Hydrazinium Hydrazinesulfinates

Year:

Abstract:

This invention relates to the reaction of organic substituted hydrazines with sulfur dioxide. In one specific aspect, it relates to a novel process for making organic substituted hydrazinium hydrazinesulfinates. In yet another aspect, it relates to the composition of matter produced thereby.

Type of document:

Language:

United States Patent Cffice

2,888,483

1

2,888,483

HYDRAZINIUM HYDRAZINESULFINATES

Bernard Rudner, Pittsburgh, Pa., and Marguerite E. i

Brooks, Baltimore, Md., assignors to W. R. Grace 8:

_Co., New York, N.Y., a corporation of Connecticut

No Drawing. Application September '16, 1958

Serial No. 761,294

13 Claims. (Cl. 260—501)

Thisinvention relates to the reaction of organic sub-

stituted" _hydrazines.with sulfur dioxide. In one specific

aspect, itrelates to a novel process for making organic

substituted hydrazinium‘hydrazinesulfinates. In yet an-

other aspect, it relates to the novel compositions of matter

produced thereby. , ’ '

The reaction of sulfur compounds with compounds con- '

taining two adjacent nitrogen atoms is not new to the art.

The useful and well known sulfonhydrazides are made

by the reaction of sulfonyl halides on hydrazine or sub-

stituted_hydrazines. Phenylhydrazine has been prepared

for many years by the reduction of phenyldiazonium salts

with sulfur dioxide usually in the form of the alkali metal

sulfite. Hydrazine itself is known to interact with sulfur

dioxide toform an .unusual compound containing three

hydrazines to two sulfurdioxides. We have discovered,

however, that the reaction of sulfur dioxide with organic

substituted hydrazines unexpectedly gives the novel or-

ganic substituted hydrazinium hydrazinesulfinates.

It is, therefore, an object of the present invention to pro-

vide a new generic class of organic compounds, heretofore

unavailable, useful as bactericides, fungicides and nema-

tocides as well as for a variety of other purposes.

In accordance with the present invention, we have dis-

covered a novel process for the synthesis of organic sub-

stituted hydrazinium hydrazinesulfinates having the gen-

eral formula (RR’NHNH2) (RR’NNHSOg). In this for-

mula R is a monovalent radical selected from the group

consisting of lower alkyl, hydroxy lower alkyl, phenyl

and benzyl. R’ is a monovalent radical selected from the

group consisting of hydrogen, lower alkyl and benzyl. It

is apparent that our novel compounds are salts containing

the 2- or _2,2v-substituted hydrazinium cation

(RR’NHNH2)+

and the corresponding 2- or 2,2-substituted hydrazine-

sulfinate anion (RR’NNHSO2)".

A brief discussion of the chemical and physical prop-

erties of these compounds will be required in order to

better understand the method used for their production.

Usually our novel compounds are insoluble in hydrocar-

bon solvents and moderately polar organic solvents. They

are soluble in water and highly polar organic solvents.

On heating, the compounds dissolve in less polar solvents

but heating ‘above 50° C. in any solvent may cause decom-

position" of the salt. Naturally the exact temperature

at which decomposition becomes undesirable depends’ on

the given salt and the solvent used. It is important to note

that certain of our compounds, when in‘ solution or wet

with solvent, are particularly susceptible to air oxidation.

When such a product is collected by filtration using suction

to aid in "the filtration and to promote drying or removal '

of solvent from the filter cake, oxidation of the product

will result as air is pulled through the wet cake. When

this occurs, suction-filtration should be done under a

rubber’ dam or in -an inert atmosphere. - g

Since -the reaction of organic substituted hydrazines

with sulfur dioxide is highly exothermic, excess substituted

[5

10

15

_20

25

30

35

40

45

50

55

60.

65

70

2

hydrazine must be present or preferably an inert solvent

should be used. By inert it is meant that the solvent

should be unreactive to the products or reactants of our ‘

invention during the course of the reaction process. Suit-

able solvents are aliphatic and aromatic hydrocarbons,

chlorinated hydrocarbons,» lower aliphatic alcohols, etc.

"Typical solvents used were xylene, trichloroethylene,

chloroform, isopropyl alcohol and various petroleum

hydrocarbon fractions.

illustrative of the types of solvents that may be used in

our invention and are not meant to be limiting. ‘Any _,

unreactive or non-interfering solvent comes within the

scope of our invention.

usually limited to one in which the reactant organic sub-

stituted hydrazine is soluble. A further choice of solvent

is made depending on whether it is desirable to isolate the

product as a solution (especially when it is particularly '

susceptible to decomposition‘ in air) or to collect it by .

In additionto 1

the use of a solvent, it is necessary to provide means for

separation (liquid) or filtration (solid).

externally cooling the reaction vessel. As mentioned and

discussed previously, the reaction is highly exothermic '

and the product decomposes on heating in solution much .

above 50° C. From the above remarks it is also obvious

that efficient operation of our process on a larger scale

requires a means for adequate stirring of the reaction

mixture at all stages of the process. ’I‘his_becomes par-

ticularly important at the’ latter stages of the process‘ when

the reaction mixture has become thickened with product.

Preferably our novel process is operated as follows: The

selected organic substituted hydrazine is dissolved in a»

solvent in which the resultant hydrazinium hydrazinesul-

finate will be insoluble. The stirred contents of the

reaction vessel are chilled by external cooling and ex—‘

cess gaseous sulfur dioxide (from a cylinder protected

by a trap) is passed into the reaction mixture. It is im- V

perative to keep the temperature of the reaction mixture

below 50° C. to avoid decomposition of the product and

preferably below 30° C. to get a purer, lighter colored

product. Temperature control is accomplished by the

aforementioned cooling bath and by adjusting the rate of

flow of sulfur dioxide into the reaction mixture. When

the temperature starts rising, the flow rate is lessened

to diminish the amount of heat formed by the exothermic

reaction. The addition of sulfur dioxide is stopped when

the reaction mixture becomes _too thick for eflicient stir-

ring and/or further absorption of the gas ceases. The

product is collected by filtration, using the precautions

previously discussed, and dried in vacuo.

The novel compositions of our invention have been

found useful as polymerization initiators and surprisingly

as rodent repellants. Our hydrazinium hydrazine sul-

finates have been tested and found useful as bactericides,

fungicides and nematocides. Microbiological activity

was tested-by means of the Oxford Cup Method, The

cups were placed on innoculated culture media, filled with “

buffered test solution and the whole incubated for the re- ’

In this method the zone of inhibition-of‘

microbial growth is a measure of the bacteriostatic or '

fungistatic activity of the given compound against the‘

quired time.

selected test organism. Using the appropriate culture

media, tests were made of bacteriostatic activity against

five representative bacterial species» and of fungistatic

activity against three selected species of fungi as described _

below:

FIVE TEST BACTERIA

(1) Micrococcus pyogenes—-can enter broken skin to

cause infection also may cause food poisoning. .

(2) Pseudomonas aerogz'nosa—a denitrifying organism ‘

which causes decay of protein.

(3) Serratia marcescens——a water-living saprophytic

Patented May—26, 1959

These remarks are meant to be -

The choice of the solvent is s

2,888,488

«I3

organism which reduces nitrates, liquefies blood serum

and coagulates and digests milk.

(4) Escherichia colz'—commonly found in the intes-

tinal canal.

(5) Klebsiella pneumom'ae—can cause infection of

respiratory and genito-urinary tracts.

THREE TEST FUNGI

(1) Candida albz'cans—has been known to cause acute

fatal moniliases (lesions of the skin, mucous membranes

and internal organs).

(2) Microsporum gypseum-—causes skin diseases such

as ring worm and barber’s itch.

(3) Clzaetomium globosum—causes deterioration of

cellulosic materials.

The scope and utility of my invention is further illus-

trated by the following examples:

Example 1

Dry sulfur dioxide gas was passed for 2 hoursthrough

a chilled solution of 20 g. of 1,1-dimethylhydrazine in

200 ml. of chloroform. A gelatinous supernatant layer

appeared which was allowed to coagulate overnight be-

fore being collected by filtration under a rubber dam.

On drying in a vacuum desiccator, the colorless solid

appeared as long needles partially subliming at 28° C.,

melting 34—37° C. and evolving gas ca. 90° C. There

resulted 7.7 g. of the product, 2,2-dimethylhydrazinium

2,2-dimethylhydrazinesulfinate.

Example II

Dry sulfur dioxide gas was passed for 2 hours through

a chilled solution of 20 g. of rnethylhydrazine in 200

ml. of chloroform as in Example I. The reaction mix-

ture separated into two liquid phases. The upper yellow

layer was essentially 2-methylhydrazinium 2-methylhy-

drazinesulfinate unstable in the presence of air. When

the same procedure was repeated using isopropyl alcohol

as the solvent, a stable solution of the product was ob-

tained.

Example III

Dry sulfur dioxide gas was passed for 2 hours through a

chilled solution of 36 g. of phenylhydrazine in 200 ml.

of trichloroethylene. A yellow solid formed immediately

and on further standing additional solid precipitated. The

crude product decomposing ca. 210° C. was collected in

good yield by filtration under a rubber darn.

Example 1 V

Eighty grams of 1,1-dimethylhydrazine dissolved in

300 ml, of trichloroethylene was thoroughly chilled in

an ice bath and kept cool during the 10 hour passage of

sulfur dioxide into the reaction mixture. Working up

the resultant 2,2-dimethylhydraziniurn 2,2—dimethylhy-

drazinesulfinate according to the procedure of Example

I, gave 134.6 g. of product.

Example V

Dry sulfur dioxide gas was bubbled through a solution

of 35 g. of 2-hydroxyethylhydrazine in 1000 ml. of iso-

propyl alcohol for 30 minutes. Evaporation of the sol-

vent left a yellow viscous liquid which contained some

white crystalline solid. The residue was dissolved in

methyl alcohol and added with stirring to an excess of

ether forming two liquid layers. The yellow product

layer was separated and dried to give 55 g. of a light

yellow viscous liquid. The product, 2-(2-hydroxyethyl)

hydrazinium 2-(2-hydroxyethyl)hydrazinesulfinate, de-

composed at 40° C. and began to char ca. 100° C.; its

aqueous solutions had a pH of 5.35.

Example VI

A flask containing 324 g. of phenylhydrazine dissolved

in 1838 g. of xylene was kept in a water bath at about

20° C. After the addition with stirring of 338 g. of

10

15

20

25

30

35

40

45

50

55

60

85

70

75

4

sulfur dioxide over a period of 97 minutes, the resultant

slurry was allowed to stand several hours before being

filtered under a rubber dam. (When an attempt was

made to dry the filter cake by pulling air through it, the

cake became very hot, began to smoke and started local-

ized decomposition with pronounced charting.) On

drying there was obtained 290 g. of 2-phenylhydraziniu.m

2-phenylhydrazinesulfinate as a pale yellow solid which

decomposed ca. 225 ° C. At room temperature, the

product was insoluble in ether, chloroform, water, lower

alcohols, ethyl acetate, benzene’ and xylene; it was solu-

ble in methyl alcohol, ethyl acetate and chloroform at

50° C. but at higher temperatures decomposition be-

came extensive. The product analyzed 51.96% C, 6.28%

H and 19.21% N as compared to the calculated values

of 51.41, 5.75 and 19.99% respectively.

Example VII

Using the same general procedure as in die previous

example, but without any stirring, 541 g. of phenylh'y-

drazine in 1620 g. of xylene was treated with 282 g.

of sulfur dioxide over a period of 71 minutes. A yield

of 392 g. of dried product was obtained. As with the

filtrate of the previous example, more product could

be isolated by evaporation of the filtrate. Here it was

found preferable to recycle the filtrate by recharging it

with another 541 g. of phenylhydrazine and 306 g. of

xylene. The passage of 262 g. of sulfur dioxide over a

period of 55 minutes gave 483 g. of product after fil-

tration and drying. .

Example VIII

2-phenylhydrazinium 2-phenylhydrazinesulfinate, a

typical compound of this invention, was tested in vitro

by the Oxford cup method for bacteriostatic activity.

Phenol and Zephiran (a refined benzalkonium chloride)

were used as controls. In each experiment, three stain-

less steel Oxford cups (10 mm. in diameter) were

placed equidistant on the innoculated culture medium

in a Petri dish and the cups filled approximately three-

quarters full with test solution containing 0.2% of the

substance to be tested. After incubation for the appro-

priate period, the plates were examined and the diameter

of the zone of the inhibition of microbial growth sur-

rounding each cup measured. Obviously, the larger the

zone of inhibition, the more effective are the bacterio-

static properties of the compound tested. Because of the

size of the Oxford cups use, 10 mm. is considered to

represent zero inhibition.

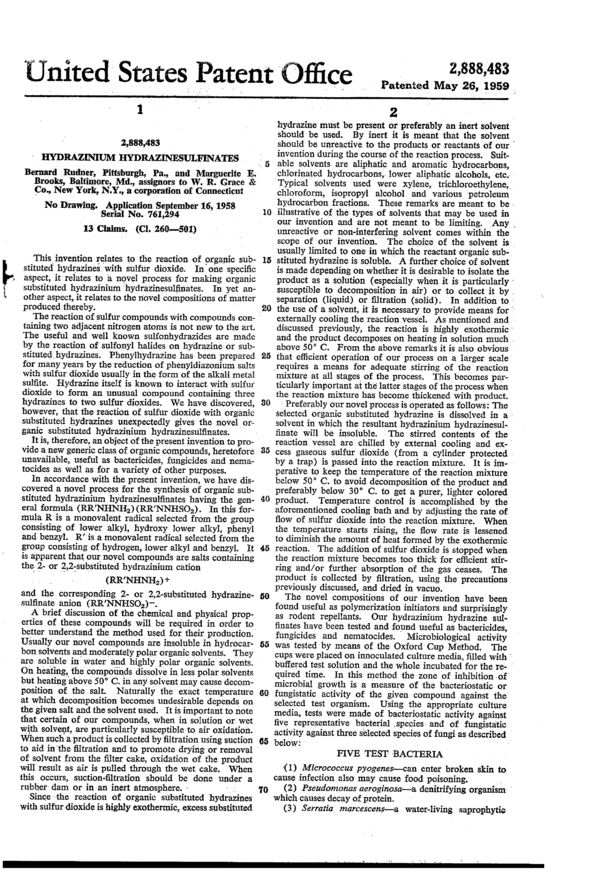

ZONE OF INHIBITION >AT pH'=3.ti

Organism Media Zephiran Phenol Sulfinate

1. M. pyogenes _____________ -_ A 21 10 14

2. P. aeruginosa_- - A 10 10 12

3. P. rzerugi7Los:z_.__ - B 10 10 10

4. S. mr1r4zscens__ A 14 10 13

5. E. ooh ....... -_ A 18 10 16

6. K. pneumaniae B 11 10 14

7. K. pneumoniae A 17 10 23

_

ZONE or INHrBI'rioN Afr pH=7.o

Sulfzlnste

Organism Media Zephiran Phenol

1. M. pyogenes ............. _- A 21 10 16

2. P. aeruginosa-- A 10 10 ¢.

3. P. aeruginosa B 10 10 14

4. S. mamscens A 14 10 16

5. E. coli _____ _. A 17 10 L0

6. K. pneumom'ae._ B 12 10 15-‘

7. K. pneumoniae .......... -- A 17 10 30

Media. A: nutrient agar.

Media B: nutrient agar + 10% horse serum.

Example IX

Using the procedure of the previous example, the in

vitro fungistatic activity of 2-phenylhydrazinium 2-

(./‘‘.,,,...,,§

2,338,483

5

phenylhydrazinesulfinate was tested by the Oxford cup

method against Phenol and Zephiran as controls.

ZONE OF INHIBITION AT pH=3.0

Organism Media Zephiran Phenol Sulfumtc

1. C’. albicans .............. -. A 15 10 27

2. C’. albicans .............. _- B 13 11 212

3. M. gypscum _____________ -- A 38 10 47

4. C’. glabosum ............. -- C 28 11 2-1

ZONE OF INHIBITION AT pH=7.0

Organism Media Zephiran Phenol Sulfmate

1 C albicans ______________ -. A 17 10 32

2. C’ albicans__ B 12 10 24

3. M. 91/pseum_-- A 35 10 2:.

4. O. qlobosum... C 23 12 48

Media A: Babourauds dextrose agar.

Media B: Babourauds dextrose agar + 10% horse serum.

Media 0: Potato agar.

We claim:

1. Chemical compounds having the general formula

(RR’NHNH2) (RR’NNHSO2) wherein R is a monovalent

radical selected from the group consisting of lower alkyl,

hydroxy lower alkyl, phenyl and benzyl and R’ is a mono-

valent radical selected from the group consisting of lower

alkyl hydroxy lower alkyl, phenyl and benzyl and R’ is

a monovalent radical selected from the group consisting

of hydrogen, lower alkyl and benzyl.

2. Compounds according to claim 1 wherein R is hy-

droxy lower alkyl and R’ is hydrogen.

3. Compounds according to claim 1 wherein R and R’

are lower alkyl.

5

10

15

20

25

6

4. Compounds according to claim 1 wherein R is lower

alkyl and R’ is hydrogen.

5. 2,2-dimethylhydrazinium 2,2-dimethylhydrazinesul-

finate.

6. 2-methylhydrazinium 2-methylhydrazinesulfinate.

7. 2-(2-hydroxyethyl)hydrazinium 2-(2-hydroxyethyl)

hydrazinesulfinate.

8. 2-phenylhydrazinium 2-phenylhydrazinesulfinate.

9. A method of making organic substituted hydrazini-

um hydrazinesulflnates having the general formula

(RBJNHNH2) (RR’NNHSO2) wherein R is a monovalent

radical selected from the group consisting of lower

alkyl, hydroxy lower alkyl, phenyl and benzyl and R’ is

a monovalent radical selected from the group consisting

of hydrogen, lower alkyl and benzyl which comprises pro-

viding a solution of an organic substituted hydrazine hav-

ing the formula RR’NNH2 wherein R and R’ are defined

as above in an unreactive solvent, maintaining at all

times a temperature below 50° C., contacting said solu-

tion with gaseous sulfur dioxide and recovering said

hydrazinesulfinate therein formed from the reaction mix-

ture.

10. A method according to claim 9 wherein R is hy-

droxy lower alkyl and R’ is hydrogen.

11. A method according to claim 9 wherein R and R’

are lower alkyl.

12. A method according to claim 9 wherein R is phenyl

and R’ is hydrogen.

13. A method according to claim 9 wherein R is lower

39 alkyl and R’ is hydrogen.

References Cited in the file of this patent

Ephraim et al.: Ber. 44, 386-394 (1911).

Coments go here:

- Log in to post comments