ARTICLE

pubs.acs.org/joc

Microwave-Assisted and Continuous Flow Multistep Synthesis of

4-(Pyrazol-1-yl)carboxanilides

David Obermayer, Toma N. Glasnov,* and C. Oliver Kappe*

Christian Doppler Laboratory for Microwave Chemistry (CDLMC) and Institute of Chemistry, Karl-Franzens-University Graz,

Heinrichstrasse 28, A-8010 Graz, Austria

S

b Supporting Information

ABSTRACT: A series of 4-(pyrazol-1-yl)carboxanilides active

as inhibitors of canonical transient receptor potential channels

were synthesized in an efficient three-step protocol using

controlled microwave heating. The general synthetic strategy

involves condensation of 4-nitrophenylhydrazine with appropriate 1,3-dicarbonyl building blocks, followed by reduction of

the nitro group to the amine, which is then amidated with

carboxylic acids. Compared to the conventional protocol a dramatic reduction in overall processing time from ∼2 days to a few

minutes was achieved, accompanied by significantly improved product yields. In addition, the first two steps in the synthetic pathway

were also performed under continuous flow conditions providing similar isolated product yields. As an alternative to the three-step

protocol, a novel two-step route to the desired 4-(pyrazol-1-yl)carboxanilides was devised involving condensation of 4-bromophenylhydrazine with appropriate 1,3-dicarbonyl building blocks, followed by Pd-catalyzed BuchwaldÀHartwig amidation with

carboxylic acid amides.

’ INTRODUCTION

The pyrazole ring is an important heterocyclic core structure

in a large number of biologically active compounds. The spectrum of pharmaceutical action of pyrazole derivatives encompasses, for example, substances acting on the central nervous

system, pharmacodynamic agents, drugs aimed at metabolic

diseases, and chemotherapeutics.1 Recent examples are the

CB1 cannabinoid receptor antagonist Rimonabant (SanofiAventis)2 and analogous molecules active as protein kinase

inhibitors, in addition to anti-estrogens acting as potential

antitumor therapeutics.3 The past decade brought the discovery

of a new class of drugs targeting the Na+/Ca2+ signaling pathways, which play a key role in many pathogenic processes

including systemic diseases, inflammation, and cancer.1,4 One

important topic in this rapidly growing field are drugs which are

tuning the activity of canonical transient receptor potential

channels (TRPC), controlling the influx of intracellular Ca2+

into a plethora of mammalian cell types.5 Mori and co-workers

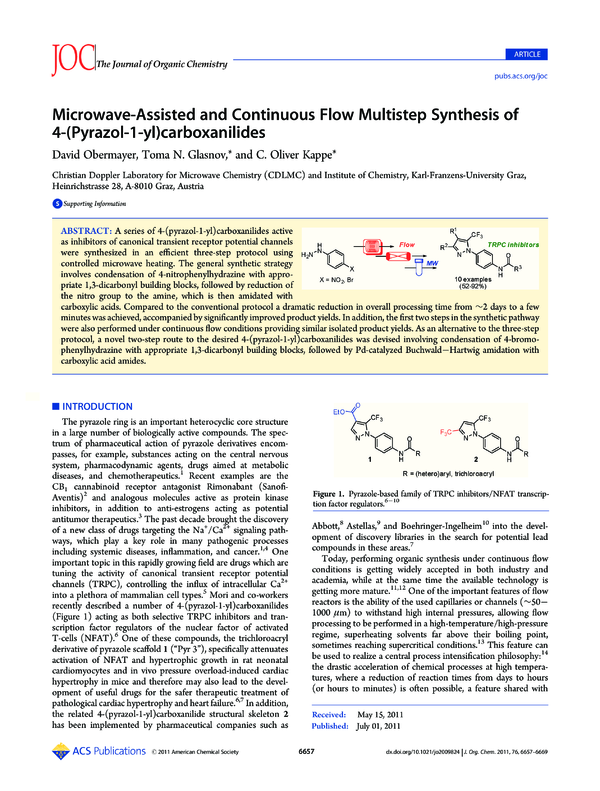

recently described a number of 4-(pyrazol-1-yl)carboxanilides

(Figure 1) acting as both selective TRPC inhibitors and transcription factor regulators of the nuclear factor of activated

T-cells (NFAT).6 One of these compounds, the trichloroacryl

derivative of pyrazole scaffold 1 (“Pyr 3”), specifically attenuates

activation of NFAT and hypertrophic growth in rat neonatal

cardiomyocytes and in vivo pressure overload-induced cardiac

hypertrophy in mice and therefore may also lead to the development of useful drugs for the safer therapeutic treatment of

pathological cardiac hypertrophy and heart failure.6,7 In addition,

the related 4-(pyrazol-1-yl)carboxanilide structural skeleton 2

has been implemented by pharmaceutical companies such as

r 2011 American Chemical Society

Figure 1. Pyrazole-based family of TRPC inhibitors/NFAT transcription factor regulators.6À10

Abbott,8 Astellas,9 and Boehringer-Ingelheim10 into the development of discovery libraries in the search for potential lead

compounds in these areas.7

Today, performing organic synthesis under continuous flow

conditions is getting widely accepted in both industry and

academia, while at the same time the available technology is

getting more mature.11,12 One of the important features of flow

reactors is the ability of the used capillaries or channels (∼50À

1000 μm) to withstand high internal pressures, allowing flow

processing to be performed in a high-temperature/high-pressure

regime, superheating solvents far above their boiling point,

sometimes reaching supercritical conditions.13 This feature can

be used to realize a central process intensification philosophy:14

the drastic acceleration of chemical processes at high temperatures, where a reduction of reaction times from days to hours

(or hours to minutes) is often possible, a feature shared with

Received: May 15, 2011

Published: July 01, 2011

6657

dx.doi.org/10.1021/jo2009824 | J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

ARTICLE

Scheme 1. Bifurcated Synthesis Path to 4-(Pyrazol-1-yl)carboxanilides of Type 1 or 2 (Figure 1) Incorporating Hydrogenation/

Peptide Coupling (Path a) or BuchwaldÀHartwig Amidation (Path b)

microwave chemistry in sealed vessels.15,16 Importantly, the

process window of microwave batch reactors (up to 300 °C

and 30 bar) employing sealed glass vessels is overlapping to a

great extent with the temperature/pressure regime of most

commercially available continuous flow reactors (200À350 °C

and up to 180 bar).13 As a consequence, microwave batch

reactors are ideal tools to initially optimize a chemical reaction

before moving to a high-temperature/high-pressure continuous

flow process (microwave-to-flow paradigm).17 As compared to

solely relying on flow equipment for the optimization step,18

using batch microwave technology allows a quick evaluation of a

large matrix of reaction conditions (different solvents, reagents,

etc.) in a very short time frame. In addition, problematic reaction

conditions (e.g., precipitation) are recognized at an early stage

before moving to flow conditions.

Herein we describe improved (process intensified) synthetic

protocols that allow the rapid multistep synthesis of 4-[trifluoromethyl-(pyrazol-1-yl-)]carboxanilides of type 1 and 2

(Figure 1).6,8À10 These procedures are based on the use of

microwave batch or continuous flow chemistry as enabling

technologies to allow the reduction of reaction times from a

few days down to minutes.19

’ RESULTS AND DISCUSSION

The known synthetic strategies for the preparation of 4(pyrazol-1-yl)carboxanilides generally pursue a pragmatic threestep approach relying on standard procedures (Scheme 1, path

a), to generate small amounts of the target compounds for

biological screenings.6À10 Starting with a cyclocondensation

reaction between 4-nitrophenylhydrazine and an enone or 1,3dicarbonyl compound under acidic conditions, the resulting

1-(4-nitrophenyl)-1H-pyrazoles 6 are further reduced to the

corresponding anilines 8 in a catalytic hydrogenation (Pd/C)

step.6À10 For diversity generation, a large number of different

amides have been synthesized from the aniline and various

carboxylic acids using EDC/DMAP (or BOP/DIPEA; HBTU/

TEA)-based peptide coupling protocols.6À10 In a similar fashion,

acid chloride couplings have also been used in the final amidation step.6À10 These methods are based on conventional

round-bottomed flask chemistry, and the overall reaction time

for the three steps is generally in the order of 2 days or more,

while the obtained overall yields range from 20% to 30% at

best.6À10 As a considerable additional improvement, we have

considered a BuchwaldÀHartwig direct amidation starting

from a 1-(4-bromophenyl)-1H-pyrazole 7 as an attractive

alternative to the reduction/peptide coupling sequence

(Scheme 1, path b).

It was therefore one of our objectives to provide a simplified,

less time-consuming, and high-yielding procedure using a combination of specifically tailored microwave-15,16 and microreaction techniques11À13 for process intensification. All reactions

performed under flow conditions were optimized and adapted to

flow equipment by a series of preceding microwave batch

experiments.17

The use of multiple flow reaction devices in series, the

synthesis of complex molecules in “automated” fashion, is an

interesting approach whereby the product solutions generated by

individual flow reactors are not collected for isolation of intermediates but directly fed to other flow reactors downstream of

the process.20 Key to this method is a very careful process design,

which has to ensure the compatibility of every individual flow

reaction with all other downstream steps.

Pyrazole Formation. For the generation of N-substituted

functionalized pyrazoles, a large number of synthetic procedures

is available.21 These methods are most commonly based on the

cyclocondensation of hydrazines with various bifunctional molecules such as 1,3-dicarbonyl compounds, R,β-unsaturated

ketones, and β-aminoenones, as well as 1,3-dipolar cycloaddition

reactions.21 Recently published approaches include, for example,

the cyclocondensation of N-arylhydrazones with nitroolefins in

ethylene glycol in the presence of air22 or the Pd-catalyzed fourcomponent reaction of a terminal alkyne, hydrazine (hydroxylamine), CO, and an aryl iodide.23 Mori and co-workers have used

a well established protocol to prepare the starting nitro-substituted pyrazoles 6a,b in the three-step synthesis of 4-[5-trifluormethyl-(pyrazol-1-yl-)]carboxanilides 1 and 2 (Figure 1),

employing enone 3a or 1,3-dicarbonyl compound 3b and

4-nitrophenylhydrazine as starting materials.6 Using controlled

microwave heating in sealed vessels as enabling technology,

6658

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

ARTICLE

Table 1. Optimized Conditions for the Microwave Batch Synthesis of 1H-Pyrazoles 6a,b and 7a,ba

a

All reactions were performed in a single-mode microwave reactor (Monowave 300) using 10 mL Pyrex vials and magnetic stirring from the hydrazinium

salts on a ∼1À2.5 mmol scale except for 7a (30 mL vial, 10 mmol scale) with 1.05 equiv of 3 in 2 mL (20 mL) of solvent. b A switch from ethanol to the

1-propanol/water 3:1 (v/v) mixture displaying a slightly lower vapor pressure was necessary in order to stay below the pressure limit of around 30 bar of

the used microwave reactor.

we sought to drastically accelerate and simplify the published

protocols, which often require an overnight reflux to reach full

conversion.6À10

With access to microwave reactors capable of superheating

organic solvents under carefully controlled internal temperature

monitoring conditions, this goal was easily achievable.24 An initial

modification of the original protocol6À10 was the replacement of

the typically employed combination of 4-nitrophenylhydrazine

base with H2SO4 or HCl acid with the more stable and commercially available phenylhydrazinium chloride salts 4, thus eliminating the addition of an acid catalyst. The cyclocondensation

of both the enone 3a or 1,3-dicarbonyl compound 3b and

arylhydrazinium chloride salts 4 to the corresponding pyrazoles

is governed by the dehydration of the intermediate 4,5-dihydro5-hydroxypyrazole 5 (Table 1) as important kinetic bottleneck.25

Depending on the substrate, the dehydration generally required

relatively high temperatures and strongly acidic conditions to

reach full conversion within the intended time scale of a few

minutes. For both the 5-trifluoromethyl-1H-pyrazole as well as

the 3,5-bis(trifluoromethyl)-1H-pyrazole scaffolds (1 and 2,

Figure 1), we synthesized the corresponding 4-nitroaryl- and

4-bromoaryl-substituted derivatives 6 and 7 (Table 1). This

provided us with the possibility to pursue two different

amidation routes (Scheme 1), allowing diversity introduction

in the last step of the synthesis. Initial experiments involved

microwave heating of a 0.45 M suspension of 4-nitrophenylhydrazinium chloride (4a) and enone 3a (1.05 equiv) in

ethanol at 160 °C for 2 min to afford pyrazole 6a in 82%

yield. For the envisaged flow implementation we switched to a

more dilute, homogeneous protocol (0.1 M) in methanol after

minor adjustments on temperature and time, obtaining a similar

yield. While the dehydration of intermediate 5 (R2 = CO2Et)

to the aromatic 4-ethoxycarbonyl-5-trifluormethyl-substituted

pyrazole ring in 6a worked sufficiently well under self-catalysis

by the liberated HCl, the replacement of the ester group by an

additional strongly electron-withdrawing CF3 group results in

the formation of a much more stable 4,5-dihydro-5-hydroxypyrazole intermediate 5 (R2 = CF3).25 Addition of conc HCl

(3 equiv) was necessary to reach full conversion at 160 °C

toward pyrazole 6b (Table 1, entry 3). During our optimization

runs, we observed that for example the 4,5-dihydro-5-hydroxypyrazole intermediate 5 is almost the exclusively formed

product (HPLC/GCÀMS), when performing the reaction at

lower temperature (100 °C, 5 min in DMF). However, complete dehydration of the formed intermediate 5 into 3,5-bis(trifluoromethyl)-1H-pyrazole 6b could be achieved within

15 min by raising the reaction temperature to 205 °C (entry 4).

In a similar manner, the arylbromides 7a,b were prepared in

excellent yields (92À98%) using 4-bromophenylhydrazinium

chloride (4b) as starting material. DMF as solvent was found

6659

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

ARTICLE

Table 2. Optimized Conditions for the Continuous Flow Synthesis of 1H-Pyrazoles 6a,6b and 7a,7ba

All reactions were performed in a stainless steel flow reactor (X-Cube Flash, Thales Nanotechnology Inc.) utilizing either a 4 mL (6a,b) or 8 mL (7a,b)

stainless steel coil (i.d. 1 mm) and a flow rate of 1.6À2.6 mL/min. For further details, see Experimental Section. b Isolated yields after flash

chromatography. c No isolated yield for compound 6b, instead the corresponding aniline 8b was obtained in 57% yield.

a

to solubilize both starting materials and product much better as

compared to ethanol and was therefore considered as the solvent

of choice in the preparation of pyrazole 7a (entry 5). Not unexpectedly, the preparation of the respective electron-deficient

3,5-bis(trifluoromethyl)-1H-pyrazole 7b did again require significantly higher temperatures (150 vs 100 °C for 5 min) and

HCl addition (10 equiv) to reach full conversion (entry 6). Arylbromide 7b is a relatively volatile liquid and was thus prepared using

a solution of the starting materials in low boiling MeOH/H2O 2:1

(v/v) to facilitate isolation. After careful evaporation of the solvent,

7b was obtained in excellent yield (98%).

The application of microreactor technology for the generation

of heterocyclic compounds was recently reviewed.26 In this

context, it is worth mentioning that Seeberger and co-workers

have reported a three-step synthesis for the antiobesity drug

Rimonabant as an example for the continuous flow synthesis of a

prominent pyrazole drug.27 The set of conditions obtained in the

microwave experiments (Table 1) served as a good starting point

for the implementation into a flow regime, by and large fulfilling

the basic requirements for a continuous flow process of being

homogeneous and reaching completion within the envisaged

reaction time of less than 5 min. Bearing in mind the wide

operating window of the chosen stainless steel flow equipment

(up to 350 °C/180 bar),28 the generated protocols in batch were

clearly aimed at exploiting the merits of the exceptionally rapid

kinetics at high temperatures, resulting in reaction times of only

1À5 min, depending on the substrate.

All continuous flow experiments for the cyclocondensation

to pyrazoles were done in a stainless steel capillary microreactor

(1 mm i.d., X-Cube Flash, Thales Nanotechnology Inc.),28 to

which the premixed reaction mixture (0.1 M) was fed by an

HPLC pump while a constant inner pressure of 120À140 bar was

maintained. The stainless steel coil was protected from the

corrosive action of HCl by the addition of 1.05À2.0 equiv of

triethylamine and, where possible, by further minimization of

residence times.29 In contrast to the corresponding microwave

protocols (Table 1, entries 1 and 2), we switched from ethanol/

methanol to acetic acid as solvent, resulting in a significantly

higher yield for 6a as compared to the procedure using ethanol

relying solely on self-catalysis by the hydrazinium chloride salt

(91% vs 81%) (Table 2).

An important side reaction that can occur in microreactors

made of stainless steel is the reduction of nitro groups to the

corresponding amines (Bechamp reduction).29 Accordingly, our

initial experiments involving the reaction of enone 3a with

4-nitrophenylhydrazinium chloride (4a) in ethanol at 160 °C

and 5 min residence time showed 10% (HPLC-UV at 215 nm or

GCÀMS) of the nitro compound being reduced to the corresponding aniline derivative 8a. Further dilution of the reaction

mixture (0.1 f 0.02 M) and conducting the reaction at lower

temperatures (100À140 °C) were improper means to alleviate

the reducing effect of the stainless steel coil. We found that at the

used temperature of 160À175 °C a reduction of residence time

was the most effective measure in order to suppress the reduction

6660

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

ARTICLE

to the aniline (8a) (14% after 5 min vs. 2% after 1.5 min). Thus,

we were able to synthesize the nitro-substituted pyrazole derivative 6a at 175 °C and 1.5 min residence time in 91% yield after

flash chromatography (Table 2).

However, the requirement of adding an acid scavenger such as

triethylamine and working with extremely short residence times

has its limits: for pyrazole 6b bearing an additional CF3 group, no

combination of temperature/residence time preventing the reduction to the aniline could be found. At the chosen conditions, a

temperature of >200 °C turned out to be essential to achieve

dehydration of the relatively electron-poor and thus quite stable

5-hydroxy-intermediate 5. We suspect that at these elevated

temperatures diffusion to the coil and reaction kinetics of the

reduction are very rapid and cannot be avoided any more by

reducing residence time. This assumption is supported by the

fact that in this case nitro compound 6b could not be isolated,

and instead only the corresponding aniline 8b was obtained in

57% yield (Table 2).

Bromide 7a was synthesized in 81% yield at 100 °C at a

residence time of 5 min employing DMF as solvent; this solvent

switch allows raising the substrate concentration to 0.5 M. The

analogous bromide 7b differing from 7a in having an additional

CF3 group did again require a higher reaction temperature

(230 °C) and acetic acid as solvent in order to achieve full

dehydration to the aromatic pyrazole ring. At the chosen concentration of 0.5 M, the addition of water in combination with an

increased amount of triethylamine (2 equiv) was needed to fully

homogenize the reaction mixture. Bromide 7b was obtained in

69% yield after flash chromatography (Table 2).

Scheme 2. Hydrogenation of 1-(4-Nitrophenyl)-1H-pyrazoles 6a,b under Microwave and Continuous Flow Conditions

Nitro Group Reduction. The reduction of aliphatic and

aromatic nitro compounds to the corresponding amines is one

of the most frequently used synthetic processes in organic

chemistry, for which a plethora of methods is available.30 However, many well-known methods for the reduction of nitro

groups, such as catalytic hydrogenations, are difficult to implement into a microwave approach. The use of molecular hydrogen

in a catalytic hydrogenation is impeded by the difficulty of introducing hydrogen into the sealed reaction vessels of most

currently available microwave reactors.31 Although recently a

microwave accessory that allows performing catalytic hydrogenations with externally supplied hydrogen gas was commercialized,31,32 we favored a catalytic transfer hydrogenation because

of the simplified overall procedure.33 Recent examples include

the reduction of nitroarenes to anilines using a hydrazine

hydrate/FeCl3 mixture34 or Mo(CO)6/DBU in ethanol35 and

the reduction of aliphatic nitro groups using ammonium formate

and catalytic amounts of Pd/C in MeOH.36

Our first optimization attempts were closely related to literature reports by groups from AMRI and GSK employing 1,4cyclohexadiene or 1-methyl-1-cyclohexene as hydrogen donor

for microwave-assisted catalytic transfer hydrogenations.33 However, these more reactive reagents can be replaced by less

expensive cyclohexene,33 which does not negatively affect the

transformation of the chosen substrates in terms of conversion or

selectivity. In an attempt to reduce the amount of catalyst and

hydrogen donor, we moved our initial protocol operating at

100 °C in ethanol toward a high-temperature regime at 160 °C.

We were pleased to see that this measure not only led to a

reduction in time from 10 to 2 min for substrate 6a but also

allowed a reduction in the amount of added Pd/C from 5% to 1%

while using 2 equiv of cyclohexene instead of 5 equiv. This

protocol furnished the corresponding anilines 8a (92%) and 8b

(96%) in high yield after isolation by flash chromatography.

In contrast to our preliminary batch microwave experiments,

the use of molecular hydrogen in the inherently safe process

environment of a flow hydrogenator was considered a particularly attractive approach.37 The hydrogenation experiments in

continuous flow were done in a benchtop flow-hydrogenator

Table 3. Screening of Reaction Conditions for the Continuous Flow Hydrogenation of 1-(4-Nitrophenyl)-1H-pyrazole 6a

(Scheme 2)

entry

catalyst (w/w%)

T (°C)

flow rate (mL/min)

solvent/concn (mol/L)

H2 pressurea (bar)

conversionb (%)

1

10% Pd/C

25

EtOH/0.02

1

atm

0

2

10% Pd/C

40

EtOH/0.02

1

atm

31

3

10% Pd/C

60

EtOH/0.02

1

atm

71

4

10% Pd/C

70

EtOH/0.02

1

atm

89

5

10% Pt/C

25

EtOH/0.02

1

atm

59 + 20c

6

7

10% Pd/Al2O3

10% Pd/Al2O3

25

50

EtOH/0.02

EtOH/0.02

1

1

atm

atm

0

89

8

10% Pd/Al2O3

70

EtOH/0.02

1

atm

>99

9

10% Pd/Al2O3

70

DMF/0.1

3

100

>99

10

RaNi

70

DMF/0.1

1

100

>99

11

RaNi

100

EtOH/0.03

3

90

>99

12

RaNi

100

EtOH/0.03

2.5

70

>99d

13

a

c

10% Pd/Al2O3

25

AcOH/0.03

2

atm

>99

14

15

10% Pd/Al2O3

10% Pd/Al2O3

40

100

AcOH/0.03

AcOH/0.03

2

2

atm

atm

>99e

86

atm = H-Cube in “full H2” mode at atmospheric pressure; 70À100 bar = H-Cube in “controlled” mode. b Purity as measured by HPLC at 215 nm.

Total percentage of byproducts. d 93% yield after isolation. e Free of impurity traces in HPLC at 215 nm.

6661

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

ARTICLE

Scheme 3. Process Scheme and Reaction Conditions for the Synthesis of 1-(4-Aminophenyl)-1H-pyrazoles 8a,b under

Continuous Flow Conditionsa

(H-Cube, Thales Nanotechnology Inc.).38 The use of heterogeneous catalysts on a fixed catalyst bed has the advantage of circumventing the need for filtering off the catalyst, a feature of general

importance in the production of pharmaceuticals. Initially, a

thorough screening of different catalysts and reaction conditions

was performed in order to indicate a range of suitable conditions

for the reduction of nitro-compound 6a as substrate (Table 3).

Starting with 10% Pd/C, a 0.02 M substrate solution at 1 mL/min,

and temperatures up to 70 °C led to partial conversion into the

corresponding aniline (Table 3, entries 1À4), whereas 10% Pt/C

seemed to be more active but even at ambient temperatures was

too unselective (Table 3, entry 5). On the other hand, the

application of 10% Pd/Al2O3 as well as RaNi led to complete and

selective reduction of the nitro functionality under a variety of

temperatures and flow rates, employing either ethanol, DMF, or

acetic acid as solvents (Table 3, entries 6À15). Despite the lower

price of RaNi, 10% Pd/Al2O3 became our catalyst of choice in

combination with AcOH as a solvent, due to the incompatibility

of AcOH with RaNi. New reaction conditions were developed,

ranging from ambient to 80 °C (0.03 M), under which the nitro

group was fully converted, with temperatures in the range of

40À60 °C being most preferable for a clean process. At a flow

rate of 2 mL/min, this corresponds to a molar throughput of

3.6 mmol/h.

Two-Step Continuous Flow Synthesis of Amines 8a and

8b. Equipped with a set of optimized conditions, carefully designed

to ensure the compatibility of the initial pyrazole formation in

continuous flow with the subsequent flow hydrogenation as downstream reaction, our next goal was to join the two individual flow

steps to generate the amine precursors 8a and 8b without isolation

and purification of the corresponding nitro-substituted pyrazoles

6a,b (Scheme 3). Using both the X-Cube Flash coil reactor and

H-Cube hydrogenator under the previously optimized conditions

for the two individual steps of the cyclocondensationÀhydrogenation sequence (Table 2, Table 3), nitro compound 6a was generated at a reaction temperature of 175 °C and 1.5 min residence

time in acetic acid (0.1 M) as solvent (Table 1). The obtained

crude product solution was directly reduced in the flow hydrogenator at 60 °C on 10% Pd/Al2O3 (Table 3), providing aniline 8a

in 86% yield after flash chromatography. As already mentioned, an

alternative synthesis path toward amine 8b arose from the inadvertent reduction of the formed nitro functionalized pyrazole 6b by

the stainless steel capillary material (Bechamp reduction).29 At the

preferred reaction temperature of 265 °C and a residence time of

1 min, the corresponding amine 8b was immediately generated

after in situ formation of 8b inside the stainless steel capillary and

was isolated in acceptable yield after flash chromatography (57%)

(Table 2).

Amidation. The amide function on the two pyrazole scaffolds

(Figure 1) is introduced in the last step of the synthesis and thus

is very well suited to diversify the molecule. In today’s chemical

literature there is a large variety of different amidation techniques, of which carbodiimide-based peptide coupling protocols

are particularly attractive owing to the broad range of applicable

substrates and its high chemoselectivity.39 Ley and co-workers

have established a very versatile and clean continuous flow

method for the generation of di- and tripeptides using immobilized peptide coupling reagents (PyBroP/HOBt) in combination

with catch and release strategies in a flow environment, with the

resulting benefit of greatly simplifying or even obviating

workup.40 Along similar lines, the Cosford group successfully

synthesized a range of imidazo[1,2-a]pyridine-2-carboxamides in

a glass-chip reactor using a homogeneous peptide protocol based

on EDC/HOBt in DMF and DIPEA as base.41

In the case of the desired 4-(pyrazol-1-yl)carboxanilides of

type 1 and 2, we have evaluated a variety of peptide coupling

conditions using both room temperature and microwave

protocols.42 Disappointingly, for all tested conditions the yields

of the anticipated coupling products were unsatisfactory (90%) by

analogous sulfonyl chloride couplings under microwave conditions at 100 °C and 5 min in acetonitrile/pyridine.

BuchwaldÀHartwig Amidation. In order to further simplify

the synthesis not only by reducing reaction time but also by an

alternative two-step approach instead of the more traditional

three-step synthetic pathway, we briefly evaluated a cyclocondesation step involving a 4-bromophenylhydrazine species

followed by a Pd-catalyzed BuchwaldÀHartwig amidation protocol to deliver the desired carboxanilides (Scheme 1, path b).

Having the cyclocondensation step already optimized under

microwave as well as under continuous flow conditions (see

above), we focused our efforts on the optimization of the CÀN

cross-coupling process. Pd-catalyzed CÀN bond-forming reactions between aryl halides and amides as nucleophiles have

received broad interest in the past two decades.44 The versatility

of the substrates and tolerated functionalities has turned this

coupling into one of the most important reactions currently under

development. The BuchwaldÀHartwig amidation process is implemented into a wide range of fine chemical and natural product

syntheses as well as into drug discovery processes. Furthermore, a

plethora of transition-metal-catalyzed coupling reactions have

been successfully translated into high-speed microwave processes,

including BuchwaldÀHartwig couplings.16 Notably, in a previous

project, we were able to successfully perform Pd-catalyzed Namidations on the somewhat related 4-(bromophenyl)-dihydropyrimidine scaffold under microwave conditions.45

6663

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

ARTICLE

Table 5. Microwave-Assisted BuchwaldÀHartwig CÀN Coupling Reactionsa

a

All reactions were performed in a single-mode microwave reactor (Monowave 300) using 10 mL Pyrex vials and magnetic stirring. b Isolated yields after

flash chromatography.

Scheme 4. Process Scheme and Reaction Conditions for the Combined Continuous Flow/Microwave Batch Synthesis of Amides

1c,d and 2a,f

We thus decided to explore the scope of the Pd-catalyzed

version of the amide N-arylation reaction. Applying our previously optimized45 microwave conditions to the current substrates [5 mol % Pd(OAc)2 as precatalyst, Xantphos as the

ligand, and Cs2CO3/THF as base/solvent combination at

150 °C and 15 min reaction time], a promising conversion of

nearly 87% was achieved. A successful microwave protocol was

developed by only slightly modifying this procedure in extending the reaction time to 30 min, otherwise keeping the remaining reaction parameters unchanged. Further trials to change

the base, ligand, or solvent to additionally optimize the process

remained unsuccessful, delivering only partial conversion of

the 1-(4-bromophenyl)-1H-pyrazoles 7a,b. These aryl bromides were effectively converted into the corresponding carboxanilides 1c,d and 2a,f in 56À92% yield after flash

chromatography (Table 5), therefore expanding the structural diversity of the desired 4-(pyrazol-1-yl)carboxanilides

scaffolds.

Very recently, continuous flow BuchwaldÀHartwig reactions

have been demonstrated.46 To overcome solid bridging and

constriction disturbing the flow regime, the reactor coil was

sonicated during the process. An attempt to translate our

optimized microwave conditions into a continuous flow protocol failed as a result of the restrictions of the available flow

equipment, as well as to the inhomogeneity of the reaction

mixture when using the optimized reaction conditions. Ultimately, the two individually optimized steps (continuous flow

cyclocondensation and microwave batch BuchwaldÀHartwig

amidation) were merged into one process, directly using the

product stream obtained in the initial flow cyclocondensation

step (Scheme 4). Applying the already optimized microwave

batch conditions allowed the isolation of the carboxamides 1c,d

and 2a,f in 45À70% overall yield after purification by flash

chromatography.

’ CONCLUSION

In conclusion, we have presented improved synthetic protocols for the generation of pyrazole-derived inhibitors of TRPC3

of type 1 and 2 that can be easily scaled to multigram quantities

for pharmacological research purposes.47 Our methods rely on

the initial optimization of reaction conditions using sealed vessel

6664

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

microwave synthesis as a process intensification technique. The

use of high-temperature/pressure conditions not only resulted

in a dramatic reduction of the required reaction and overall

processing times but also provided consistently better product

yields than the conventional methods. This new method will be

very useful for generating compound libraries of these (and

related) scaffolds, in particular considering the translation of the

method disclosed herein to a parallel microwave synthesis

approach. In addition, we have demonstrated that for strictly

homogeneous transformations the high-temperature microwave

conditions were readily transferable to a conventionally heated

continuous flow regime, which would in principle allow a

simple scale-up option to prepare larger quantities of compounds. As an alternative to the original three-step method, a

two-step microwave-assisted protocol for the synthesis of 4(pyrazol-1-yl)carboxanilides that relies on a Pd-catalyzed BuchwaldÀHartwig amidation chemistry was also developed.

’ EXPERIMENTAL SECTION

General Remarks. 1H and 13C NMR spectra were recorded on a

300 MHz instrument. Chemical shifts (δ) are expressed in ppm downfield

from TMS as internal standard. The letters s, d, t, q, and m are used to

indicate singlet, doublet, triplet, quadruplet, and multiplet, respectively.

Low resolution mass spectra were either obtained on a LCÀMS instrument using atmospheric pressure chemical ionization (APCI) or electrospray ionization (ESI) in positive or negative mode. GCÀMS monitoring

was based on electron impact ionization (70 eV) using a HP/5MS column

(30 m  0.250 mm  0.025 mm). After 1 min at 50 °C the temperature

was increased in 25 °C/min steps up to 300 °C and kept at 300 °C for

4 min. The carrier gas was helium, and the flow rate was 1.0 mL/min in

constant-flow mode. High-resolution mass spectra were recorded on a

FT-ICR-MS instrument using electrospray ionization (ESI) in positive

mode. Analytical HPLC analysis was carried out on a C18 reversed-phase

(RP) analytical column (150 Â 4.6 mm, particle size 5 μm) at 25 °C using

a mobile phase A (water/acetonitrile 90:10 (v/v) + 0.1% TFA) and B

(MeCN + 0.1% TFA) at a flow rate of 1.0 mL/min. The following

gradient was applied: linear increase from solution 30% B to 100% B in

9 min, hold at 100% solution B for 1 min. All chemicals, solvents, catalysts,

and ligands were obtained from known commercial suppliers and were

used without any further purification. Microwave irradiation experiments

were carried out in a single-mode microwave instrument in Pyrex vials

using standard procedures.24 Reaction times refer to hold times at the

temperature indicated, not to total irradiation times. The temperature was

measured using the IR temperature sensor of the instrument. The flow

chemistry examples described herein were performed using a stainless

steel capillary microreactor and a flow hydrogenation reactor according to

established principles.28,38 The synthesized compounds were purified

using an automated chromatography system on cartridges packed with

KP-SIL, 60 Å (40À63 mm particle size) and ethyl acetate (or ethyl acetate

containing 1% triethylamine for the purification of anilines 8a, 8b)/

petroleum ether mixtures as eluent. The purity of all synthesized

compounds (>98%) was either established by HPLC at 215 nm and/or

1

H NMR spectroscopy. Melting points were determined on a standard

melting point apparatus and are uncorrected.

Ethyl 1-(4-Nitrophenyl)-5-(trifluoromethyl)-1H-pyrazole4-carboxylate (6a). Microwave Batch Preparation, Method A (entry

1, Table 1). To a stirred mixture of 4-nitrophenylhydrazine hydrochloride

(4a) (171 mg, 0.9 mmol) and ethanol (2 mL) in a 10 mL Pyrex microwave

vial was added ethyl 2-(ethoxymethylene)-4,4,4-trifluoro-3-oxobutyrate

(3a) (228 mg, 1.05 equiv). The reaction vial was sealed with a snap-on

cap, and the suspension was subjected to microwave heating for 2 min (hold

time) at 160 °C after which the reaction mixture was cooled to 50 °C. After

ARTICLE

evaporation of the solvent, the residue was put on a silica column and

purified by flash chromatography to afford ethyl 1-(4-nitrophenyl)5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (6a) as a yellowish solid

(240 mg, 81%), mp 106À108 °C.6 1H NMR (300 MHz, DMSO-d6) δ

1.31 (t, J = 7.1 Hz, 3H), 4.44 (q, J = 9.0 Hz, 2H), 7.89 (d, J = 8.9 Hz, 2H),

8.39 (s, 1H), 8.43 (d, J = 9.0 Hz, 2H). MS (neg APCI): m/z (%) 330

(100) [M À 1].

Method B (entry 2, Table 1). To a solution of 4-nitrophenylhydrazine

hydrochloride (4a) (189.6 mg, 1 mmol) in methanol (10 mL) in a

30 mL Pyrex microwave vial was added ethyl 2-(ethoxymethylene)4,4,4-trifluoro-3-oxobutyrate (3a) (247.4 mg, 1.03 equiv). The mixture

was stirred/sonicated for 1 min and sealed with a snap-on cap. The

reaction mixture was subjected to microwave heating for 1.5 min (hold

time) at 175 °C and then cooled to 50 °C. After evaporation of the

solvent, the residue was purified by flash chromatography to afford ethyl

1-(4-nitrophenyl)-5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (6a) as

a yellowish solid (271 mg, 82%).

Continuous Flow Preparation. To a stirred solution of 4-nitrophenylhydrazine hydrochloride (4a) (189.6 mg, 1 mmol, 0.1 M) in

acetic acid (10 mL) in a cylindrical glass vessel were added ethyl

2-(ethoxymethylene)-4,4,4-trifluoro-3-oxobutyrate (3a) (252.2 mg,

1.05 equiv) and triethylamine (106.3 mg, 1.05 equiv). After stirring/

sonication for 2 min, the homogeneous reaction mixture was subjected

to flow processing in the X-Cube Flash. A 4 mL stainless-steel coil was

mounted, and the instrument flushed with acetic acid at a constant flow

rate of 2.6 mL/min (1.5 min residence time) and a backpressure of 140

bar. After reaching the temperature set point of 175 °C, the inlet tubing

was quickly changed from the solvent reservoir to the sample vessel and,

after collection of the main fraction of the product mixture on the outlet,

placed back into the solvent reservoir for flushing the instrument

(∼5 min). The collected product solution (∼25 mL) was reduced

under vacuum, and the residue was purified by flash chromatography to

afford ethyl 1-(4-nitrophenyl)-5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (6a) as yellowish crystals (299 mg, 91%).

1-(4-Nitrophenyl)-3,5-bis(trifluoromethyl)-1H-pyrazole

(6b). Microwave Batch Preparation, Method A (entry 4, Table 1).

To a stirred mixture of 4-nitrophenylhydrazine hydrochloride (4a)

(171 mg, 0.9 mmol) and ethanol (2 mL) in a 10 mL Pyrex microwave

vial was added 1,1,1,5,5,5-hexafluoroacetylacetone (3b) (197 mg, 1.05

equiv) was added, followed by dropwise addition of conc HCl (300 μL,

4 equiv). The reaction vial was sealed with a snap-on cap, and the

suspension was subjected to microwave heating for 5 min (hold time)

at 160 °C and subsequently cooled to 50 °C. The so-formed yellow

reaction mixture was concentrated under reduced pressure, and the residue

purified by flash chromatography (petrol ether/ethyl acetate 6:1) to afford

1-(4-nitrophenyl)-3,5-bis(trifluoromethyl)-1H-pyrazole (6b) as a yellow

oil (260 mg, 89%).8a 1H NMR (300 MHz, DMSO-d6) δ 7.94À7.98 (m,

3H), 8.45À8.49 (m, 2H). MS (pos APCI): m/z (%) 326 (100) [M + 1].

Method B (entry 5, Table 1). To a stirred solution of 4-nitrophenylhydrazine hydrochloride (4a) (462.4 mg, 2.44 mmol) in n-propanol/

water 3:1 (v/v) (4 mL) in a 10 mL Pyrex microwave vial was added

1,1,1,5,5,5-hexafluoroacetylacetone (3b) (532.8 mg, 1.05 equiv). The

mixture was stirred/sonicated for 1 min, and the reaction vial was sealed

with a snap-on cap. The homogeneous reaction mixture was subjected to

microwave heating for 15 min (hold time) at 205 °C and then cooled to

50 °C. The reaction mixture was carefully reduced in vacuum (40 °C,

10 mbar), and the oil residue was taken up in 25 mL of diethyl ether,

washed with satd sodium bicarbonate (3 Â 10 mL) and brine, and dried

over MgSO4. After evaporation of the diethylether, nitrophenyl-3,5bis(trifluoromethyl)-1H-pyrazole (6b) was obtained as a yellow oil

(688 mg, 87%).

Ethyl 1-(4-Bromophenyl)-5-(trifluoromethyl)-1H-pyrazole4-carboxylate (7a). Microwave Batch Preparation (entry 5, Table 1).

To a stirred solution of 4-bromophenylhydrazine hydrochloride (4b)

6665

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

(1.88 g, 10 mmol) in DMF (20 mL) in a 30 mL Pyrex microwave vial

was added ethyl 2-(ethoxymethylene)-4,4,4-trifluoro-3-oxobutyrate (3a)

(2.52 g, 1.05 equiv). The mixture was stirred/sonicated for 1 min, and the

reaction vial sealed with a snap-on cap. The homogeneous reaction

mixture was subjected to microwave heating for 5 min (hold time) at

100 °C and then cooled to 50 °C. The reaction mixture was reduced in

vacuum (60 °C, 2 mbar), and DMF traces were removed azeotropically

(toluene) to afford ethyl 1-(4-bromophenyl)-5-(trifluoromethyl)-1Hpyrazole-4-carboxylate (7a) as a pale yellow residue (3.33 g, 92%) or as

yellow needles after recrystallization in methanol/water 2:1 (v/v): mp

69À72 °C. 1H NMR (300 MHz, DMSO-d6) δ 1.30 (t, J = 7.2 Hz, 3H),

4.32 (q, J = 7.2 Hz, 2H), 7.53 (d, J = 8.7 Hz, 2H), 7.80 (d, J = 8.7, 2H), 8.31

(s, 1H); 13C NMR (75 MHz, DMSO-d6) δ 14.3, 61.5, 116.82, 116.83,

119.3 (q, JCF = 269.4 Hz), 123.9, 128.7, 132.1 (q, JCF = 39.4 Hz), 138.6,

142.8, 160.7 ppm. HRMS (ESI) calcd for C13H11BrF3N2O2 362.9956

[M + H]+, found 362.9954

Continuous Flow Preparation. To a stirred solution of 4-bromophenylhydrazine hydrochloride (4b) (0.752 g, 4 mmol, 0.5 M) in DMF

(8 mL) in a cylindrical glass vessel was added ethyl 2-(ethoxymethylene)4,4,4-trifluoro-3-oxobutyrate (3a) (1.01 g, 1.05 equiv) was added. After

stirring/sonication for 2 min, the homogeneous reaction mixture was

subjected to flow processing in the X-Cube Flash. A 8 mL stainless-steel

coil was mounted, and the instrument was flushed with DMF at a constant

flow rate of 1.6 mL/min (5 min residence time) and a backpressure of 100

bar. After reaching the temperature set point of 100 °C, the inlet tubing

was quickly changed from the solvent reservoir to the sample vessel and,

after collection of the main fraction of the product mixture on the outlet,

put back into the solvent reservoir for flushing the instrument (∼ 10 min).

The product solution (∼25 mL) was reduced under vacuum, and DMF

traces were removed azeotropically (toluene), taken up in 30 mL of ethyl

acetate, washed with water (3 Â 10 mL) and brine (3 Â 10 mL), dried

over MgSO4, and evaporated to afford ethyl 1-(4-bromophenyl)-5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (7a) as a pale yellow residue

(1.174 g, 81%).

1-(4-Bromophenyl)-3,5-bis(trifluoromethyl)-1H-pyrazole

(7b). Microwave Batch Preparation (entry 6, Table 1). To a stirred

solution of 4-bromophenylhydrazine hydrochloride (4b) (564.1 mg,

2.52 mmol) in methanol/water 2:1 (v/v) (3 mL) in a 10 mL Pyrex

microwave vial were added 1,1,1,5,5,5-hexafluoroacetylacetone (3b)

(655.4 mg, 1.05 equiv) and conc HCl (1 mL, ∼10 equiv). The mixture

was stirred/sonicated for 1 min, and the reaction vial sealed with a snapon cap. The homogeneous reaction mixture was subjected to microwave

heating for 5 min (hold time) at 150 °C and then cooled to 50 °C. The

solvent was carefully evaporated (40 °C, 2 mbar), and 1-(4-bromophenyl)-3,5-bis(trifluoromethyl)-1H-pyrazole (7b) was either directly

obtained as a dark oil (895 mg, 99%) or further purified by flash

chromatography and obtained as a pale yellow oil (832 mg, 92%). 1H

NMR (300 MHz, DMSO-d6) δ 7.61 (d, J = 8.4, 2H) 7.82À7.85

(m, 3H); 13C NMR (75 MHz, DMSO-d6) δ 108.9, 119.2 (q, JCF =

268.0 Hz), 120.9 (q, JCF = 267.4 Hz), 124.5, 128.8, 133.0, 134.2 (q, JCF =

39.8 Hz), 137.3, 142.1 (q, JCF = 38.7 Hz) ppm; HRMS (ESI) calcd for

C11H6N2F6Br 358.9619 [M + H]+, found 358.9615

Continuous Flow Preparation. To a stirred solution of 4-bromophenylhydrazine hydrochloride (4b) (0.752 mg, 4 mmol, 0.5 M) in

acetic acid/water 40:3 (8 mL of acetic acid + 0.6 mL of water) in a

cylindrical glass vessel were added 1,1,1,5,5,5-hexafluoroacetylacetone

(3b) (873.8 mg, 1.05 equiv) and triethylamine (809.5 mg, 2 equiv). After

stirring/sonication for 2 min, the homogeneous reaction mixture was

subjected to flow processing in the X-Cube Flash. An 8 mL stainless steel

coil was mounted, and the instrument was flushed with acetic acid at a

constant flow rate of 1.6 mL/min (5 min residence time) and a

backpressure of 140 bar. After reaching the temperature set point of

230 °C, the inlet tubing was quickly changed from the solvent reservoir

to the sample vessel and, after collection of the main fraction of the

ARTICLE

product mixture on the outlet, put back into the solvent reservoir for

flushing the instrument (∼10 min). The product solution (∼25 mL)

was diluted with 10 mL of brine and extracted with ethyl acetate (3 Â

10 mL). After successive washings with satd sodium bicarbonate

(10 mL), water (3 Â 10 mL) and brine, the organic phase was dried

over MgSO4 and evaporated carefully (40 °C, 2À5 mbar) to afford 1-(4bromophenyl)-3,5-bis(trifluoromethyl)-1H-pyrazole (7b) as a yellowbrown oil (988 mg, 69%).

Catalyst Screening for the Continuous Flow Hydrogenation of Nitro-Compound 6a (Table 3). All screenings were done in

the H-Cube continuous flow hydrogenator (Thales Nanotechnology

Inc.). Stock solutions of ethyl 1-(4-nitrophenyl)-5-(trifluoromethyl)1H-pyrazole-4-carboxylate (7a) in various polar solvents were prepared

(0.02À0.1 M in ethanol, DMF, acetic acid, as appropriate; see Table 3

for more details). Prior to every screening series, the instrument was

equipped with a fresh catalyst cartridge (10% Pd/C, 10% Pt/C, 10% Pd/

Al2O3, or RaNi). The desired values for the flow rate (1À3 mL/min), H2

pressure (“Full H2” atmospheric pressure up to 100 bar H2 overpressure),

and cartridge temperature (rtÀ100 °C) were set on the input panel of the

instrument, and a constant flow of pure solvent was pumped through the

instrument until the system had stabilized at the chosen set points. At that

moment the inlet filter frit of the H-Cube was switched from the solvent

reservoir into the stock solution and the nitro-compound was pumped

into the H-Cube; simultaneously, the outlet was changed to a fresh 1 mL

HPLC vial. After processing ∼1 mL of stock solution, the inlet was again

changed to the solvent reservoir, a new set point (temperature, time, flow

rate) was programmed, the instrument was flushed with solvent until the

set points were reached, the inlet changed to the stock solution, and so

forth. The collected product solutions were subjected to HPLC analysis at

215 nm to determine conversions/purities (see Table 3).

Ethyl 1-(4-Aminophenyl)-5-(trifluoromethyl)-1H-pyrazole4-carboxylate (8a). Microwave Batch Preparation. To a stirred

mixture of ethyl 1-(4-nitrophenyl)-5-(trifluoromethyl)-1H-pyrazole-4carboxylate (6a) (200 mg, 0.61 mmol) and ethanol (2 mL) in a 10 mL

Pyrex microwave vial was added cyclohexene (100 mg, 1.21 mmol,

125 μL), immediately followed by 10% (w/w) Pd/C (6.5 mg, 0.0061

mmol, 1 mol %). The reaction vial was sealed with a snap-on cap, and the

suspension was subjected to microwave heating for 2 min (hold time) at

160 °C and then cooled to 50 °C. After evaporation of the solvent, the

residue was subjected to flash chromatography to afford ethyl 1-(4aminophenyl)-5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (8a) as a

white solid (167 mg, 92%), mp 107À109 °C.6 1H NMR (300 MHz,

DMSO-d6) δ 1.28 (t, J = 7.1 Hz, 3H), 4.28 (q, J = 7.1 Hz, 2H), 5.61

(s, 2H), 6.63 (d, J = 8.7 Hz, 2H), 7.09 (d, J = 8.6 Hz, 2H), 8.17 (s, 1H).

MS (pos APCI): m/z (%) 300 (100) [M + 1].

Continuous Flow Hydrogenation (entry 15, Table 3). A 0.03 M

solution of ethyl 1-(4-nitrophenyl)-5-(trifluoromethyl)-1H-pyrazole-4carboxylate (6a) (148.2 mg, 0.45 mmol) in ethanol (15 mL) was

prepared. Using a fresh RaNi cartridge, the H-Cube was first flushed

with pure ethanol, while ramping to the desired set point (H2 “Controlled” mode, 70 bar hydrogen overpressure, a flow rate of 2.5 mL/min

and a cartridge temperature of 100 °C). Next, the inlet of the H-Cube

was quickly changed from the solvent reservoir to the substrate solution,

and the outlet was simultaneously changed to a collection flask. After

processing the whole volume of starting material, the inlet was changed

back to the solvent reservoir, and the instrument was flushed with

a further 15À20 mL. After evaporation of the solvent, ethyl 1-(4aminophenyl)-5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (8a) was

obtained as yellowish residue (125 mg, 93%).

4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)aniline (8b). Microwave Batch Preparation. To a stirred mixture of 1-(4-nitrophenyl)3,5-bis(trifluoromethyl)-1H-pyrazole (6b) (355 mg, 1.1 mmol) and

ethanol (2 mL) in a 10 mL Pyrex microwave vial was added cyclohexene (448 mg, 5.5 mmol, 554 μL), immediately followed by 10% (w/w)

6666

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

Pd/C (35 mg, 0.0033 mmol, 3 mol %). The reaction vial was sealed

with a snap-on cap, and the reaction mixture was subjected to

microwave heating for 5 min (hold time) at 150 °C and subsequently

cooled to 50 °C. After evaporation of the solvent, the residue was

subjected to flash chromatography (petrol ether/ethyl acetate + 1%

triethylamine 3:1) to afford 4-(3,5-bis(trifluoromethyl)-1H-pyrazol-1yl)aniline (8b) as a white solid (312 mg, 96%), mp 140À142 °C; lit.48

130À133 °C.8a 1H NMR (300 MHz, DMSO-d6) δ 5.68 (s, 2H), 6.64

(d, J = 8.7 Hz, 2H), 7.16 (d, J = 8.6 Hz, 2H), 7.67 (s, 1H). MS (pos

APCI): m/z (%) 296 (100) [M+1].

Two-Step Continuous Flow Synthesis of Amines 8a,b

(CyclocondensationÀReduction Sequence). Ethyl 1-(4Aminophenyl)-5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (8a). The optimized continuous flow-procedures for the individual single-step preparations of 6a (X-Cube Flash, procedure as

disclosed in the single-step protocol) and 8a (H-Cube, procedure as

disclosed in the single-step protocol) were used to assemble a continuous two-step flow protocol (1 mmol scale) without isolation of the

intermediate. According to the single-step procedure, 6a was prepared at

175 °C and a flow rate of 2.6 mL/min in a 4 mL stainless steel coil (1.5

min residence time) in acetic acid (0.1 M) with addition of 1.05 equiv of

triethylamine. The crude product solution exiting the X-Cube Flash

containing 6a was collected, diluted to 0.03 M concentration, and

directly pumped into the H-Cube. After hydrogenation of the crude

product solution in “Full H2” mode at 60 °C and a flow rate of 2 mL/min

using Pd/Al2O3 as catalyst, the collected product solution was reduced

under vacuum, brought onto a sample holder, and subjected to flash

chromatography (petrol ether/ethyl acetate + 1% triethylamine 3:1) to

afford ethyl 1-(4-aminophenyl)-5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (8a) as yellow crystals (259 mg, 86%).6

4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)aniline (8b).

To a stirred solution of 4-nitrophenylhydrazine hydrochloride (4a)

(189.6 mg, 1 mmol, 0.1 M) in acetic acid (10 mL) in a cylindrical glass

vessel were added 1,1,1,5,5,5-hexafluoroacetylacetone (3b) (214.3 mg,

1.03 equiv) and triethylamine (106.3 mg, 1.05 equiv). After stirring/

sonication for 2 min, the homogeneous reaction mixture was subjected

to flow processing in the X-Cube Flash. A 4 mL stainless-steel coil was

mounted, and the instrument was flushed with acetic acid at a constant

flow rate of 4 mL/min (1 min residence time) and a backpressure of 140

bar. After reaching the temperature set point of 265 °C, the inlet tubing

was quickly changed from the solvent reservoir to the sample vessel and,

after collection of the main fraction of the product mixture on the outlet,

put back into the solvent reservoir for flushing the instrument (∼5 min).

The collected product solution (∼25 mL) was reduced under vacuum

and subjected to flash chromatography (petrol ether/ethyl acetate + 1%

triethylamine 3:1) to afford 4-(3,5-bis(trifluoromethyl)-1H-pyrazol-1-yl)aniline (8b) as an off-white solid (186 mg, 57%).8a

General Procedure for the Amidation of 4-(Pyrazol-1yl)anilines 8a,b to Carboxamides (1a,b; 2aÀe) and Sulfonamides (10a,b) (Table 4). Carboxamides (1a,b; 2aÀe). To a

stirred mixture of either ethyl 1-(4-aminophenyl)-5-(trifluoromethyl)1H-pyrazole-4-carboxylate (8a) (150 mg, 0.5 mmol) or 4-(3,5-bis(trifluoromethyl)-1H-pyrazol-1-yl)aniline (8b) (200 mg, 0.5 mmol)

and acetonitrile (2 mL) in a 10 mL Pyrex microwave vial was added

the selected carboxylic acid (0.55 mmol for 1b, 2c and 0.75 mmol for 1a,

2a, 2b, 2d) was added, followed by dropwise addition of phosphorus

trichloride (103 mg, 0.75 mmol, 66 μL). The reaction vial was sealed

with a snap-on cap, and the suspension subjected to microwave heating

for 5 min (hold time) at 150 °C and then cooled to a temperature of

50 °C. The solvent was evaporated, and the residue was subjected to

flash chromatography to obtain the pure products.

Ethyl 1-(4-(2,3,3-Trichloroacrylamido)phenyl)-5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (1a)6. White solid (175 mg,

76%), mp 151À153 °C (toluene). 1H NMR (300 MHz, DMSO-d6) δ

ARTICLE

1.29 (t, J = 7.1 Hz, 3H), 4.31 (q, J = 7.1 Hz, 2H), 7.56 (d, J = 8.8 Hz, 2H),

7.80 (d, J = 8.8 Hz, 2H), 8.28 (s, 1H), 11.33 (s, 1H). MS (pos APCI): m/z

(%) 458 (100) [M + 1].

Ethyl 1-(4-(4-Methyl-1,2,3-thiadiazole-5-carboxamido)phenyl)-5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (1b)6,10c.

White solid (180 mg, 78%), mp 119À120 °C; lit.10c mp 118À120 °C.

1

H NMR (300 MHz, DMSO-d6) δ1.31 (t, J = 7.2, 3H), 2.83 (s, 3H),

4.32 (q, J = 7.2, 2H), 7.57 (d, J = 8.7, 2H), 7.88 (d, J = 8.7, 2H), 8.30 (s,

1H), 11.03 (s, 1H). MS (neg ESI): 424 (100) [M À 1].

N-(4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)phenyl)-4chlorobenzamide (2a)9c. Off-white powder (215 mg, 86%), mp

195À197 °C (toluene); lit.9c mp 196À197 °C. 1H NMR (300 MHz,

DMSO-d6) δ 7.61À7.66 (m, 4H), 7.83 (s, 1H), 7.99À8.04 (m, 4H),

10.66 (s, 1H). MS (neg APCI): m/z (%) 432 (100) [M À 1].

N-(4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)phenyl)-4methyl-1,2,3-thiadiazole-5-carboxamide (2b)9c. Brownish so-

lid (179 mg, 63%), mp 165À167 °C; lit.9c mp 164À166 °C. 1H NMR

(300 MHz, DMSO-d6) δ 3.25 (s, 3H), 7.64 (d, J = 8.7 Hz, 2H), 7.82

(s, 1H), 7.91 (d, J = 8.8 Hz, 2H), 11.06 (s, 1H). MS (neg APCI): m/z

(%) 420 (100) [M À 1].

N-(4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)phenyl)-2,

3,3-trichloroacrylamide (2c)6. White solid (192 mg, 85%), mp

147À149 °C (toluene). 1H NMR (300 MHz, DMSO-d6) δ7.64 (d, J =

8.7, 2H), 7.82À7.85 (m, 3H), 11.35 (s, 1H). MS (neg ESI): 450 (100)

[M À 1].

N-(4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)phenyl)isonicotinamide (2d)8a. White solid (101 mg, 89%), mp 170À172 °C;

lit.8a mp 156À157 °C. 1H NMR (300 MHz, DMSO-d6) δ7.64 (d, J =

8.7 Hz, 2H), 7.82 (s, 1H), 7.87À7.89 (m, 2H), 7.97À8.01 (m, 2H),

8.80À8.82 (m, 2H), 10.84 (s, 1H). MS (pos APCI): m/z (%) 401 (100)

[M + 1].

N-(4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)phenyl)-3fluoroisonicotinamide (2e)9c. White solid (147 mg, 52%), mp

162À163 °C; lit.9c mp152À153 °C. 1H NMR (300 MHz, DMSO-d6) δ

7.64 (d, J = 8.7 Hz, 2H), 7.77 (t, J = 5.3 Hz, 1H), 7.84 (s, 1H), 7.92 (d, J =

8.7 Hz, 2H), 8.62 (d, J = 4.7, 1H), 8.79 (s, 1H), 11.06 (s, 1H). MS (neg

APCI): m/z (%) 417 (100) [M À 1].

Sulfonamides (10a,b). To a stirred mixture of 4-(3,5-bis(trifluoromethyl)-1H-pyrazol-1-yl)aniline (8b) (200 mg, 0.5 mmol)

and acetonitrile (2 mL) 10 mL Pyrex vial was added either 4-chlorobenzenesulfonyl chloride (158 mg, 0.75 mmol) or 4-methylbenzenesulfonyl chloride (142 mg, 0.75 mmol), followed by dropwise addition of

pyridine (100 μL). The reaction vial was sealed with a snap-on cap, and

the suspension was subjected to microwave heating for 5 min (hold

time) at 100 °C and then cooled to a temperature of 50 °C. The solvent

was evaporated, and the residue was subjected to flash chromatography

to obtain the pure products.

N-(4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)phenyl)-4chlorobenzenesulfonamide (10a). White powder (211 mg, 90%),

mp 126À128 °C. 1H NMR (300 MHz, DMSO-d6) δ 7.29 (d, J = 8.7 Hz,

2H), 7.52 (d, J = 9 Hz, 2H), 7.68 (d, J = 8.7 Hz, 2H), 7.79 (s, 1H), 7.84

(d, J = 8.7 Hz, 2H) 10.91 (s, 1H); 13C NMR (75 MHz, DMSO-d6) δ

108.4, 119.1 (q, JCF = 267.9 Hz), 120.3, 120.9 (q, JCF = 270.0 Hz), 127.8,

129.1, 130.0, 133.7, 134.1 (q, JCF = 39.6 Hz), 138.5, 138.7, 140.0, 141.9

(q, JCF = 38.6 Hz) ppm; HRMS (ESI) calcd for C17H11O2N3F6SCl

470.0165 [M + H]+, found 470.0165.

N-(4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)phenyl)-4methylbenzenesulfonamide (10b). White powder (225 mg,

92%), mp 105À107 °C. 1H NMR (300 MHz, DMSO-d6) δ2.34

(s, 3H), 7.24À7.29 (m, 2H), 7.38 (d, J = 8.1 Hz, 2H), 7.48 (d, J =

8.7 Hz, 2H), 7.71 (d, J = 8.1 Hz, 2H), 7.77 (s, 1H), 10.73 (s, 1H); 13C

NMR (75 MHz, DMSO-d6) δ 21.4, 108.4, 119.2 (q, JCF = 268.0 Hz),

119.8, 120.9 (q, JCF = 267.4 Hz), 127.2, 127.8, 130.3, 133.3, 134.1 (q, JCF =

6667

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

39.5 Hz), 136.8, 140.5, 141.8 (q, JCF = 38.6 Hz), 144.2 ppm; HRMS (ESI)

calcd for C18H14O2N3F6S 450.0711 [M + H]+, found 450.0706.

General Procedure for the Direct Amidation via BuchwaldÀHartwig Pd-Cross-Coupling Reaction (Table 5). To a

stirred mixture of either ethyl 1-(4-bromophenyl)-5-(trifluoromethyl)1H-pyrazole-4-carboxylate (7a) (54.5 mg, 0.15 mmol) or 1-(4-bromophenyl)-3,5-bis(trifluoromethyl)-1H-pyrazole (7b) (53.9 mg, 0.15

mmol) and THF (2 mL) in a 10 mL Pyrex microwave vial was added

benzamide (36.3 mg, 2 equiv) or 4-chlorobenzamide (46.7 mg, 2 equiv),

followed by addition of Xantphos (8.71 mg, 10 mol %), cesium

carbonate (97.8 mg, 2 equiv), and palladium acetate (1.7 mg, 5 mol %).

The reaction vial was sealed with a snap-on cap, and the suspension was

subjected to microwave heating for 30 min (hold time) at 150 °C and

then cooled to a temperature of 50 °C. The solvent was evaporated, and

the residue was subjected to flash chromatography to obtain the pure

products.

Ethyl 1-(4-Benzamidophenyl)-5-(trifluoromethyl)-1H-pyrazole-4-carboxylate (1c). White powder (52 mg, 86%), mp

212À214 °C. 1H NMR (300 MHz, DMSO-d6) δ 1.01 (t, J = 6.9 Hz,

3H), 4.33 (q, J = 7.2 Hz, 2H), 7.52À7.63 (m, 5H), 7.97À8.00 (m, 4H),

8.29 (s, 1H) 10.57 (s, 1H); 13C NMR (75 MHz, DMSO-d6) δ 14.4, 61.5,

116.5, 119.5 (JCF = 269.4 Hz), 120.8, 127.0, 128.2, 128.9, 131.9 (JCF =

39.2 Hz), 132.3, 134.5, 135.1, 141.2, 142.5, 160.8, 166.4 ppm; HRMS

(ESI) calcd for C20H17O3N3F3 404.1222 [M + H]+, found 404.1218.

Ethyl 1-(4-(4-Chlorobenzamido)phenyl)-5-(trifluoromethyl)1H-pyrazole-4-carboxylate (1d)9d. White powder (37 mg, 56%),

mp 189À191 °C; lit.9d mp 201À202 °C. 1H NMR (300 MHz, DMSOd6) δ 1.31 (t, J = 7.2 Hz, 3H), 4.32 (q, J = 7.2 Hz, 2H), 7.52À7.66 (m,

4H), 7.95À8.00 (m, 4H), 8.29 (s, 1H) 10.62 (s, 1H). MS (neg APCI):

m/z (%) 436 (100) [M À 1].

N-(4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)phenyl)-4chlorobenzamide (2a)9c. White powder (60 mg, 92%), mp 195À

197 °C (toluene); lit.9c mp 196À197 °C. 1H NMR (300 MHz, DMSOd6) δ 7.60À7.65 (m, 4H), 7.83 (s, 1H), 7.99À8.03 (m, 4H), 10.65

(s, 1H). MS (neg APCI): m/z (%) 432 (100) [M À 1].

N-(4-(3,5-Bis(trifluoromethyl)-1H-pyrazol-1-yl)phenyl)benzamide (2f). White powder (55 mg, 92%),10c mp 238À240 °C;

lit.10c mp 243À245 °C. 1H NMR (300 MHz, DMSO-d6): 7.53À7.68

(m, 5H), 7.81 (s, 1H), 7.97À8.03 (m, 4H), 10.60 (s, 1H). MS (neg ESI):

398 (100) [M À 1].

’ ASSOCIATED CONTENT

S

b

Supporting Information. Copies of NMR spectra and

compound characterization data. This material is available free of

charge via the Internet at http://pubs.acs.org.

’ AUTHOR INFORMATION

Corresponding Author

*E-mail: toma.glasnov@uni-graz.at; oliver.kappe@uni-graz.at.

’ ACKNOWLEDGMENT

This work was supported by a grant from the Christian

Doppler Research Society (CDG).

’ REFERENCES

(1) Elguero, J.; Goya, P.; Jagerovic, N.; Silva, A. M. S. In Targets in

Heterocyclic SystemsÀChemistry and Properties; Attanasi, A., Spinelli, D.,

Eds.; Societ� Chimica Italiana: Urbino, 2002; Vol. 6, pp 167À203.

a

(2) (a) Lange, J. H. M.; Kruse, C. G. Drug Discovery Today 2005,

10, 693. (b) Jagerovic, N.; Fernandez-Fernandez, C.; Goya, P. Curr. Top.

Med. Chem. 2008, 8, 205.

ARTICLE

(3) (a) Inhibitors of Cyclin-dependent Kinases as Anti-Tumor Agents;

Smith, P. J., Yue, E. W., Eds.; CRC Press: Boca Raton, London,

New York, 2007. (b) Persson, T.; Yde, C. W.; Rasmussen, J. E.; Rasmussen,

T. L.; Guerra, B.; Issinger, O.-G.; Nielsen, J. Org. Biomol. Chem. 2007,

5, 3963. (c) Farag, A. M.; Mayhoub, A. S.; Eldebss, T. M. A.; Amr, A.-G. E.;

Ali, K. A. K.; Abdel-Hafez, N. A.; Abdulla, M. M. Eur. J. Med. Chem. 2010,

45, 5887.

(4) (a) Yang, J.; Gharagozloo, P.; Yao, J.; Ilyin, V. I.; Carter, R. B.;

Nguyen, P.; Robledo, S.; Woodward, R. M.; Hogenkamp, D. J. J. Med.

Chem. 2004, 47, 1547. (b) Nilius, B.; Owsianik, G.; Voets, T.; Peters, J. A.

Physiol. Rev. 2007, 87, 165. (c) Handbook of Experimental Pharmacology:

Analgesia; Stein, C., Ed.; Springer: Berlin, Heidelberg, 2007; Vol. 177.

(5) (a) Abramowitz, J.; Birnbaumer, L. FASEB J. 2009, 23, 297.

(b) Yonetoku, Y.; Kubota, H.; Miyazaki, Y.; Okamoto, Y.; Funatsu, M.;

Yoshimura-Ishikawa, N.; Ishikawa, J.; Yoshino, T.; Takeuchi, M.; Ohta,

M. Bioorg. Med. Chem. 2008, 16, 9457.

(6) Kyonaka, S.; Kato, K.; Nishida, M.; Mio, K.; Numaga, T.;

Sawaguchi, Y.; Yoshida, T.; Wakamori, M.; Mori, E.; Numata, T.; Ishii,

M.; Takemoto, H.; Ojida, A.; Watanabe, K.; Uemura, A.; Kurose, H.;

Morii, T; Kobayashi, T.; Sato, Y.; Sato, C.; Hamachi, I.; Mori, Y. Proc.

Natl. Acad. Sci. U.S.A. 2009, 106, 5400.

(7) For a concise review on the biological role of 4-(pyrazol-1yl)carboxanilides as Ca2+-channel inhibitors, see: Sweeney, Z. K.;

Minatti, A.; Button, D. C.; Patrick, S. Chem. Med. Chem. 2009, 4, 706.

(8) (a) Djuric, S. W.; BaMaung, N. Y.; Basha, A.; Liu, H.; Luly, J. R.;

Madar, D. J.; Sciotti, R. J.; Tu, N. P.; Wagenaar, F. L.; Wiedeman, P. E.;

Zhou, X.; Ballaron, S.; Bauch, J.; Chen, Y.-W.; Chiou, X. G.; Fey, T.;

Gauvin, D.; Dubbins, E.; Hsieh, G. C.; Marsh, K. C.; Mollinson, K. W.;

Pong, M.; Shaughnessy, T. K.; Sheets, M. P.; Smith, M.; Trevillyan, J. M.;

Warrior, U.; Wegner, C. D.; Carter, G. W. J. Med. Chem. 2000, 43, 2975.

(b) Bamaung, N. Y.; Basha, A.; Djuric, S. W.; Gubbins, E. J.; Luly, J. R.;

Tu, N. P.; Madar, D. J.; Warrior, U.; Wiedeman, P. E.; Zhou, X.; Sciotti,

R. J.; Wagenaar, F. L. (Abbott) U.S. Patent 20010044445, 2001.

(9) (a) Ishikawa, J.; Ohga, K.; Yoshino, T.; Takezawa, R.; Morio, H.;

Okada, Y.; Honda, K.; Yamada, T. J. Immunol. 2003, 170, 4441.

(b) Yonetoku, Y.; Kubota, H.; Miyazaki, Y.; Okamoto, Y.; Funatsu, M.;

Yoshimura-Ishikawa, N.; Ishikawa, J.; Yoshino, T.; Takeuchi, M.; Ohta, M.

Bioorg. Med. Chem. 2008, 16, 9457. (c) Yonetoku, Y.; Kubota, H.; Okamoto,

Y.; Ishikawa, J.; Takeuchi, M.; Ohta, M.; Tsukamoto, S.-I. Bioorg. Med.

Chem. 2006, 14, 5370. (d) Kubota, H.; Yonetoku, Y.; Sugasawa, K.;

Funatsu, M.; Kawazoe, S.; Toyoshima, A. Okamoto, Y.; Ishikawa, J.

Takeuchi, M. (Yamanouchi Pharmaceutical) U.S. Patent 6348480,

2002.

(10) (a) Betageri, R. (Boehringer Ingelheim Pharmaceuticals) Patent

WO2001070703, 2001. (b) Erickson, D.; Grob, P. M.; Hoffman, A. F.;

Warren, T. C. (Boehringer Ingelheim Pharmaceuticals) Patent WO2000023060, 2000. (c) Betageri, R. C.; Cywin, C. L.; Hargrave, K.; Hoermmann, M. A.; Kirrane, T. M.; Parks, T. M.; Patel, U. R.; Proudfoot, J. R.;

Sharma, R.; Sun, S.; Wang, X.-J. (Boehringer Ingelheim Parmaceuticals)

Patent WO1999062885, 1999.

(11) For a collection of reviews on flow chemistry, see: (a) Geyer, K.;

Gustafson, T.; Seeberger, P. H. Synlett 2009, 2382. (b) Hartman, R. L.;

Jensen, K. F. Lab Chip 2009, 9, 2495. (c) Mak, X. Y.; Laurino, P.;

Seeberger, P. H. Beilstein J. Org. Chem. 2009, 5, 19. (d) Wiles, C.; Watts,

P. Eur. J. Org. Chem. 2008, 1655. (e) Fukuyama, T.; Rahman, M. T.; Sato,

M.; Ryu, I. Synlett 2008, 151. (f) Ahmed-Omer, B.; Brandt, J. C.; Wirth,

T. Org. Biomol. Chem. 2007, 5, 733. (g) Watts, P.; Wiles, C. Chem.

Commun. 2007, 433. (h) Mason, B. P.; Price, K. E.; Steinbacher, J. L.;

Bogdan, A. R.; McQuade, D. T. Chem. Rev. 2007, 107, 2300.

(i) Kobayashi, J.; Mori, Y.; Kobayashi, S. Chem. Asian J. 2006, 1, 22.

(12) For a selection of books on flow chemistry, see: (a) Wiles, C.;

Watts, P. Micro Reaction Technology in Organic Synthesis; CRC Press:

Boca Raton, London, New York, 2011. (b) Microreactors in Organic

Synthesis and Catalysis; Wirth, T., Ed.; Wiley-VCH: Weinheim, 2008.

(c) Handbook of Micro Reactors; Hessel, V., Schouten, J. C., Renken,

A., Wang, Y., Yoshida, J.-I., Eds.; Wiley-VCH: Weinheim, 2009.

(d) Yoshida, J.-i. Flash Chemistry - Fast Organic Synthesis in Microsystems;

Wiley-VCH: Weinheim, 2008.

6668

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�The Journal of Organic Chemistry

(13) Razzaq, T.; Kappe, C. O. Chem. Asian J. 2010, 5, 1274.

(14) (a) Hessel, V. Chem. Eng. Technol. 2009, 32, 1655. (b) van

Gerven, T.; Stankiewicz, A. Ind. Eng. Chem. Res. 2009, 48, 2465.

(15) Kappe, C. O.; Dallinger, D. Nat. Rev. Drug Discovery 2006, 5, 51.

(16) For recent reviews on microwave chemistry, see: (a) Caddick,

S.; Fitzmaurice, R. Tetrahedron 2009, 65, 3325. (b) Kappe, C. O.;

Dallinger, D. Mol. Diversity 2009, 13, 71.

(17) (a) Damm, M.; Glasnov, T. N.; Kappe, C. O. Org. Process Res.

Dev. 2010, 14, 215. (b) Razzaq, T.; Glasnov, T. N.; Kappe, C. O. Eur. J.

Org. Chem. 2009, 1321. (c) Bedore, M. W.; Zaborenko, N.; Jensen, K. F.;

Jamison, T. F. Org. Process Res. Dev. 2010, 14, 432. (d) Hodgkinson, J. T.;

Galloway, W. R. J.; Saraf, S.; Baxendale, I. R.; Ley, S. V.; Ladlow, M.;

Welch, M.; Spring, D. R. Org. Biomol. Chem. 2011, 9, 57. (e) Glasnov,

T. N.; Kappe, C. O. Adv. Synth. Catal. 2010, 352, 3089.

(18) (a) McMullen, J. P.; Stone, M. T.; Buchwald, S. L.; Jensen, K. F.

Angew. Chem., Int. Ed. 2010, 49, 7076. (b) McMullen, J. P.; Jensen, K. F.

Org. Process Res. Dev. 2010, 14, 1169. (c) Qian, Z.; Baxendale, I. R.; Ley,

S. V. Chem.—Eur. J. 2010, 16, 12342. (d) Leung, S.-A.; Winkle, R. F.;

Wootton, R. C. R.; deMello, A. J. Analyst 2005, 130, 46.

(19) For a preliminary communication, see: Glasnov, T. N.; Groschner,

K.; Kappe, C. O. Chem. Med. Chem. 2009, 4, 1816.

(20) Reviews on multistep flow-synthesis: (a) Webb, D.; Jamison,

T. F. Chem. Sci. 2010, 1, 675. (b) Ahmed-Omer, B.; Barrow, D. A.; Wirth,

T. ARKIVOC 2011, No. iv, 26.

(21) For reviews focusing on pyrazole synthesis, see: (a) Fustero, S.;

Sim�n-Fuentes; Sanz-Cervera, J. Org. Prep. Proced. Int. 2009, 41, 253.

o

(b) Pereira, C. M. P.; Quina, F. H.; Silva, F.A. N.; Emmerich, D. J.;

Machulek, A., Jr. Mini-Rev. Org. Chem. 2008, 5, 331.

(22) Deng, X.; Mani, N. S. J. Org. Chem. 2008, 73, 2412.

(23) Ahmed, M. S. M.; Kobayashi, K.; Mori, A. Org. Lett. 2005,

7, 4487.

(24) For more information on the used microwave reactor and the

importance of temperature measurement, see: (a) Obermayer, D.;

Kappe, C. O. Org. Biol. Chem. 2010, 8, 114. (b) Obermayer, D.;

Gutmann, B.; Kappe, C. O. Angew. Chem., Int. Ed. 2009, 48, 8321.

(c) Gutmann, B.; Obermayer, D.; Reichart, B.; Prekodravac, B.; Irfan,

M.; Kremsner, J. M.; Kappe, C. O. Chem.—Eur. J. 2010, 16, 12182.

(25) Singh, S. P.; Kumar, D.; Junes, B. G.; Threadgill, M. D.

J. Fluorine Chem. 1999, 94, 199.

(26) For a recent review on flow synthesis of heterocyclic compounds

including pyrazoles, see: Glasnov, T. N.; Kappe, C. O. J. Heterocycl. Chem.

2011, 48, 11.

(27) Gustafsson, T.; Pont�n, F.; Seeberger, P. H. Chem. Commun.

e

2008, 1100.

(28) Razzaq, T.; Glasnov, T. N.; Kappe, C. O. Chem. Eng. Technol.

2009, 32, 1702.

(29) Gutmann, B.; Glasnov, T. N.; Razzaq, T.; Goessler, W.;

Roberge, D. M.; Kappe, C. O. Beilstein J. Org. Chem. 2011, 7, 503.

(30) Kabalka, G. W.; Varma, R. S. Reduction of Nitro and Nitroso

Compounds. In Comprehensive Organic Synthesis; Trost, B. M., Fleming,

I., Eds.; Pergamon: Oxford, 1991.

(31) Kappe, C. O.; Dallinger, D.; Murphree, S. S. Practical Microwave

Synthesis for Organic Chemists - Strategies, Instruments, and Protocols;

Wiley-VCH: Weinheim, 2009.

(32) (a) Vanier, G. S. Synlett 2007, 131. (b) Piras, L.; Genesio, E.;

Ghiron, C.; Taddei, M. Synlett 2008, 1125.

(33) (a) Quinn, J. F.; Razzano, D. A.; Golden, K. C.; Gregg, B. T.

�

Tetrahedron Lett. 2010, 51, 786. (b) Chapman, N.; Conway, B.; OGrady,

F.; Wall, M. D. Synlett 2006, 1043.

(34) Vass, A.; Dud�s, J.; T�th, J.; Varma, R. S. Tetrahedron Lett. 2001,

a

o

42, 5347.

(35) Spencer, J.; Anjum, N.; Patel, H.; Rathnam, R. P.; Verma, J.

Synlett 2007, 2557.

(36) Díaz-Couti~o, F. D.; Escalante, J. J. Mex. Chem. Soc. 2009, 53, 93.

n

(37) For a review on flow hydrogenations, see: Irfan, M.; Glasnov,

T. N.; Kappe, C. O. ChemSusChem 2011, 4, 300.

(38) Irfan, M.; Petricci, E.; Glasnov, T. N.; Taddei, M.; Kappe, C. O.

Eur. J. Org. Chem. 2009, 1327.

ARTICLE

(39) ReviewMontalbetti, C. A. G. N.; Falque, V. Tetrahedron 2005,

61, 10827.

(40) Baxendale, I. R.; Ley, S. V.; Smith, C. D.; Tranmer, G. K. Chem.

Commun. 2006, 4835.

(41) Herath, A.; Dahl, R.; Cosford, N. Org. Lett. 2010, 12, 412.

00

(42) Bacsa, B.; Horv�ti, K.; Bosze, Sz.; Andreae, F.; Kappe, C. O.

a

J. Org. Chem. 2008, 73, 7532.

(43) Colombo, M.; Bossolo, S.; Aramini, A. J. Comb. Chem. 2009,

11, 460.

(44) (a) Yin, J.; Buchwald, S. L. J. Am. Chem. Soc. 2002, 124, 6043.

(b) Dallas, A. S.; Gothelf, K. V. J. Org. Chem. 2005, 70, 3321.

(c) Chandresekar, S.; Sultana, S. S.; Yaragorla, S. R.; Reddy, N. R.

Synthesis 2006, 839. (d) Piguel, S.; Legraverend, M. J. Org. Chem. 2007,

72, 7026. (e) Audisio, D.; Messaoudi, S.; Peyrat, J.-F.; Brion, J.-D.; Alami,

M. Tetrahedron Lett. 2007, 48, 6928. (f) Bhagwanth, S.; Waterson, A. G.;

Adjabeng, G. M.; Hornberger, K. R. J. Org. Chem. 2009, 74, 4634.

(g) Salome, C.; Schmitt, M.; Bourguignon, J.-J. Tetrahedron Lett. 2009,

50, 3798. (h) Barfoot, C.; Brooks, G.; Brown, P.; Dabbs, S.; Davies,

D. T.; Giordano, I.; Hennessy, A.; Jones, G.; Markwell, R.; Miles, T.;

Pearon, N. Tetrahedron Lett. 2010, 51, 2685. (i) Qin, L.; Cui, H.; Li, J.;

Wu, Y.; Zhu, Z.; Wu, Y. Tetrahedron Lett. 2010, 51, 4445. (j) Surry, D. S.;

Buchwald, S. L. Chem. Sci. 2011, 2, 27.

(45) Wannberg, J.; Dallinger, D.; Kappe, C. O.; Larhed, M. J. Comb.

Chem. 2005, 7, 574.

(46) (a) Hartman, R. L.; Naber, J. R.; Zaborenko, N.; Buchwald,

S. L.; Jensen, K. F. Org. Process Res. Dev. 2010, 14, 1347. (b) Naber, J. R.;

Buchwald, S. L. Angew. Chem., Int. Ed. 2010, 49, 9469. (c) No€l, T.;

e

Naber, J. R.; Hartman, R. L.; McMullen, J. P.; Jensen, K. F.; Buchwald,

S. L. Chem. Sci. 2011, 2, 287.

(47) The current price for pyrazole derivative 1a (Pyr 3, Sigma,

P0032) is 488.50 h for 25 mg. For a recent publication describing an

evaluation of Pyr 3, see: Poteser, M.; Schleifer, H.; Lichtenegger, M.;

Schernthaner, M.; Stockner, T.; Kappe, C. O.; Glasnov, T. N.; Romanin,

C.; Groschner, K. Proc. Nat. Acad. Sci. U.S.A. 2011, 108, 10556.

(48) Neubauer, H. J.; Kuenast, C.; Hofmeister, P. (BASF AG) Patent

DE732541, 1989.

6669

dx.doi.org/10.1021/jo2009824 |J. Org. Chem. 2011, 76, 6657–6669

�