid derivatives,

acrylic/methacrylic esters oftris(hydroxyalkyl)cyanuric acid

derivatives, acrylonitrile-butadiene-styrene terpolymer,

polyvinylidene fluoride, polycarbonates, polyethylenes, and

acrylic block copolymer resins containing saturated elas-

tomer segments.

Suitable metals (and salts and/or oxides thereof) include

for instance titanium, zinc, tin, aluminum, iron and copper.

Fillers such as inorganic ones like silica, quartz, and cal-

cium may be used.

And in the construction setting, fillers such as foams, rub-

bers, stones, sand, paper, cardboard and clays may be used.

In addition, expandable microspheres may also be used to

fill the depression, hole, crack or space. These microspheres

generally may be constructed from a material that can soften

at the temperature experienced during the exotherm produced

for cyanoacrylate polymerization. As the material softened,

the gas (whether it is simply air or a gas, such as a hydrocar-

bon or noble gas) contained within the microsphere would be

released during polymerization creating an expandable or

foaming composition. A commercially available example of

such a microsphere is available from Akzo Nobel, Nether-

lands under the tradename EXPANCEL. EXPANCEL-brand

microspheres are small spherical plastic particles. The micro-

spheres consist of a polymer shell encapsulating a gas. When

the gas inside the shell is heated, it increases its pressure and

the thermoplastic shell softens, resulting in a dramatic

US 8,071,675 B2

7

increase in the volume of the microspheres. When fully

expanded, the volume of the microspheres increases more

than 40 times.

Alternatively, the microp sheres may be constructed from a

more brittle material, which may crack or fracture as pressure

therewithin increased as the gas expanded at the temperature

experienced during the exotherm produced for cyanoacrylate

polymerization. This too would create an expandable or

foaming composition. In the context of silicone composi-

tions, see U.S. Pat. No. 5,246,973 (Nakamura), where a foam-

able silicone is disclosed using thermally expansible hollow

plastic particles. See also Canadian Patent No. 7 1 5, 140, in the

context of closed cell sponge rubber production.

The size and shape of the filler is of no importance, except

to say that the filler should fit within the depression, hole,

crack or space that it is intended to fill at least in part. Of

course, combinations of these fillers may be used and differ-

ent sizes and shapes may also be used, particularly if some

aesthetic importance is to be gleaned from the inventive sys-

tem.

Accelerators and inhibitors (such as those materials

referred to above as anionic stabilizers) of cure for cyanoacry-

late compositions are well known. Conventionally, if one

wanted to accelerate or inhibit the rate of cure of a cyanoacry-

late composition, one may choose to add an accelerator and/

or inhibitor directly to the composition. That may be done

here as well. In addition, or alternatively, one may choose to

add an accelerator or inhibitor of cyanoacrylate cure to a

tackifying resin, if used. The filler chosen for use may be

pretreated, or for that matter the substrate to which the system

is to be applied, with an activator in order to speed the cure of

the cyanoacrylate or an inhibitor to retard the cure.

The accelerators may be selected from a host of different

chemical families, such as are noted below.

Useful accelerators may be selected from calixarenes and

oxacalixarenes, silacrowns, crown ethers, cyclodextrins, poly

(ethyleneglycol)di(meth)acrylates, ethoxylated hydric com-

pounds and combinations thereof.

Of the calixarenes and oxacalixarenes, many are known,

and are reported in the patent literature. See e.g., U.S. Pat.

Nos. 4,556,700, 4,622,414, 4,636,539, 4,695,615, 4,718,966,

and 4,855,461, the disclosures of each of which are hereby

expressly incorporated herein by reference.

For instance, as regards calixarenes, those within structure

I below are useful herein:

R2

CH2

0 H

I

CHZCRI

II

o

where R1 is alkyl, alkoxy, substituted alkyl or substituted

alkoxy; R2 is H or alkyl; and n is 4, 6 or 8.

One particularly desirable calixarene is tetrabutyl tetra[2-

ethoxy-2-oxoethoxy]calix-4-arene.

A host of crown ethers are known. For instance, examples

which may be used herein either individually or in combina-

tion, or in combination with other first accelerators include

15-crown-5, 18-crown-6, dibenzo-18-crown-6, benzo-15-

crown-5-dibenzo-24-crown-8, dibenzo-30-crown-10,

10

15

20

25

30

35

40

45

55

60

65

8

tribenzo-18-crown-6, asym-dibenzo-22-crown-6, dibenzo-

14-crown-4, dicyclohexyl-18-crown-6, dicyclohexyl-24-

crown-8, cyclohexyl-12-crown-4, 1,2-decalyl-15 -crown-5,

1,2-naphtho-15 -crown-5, 3,4, 5-naphtyl- 1 6-crown-5, 1,2-

methyl-benzo-18-crown-6, 1,2-methylbenzo-5, 6-methyl-

benzo-18-crown-6, 1 ,2-t-butyl-18-crown-6, 1,2-vinylbenzo-

15-crown-5, 1,2-vinylbenzo-18-crown-6, 1,2-t-butyl-

cyclohexyl-18-crown-6, asym-dibenzo-22-crown-6 and 1,2-

benzo-1,4-benzo-5-oxygen-20-crown-7. See U.S. Pat. No.

4,837,260 (Sato), the disclosure ofwhich is hereby expressly

incorporated here by reference.

Of the silacrowns, again many are known, and are reported

in the literature. For instance, a typical silacrown may be

represented within structure II below:

R4

R3 — Li : O il

L (OCH2(|:H)n

R5

where R3 and R4 are organo groups which do not themselves

cause polymerization of the cyanoacrylate monomer, R3 is H

or CH3 and n is an integer of between 1 and 4. Examples of

suitable R3 and R4 groups are R groups, alkoxy groups, such

as methoxy, and aryloxy groups, such as phenoxy. The R3 and

R4 groups may contain halogen or other sub stituents, an

example being trifluoropropyl. However, groups not suitable

as R4 and R3 groups are basic groups, such as amino, substi-

tuted amino and alkylamino.

Specific examples of silacrown compounds herein include:

111

H3C

dimethylsila-1 1-crown-4 (III);

IV

WW.

{

0&8/O

/ \

H3C CH3

1

dimethylsila-14-crown-5 (IV);

US 8,071,675 B2

H3C CH3

/

\Si

0/ \.

o( W.

xv)

and dimethylsila-17-crown-6 (V). See e.g. U.S. Pat. No.

4,906,317 (Liu), the disclosure of which is hereby expressly

incorporated herein by reference.

Many cyclodextrins may be used in connection with the

present invention. For instance, those described and claimed

in U.S. Pat. No. 5,312,864 (Wenz), the disclosure ofwhich is

hereby expressly incorporated herein by reference, as

hydroxyl group derivatives of an (X, [3 or y-cyclodextrin which

is at least partly soluble in the cyanoacrylate would be appro-

priate choices for use herein as the first accelerator compo-

nent.

For instance, poly(ethylene glycol)di(meth)acrylates suit-

able for use herein include those within structure VI below:

V1

CH3 H3C

H2C=C C=CH2

C—[-O—CH2—CH2-]n—O—C

11 A

where n is greater than 3, such as within the range of 3 to 12,

with n being 9 as particularly desirable. More specific

examples include PEG 200 DMA, (where n is about 4) PEG

400 DMA (where n is about 9), PEG 600 DMA (where n is

about 14), and PEG 800 DMA (where n is about 19), where

the number (e.g., 400) represents the average molecular

weight of the glycol portion of the molecule, excluding the

two methacrylate groups, expressed as grams/mole (i.e., 400

g/mol). A particularly desirable PEG DMA is PEG 400

DMA.

10

15

20

25

30

35

40

45

50

1 0

And of the ethoxylated hydric compounds (or ethoxylated

fatty alcohols that may be employed), appropriate ones may

be chosen from those within structure V11:

V11

"OH

C 0 CH2

m—[" \(|:H/ K

R

where Cm can be a linear or branched alkyl or alkenyl chain,

m is an integer between 1 to 30, such as from 5 to 20, n is an

integer between 2 to 30, such as from 5 to 15, and R may be

H or alkyl, such as C1_6 alkyl.

Commercially available examples of materials within

structure V11 include those offered under the DEHYDOL

tradename from Henkel KGaA, Dusseldorf, Germany, such

as DEHYDOL 100.

Additional accelerators are embraced by structure V111

where R is hydrogen, alkyl, alkyloxy, alkyl thioethers,

haloalkyl, carboxylic acid and esters thereof, sulfinic, sul-

fonic and sulfurous acids and esters, phosphinic, phosphonic

and phosphorous acids and esters thereof, X is optional, but

when present is an aliphatic or aromatic hydrocarbyl linkage,

which may be substituted by oxygen or sulfur, and Z is a

single or double bond, such as

where R and X are as defined above, and n is 1-12, m is 1-4,

and p is 1-3.

For instance, a particularly desirable chemical class

embraced by structure V11 is

R®owO1.wokJo4».«O1.wo%@Ri

US 8,071,675 B2

11

where R, Z and n are as defined above, and R‘ is the same as

R, where g is the same as n, with a particularly desirable

chemical within this class being

H19C9

12

instance a hanging plant in a brick or stone hole into which the

hook has been secured by the inventive cyanoacrylate com-

posite forming system.

O\4/\o)f\/OW‘/\j\o/\/(O\/1:0

where n and m combined is greater than or equal to 12.

When cured the accelerator should be present, either in the

cyanoacrylate composition directly or after coming into con-

tact with the filler and/ or the substrate in an amount within the

range of from about 0.01% to about 10% by weight, with the

range of about 0.1 to about 0.5% by weight being desirable,

and about 0.4% by weight of the total composition being

particularly desirable. Thus, when the accelerator is desirably

mixed into a tackifying resin, it may be at the concentrations

given above. Where the accelerator is used as a pretreatment

on the filler or the substrate, it may be used in that concentra-

tion in a carrier that may evaporate either under atmospheric

conditions or under modest temperature conditions.

Similarly, as noted above, it may be desirable in certain

applications to retard the rate of cure of the cyanoacrylate.

This may be achieved by using an acidic material, whether

strong or weak acids, as is well known in the art.

These accelerators or inhibitors allow the end user to adjust

the working to suit the particular needs or desires of a certain

application.

Once the depression, hole, crack or space is filled at least in

part with the combination of cyanoacrylate and filler, a can-

tilevered member may be placed into the at least partially

filled depression, hole, crack or space. The cantilevered mem-

ber may also be placed into the depression, hole, crack or

space after the filler has been introduced but prior to the

cyanoacrylate. Altematively, the filler may be applied to and/

or around the cantilevered member, which may be inserted

into the depression, hole, crack or space followed by the

cyanoacrylate, or which may then be exposed to the

cyanoacrylate and the combination of cantilevered member/

filler/cyanoacrylate is inserted into the depression, hole,

crack or space. Of course, in either of these processes, the

cyanoacrylate is allowed to cure.

In either event, the cantilevered member may be placed

within an orifice that is pre-made within the filler that is

dispersed within the depression, hole, crack or space in the

article. Or, the cantilevered member itself may make an ori-

fice within the filler that is dispersed within the depression,

hole, crack or space of the article as it is being placed therein.

The cyanoacrylate may be applied in and around the filler

either before or after the cantilevered member is introduced.

As just noted, the cantilevered member, if introduced to the

depression, hole, crack or space after the cyanoacrylate, may

be so introduced immediately after some or all of the

cyanoacrylate has been applied, or may be introduced after a

short period time to allow the cyanoacrylate to begin to cure.

The precise timing or order of assembly in this regard is left to

the discretion of those of skill in the art.

The cantilevered member is a support mechanism, and may

be an item such as a hook, pole or other support mechanism,

such as a shelf support. Once secured, the hook mechanism

wherein the form of a hook, may be used to support for

15

20

25

30

35

40

45

50

55

60

65

C9H19

Reference to FIGS. 1-3 shows the cantilevered member

(10, 20 or 30) set within a hole in the substrate 11 and sur-

rounded by the cyanoacrylate filler mixture, where the

cyanoacrylate has cured 12.

FIG. 1 shows the cantilevered member as a headed bolt 10;

FIG. 2 shows it as a threaded bolt 20; and FIG. 3 shows it as

a rod-like member 30.

The viscosity of the cyanoacrylate should be adjusted so

that it can effectively wet the filler and penetrate within the

interstices created when the filler is introduced and disposed

within the depression, hole, crack or space. If the viscosity is

too great and the interstices too tight, the cyanoacrylate will

have difficulty passing in and about the filler within the

depression, hole, crack or space, at least within an appropriate

work time prior to cure of the cyanoacrylate.

However, the reactivity of the cyanoacrylate should be

adjusted so as to optimize the work time for the end user, so

that cure does not occur prior to penetrating substantially

fully within and through the interstices of the filler, either

outside of or within the depression, hole, crack or space.

One of the benefits and advantages of the present invention

is the ability to use the system for a depression, hole, crack or

space that is oriented overhead or vertically, without accom-

panying the typically flow out or dripping that one may find

using either a conventional cyanoacrylate without the filler, or

using an adhesive or sealant based on another type of tech-

nology. This is achieved in part by mixing the filler with a

binder that makes a thickened slurry, having tack.

The invention is illustrated further by the following

examples.

EXAMPLES

Example 1

A paste of glass beads with a high solid content was pre-

pared by mixing 2 grams of ACRONAL LR8820 (acrylic

ester polymer dispersion from BASF Aktiengesellschaft)

with 98 grams of glass beads (obtained from Baud Minerals

and Polymers, UK & Sweden) with particle size in the range

150-200 microns. The ACRONAL resin acted as an effective

binder for the glass particles forming a non-mobile but easily

malleable paste with sufficient surface tack to permit the paste

to remain where it was placed. The paste was used to fill a 10

mm diameter hole which had been drilled horizontally to a

depth of 10 mm in a standard red construction brick. The paste

was applied with a spatula to completely fill the hole to the

same level as the surrounding brick surface. A low viscosity

cyanoacrylate composition was then applied to the centre of

the paste-filled hole in an amount sufiicient to wet the paste

throughout. After a period of time of about 45-60 seconds, the

cyanoacrylate composition started to cure to form a solid

composite in the hole that quickly developed a hardness simi-

lar to or greater than the surrounding brick. In addition the

US 8,071,675 B2

13

paste was firmly anchored within the hole due to the adhesive

properties of the cyanoacrylate liquid. No shrinkage of the

cured paste composition occurred due to the high solid con-

tent. Any excess of the cured material could be easily levelled

by sanding or similar abrasion method. The cyanoacrylate

adhesive used in this example was an ethyl cyanoacrylate

formulation with a viscosity of 1-3 mPas stabilised with

15-30 ppm of sulphur dioxide or equivalent acidic material

and 1000 ppm hydroquinone.

Example 2

The materials and procedures employed in Example 1 were

repeated but in this example the hole was drilled in the brick

in a vertical orientation. Again the hole was filled with the

paste, and due to its rheology and tackiness, the paste

remained in place without falling out. The cyanoacrylate

composition was applied as in Example 1, to yield a hard and

durable composite which successfully completed the task of

filling the hole.

Example 3

A paste was prepared as in Example 1, and was used to fill

a 10 mm diameter hole which had been drilled to a depth of 15

mm in a teak plank. The paste was applied with a spatula to

completely fill the hole to the same level as the surrounding

wood surface. A low viscosity (1-3 mPa~s) ethyl cyanoacry-

late composition containing 0.4% calixarene as an accelera-

tor was applied dropwise to wet the paste. After about 10

seconds the cyanoacrylate composition cured to a hard mass

which had powerful adhesion to the sides and base of the 10

mm diameter hole described above.

Example 4

Example 3 was repeated though in place of teak mahogany

wood was used instead. The cyanoacrylate composition was

applied as above, and after about 10 seconds a cured mass was

observed to have formed which bonded tenaciously to the

wood.

Example 5

Example 3 was repeated though in place of teak MDF

wood (medium-density fibreboard) was used instead. The

cyanoacrylate composition was applied as above, and after

about 10 seconds a cured mass was observed to have formed

which bonded tenaciously to the wood.

Example 6

Example 3 was repeated though in place of teak plaster-

board with a thickness of 10 mm was used instead. The

cyanoacrylate composition was applied as above, and after

about 10 seconds a cured mass was observed to have formed

which bonded tenaciously to the plasterboard as a solid plug.

Example 7

The glass-bead paste described in Example 1 was used to

fill a hole drilled in teak wood. The hole had a diameter of 15

mm and a depth of 20 mm. The low viscosity cyanoacrylate

composition described in Example 1 was applied dropwise to

wet the paste. After about 30 seconds, the cyanoacrylate

composition started to cure and increase the structure and

viscosity of the paste. At this stage the threaded part of a

standard metal cup hook was inserted (using a screwing

action) into the midpoint of the paste to a depth of 15 mm. As

10

15

20

25

30

35

40

45

50

55

60

65

14

the paste progressively cured over the next 30 seconds, the

cup hook was unscrewed to prevent bonding.

Upon inspection, it was discovered that threads had been

created in the solidified paste and the cup hook could be easily

reinserted and removed at will. When the cup hook was

screwed into the solid paste to a depth of 15 mm, the hook

formed a cantilever device capable of supporting a weight of

5 kg for an indefinite period of time.

Example 8

A filler paste was prepared on a percent by weight basis

from the following constituents:

93% glass beads of particle size 250-400 microns

3.5% EXPANCEL-brand microspheres (Akzo Nobel)

3.5% ACRONAL LR8820 (BASF Aktiengesellschaft)

A series of 10 mm deep holes were drilled into a flat sheet

of obeche timber to a depth of 7 mm. The sheet was then

placed in a vertical orientation. The holes were completely

packed with the filler paste using a spatula to ensure a level

finish with the surrounding wood surface. A low viscosity

cyanoacrylate composition as described in Example 1 was

carefully injected into the paste with a syringe and needle

applicator until the paste was wetted. About 0.5 gram of the

cyanoacrylate composition was used to accomplish that.

After about 60 seconds, the cyanoacrylate cured to a solid

structure that proceeded to expand about 1 mm proud of the

surface. The heat generated by the polymerisation of the

cyanoacrylate composition was sufiicient to activate the

expanding properties of the EXPANCEL micro spheres, caus-

ing the expansion so observed.

Example 9

The 20 mm diameter cavity in a red construction brick was

filled to a depth of 20 mm with MATLINE 200 non-woven

core fabric material (N ida-Core Corp., Florida, USA), by first

rolling the fabric to form a cylinder wad and then pushing the

wad firmly and tightly into the brick cavity. Any excess fabric

was trimmed so that it was flush with the brick surface.

Sufiicient low viscosity ethyl cyanoacrylate adhesive was

applied to the centre of the fabric packing to ensure that all the

material in the cavity was wetted. Approximately 1 gram of

the cyanoacrylate composition was used to accomplish that.

After about 60-90 seconds, the cyanoacrylate composition

started to cure. The fabric/cyanoacrylate composition combi-

nation formed a solid plug for the cavity with excellent adhe-

sion to the intemal brick surfaces. As in Example 6 above, a

cup hook was screwed into the solid plug-filled cavity before

the cyanoacrylate composition had fully cured, to allow the

cup hook to be screwed in or out at will. When the hook was

fully screwed into the solid plug-filled cavity and cure was

allowed to proceed for 2 minutes, the hook was able to sup-

port the weight of the brick (2.3 kg) for an indefinite period of

time.

Example 10

A filler paste was prepared on a percent by weight basis

from the following constituents:

98% glass beads of particle size 250-400 microns

2.0% ACRONAL LR8820 (BASF Aktiengesellschaft)

A standard brass bolt, 10 mm>

Coments go here:

- Log in to post comments