Thixotropic Cyanoacrylate Compositions

Folder:

Year:

Abstract:

Cyanoacrylate compositions which employ fumed silicas treated with polydimethylsiloxane or trialkoxyalkylsilane are stable and exhibit an unexpectedly high thixotropic ratio. Such compositions are useful in adhesive applications or, when stabilized so as to prevent polymerization in contact with moisture, in latent fingerprint developing applications.

Type of document:

Language:

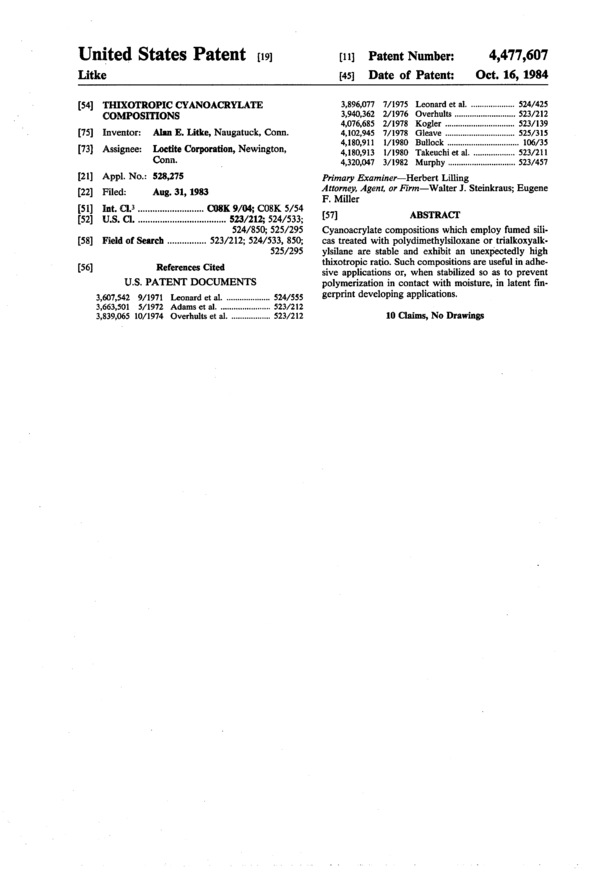

United States Patent 119]

Litke

[541

[75]

[73]

[21]

[22]

[51]

[52]

[58]

[561

THIXOTROPIC CY ANOACRYLATE

COMPOSITIONS

Alan E. Litke, Naugatuck, Conn.

Loctite Corporation, Newington,

Conn.

App]. No.: 523,275

Filed: Aug. 31, 1983

Int. C13 ......................... .. C08K 9/04; C08K 5/54

U.S. Cl. .................................. .. 523/212; 524/533;

524/850; 525/295

Field of Search .............. .. 523/212; 524/533, 850;

525/295

Inventor:

Assignee:

References Cited

U.S. PATENT DOCUMENTS

3,607,542 9/1971 Leonard et al. .................. .. 524/555

3,663,501 5/1972 Adams et al. 523/212

3,839,065 10/1974 Overhults et al. ................ .. 523/212

[11] Patent Number: 4,477,607

[45] Date of Patent: Oct. 16, 1984

3,395,077 7/1975 Leonard eta]. .......... .. 524/425

3,940,362 2/1975 Overhults .. .. 523/212

4,075,535 2/1973 Kogler . . . . . . . . . . .. 523/139

4,102,945 7/1978 Gleave .......................... .. 525/315

4,130,911 1/1930 Bullock ............................... .. 106/35

4,130,913 1/1930 Takeuchietal.. .... .. 523/211

4,320,047 3/1932 Murphy ............................. .. 523/457

Primary Examiner—Herbert Lilling

Attorney, Agent, or F1'rm—Walter J. Steinkraus; Eugene

F. Miller

[57] ABSTRACT

Cyanoacrylate compositions which employ fumed sili-

cas treated with polydimethylsiloxane or trialkoxyalk-

ylsilane are stable and exhibit an unexpectedly high

thixotropic ratio. Such compositions are useful in adhe-

sive applications or, when stabilized so as to prevent

polymerization in contact with moisture, in latent fin-

gerprint developing applications.

l0 Claims, No Drawings

4,477,607

‘I

I THIKOTROPIC CY AN OACRYLATE

COMPOSITIONS

BACKGROUND OF THE INVENTION

Cyanoacrylate adhesives based on esters of a-cyanoa-

crylic acid have gained wide acceptance in recent years

for a broad range of industrial and consumer uses. The

cyanoacrylate esters themselves, however, are very low

viscosity liquids which makes the use of unfilled com-

positions difficult. Such compositions often migrate

from the bondline or are absorbed into porous surfaces.

Accordingly, there have been developed a variety of

thickened cyanoacrylate adhesive compositions which

incorporate organic polymers and/or inorganic fillers

to reduce adhesive migration. Examples of such compo-

sitions are described in U.S. Pat. Nos. 3,607,542;

3,896,077, 4,105,715, 4,180,913 and in Chemical Ab-

stracts 89:117907c; 89:216475u; 91:40425c; and

92:95114b.

In the art of thickened cyanoacrylates it is sometimes

desirable that the composition display thixotropic prop-

erties. Thus, under high shear conditions the composi-

tion can be processed and easily applied to the substrate

but once applied, will display significantly reduced

migratory tendencies. It is also well known that the

inclusion of fumed silicas in many organic liquid com-

positions produces thixotropic effects. The use of such

silicas has been reported in cyanoacrylate compositions.

At least certain of the prior art cyanoacrylate compo-

sitions employing fumed silicas have displayed stability

problems, however. Thus U.S. Pat. No. 3,607,542 de-

scribes organically filled cyanoacrylate compositions in

which fumed silica is an optional ingredient. These

compositions are reportedly stable for only up to 4

hours. Furthermore, the same patent states that silica by

itself does not readily mix with cyanoacrylate monomer

to form a paste.

Cyanoacrylate formulations also occasionally find

non-adhesive applications. Thus, for instance, the va-

pors of methyl and ethyl cyanoacrylates have found use

for developing latent fingerprints in law enforcement

applications. For such applications it would be desirable

to develop a nonflowable form of cyanoacrylate mono-

mer so that small open containers of the monomer can

be placed throughout a room or automobile to release

vapors without the danger of accidental monomer spill-

age. Desirably the thixotropic additives will also be

kept to a minimum so as not to substantially" reduce the

monomer vapor pressure. '

In certain applications it has been discovered that

hydrophobic silicas produced by treatment of fumed

silica with dimethyldichlorosilane can be used to give

thixotropic cyanoacrylate compositions with improved

stability. However, these fillers add cure retarding

strong acid to the cyanoacrylate composition. Also, the

thixotropic ratio of these silicas in cyanoacrylate esters

(the ratio of apparent viscosity is measured under speci-

fied high and low shear conditions) is quite low. There-

fore, when very high thixotropic effects are desired,

such as when a pasty composition is desired, the amount

of acid introduced by the silica can substantially reduce

the cure time of the composition. Also, for latent finger-

print developing type applications, higher silica levels

may result in lower monomer vapor pressures.

Commercially available fumed silicas are also known

which have been treated with hexamethyldisilazane. It

has discovered that thixotropy ratios are also very low

5

10

15

20

25

30

35

45

50

55

65

2

for these materials and that at least some of these materi-

als tend to destabilize cyanoacrylate compositions. The

destabilization effect is thought to result from residual

ammonia or amine in the filler.

Accordingly there exists a need for a cyanoacrylate

thixotrope, stable to the cyanoacrylate monomer,

which has a significantly improved thixotropy ratio

over dimethyldichlorosilane or hexamethyldisilazane

treated silicas, and which does not adversely affect the

fixture time of adhesive formulations.

SUMMARY OF THE INVENTION

The present application relates to cyanoacrylate com-

positions which employ fumed silicas treated with a

polydimethylsiloxane or a trialkoxyalkylsilane as a

thixotropic additive. It has been unexpectedly found

that such silicas when incorporated into cyanoacrylate

compositions do not adversely effect the stability of the

composition, display a significantly higher thixotropy

ratio than the previously mentioned treated silicas and,

in adhesive compositions, do not adversely effect fix-

ture time even at levels of about 10-12% where the

compositions become pasty and very difficult to stir or

apply uniformly. .

The inventive compositions may consist primarily of

an appropriately stabilized cyanoacrylate ester mono-

mer and the specified silica. However, it is preferred

that a small amount of an organic polymer such as poly-

methylmethacrylate be dissolved in the monomer.

The inventive compositions are also useful in nonad-

hesive applications such as nonflowable latent finger-

print developing formulations.

DETAILED DESCRIPTION OF THE

INVENTION

Fumed silicas which have been found to impart de-

sired thixotropic properties to the inventive composi-

tions fall into two categories. The first, and most pre-

-ferred, are polydimethylsiloxane treated silicas such as

Cab-O-Sil N70-TS TM, sold by the Cabot Corporation.

The-silica has a carbon content of 5 weight percent and

a surface area of 70M2/gm according to the manufac-

turer.

The second category of silicas usable in the inventive

compositions are trialkoxyalkylsilanes. An example is

Aerosil R805 TM , an experimental product available

from Degussa Corporation. Aerosil R805 TM is a trime-

thoxyoctylsilane treated silica having a surface area of

150 m2/ gm.

The superior thixotropic performance of the inven-

tive cyanoacrylate compositions is best obtained at sil-

ica levels of about 4-8%. These properties were demon-

strated by comparative testing of an ethyl cyanoacry-

late formulation containing 6% of a 0.4-0.5 million mw

polymethylmethacrylate and 6% hydrophobic silica.

The composition was stabilized with 5 ppm methanesul-

fonic acid (MSA) approximately 2500 ppm hydroqui-

none and 5 ppm S02. The formulations were prepared

with the aforementioned Cab-O-Sil N70-TS TM and

Aerosil R805 TM as well as two hexamethyldisilazane

treated silicas (Tellenox 500 TM solb by Tulco, Inc. and

Wacker HDK 2000 TM sold by Wacker-Chemie) and

three-dimethyldichlorosilane treated silicas (Aerosils

R972 TM , R974 TM and R976 TM , all sold by Degussa).

Table I gives the results of comparative Brookfield

viscosity and acid level (calculated as ppm MSA) deter-

minations.

4,477,607

3 4-

TABLE I

Brookfield Viscosity

2.5 RPM 20 RPM

helipath helipath Ratio Total

Comp. Silica (spindle) (spindle) 2.5/20 Acid

A Cab-O-Sil N70-TS m 2.9 x 105 (TB) 4.2 x 104 (TB) 6.9 27

13 Aerosil R805 m 1.4 x 105 (TB) 2.8 x 1 (TB) 5.0 32

c Tellenox 500 m 4.4 x 104 (TB) 2.1 x 104 (TB) 2.1 26

D Wacker HDKZOOO m 3.3 x 102 (TA) 3.0 x 102 (TA) 1.1 29

E Aerosil R972 m 1.2 x 104 (Tc) 3.8 x 103 (TC) 3.2 33

F Aerosil R974 m 2.1 x 104 (TC) 5.2 x 103 (TC) 4.0 40

G Aerosil R976 m 2.6 x 104 (TC) 3.1 x 103 (TC) 3.2 39

As can be seen from the table, compositions A and B,

which are within the invention, show much higher low

shear viscosity and substantially higher thixotropic ra-

tios than compositions C—G which are not within the

invention. It was also observed that, when unagitated,

compositions A and B were nonflowable gels whereas

compositions C—G were all ungelled and pourable.

Compositions similar to formulation E but com-

pounded with sufficient Aerosil R972 TM to produce

non-flowable gels comparable to those of compositions

A and B in Table I have been prepared and have been

observed to require longer fixture times than those of

compositions A and B. This is believed to result from

increased strong acid imparted by the dimethyldichlo-

rosilane treated silica. The significantly higher acid

numbers of compositions E—G is evidence that the di-

chlorosilane treated silicas do contribute strong acid to

the cyanoacrylate formulations.

Both hexamethyldisilazine treated silicas had imprac-

tically low thixotropic ratios as shown by Table I. Fur-

thermore, at least one of the hexamethyldisilazane

treated silicas appars to destabilize cyanoacrylate mono-

mers. Formulation C, which utilizes the Tellenox

500 TM silica polymerized in less than one day in a

sealed tube at 82° C. while compositions A, B and D—G

all lasted at least l5 days under the same conditions.

It is preferred that the cyanoacrylate compositions of

the invention include a minor amount of dissolved or-

ganic polymer. Suitable polymers include polyacrylates

and polymethacrylates, polycyanoacrylates such as

poly(ethyl cyanoacrylate), and poly(vinyl acetate) pol-

ymers and copolymcrs. The organic polymers are pref-

erably included witin the range of approximately

1-15% of the composition by weight. Preferably, the

organic polymers are included in the range of 3—l0%.

The inclusion of the organic polymer is recommended

in order to prevent or significantly diminish the settling

out of the silica from the inventive compositions. The

compositions containing dissolved polymer are also

observed to produce higher viscosities at equivalent

silica concentrations and to recover thixotropic behav-

ior faster after agitation than without dissolved poly-

mers.

Other additives, conventional within the cyanoacry-

late formulation art, may be included within the compo-

sitions of the invention without departing from the

teaching hereof. Examples of such additives need not be

15

20

25

30

‘35

40

45

50

55

60

65

specified since they are within the skill of those working

in the art.

As mentioned above, it would be desirable for latent

fingerprint developing applications to have a nonflow-

able form of cyanoacrylate with high vapor pressure.

Gel compositions of the invention which have been

stabilized to the point where they will not polymerize

on contact with moisture are especially useful for such

applications. The gel form pevents spillage and the

over-stabilization guards against bonding of fingers

(“finger-stick”) are other articles. A typical such formu-

lation includes 88% methylcyanoacrylate stabilized

with 0.2% methane sulfonic acid and 2500 hydroqui-

none, 6% polymethylmethacrylate and 6% polydimeth-

ylsiloxane treated silica.

From the foregoing it can be seen that the invention

is not limited by the specific examples set forth above,

the invention being limited only as set forth in the fol-

lowing claims.

I claim:

1. In a composition comprising an a-cyanoacrylate

ester monomer and a thixotropic agent, the improve-

ment comprising that said composition is a non-flowa-

ble gel, said thixotropic agent is present in an amount of

12% or less and is a fumed silica having a surface

treated with a trialkoxyalkylsilane and the said compo-

sition has a 2.5 RPM Brookfield viscosity of about

1X 105 or greater.

2. A composition as in claim 1 wherein the silica

surface is treated with trimethoxyoctylsilane.

3. A composition as in claim 1 comprising an organic

polymer dissolved in said monomer.

4. A composition as in claim 3 wherein said polymer

is selected from polyvinyl acetate polymers and copoly—

mers, polyacrylates, polymethacrylates and

polycyanoacrylates.

5. A composition as in claim 1 stabilized so as to be

nonpolymerizable on contact with moisture.

6. A composition as in claim 3 wherein said polymer

is present at levels of between 1 and 15% by weight.

7. A composition as in claim 6 wherein said polymer

is present at levels of between 3 and 10% by weight.

8. A composition as in claim 7 wherein said polymer

is polymethylmethacrylate.

9. A composition as in claim 1 wherein said silica is

present in an amount between about 4 and 8% by

weight.

10. A composition as in claim 9 wherein said silica is

present in an amount of about 6% by weight.

Sit ill Ill Ill 31¢

Coments go here:

- Log in to post comments