Sterilized Cyanoacrylate Adhesive Composition, and a Method of Making such a Composition

Sterilized Cyanoacrylate Adhesive Composition, and a Method of Making such a Composition

US5530037

Company:

Folder:

Year:

Abstract:

A curable cyanoacrylate adhesive composition intended for medical and/or veterinary uses is sterilized in liquid form by gamma irradiation. The composition comprises

a) a cyanoacrylate monomer

b) a combination of an anionic stabilizer in amounts effective to stabilize the composition during storage prior to cure, wherein the free radical stabilizer is a selected phenolic antioxidant (but not including hydroquinone).

The preferred free radical stabilizer is butylated hydroxyanisole. After irradiation the cyanoacrylate monomer is substantially ungelled.

Type of document:

Language:

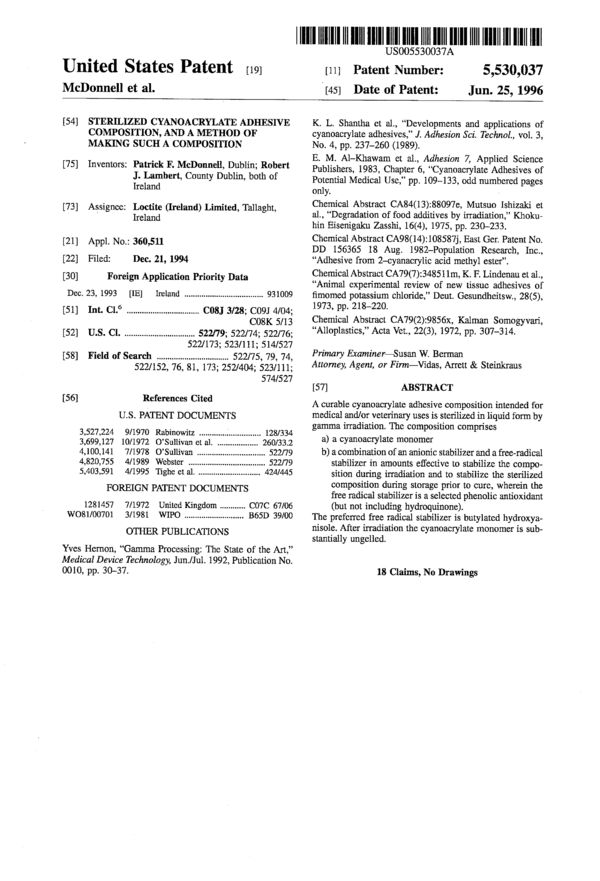

United States Patent [19]

McDonnell et al.

H||||||l|||l||l|l||||||||l|||||||||l|llIll||||||||||||||llllllllllllllllll

US005530037A

[11] Patent Number:

"[45] Date of Patent:

5,530,037

Jun. 25, 1996

[54] STERILIZED CYANOACRYLATE ADHESIVE

COMPOSITION, AND A METHOD OF

MAKING SUCH A COMPOSITION

[75] Inventors: Patrick F. McDonnell, Dublin; Robert

J. Lambert, County Dublin, both of

Ireland

[73] Assignee: Loctite (Ireland) Limited, Tallaght,

Ireland

[21] Appl. No.: 360,511

[22] Filed: Dec. 21, 1994

[30] Foreign Application Priority Data

Dec. 23, 1993 [IE] Ireland ................................... .. 931009

[51] Int. Cl.“ ................................ .. C08J 3/28; C09] 4/04;

C08K 5/13

[52] U.S. Cl. ............................... .. 522/79; 522/74; 522/76;

522/173; 523/111; 514/527

[58] Field of Search ................................ .. 522/75, 79, 74,

522/152, 76, 81, 173; 252/404; 523/111;

574/527

[56] References Cited

U.S. PATENT DOCUMENTS

3,527,224 9/1970 Rabinowitz ........................... .. 128/334

3,699,127 10/1972 0’Sul1ivanetal. . 260/33.2

4,100,141 7/1978 0’Su11ivan 522/79

4,820,755 4/1989 Webster ...... .. 522/79

5,403,591 4/1995 Tighe et a1. ........................... .. 424/445

FOREIGN PATENT DOCUMENTS

1281457 7/1972 United Kingdom .......... .. C07C 67/06

W081/00701 3/1981 WIPO .......................... .. B65D 39/00

OTHER PUBLICATIONS

Yves Hemon, “Gamma Processing: The State of the Art,”

Medical Device Technology, Jun./Jul. 1992, Publication No.

0010, pp. 30-37.

K. L. Shantha et a1., “Developments and applications of

cyanoacrylate adhesives,” J. Adhesion Sci. Technol., vol. 3,

No. 4, pp. 237-260 (1989).

E. M. Al-Khawam et al., Adhesion 7, Applied Science

Publishers, 1983, Chapter 6, “Cyanoacrylate Adhesives of

Potential Medical Use,” pp. 109-133, odd numbered pages

only.

Chemical Abstract CA84(13):88097e, Mutsuo Ishizaki et

al., “Degradation of food additives by irradiation,” Khoku—

hin Eisenigaku Zasshi, 16(4), 1975, pp. 230-233.

Chemical Abstract CA98(14):108587j, East Ger. Patent No.

DD 156365 18 Aug. 1982—Population Research, Inc.,

“Adhesive from 2—cyanacrylic acid methyl ester”.

Chemical Abstract CA79(7):348511m, K. F. Lindenau et al.,

“Animal experimental review of new tissue adhesives of

fimomed potassium chloride,” Dent. Gesundheitsw., 28(5),

1973, pp. 218-220.

Chemical Abstract CA79(2):9856x, Kalman Somogyvari,

“Alloplastics,” Acta Vet., 22(3), 1972, pp. 307-314.

Primary Examiner—Susan W. Berrnan

Attorney, Agent, or Firm—Vidas, Arrett & Steinkraus

[57] ABSTRACT

A curable cyanoacrylate adhesive composition intended for

medical and/or veterinary uses is sterilized in liquid form by

gamma irradiation. The composition comprises

a) a cyanoacrylate monomer

b) a combination of an anionic stabilizer and a free-radical

stabilizer in amounts effective to stabilize the compo-

sition during irradiation and to stabilize the sterilized

composition during storage prior to cure, wherein the

free radical stabilizer is a selected phenolic antioxidant

(but not including hydroquinone).

The preferred free radical stabilizer is butylated hydroxya-

nisole. After irradiation the cyanoacrylate monomer is sub-

stantially ungelled.

18 Claims, No Drawings

5,530,037

1

STERILIZED CYANOACRYLATE ADHESIVE

COMPOSITION, AND A METHOD OF

MAKING SUCH A COMPOSITION

BACKGROUND OF THE INVENTION

1) Field of the Invention

This invention relates to a sterilized cyanoacrylate adhe-

sive composition, and to a method of making such a com-

position. The composition is suitable for bonding a wide

range of substrates but is especially intended for medical

and/or veterinary uses such as wound closure and general

surgical applications.

2) Description of the Related Art

There is considerable experience in the use of cyanoacry-

late adhesives in medical and veterinary practice (Shantha et

al. “Developments and Applications of Cyanoacrylate Adhe-

sives”, J. Adhesion Sci. Technol Vol. 3, No. 4, pp 237-260

(1989)). Cyanoacrylate adhesives have been proposed for

surgical treatment such as wound adhesives, hemostatics

and tissue adhesives, particularly for sutureless skin bond-

ing. It is desirable that an adhesive for medical or veterinary

use should be sterilizable (Al-Khawan et al. “Cyanoacrylate

adhesives of potential medical use”, Adhesion 7 (Allen K.

W.) Applied Science Publishers, Chap. 6, 109-133 (1983).

Cyanoacrylate adhesives must be stabilized against

anionic and free radical polymerization. W0 8100701 Krall

describes a methyl cyanoacrylate adhesive composition for

sealing fallopian tubes in female sterilization containing a

polymerisation inhibitor such as an organic carboxylic acid,

S02 and an antioxidant selected from hydroquinone, hyd-

roquinone mono-methyl ether, butylated hydroxyanisole and

their mixtures.

A cyanoacrylate adhesive composition for medical use is

commercially available under the Trade Mark HIS-

TOACRYL BLUE from B. Braun Melsungen AG. This

composition is not sterilized.

Several methods which are available for positively ster-

ilising liquids could be considered for application to

cyanoacrylate adhesives. These include ionising radiation

(electron accelerators or gamma radiation from a radioactive

source such as Cobalt 60 or Caesium 137), dry-heat, steam,

gas, filtration and liquid sterilisation. Aseptic filling of the

adhesive immediately following manufacture is also an

option. Factors to consider in choosing a sterilisation

method include (a) the reactive nature of cyanoacrylates, (b)

contamination due to induced chemical changes in the

adhesive composition, (c) subsequent storage stability, (d)

effect on bonding performance (immediate and long-term),

(e) viscosity changes, (f) effect on the package or vessel used

to contain the adhesive and (g) the maintenance of sterility

on storage up to the time of utilisation. -

Most of the above sterilisation methods are unsuitable or

suffer from severe limitations in their applicability to

cyanoacrylate adhesives. Electron beam accelerators have

relatively low penetrating ability and would be efl"ective

only in sterilising the outer surfaces of thee container or

package. Dry-heat sterilisation generally involves a heating

cycle at 160°—170° C. for 22 hours. This treatment would be

extremely detrimental to cyanoacrylate adhesives with the

strong likelihood that polymerisation would occur before the

cycle was complete. Even if the adhesive survived (e.g. by

incorporation of excessive levels of stabilizers) the treated

product would have an adverse effect on performance and

induce gross discoloration. Steam sterilisation using moist

heat also involves exposure to an undesirably high tempera-

5

10

20

25

30

35

40

45

50

55

60

65

2

ture cycle (l21°—l41° C.) with the same adverse effects on

the adhesive as mentioned above under the dry-heat process.

In addition, the extreme sensitivity of cyanoacrylate adhe-

sives to moisture would limit the adhesive container to a

totally moisture impermeable package such as a sealed glass

arnpoule. Gas sterilisation usually involves the use of eth-

ylene oxide. While this process can be carried out at rela-

tively low temperatures the reactivity of the gas combined

with that of the cyanoacrylate adhesives would induce rapid

polymerisation and make the treatment unworkable. Sterili-

sation by filtration is not a viable method for cyanoacrylate

adhesives because the pores of the filter will inevitably

become blocked due to localised polymerisation. Likewise

sterilisation by contact with a liquid such as formalin will

only be effective on the outer surface of the container.

Aseptic filling of the adhesive direct from the final

receiving vessel used in the distillation stage of manufacture

would in theory yield a sterile product. This follows because

the cyanoacrylate prepolymer is cracked at temperatures of

over 190° C. in a sealed vessel during manufacture. The

composition of the final adhesive would be very limited

however, as necessary additives such as stabilizers could not

be conveniently added and mixed in a controlled fashion. If

required, viscosity modifiers such as polymethylmethacry-

late would require heating in a separate vessel to achieve

dissolution and this step would destroy the sterility.

Following on the unsuitable nature of the sterilisation

methods discussed above it was decided to investigate the

viability of using gamma irradiation from a Cobalt 60 source

as an eifective method of sterilising cyanoacrylate adhe-

sives.

The gamma radiation emitted from a cobalt 60 source

consists of high energy photons which have the ability to

penetrate many materials including various plastics, liquids

and metal foils. Any living microorganisms contaminating

the product are deactivated and their metabolism and repro-

ductive capabilities destroyed when they are exposed to a

gamma radiation dose of 25 kGy. (Henon Y., “Gamma

Processing, The State of the Art” in Medical Device Tech-

nology, June/July 1992, pages 30-37).

GB 1 281 457 (DE-OLS-2 055 658) Stehlik dating from

November 1970 describes a process for irradiating mono-

meric or oligomeric esters of —cyanoacrylic acid for the

purpose of sterlization of tissue binding adhesives. The

monomers or oligomers may be stablized with from 0.001 to

0.14 by weight of a gaseous Lewis acid inhibitor, acids such

as sulphur dioxide, nitrogen oxide, boron trifluoride and

hydrogen fluoride, and with from 0.1 to 0.54 by weight of a

phenolic free radical polymerisation inhibitor, preferably

with a mixture of sulphur dioxide and hydroquinone. The

patent states that as the monomeric or oligomeric com-

pounds polymerise very readily, normal sterilisation pro-

cesses including ionising radiation at room temperature are

completely useless. The patent also teaches that sterilization

by ionising radiation of the adhesive composition in liquid

form deleteriously affects the properties of the adhesive to

the extent that it becomes unuseable. The patent states that

only when solid adhesive material is irradiated is it possible

to prevent damage to the substance both as regards its

surgical usefulness and its adhesive properties as well as

viscosity and stability; the patentees therefore prefer to cool

the monomeric or oligomeric compounds to a temperature of

not more than —30° C. The three working examples in the

patent are carried out at —l96° C., —80° C. and —183° C.

respectively. No stabilizers are used in any of the working

examples. Example 1 states that an adhesive substance

which was exposed to 0.2 Mrad (2 kGy) gamrna-ray dose at

room temperature polymerised completely.

5,530,037

3

To carry out irradiation at low enough temperatures to

achieve solidification of the adhesive composition is not a

practical proposition for industrial production. Sterilization

should be performed on the liquid adhesive temperature at or

near to room temperature.

A minimum dose requirement of 25 kGy (2.5 Mrad)

gamma radiation is generally accepted as adequate for the

purpose of sterilization (U.K. Department of Health “Qual-

ity Systems for Sterile Medical Devices and Surgical Prod-

ucts”, 1990 Good Manufacturing Practice, HMSO, London).

A dose of 2 kGy (0.2 Mrad) would be wholly inadequate for

achieving sterilization.

U.S. Pat. No. 3,527,224 Rabinowitz describes a method of

surgically bonding tissue using an adhesive composition

based on n-pentyl alpha-cyanoacrylate which is subjected to

partial polymerisation to increase its viscosity. Radiation

such as gamma rays can be used to get both the desired

partial polymerisation and sterilization in a one-step process.

However a free-radical inhibitor must be introduced into the

composition after the irradiation, with the risk of introducing

bacterial contamination. The method of thickening would be

diflicult to quench effectively after the desired viscosity is

achieved.

The present Applicants have invented a sterilized adhe-

sive composition which contains monomeric cyanoacrylate

in a substantially ungelled condition and which therefore is

of low viscosity. The composition contains all of the nec-

essary ingredients before it is sterilized by irradiation. The

composition can be readily and fully sterilized by gamma

irradiation with a minimum dose of 25 kGy (2.5 Mrad) at

room temperature without any significant increase in vis-

cosity while mantaining the necessary performance and

shelf-life of the adhesive.

Hydroquinone is generally used as the free-radical stabi-

lizer for cyanoacrylate adhesives under normal ageing con-

ditions. If a sufficient concentration (e.g. 500-1000 ppm) is

present it will also be an elfective stabilizer to prevent

polymerisation during gamma irradiation treatments. How-

ever chemical changes to the hydroquinone molecule occur

during the treatment, resulting in the conversion of approxi-

mately 25% of the hydroquinone to 1,4-benzoquinone. This

material is known to be toxic and its presence in an adhesive,

especially if used for medical applications, would be unde-

sirable.

It is an object of the present invention to provide a

sterilized cyanoacrylate composition which does not have

the disadvantages discussed above.

It is a particular object of the invention to provide a

sterilized cyanoacrylate composition which is substantially

free of toxic contaminants, especially 1,4-benzoquinone.

SUMMARY OF THE INVENTION

The present invention provides a curable cyanoacrylate

adhesive composition for use in bonding, wherein the com-

position has been sterilized in liquid form by gamma irra-

diation and is the irradiation product of a composition

comprising

a) a cyanoacrylate monomer; and

b) a combination of an anionic stabliser and a free-radical

stabilizer in amounts effective to stabilize the compo-

sition during irradiation and to stabilize the sterilized

composition during storage prior to cure,

wherein the free-radical stabilizer is a phenolic antioxidant

selected from compounds of the formula I and II:

10

20

25

30

35

40

45

50

55

60

65

4

OH 1

R5 R1

R4 R2

R3

wherein

R3 is —H, an alkyl group having 1 to 20 carbon atoms, an

alkenyl group having 2 to 20 carbon atoms or an aryl

group having 6 to 36 carbon atoms;

R1, R2, R3 and R4, which may be the same or different, are

each R3 or —OR5;

provided that when R1, R2, R4 and R3 are each —H, R3 is

not —OH;

OH

R5 CH

01‘

wherein

R2, R3, R4 and R3 are as hereinbefore defined;

R6, R7, R8, R9 and R10, which may be the same or

diiferent are each R3 or —OR5;

the cyanoacrylate monomer in the stabilized liquid compo-

sition after irradiation being substantially ungelled.

The invention further provides a method of making a

curable sterile cyanoacrylate adhesive composition for use

in bonding which comprises preparing a liquid composition

comprising

(a) a cyanoacrylate monomer

(b) a combination of an anionic stabilizer and a free-

radical stabilizer in amounts effective to stabilize the

composition during sterilization by gamma irradiation

and to stabilize the sterilized composition during stor-

age prior to cure,

wherein the free-radical stabilizer is a phenolic antioxidant

selected from compounds of the formula I or II as defined

above, and exposing the composition in liquid form to

gamma irradiation in a dose suflicient to sterilize the com-

position without substantial gelling of the cyanoacrylate

monomer.

In the compounds of Formula I or H an alkyl or alkenyl

group preferably has up to 10 carbon atoms, more particu-

larly up to 5 carbon atoms, most preferably up to 4 carbon

atoms, and an aryl group preferably has up to 20 carbon

atoms, more particularly up to 10 carbon atoms.

In particularly preferred compounds of Formula I or II, at

least one of R1, R2, R4 and R3 (and in the case of compounds

of Formula II at least one of R7, R3 and R10) is -——C(CH3)3.

Preferably also, R3 (and in the case of compounds of

Formula II also R9) is selected from —CH3 and —OCH3.

The most preferred compound of Formula I is butylated

hydroxyanisole (BHA) which is a blend of isomers (2-tert-

butyl-4-methoxy phenol and 3-tert-butyl-4-methoxy phe-

ml).

The preferred cyanoacrylate monomers are alkyl, alkenyl

and alkoxy cyanoacrylate esters, more particularly such

esters wherein the alkyl or alkenyl group has up to 10 carbon

atoms, especially up to 5 carbon atoms.

The cyanoacrylate monomer may be selected from

methyl, ethyl, n-propyl, iso-propyl, n-butyl, iso-butyl, sec-

butyl, tert-butyl, n-pentyl, iso-pentyl, n-hexyl, iso-hexyl,

5,530,037

5

n-heptyl, iso-heptyl, n-octyl, n-nonyl, allyl, methoxyethyl,

ethoxyethyl, 3-methoxybutyl and methoxyisopropyl

cyanoacrylate esters.

The preferred monomers are n-butyl, iso-butyl and sec-

butyl cyanoacrylates because of their well known ability to

bond tissue, bone tendons, etc. Other cyanoacrylate esters

such as methyl, ethyl, n-propyl, n-hexyl, n-heptyl, n-octyl

can also be used in such applications but suffer from certain

disadvantages; e.g. methyl, ethyl and n-propyl cyanoacry-

lates have less satisfactory spreadibility on wound areas and

tend to induce localised inflammation. The higher homo-

logues are well tolerated by the tissues but they are slower

curing, give weaker bond strengths and are generally more

difficult to synthesise on a commercial basis. n-Butyl

cyanoacrylate is preferred for the compositions of this

invention.

The preferred method of the invention involves firstly the

manufacture of an alkyl cyanoacrylate adhesive monomer,

e.g. n-butyl cyanoacrylate, to a high and reproducible state

of purity using the Knoevenagel reaction between the cor-

responding alkyl cyanoacetate and paraforrnaldehyde fol-

lowed by pyrolysis and distillation to remove process con-

taminants. Anionic stabilizers, free-radical stabilizers, and

optionally thickeners, dyes, thixotropic agents, etc. are

added as required. The adhesive formulations are then

packed into suitable bottles, tubes, vials etc. The filled

bottles are then sealed in metal foil (e.g. aluminium foil)

pouches and subjected to gamma irradiation with a dose of

25 kGy under conventional conditions i.e. at room tempera-

ture. Following this treatment the adhesives and untreated

controls are fully assayed and evaluated for bonding per-

formance, viscosity, shelf life and especially any chemical

changes which may have occurred during the irradiation

stage.

A range of alternative anti-oxidants were evaluated for

their ability to stabilize n-butyl cyanoacrylate under normal

conditions (see Example No. 3) and after gamma irradiation

treatment (see Example No. 4). From examination of these

findings on the basis of solubility, accelerated stability,

condition after irradiation and toxicity considerations, it was

found that butylated hydroxyanisole (BHA) was most suit-

able. During the irradiation treatment approximately 900

ppm of BHA is degraded with the formation of a number of

derivatives. These have been identified and none are deemed

to be harmful (Ishizaki et al., Shokuhin Eiseigaku Zasshi,

16(4), 230-3). BHA is a well known pharmacopoieal sub-

stance which is widely used as an anti-oxidant in foods and

medicines and poses no significant toxicological hazard. The

useful concentrations of BHA needed for the compositions

of this invention are usually in the range 1000-5000 ppm.

Variations may occur in the stability of the raw cyanoacry-

late monomer from batch to batch, and levels of the anti-

oxidant may be adjusted accordingly. Preferred concentra-

tions are in the range 1500-3500 ppm, particularly above

2000 ppm. At levels less than 1000 ppm the adhesive may

solidify or thicken excessively during radiation treatment

due to the degradiation of 900 ppm as discussed above. At

levels greater than 5000 ppm there is no additional benefit in

the stabilizing efi'ect.

Another preferred antioxidant is butyl hydroxy toluene

(BHT, or 4-methyl-2,6-di-tert-butylphenol) which is also a

well known antioxidant for food and therefore is non-toxic.

However it needs to be used in larger amounts than BHA e. g.

more than 2000 ppm and particularly above 2500 ppm.

Other anti-oxidants which may be used include methyl

hydroquinone, catechol, tert-butyl hydroquinone, 4—tert-bu-

toxyphenol, 4-ethoxyphenol, 3-methoxyphenol, 2-tert-bu-

10

20

25

30

35

40

45

50

55

60

65

6

tyl-4-methoxyphenol, and 2,2-methylene-bis-(4—methyl—6-

tert-butylphenol). These antioxidants may be used in

different concentrations from BHA but generally in the

range 500 to 10,000 ppm. The appropriate concentration can

be determined by testing along the lines described below.

Known anionic (acid) stabilizers for cyanoacrylate adhe-

sives include Sulphur Dioxide, Sulphonic Acids, Sulphuric

Acid, Sulphur Trioxide, Phosphorous Acids, Carboxylic

Acids, Picric Acid, Boron Trifluoride, BF3-ether complexes,

Citric Acid, Hydrofiuoric Acid, Tin (IV) Chloride, Iron (IH)

Chloride, and mixtures of two or more thereof.

Sulphur dioxide is particularly well known as a satisfac-

tory stabilizer for cyanoacrylate adhesives under normal

conditions of storage and use. Sulphur dioxide was also

found to be a satisfactory anionic stabilizer during gamma

irradiation treatment (EXAMPLE 6). The fate of sulphur

dioxide during gamma irradiation was also investigated. It

was found that all the sulphur dioxide remaining in the

adhesive after irradiation was in the form of sulphuric acid.

A proportion of the stabilizer was also found to be consumed

during the treatment as it acted in its normal role as a

polymerisation inhibitor (see Example No 6). The initial

concentrations of sulphur dioxide needed to stabilize the

adhesive compositions of this invention are in the range

20-150 ppm. Preferred concentrations are in the range

40—l20 ppm. At levels less than 20 ppm the adhesives may

solidify or thicken excessively during irradiation or there

may be insuflicient sulphur dioxide remaining to give a

useful shelf-life after irradiation. The composition after

irradiation should preferably contain sulphuric acid in an

amount equivalent to at least 16 ppm of S02. At levels

higher than 150 ppm the cure speed and general perfor-

mance of the adhesive may be adversely impaired (see

Example No 6). Concentration levels for other anionic

stabilizers which are strong acids such as sulphonic acids,

sulphuric acid, BF3 etc. are likely to be in the range of 15 to

150 ppm, and for weaker acids such as carboxylic acids are

likely to be in the range of 25 to 500 ppm.

As already noted, the stability of the raw cyanoacrylate

monomer may vary from batch to batch, and levels of

antioxidant and/or anionic stabilizer may be adjusted

accordingly.

The bond strength and cure speed of the adhesive com-

positions described in this application were determined on

nylon 66 (a polyarnide with a chemical reaction simulating

skin in the context of bonding with cyanoacrylate adhesives)

and pig skin. In each case adequate strengths and cure

speeds were obtained. (see Example No. 6 and Example No.

7).

While cyanoacrylate adhesives can be manufactured to a

very high state of purity this standard may be compromised

to meet the minimum requirements of industrial or consumer

instant adhesives. No such compromise would be acceptable

for adhesives supplied for medical and veterinary applica-

tions. It is therefore desirable that the concentrations of all

impurities should be identified where practical and mini-

rnised by careful control of the manufacturing process. The

adhesive compositions of this invention were assayed for

total purity before and after sterilisation by gamma irradia-

tion at a dose‘ of 25-35 kGy. (Example No 7). The effect of

room temperature and refrigerated ageing on the levels of

these impurities are also included in Example No. 7.

Conventional additives such as thickeners, dyes and

thixotropic agents may be included in the compositions as

required. However for medical or veterinary use care must

be taken to ensure that additives do not introduce toxic

contaminants which survive or are produced by irradiation.

5,530,037

7

Polymethyl methacrylate, for example, may contain a resi-

due of peroxide. Irradiation may itself cause some thicken-

ing of the composition. For medical or veterinary use a

maximum composition viscosity after irradiation of about

200 mPas is desirable, preferably less than 50 mPas, espe-

cially less than 25 mPas.

The adhesive compositions of this invention will retain

their usability in bonding applications for extended periods

at room temperature but are preferably stored under refrig-

eration for maximum shelf-life (see Example No 7). When

packaged in screw-cap bottles or tubes, an outer sealed metal

foil pouch is required to preserve sterility. This barrier also

prevents absorption of atmospheric moisture which can

initiate premature gellation of the adhesive.

The invention discloses a process and a formulation

resulting in a shelf-stable, sterilisable cyanoacrylate adhe-

sive which can be used for the bonding of tissue in medical

and veterinary applications.

The term “ppm” as used in this specification means parts

per million by weight.

All irradiation treatments in the following Examples were

carried out in conventional manner at ambient temperature.

DESCRIPTION OF THE PREFERRED

EMBODIMENTS

EXAMPLE 1

(Comparative)

A batch of n-Butylcyanoacrylate (BCA) was distilled

under. reduced pressure of 1 mg Hg. The distillate was

collected in a receiving vessel containing a concentrated

solution of sulphur dioxide (S02) in a small volume of

previously purified BCA monomer. The yield of distillate

was weighed and the concentration of S02 adjusted to

0.0lO0% (100 ppm).

This stabilized control BCA monomer was then divided

into ainumber of parts. To these parts was added hydro-

quinone (free radical stabilizer) to give the following series

of samples containing the stated concentrations of hydro-

quinone (HQ).

Sample A 0.05% (500 ppm) HQ

Sample B 0.l406% (1406 ppm) HO

Sample C 0.1580% (1580 ppm) HQ

Sample D 0,1714% (1714 ppm) HQ

Sample E 0.2560% (2560 ppm) HQ

Sample F 0.2574% (2574 ppm) HQ

Portions of sample A to F were packed into small plastic

bottles with screw cap closure. Each bottle was enclosed in

an aluminium foil sachet which was heat sealed. The sachets

and contents were then subjected to a gamma irradiation

treatment, using a cobalt 60 source, with a dose of 25

Kilogray (kGy).

After treatment the samples were removed from the

sachets and examined visually. Sample A was found to have

solidified. Samples B to F inclusive were low viscosity on

inspection and the HQ content was assayed by the HPLC

technique. The HQ concentrations before and after irradia-

tion were as follows:

5

10

20

25

30

35

40

45

50

55

60

65

8

TABLE 1

HQ (ppm)

Sample Ref. Before Irradiation After Irradiation

A 500 Solidified

B 1406 812

C 1580 988

D 1714 953

E 2560 1782

F 2574 1857

The results show a reduction in HQ concentration fol-

lowing gamma irradiation.

EXAMPLE 2

(Comparative)

A sample of BCA containing 53 ppm S02 and 2983 ppm

HQ was prepared as described in Example 1. A portion of the

sample was subjected to a gamma irradiation dose of 25 kGy

under the conditions described in Example 1.

Both the untreated control and the irradiated sample were

assayed to determine if any cherrrical or physical changes

had occurred during the treatment. Results of the assay are

in TABLE 2.

TABLE 2

Untreated Control Irradiated

HQ (ppm) 2983 2076

S02 (ppm) 53 ND

H2SO4 (ppm) ND 60

1,4-Benzoquinone ND 552

n—Butylcyanoacetate (%) 0.20 0.20

Viscosity (rnPaS) 2.4 7.4

The detectable chemical and physical changes in the BCA

composition following irradiation can be summarized as

follows:

(a) Approximately 25% of the hydroquinone was con-

verted to 1,4-benzoquinone.

(b) All the S02 was converted to sulphuric acid with 13

ppm of S02 being consumed.

(c) The viscosity of the BCA monomer increased from 2.4

to 7.4 mPaS.

EXAMPLE 3

(Stability Tests Without Irradiation)

A batch of BCA monomer was prepared as in Example 1

and stabilized with 100 ppm S02. No free radical stabilizer

was added at this stage.

The batch of S02 stabilized BCA monomer was then

sub-divided into a number of parts to each of which was

added a known antioxidant material at a concentration of

0.54. These were mixed at room temperature and all dis-

solved readily in BCA monomer except 4-tert-butoxyphe-

nol. This material had poor solubility even after mixing and

heating for an extended period.

The efliciency of the antioxidants to act as free radical

stabilizer in BCA was assessed by aging small samples of

each antioxidant solution in corked glass tubes at 80° C. and

55° C. (in air circulating ovens). The time for gellation or

5,530,037

9

solidification to occur was determined by daily inspection.

The Gel Time results are summarized in TABLE 3.

TABLE 3

Antioxidant Gel Time (Days)

(0.5% in BCA) 80° C. 55° C.

Butyrated Hydroxy Anisole 18-19 83-89

Butylated Hydroxy Toluene 15-18 83-89

Methyl Hydroquinone 19-20 90-97

Catechol 20-22 104-108

tert—Buty1hydroquinone 4-7 89-90

4-t_eg-Butoxyphenol 1-3 10-12

4-Ethoxyphenol 19-20 90-92

3-Methoxyphenol 10-11 83-89

2-tert—Butyl-4—methoxyphenol 18-19 83-89

Hydroquinone 24-25 104-108

The above results, under accelerated conditions, predict

with a few exceptions, that most of the antioxidants evalu-

ated would be elfective free-radical stabilizers for BCA. The

results also confirm that Hydroquinone is most effective in

this regard. It is widely used to stabilize cyanoacrylate

adhesives for industrial and household use. However it is

unsuitable for use in a composition for irradiation for the

reasons shown in Example 2.

EXAMPLE 4

A batch of BCA monomer was prepared, free of antioxi-

dants, by vacuum distillation at 1 mg Hg. Distillation of

631.1 g of relatively impure BCA gave 436 g of purified

material. This was collected in a receiver containing suffi-

cient SO2 concentrate to give a final concentration of 100

ppm S02.

Solutions of various antioxidants were prepared in above

BCA monomer at concentrations between 1000 ppm and

10,000 ppm. Details of the test solutions are in TABLE 4.

Samples of each test solution were packed in small

polyethylene bottles with screw-cap closures which were

overwrapped individually in sealed aluminium foil pouches.

The packaged samples were treated by gamma irradiation at

a dose of 28.53 kGy. The viscosity of each test solution was

determined before and after irradiation. The results are

summarized below in TABLE 4.

TABLE 4

VISCOSITY

mPas

TEST SOLUTION DETAILS Before After

Ref. Conc. Irradi- Irradi-

No. ANTIOXIDANT ppm ation ation

1 2,2‘-methylenebis(4-methyl— 2490 3.4 Gelled

6-tert—butylpheno1)

2 2,2'-methylenebis(4—methy1- 4970 3.4 Soft

6-tert-butylphenol) Gel

3 2,2'—methy1enebis(4-metl1yl— 10000 3.4 267.0

6-tert~buty1phenol)

4 Catechol 5000 3.4 9.9

5 t—Butylhydroquinone 50()0 3.4 3.4

6 4-Ethoxypbenol 5000 3.4 14.1

7 3-Methoxyphenol 50()0 3.4 Gelled

8 Butylated hydroxyanisole 10()0 3.4 Gelled

9 Butylated hydroxyanisole 2500 3.4 4.9

10 Butylated hydroxytoluene 1500 3.4 Gelled

11 Methyl hydroquinone 1500 3.4 Soft

gel

20

25

30

35

40

45

50

55

60

65

10

TABLE 4-continued

VISCOSITY

mPas

TEST SOLUTION DETAILS Before After

Ref. Conc. Irradi- Irradi-

No. ANTIOXIDANT ppm ation ation

12 Hydroquinone 1500 3.4 17.8

The above trials demonstrate that selection of both the

type and concentration of antioxidant is necessary to obtain

an efiicient free radical stabilizer for BCA to prevent gella-

tion during gamma irradiation treatment. Butylated

hydroxyanisole (BHA) at a concentration substantially

above 1000 ppm before irradiation is the most suitable, with

the preferred level being 2500 ppm. For butylated hydroxy-

toluene (BHT) a higher concentration is needed than for

BHA. Hydroquinone is effective as a stabilizer at relatively

low levels. Derivatives of hydroquinone which do not have

toxic break-down products may be selected by tests as

described above.

EXAMPLE 5

A batch of Ethyl Cyanoacrylate monomer was prepared

using the techniques described in Example 1 and used as the

basis of formulations A and B which had the following

compositions:

A. Ethyl cyanoacrylate stabilized with 20 ppm Boron

Trifluoride and 5000 ppm Hydroquinone and thickened

to a viscosity of 30 mPas by addition of 5% by weight

of finely powdered polymethylmethacrylate.

B. The same as formulation A above but with 20 ppm S02

added.

Samples from each formulation were packaged in small

polyethylene bottles with screw-cap closures and subjected

to a sterilization process consisting of gamma irradiation

from a Cobalt 60 source at a dose of 25 kilogray (kGy). After

sterilization treatment the samples were examined visually

and no significant change in viscosity was observed in either

case. This example illustrates the successful sterilization of

a cyanoacrylate adhesive containing thickener and anionic

stabilizers alone or in combination and in conjunction with

an effective concentration of a free radical stabilizer.

EXAMPLE 6

A batch of BCA monomer was distilled as in Example i

and stabilized with various levels of S02 and BHA as

detailed below in Table 5.

TABLE 5

BCA Composition

Ref. BHA (ppm) S02 (ppm)

1 3034 31

2 2997 42

3 3189 50.4

4 3289 66.7

5 3267 79.8

6 3229 94

Samples of each liquid composition were packed in

polyethylene bottles, overwrapped with sealed aluminium

foil pouches and treated with gamma irradiation at a dosage

of 25 kGy.

5,530,037

11

The irradiated samples and untreated controls were tested

as follows:

(a) BHA assay by HPLC.

(b) S02 or 112804 by potentiometric Titration.

5

(c) Viscosity by Cannon Fenske capillary viscometer

method.

(d) Bond strength on Nylon 66 lapshears of dimensions

100 mm x 25 mm X 2 mm with an overlap bonded area

of 312.5 ml. The bonds were clamped and cured for

12

The tests included assays for BHA, S02, viscosity and

bond strength on Nylon 66 and the test methods are

described in Example No. 7. Total purity as BCA was

determined by gas chrornotography.

10

24 hours at RT. The bond strength was determined

using a Tensile testing machine at a crosshead speed of

2 mrn/min.

(e) Time to gel when aged in glass test tubes at 82° C. in

an air circulating oven. 15

(1') Time to gel when aged in a polyethylene bottle at 55°

C. in an air circulating oven.

See Test results before irradiation (Table 6A) and after

irradiation (Table 6B).

TABLE 6A

(Before Irradiation)

Bond Gel Gel

BCA Strength Time at Time at

Composition BHA S02 Viscosity Nylon 66 82° C. 55° C.

Ref. No. (ppm) (ppm) (mPaS) (daNcm’z) (days) (days)

1 3034 31 13.7 25 10+ 50+

2 2997 42 14.2 27 10+ 50+

3 3189 50.4 14.5 32 10+ 50+

4 3289 66.7 14.5 26 10+ 50+

5 3267 79.8 14.5 24 10+ 50+

6 3229 94 14.5 24 10+ 50+

TABLE 6B

__

(After Irradiation)

Bond Gel Gel

BCA Strength Time at Time at

Composition BHA S02 Viscosity Nylon 66 82° C. 55° C.

Ref. No. (ppm) (ppm) (mPaS) (daNcm‘2) (days) (days)

1 1995 2 9.4 21 1.5

Coments go here:

- Log in to post comments