Sealant Composition

Sealant Composition

EP0206707

Folder:

Year:

Abstract:

The invention described herein comprises a two component sealant composition and process fro applying the sa,e for repair of ruptures, holes, cracks, etc., in hoses, pipes, tires, etc. The first component is alpha-cyanoacrylate glue which is applied as a layer covering the rupture or crack and after a very short period the second component, a powder, is applied to the surface of the alpha-cyanoacrylate. This second component comprises a polymerization initiator having hydroxyl and/or carboxylate groups therein, such as carbohydrates, i.e., saccharides, etc., hydrolyzed polyvinylacetate, etc. A particularly preferred initiator is alginate.

Type of document:

Language:

1

<

EP 0 206 707

Européisches Patentamt

0’ European Patent Office

Office européen des brevets

® Publication number:

0 206 707

A1

® EUROPEAN PATENT APPLICATION

® Application number: 86304597.?

@ Date of filing: 16.06.86

69 Priority: 21.06.85 us 747326

® Date of publication of application: 30.12.86

Bulletin 86/52 —

® Designated Contracting States: AT BE CH DE FR GB IT Li

LU NL SE

@ Sealant composition.

@ The invention described herein comprises a two com-

ponent sealant composition and process for applying the same

for repair of ruptures, holes, cracks, etc., in hoses, pipes, tires,

etc. The first component is an alpha—cyanoacrylate glue which

is applied as a layer covering the rupture or crack and after a

very short period the second component, a powder, is applied

to the surface of the a|pha—cyanoacrylate. This second com-

ponent comprises a polymerization initiator having hydroxyl

and/or carboxylate groups therein, such as carbohydrates, i.e.,

saccharides, etc., hydrolyzed polyvinylacetate, etc. A par-

ticularly preferred initiator is alginate.

ACTOFIUM AG

@ lnt.C|.‘: C 09J 3/14, C 08 F 222/O0,

CO9K 3/12

® Applicant: Jlminez, Rene, 9201 Tudor Dr. Suite 215,

Tampa Florida 33615 (US)

Inventor: Jiminez, Rene, 9201 Tudor Dr. Suite 215,

Tampa Florida 33615 (US)

Representative: Abbie, Andrew Kenneth et al, A.A.

THORNTON & CO. Northumberland House 303/306 High

Holbom, London, WC1V 7LE (GB)

0206707

SEALANT COMPOSITION

Field of the Invention

This invention relates to a new sealant composition. l\1oro

specifically it relates to a sealant composition whichpcan be easily applied

to seal punctures and ruptures in various materials and is cured in a

short time to make a very effective seal. Still more specifically, this

invention relates to the application of a cyanoacrylate to the puncture or

rupture and shortly thereafter applying a material, ' preferably an

powdered solid material having hydroxyl and/or carboxylatefl 5-mugs

therein. ~

Description of the Prior Art

Anyone who has had an automobile radiator or heater hose rupture

when some distance from a service station or when service stations are

closed can appreciate the need and desirability of a sealant that can be

easily and quickly applied to repair the rupture. Moreover there are

_ any number of other types of ruptures, holes, cracks, etc. in various

other articles that show a need for such a sealant.

Various compositions advertised as sealants for such purposes have

proved very unsatisfactory. Even such products as the fast setting

super glues. while very ‘competent for adhering; and gluing pieces

together have not been found suitable as a sealant to repair ruptures.

flrbreaks and other types of openings in hoses. pipes. etc. Since the

addition of activators and other materials which ‘might? have fast

I, ci';os"slinking and other hardening effects when incorporated within the

cyanoacrylate would only serve to effect premature setting. this makes

such additions highly impractical.

I/'

‘ ‘V I

, .

.....»..u..‘........... ..‘w....... .;......................_..........‘......_..l.‘.

0206707

. _ -_. _

U. S. Patent No. 3,836,377 describes the method of priming-

isurfaces of pieces to improve adhesion by means of alpha-cyanoacrylate

with compounds containing a

\ I I

N-C = S or a —N = C-S- group

These dithiocarbamates, sulfenamides, etc. may also be incorporated

directly into the cyanoacrylate to improve the cure. This latter fact

shows these particular compounds cannot be as active as the accelerator

or initiator of the present invention. T

U; s. Patent No. 4,180,913 describes a dental material comprising

an alpha-cyanoacrylate containing as filler a silica power coated with In

......—...

solid having a weak catalytic activity for the alpha-cyanoacry-late. After

the composition is applied to the tooth a "setter" composition comprising

a basic amine compound having a strong catalytic activity to the‘

alpha—cyanoacrylate is applied to cure the dental material. The curing

promoters or "setters" are tertiary amines such as N,N—dimethyl-p-

I

toluidine, N,N—dimethylamiline, etc.‘

No systems have been found in which solid compounds containing

hydroxyl or carboicylate H ' groups initiate or activate cure from the

outer surface of a cyanoacrylate layer.

SUMMARY GF THE INVENTION .

E In accordance with the present invention it has been found that a

two component sealant for repairing ruptures, breaks, tears and other

openings in various devices comprises a first ‘component of an

alpha-cyanoacrylate in which the acrylate ester group has 1-10 carbon

atoms, and as a second component an initiator having hydroxyl andlor

carboxylate groups therein. In applying the sealant to the

rupture, etc. , the cyanoacrylate is applied to the rupture, etc. and to

an area around the rupture, preferably after the surrounding surface

has been cleaned and dried by wiping or by other suitable means. After

.‘ ............

the cyanoacrylate has been allowed to set for a very short period

0206707

_sufficient of the activator, preferably in a powdered, solid condition. is

i applied over the surface of the cyanoacrylate,sufficient being used to

1

5

i

cover the area above the rupture and the surrounding area.

While applicant does not wish to rely upon any particular mechanism

or explanation of what reaction occurs during the hardening or sealing

operation, it is believed that the activator or initiator promotes ‘a chain

reaction at the surface of the cyanoacrylate layer and the chain reaction

proceeds downward through the thickness of the cyanoacrylate and

"effects hardening, possibly by further propagation of polymer molecules

in the cyanoacrylate. In any case. the cyanoacrylate is hardened to’

effect the sealant functionf -

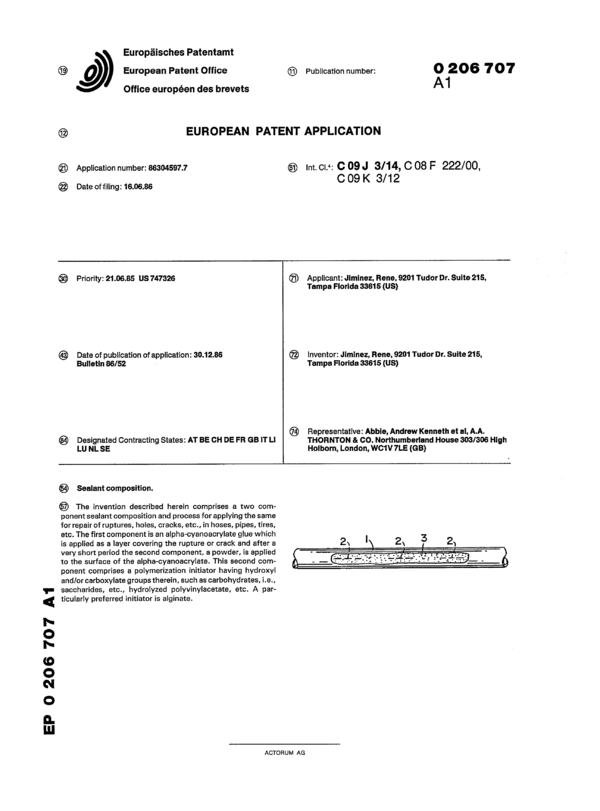

The accompanying drawings illustrate the manner in which the

sealing power of the sealant of this invention can be tested. .

Fig. 1 shows side a elevational view of a sectiongof hose or tubing ' V

which has a single slit parallel to the axis_of the hose.

Fig. 2 shows a side eleyational view of another section of hose or

tubing with three slits parallel to the "axis of the hose.

Fig. 3 is a schematic view of equipment for controlling the pressure

and temperature for sealant testing.

The initiators‘ which are‘ useful in the practice of this invention to

effect curing through the layer of cyanoacrylate by external application

to the surface of the cyanoacrylate include a wide variety of materials

containing one or more hydroxyl and/or carboxylate groups. This

material is preferably a powdered solid material so that it will stay

positioned on the surface of the cyanoacrylate. ‘Excess material may

subsequently be brushed away after the curing or hardening is

completed. This material may be diluted with an inert material. such as

an inactive powder. provided the concentration of active material is

sufficient to provide the desired curing activity.

Preferred materials include but are not limited to carbohydrates.

particularly saccharides, namely mono-saccharides and poly—sacchaz-ides

and other monomeric and polymeric materials containing hydroxyl and/or

carboxylate groups. Polysaccharides such as alginates, xnnthan gum.

'/

0206707

-4-

cellulose, various types of starch including various types of flour, gum-

Ygum, gum arabic, pectin, cellulose, Lambda carrageenan, locust bean

Egum, sucrose, heparin, _ glycogen, amylase, amylopectin, maltose",

gisomaltose, ‘chitin, etc. Suitable monosaccharidcs include glucose,

fructose, aldose, aldonic acid, aldaric acid, alditol, uronic acid, tartaric

acid, glucosides, etc.

Suitable polymeric materials containing hydroxyl or carboxylate

groups also include polyvinylalcohol, hydrolyzed polyvinylacetatc

advantageously containing less than 75% and preferably containing less

-than 25% acetate groups, phenol-formaldehyde polymers having methylol

CH OH

groups (-6611:-CHZOH) , etc. Monomeric materials which are suitable

\ u

include the dimethylol ethers of cycloh_exane' dimethanol and

.......-........«

bisphenol, etc. , metal salts, such_ as the sodium salts of fumaric acid,

itaconic "acid, succinic acid, Alauric acid, oleic acid, benzoic acid,

phenylacetic acid, cyclohexanecarboxylic , acid, polymethacrylic acid,

poly(ac1-ylic acid) , etc. , monosodium salts, etc. of dibasic acids such as

succinic acid’, maleic acid, terephthalic acid, etc. The corresponding

ammonium and substituted ammonium salts of these same acids are also

suitable. Inorganic materials having hydroxyl or carboxylate groups

such as diatomaceo'us' earth are likewise suitable as initiators for the

practice of this invetion. H

I The expression "carboxylate" is used herein to designate various

metal and ammonium salts of carboxylic acids. While any convenient metal

an be used, the preferred metals are alkali metal and alkaline earth

metals, preferably sodium. ‘potassium, lithium, calcium, magnesium.

barium, etc. The ammonium salts include various substituted ammonium

compounds, such as the trimethyl ammonium, dimethyl ammonium.

monomethyl ammonium , triethyl ammonium , phenyl ammonium ,

diphenlyammonium, triphenyl ammonium. .cyclohexy1 ammonium,

dicyclohexyl ‘ammonium, etc. As will be noted from the above illustrative

compounds, the hydroxyl group is attached to an aliphatic carbon atom.

The alpha-cyanoacrylates useful in the practice of this invention are

= preferably liquid monomers having the formula H2C=C(CN)—COOR wherein

0206.707

.. 5 _

R is an aliphatic, aromatic (preferably benzoid aromatic) or cylcoalphatic

hydrocarbon. having from 1 to 10 carbon atoms, preferably alkyl. for

example. methyl, ethyl, propyl, isopropyl, butyl, isobutyl, amyl.

pentyl, hexyl, heptyl, ethylhexyl, octyl. nonyl and decyl. From among

these, it is particularly advantageous to employ those wherein R is alkyl

having from 1 to 6 carbon atoms, either straight or branched chain.

The aromatic and cycloalphatic groups may have substituent groups such

:as an alkyl having from 1 to 10 carbon atoms. The substituents are

are lower alkoxy having from 1 to 4 carbon atoms [ethoxyethyl—a1pha-

cyanoacrylate] and halo, e.g., chloro and fluoro [trifluoro-isopropyl-

I

} unlimited as long as the monomers are liquid. Illustrative substituents

alpha-cyanoacrylate]. In the trifluoro-isopropyl group the -three fluorine

atoms are preferably bonded to the same carbon. atom.- In‘additiong, R

can also be, for example,’ cyclohexyl, methylcyclohexyl. phenyl, tolyl.

chlorophenyl. propargyl, butynyl, bu,tenyl or allyl. The sole

restrictions ‘on R are that the monomer must be liquid at room

temperature (20°C) and atmospheric pressure and a carbon atom of R

must be directly bound to the 'l-l2C=C(CN)-C0O- group.

These alpha-cyanoacrylate monomers can contain any ‘of the other

compounding ingredients which are normally employed such as viscosity

modifiers, coloring agents. fillers, pigments and the like.

Polymerization inhibitors such as sulfur dioxide may also be

present. In lieu of sulfur dioxide other acidic inhibitors (against anionic

polymerization). such as nitric oxide, nitrous _oxide, carbon ,dioxide,

p-toluene sultbnicacid, hydrogen fluoride. trichloroacetic acid and acetic

anhydride, can be used to stabilize the monomer. Carbon dioxide is

recommended only for monomers wherein R has at least four carbon

atoms. In combination with the acidic inhibitor a free radical inhibitor.

such as hydroquinone. monomethylether of hydroquinone, picric acid and

t-butyl—catechol, pyrocatechold, p-methyoxyphenyl and the like. may be

concurrently employed. The monomethylether of hydroquinone is the

preferred stabilizer against free radical polymerization. Moreover. it

gimparts good color stability to both the monomeric alpha—cyanonm~ylntn

...u '1 w...».A....-...................._........... ,

0206707

_ (3 -

and the polymerized product therefrom. Free radical inhibition may be

obtained with 10 parts of the monomethylether of hydroquinone per

million parts of 1-cyanoacrylic acid ester, in practice from 15 to 200

parts per million are employed.

The free radical anionic

polymerization inhibitor, like the

: polymerization inhibitor, is normally added during the processing of the

alpha-cyanoacrylate ester. Hence, a free radical polymerization inhibitor

é is generally introduced into the distillation vessel and the receiver to

stabilize the ester in the synthesis thereof. As a result, commercially

available alpha-cyanoacrylate esters may already contain a certain amount

of a conventional free radical polymerization inhibitor such as those

mentioned hereinabove. — . ' i

There may also be present in the adhesive compositions of this

invention various other optional ingredients including, for example,

plasticizers and thickeners. Plasticizers improve the aging

characteristics of the cured bonds by lessening the brittleness thereof.

For the best performance the amount of plasticizer to be used should

not exceed 20% by weight of the total composition. Suitable plasticizers

include monofunctional and difunctional aliphatic esters of acids having I

to 10 carbon atoms such as ,' for example, dimethyl octyl sebacatc and

esters of malonic acid, difunctional aromatic esters, phosphates and

phosphonates. Thickeners. which may be used in amounts of up to 25%

by weight, depending in part on their degree of fluidity at room

temperature, serve to increase the viscosity ‘of the adhesives. so that

they may be more easily applied. Among the suitable thickeners for this

purpose are included, for example, polymeric alkyl alpha—cyanoacrylatcs,

cellulose esters including cellulose acetate butyrate, acrylate resins such

as poly(methyl methacrylate) and poly(ethy1 methacrylate) , and

po1y(vinyl alkyl ethers) such as poly(vinyJ1 methyl ether).

. .....,... ....._.._...._....___.._...._.. .

.... .....-...._......—.—.—.........__ .

0206707

.— 7 ~

SPECIFIC EMBODIMENT OF THE INVENTION

In order to perform various tests on the efficiency of the sealant

composition of this invention. the equipment shown in the drawings is

used .

Fig. 1 shows a section of garden hose. Hose 1 has a slit 2 having

a slit length of 1 inch running parallel to the axis of the hose. This

slit is covered with a layer of alpha-cyanoncrylate 3 (commercial type

Super Glue as marketed by Super Glue Corp.) with the layer of glue

extending over an area of the tube adjacent to the slit.

Fig. 2 shows a section of lleoprene rubber hose having three such

slits 1 with a spacing of 1 inch between adjacent slits in the tube with a

layer of alpha-cyanoacrylate 3 covering the three slits and adjacent area.

Fig. 3 shows equipment for testing such tubing on which the layer

has been cured by covering the alpha-cyanoacrylate layer with "the

powdered initiator (not shown) to effect, curing and hardening of the

cyanoacrylate to function as a sealant. Tank 6 is more than half filled

with water 7. Pump 5 positioned between pipe or tubing 8 and pipe or

tubing 8' is supported by pl'ate 13'. Hose 1 is fastened by clamps 4 ~to

join pipe 8' with pipe 8" which latter pipe is supported on plate 13.

Plates 13 and 13' rest on supporting means which are not shown. Valve

10 is positioned on pipe 8" to control the flow of water therethrough.

Catch pipe 11 catches water flowing out of pipe 8" and returns it to

tank 6.’ Heater 12 is used to heat the water to desired temperatures so

that the repaired hose can be operated under temperature and pressure

conditions that the hose may be exposed to in actual use.

EXAMPLE I

The radiator hose of a 1970 Dodge automobile is punched with a 1/8

inch awl to make an opening therein. This opening and the surrounding

area are covered with an alpha-cyanoacrylate (Super Glue) and then a

layer of dental alginate is applied over the Super Glue layer. Then the

automobile is operated under normal conditions with the water

temperature at 130°C. After 15 hours the radiator hose is still operating

:~ntis:f.-u*tox'il_V. "i‘h:*sv results nrv i.-ihulntoci hr-low in ’l‘.=xl,-‘.- l.

A m. ,,‘~.4 ....-can-..

..‘ w.4*‘......l.-. . l.

0206707

_ 3 _ V

TABLE I

Maximum Water

’ .= Curing Applied Temp . Test

3 Agent Pressure °C Period Remarks

: 7Alg'inater 16 psi 130 >15 hrs. Radiator hose on car

EXAMPLE I:

' In a first test a hole is punched into a Neoprene fuel line hose of

53/ 8 inch inside diameter with a 1/8 inch awl. An alpha—cyanoacrylate

S .

§(Super Glue) is applied over the hole so as to cover an area extending

at least 1/4 inch in all directions beyond the hole. The curing agent

(initiator) is applied immediately to cover the entire surface of the

cyanoacrylate. The conditions of testing and the results are given below

in Table II. In order to raise the hose to the desire temperature the

water in the tank 6 is heated to the desired temperature. and pumped

through hose 1 until well heated. Then valve 10 is partially closed to

E

3 maintain the desired pressure.

. .. TABLE I ’

5 Maximum Water Failure‘

Curing Applied ‘Temp . Time

' Aggnt Pressure °C ' Remarks

Pectin (citrus) an psi 1011 >15 min.* Slow cure.(5 min.)

Oxidized corn ' ' '

starch 60 psi 100 >15 min.

Lambda Carra— _

geenan 50 psi 90 >15 min. Rapid cure

" a" I" 45 psi 25 >15 min. Rapid cure

Pillsbury all

purpose flour 20 psi 25 >15 min.

.

Acid Converted

Starch 20 psi 25 >15 min. Slow cure (5 min.)

* >This designation means that the test was successfully operated for 15

minutes and then the test was discontinued.

0206707

-9-

EXAMPLE‘ III

In a vinyl garden hose of 3/8 inch inside diameter a single slit one

inch long is cut as shown in Fig. 1. This slit together with the adjacent

:' area extending about 1/4 inch in all directions around the slit is covered.‘

with a layer of alpha—cyanoacrylate (Super Glue). Shortly thereafter the

powdered activator is applied to cover completely the layer of

cyanoacrylate. Then after about 5 minutes of curing, tests as described

above in Example ll are performed with the water at about 23°C and

about 60 psi. The specific curing agents. conditions and duration of

tests are reported below in Table II.

p 0

TABLE 1:

Maximum Water Failure

Curing Applied Temp. Time . ,

Agent Pressure °C (min . ) Remarks

Lambda

Carrangeenan 60 psi 23 715*

Pectin (citrus) 60 psi - 23 - >15 0 Requires 3 min.

—- « ' - to cure .

Locust bean _ - -

gum 60 psi - 23 >15

Alginate 60 psi 23 >15

Xanthum gum 60_ps_i 23 >15

* - The designation >15 means that there is no failure and the test is

discontinued after 15 minutes.

. ......_.._...................‘......._........._._;......_.........4___..._._.._;.._..a,._.__..__.....__._._....._._..___.._....._.

:

E

:

0206707

.. 10 -

EXAMPLE IV

: In a Neoprene fuel line hose having an inside diameter of 3/8 inch.

three slits each one inch long and one inch apart as shown in Fig. 2 are

{cut into the hose as shown in Fig. 2. These slits together with the

1

isdjacent area extending about at least 1/4 inch in all directions around

the slits. is covered with a layer of alpha-cyanoaerylate (Super Glue).

Shortly thereafter the powdered activator is applied to cover completely

the layer of Super Glue. Then after at least 5 minutes of curing. tests

are performed as described in Example II with the water at about 22°C

and about 50 psi _pressure. The specific curing agent. the pressure

applied, the water temperature and duration of tests ‘are reported below

in Table III.

TABLE IV

Maximum l'la‘ter Failure

Curing Applied Temp . Time

Agent Pressure °C (min.) . Remarks

Control‘ 50 psi i 22 5 Cure time 30 min.

Alginate 50 psi 22 >15"

Xanthate gum 50 psi 22 >15

Lambda u

Curr a geenana 50 psi 22 2715

Dextran 50 psi 22 >15 Slow cure 5 min.

Cellulose (100 .

micro fibers) 50_psi 22 715 Slow cure 5 min.

Diatomaceous ' . -

earth 50 psi 22 715

Pectin (citrus) 50 psi 22 715 — .

Guar Gum b 50 psi 22 715

Gum arable 50 psi 22 >15 Slow cure -

Na bicarb 50 psi 23 >15 Very sensitive to cracking

PVA-12 50 psi 23 >15 Ruptured when raised to 80

psi

PVA-25 50-80 psi 23 v 715

Oxidized

Corn starch‘“50 psi 22 >15 Slow cure

" " 50 psi 22 1 Slow cure

" " 50 psi ' 22 1 Slow cure

‘ Control is run only with cyanoacrylate layer and no powder applied.

“‘ The designation 15 means that there is no failure and the test is

discontinued after 15 minutes.

a - Average of 6 runs with only one failure.

b - Average of 3 runs. Soaking time 2-3. minutes unless otherwise

indicated.

. . .-_ -..__... .

_‘_ ._,j._._..__......_...._.... ......... .. ....

0206707

-11..

"‘ — Oxidized corn starch is a mixture of amylose and amylpectin which

has been treated with Na0Cl at pH 8—l0 ut 21—38°C. This oxidizes a

number of the OH groups to aldehyde, ketone and COOH groups with

concomitant cleavage of the glucoside bonds. Apparently this has a

deleterious effect since only one out of three oftlieae tests is

successful. However in Example ll this same material is used

successfully with a smaller opening.

EXAMPLE V

The procedure of Example IV is repeated except that during the

testing the water temperature is raised to 90°C and the hose is raised to

approximately that temperature. After applying the alpha-cyanoacrylate

over the slits and at least 1/2 inch in each direction beyond the slits.

the powder is applied over the layer of acrylate and allowed to cure for

at least 5 piinutes before testing. The specific powder, the conditions

and the results are reported below in Table V.

TABLE V

T Maximum Water Failure

Curing Applied Temp. Time

Agent Pressure °C (min . ) Remarks

Alginate‘ 16 psi 90 >15"

Lambda 1

Carr a.geenan 16 psi 90 >15

Lambda - ' .

Carr ageenan 45 psi 90 - Hose begins to balloon

Dextran 16 psi I 90 e 5 0

Dextran 20 psi. 90 . - One rupture*'"'

Dextran 30 psi 90 - One rupture***

Dextran 50 psi 90 - All three rupture

Diatomaceous 0

earth 16 psi 90 >15

Guar Gum 16 psi 0 so . >15

Gum arabic 16 psi 90 >15

PVA-25 35 psi 90 2 out of-3 ruptured

Pectin (citrus) 16 psi 90 >15 Slow cure 5 min.

" Dental type alginate

“' The designation 15 means there is no failure and the test is

discontinued after 15 minutes.

""* - One slit ruptured immediately - other two held. Example IV shows

that dextran is much more effective with water temperature at 22°C even

with 50 psi. .

. . .._....i_......__......-.—..—..—-....._-...——-—..._......;.—a

0206707

-13-

EXAMPLE VI

The procedure of Exampie IV is repeated using "Tygon" tubing

having an inside diameter of 3/8 inch (Tygon is the registered trademark

of Goodrich Chemical Company for its polyvinylchloride tubing).

Maximum Water Failure

Curing Applied Temp . Time

Agent Pressure °C (Min . )

Locust Bean Gum 80 psi 23 15

EXAMPLE VII

A chromium plated copper tube having an inside diameter of 3/8

inch has a 3/32 inch hole drilled therein. This hole is covered with

Super Glue and then with alginate as described above following which

testing in the equipment of Fig. IV’ shows that the sealant withstands a

pressure of 100 psi at 23°C for 15 minutes. — t

' EXAMPLE VIII

The procedure of Example II is repeated a number of times with

similar successful results using as the_a1pha—cyanoacrylate the following

respectively:

(a) A 50-50 mixture of methyl and ethyl alpha-cyanoacrylate;

(b) Butyl alpha-cyanoacrylatez .

(c) Hexyl alpha-cyanoacrylate;

- (d) Phenyl alpha—cyanoac1-ylate; and

(e) Cyclohexyl alpha-cyanoacrylate. ’

EXAMPLE IX

The procedure of Example II is repeated a number of times with

similar successful results using the following ‘respectively as the

initiator:

(a) Polyacrylic acid with 2.5 percent of the carboxylic acid

groups neutralized with Natm.

(b) Polymethacrylic acid with 15 .percent of the carboxylic

acid groups neutralized with KOH.

(c) _Monosodium salt of succinic acid.

(d) Disodium salt of maleic acid.

(e) Monammonium salt of fumaric acid.

(f) Di(trimethl.-immonium) salt of tcrophthnlic acid.

0206707

_ 13 _

The sealant offthis ‘invention can be used to seal openings or

ruptures in any type of material. The only requirement is that the

alpha-cyanoacrylate adheres effectively to the material.

The initiator material may be used in various mixtures with each

other or with inert materials provided there is at least 25%. preferably at

least 50% of the active ingredient. The balance can be of various inert

fillers or less active materials such as finely divided silica. graphite,

etc.

0

While certain features of this invention have been described. in

detail with respect to various embodiments thereof. it will of course be

apparent that other modifications can be mde within the spirit and scope

of this invention and it is not intended to limit 'the invention ' to the

exact details shown above except insofar as they are defined in the

following claims . .

10

15

020

25

0206707

-14-

CLAIMS:

1. A process for applying a sealant comprising the

steps of:

(a) applying a layer of an alpha-cyanoacrylate

over the rupture or opening to be sealed and over the

area adjacent to said rupture or opening, said alpha-it

cyanoacrylate being liquid at 20°C and having the formu-

la CH2=C(CN)-COOR wherein R is a hydrocarbon radical

selected from the group consisting of aliphatic, aromatic

and cycloaliphatic hydrocarbon groups of 1-10 carbon

atoms and alkoxy, chloro and fluoro derivatives of said

‘hydrocarbon groups in which alkoxy groups there are 1+4

carbon atoms therein: and

(b) spreading on the said layer of a1phaecyano—

acrylate a layer of a powdered solid having hydroxyl,

a carbonylate or both hydroxyl and carboxylate groups 0'0

therein.

2. A process as claimed in claim 1, in which said h

group is an alkyl group of 1-6 carbon atoms.

3. A process as claimed in claim 2, in which said

powdered solid is a carbohydrate or a saccharide.

. . 0

4. A process as claimed in claim 3, in which said

saccharide is a monosaccharide.or a polysaccharide._ _g

5. A process as claimed in claim 4, in which said poly-

saccharide is an alginate, a starch, pectin, carrageenan

or locust bean gum.

6. A process as claimed in claim l,inwhichsaid powd-

ered solidij;se1ected from the group consisting of a1gin—

ate,pectin,starch,cellulose,locust bean gum, xanthate

gum,dextran,guar gum, gum arabic, Na bicarbonate,poly-

vinylalcohol, a vinylalcohol—vinylacetate copolymer

havingzflzleast 25%viny1alcohol groups therein, sodium

10

15

20

25

30

35

_ 15 -

0206707

bicarbonate, a sodium salt of polyacrylic acid, a sodium

salt of polymcthacrylic acid, an ammonium salt of poly- I

acrylic acid and an ammonium salt of polymethacrylic

acid.

7. A process as claimed in claim 6, in which said alpha-

cyanoacrylate is a methyl ester, an ethyl ester, a ti’

mixture of methyl and ethyl esters, a butyl ester, or

a propyl ester. 0 I _ ; .

8. A process as claimed in any one of the preceding:

claims, in which said alpha—cyanoacrylate contains a T.

polymeflization inhibitor,

9., A process as claimed in claim 3, in which said in— -"'

hibitor is sulfur dioxide.

10. A process as claimed in any one of the precedingif

claims, in which said alpha-cyanoacrflateficontiingiamg

filler. I '

11. A process as claimed in claim 10, in which said

filler is silica.

12. A two-component sealant composition, each componentwgy _

being separately packaged prior to application, which oon;} V4‘

sists essentially as component (a) of an adhesive co@g_“q_{_fi

prising a liquid alpha cyanoacrylate having the formula

CHz=C(CN)—COOR wherein R is a hydrocarbon radical selec-

ted from the group consisting of aliphatic, aromatic and

cycloaliphatic hydrocarbon groups of 1-10 carbon atoms and‘

alkoxy, chloro and fluoro derivatives of said hydrocarbon

groups in which alkoxy groups there are 1-4 carbon atoms

therein; and as component Uo)of2ipowdered solid having 0

hydroxyl, carboxylate or both hydroxylgand carboxylate

therein.

[T10

150

0206707

-16-

13. \ composition as claimed in claim 12, in which said

R group is an alkyl group of 1-6 carbon atoms.

14. A comoosition as claimed in claim l3, in which said

powdered solid is a carbohydrate or a saccharide.

15; A composition as claimed in claim 14, in which ,

said saccharide is a monosaccharide, or a polysaccharide,

16. A composition as claimed ih claim 15, in which said

polysaccharide is an alginate, a starch, pectin,

carrogeenan or locust bean gum.

7

.r.U

«3

,2 K _

uduff

FIG.

F|G.2

F|G.3

3285707

§;’,';;’°‘” Pam EUROPEAN SEARCH REPORT """"°"'°” ""”‘°e’

EP 86 30 4597

DOCUMENTS CONSIDERED TO BE RELEVANT

Citation of document with indication. where appropriate. Relevant CLASSIFICATION OF THE

C-‘£990’? of relevant passages to claim APPLICATION (int, Cl 4)

X

Us-A-4 364 473 (J.P. BOGAERT) 1,2,12

,13 c 09 J 3/14

c 08 F 222/oo

c 09 K 3/12

* Claims; column 2, lines (5-7;

column 1, lines 44-50 *

TECHNICAL FIELDS

SEARCHED (Int. CH )

C 09 J

CO8}?

CO9K

E

THEP'afI°z§E;UE '' V °‘§

Coments go here:

- Log in to post comments