Adhesive Composition

Folder:

Year:

Abstract:

An adhesive composition characterized in that the composition is prepared by subjecting finely divided hydrophobic silica surface-treated with hexamethyldisilazane to a heat treatment under a reduced pressure, subsequently treating the silica with an acid gas, and admixing the resulting silica with an alpha-cyanoacrylate.

Type of document:

Language:

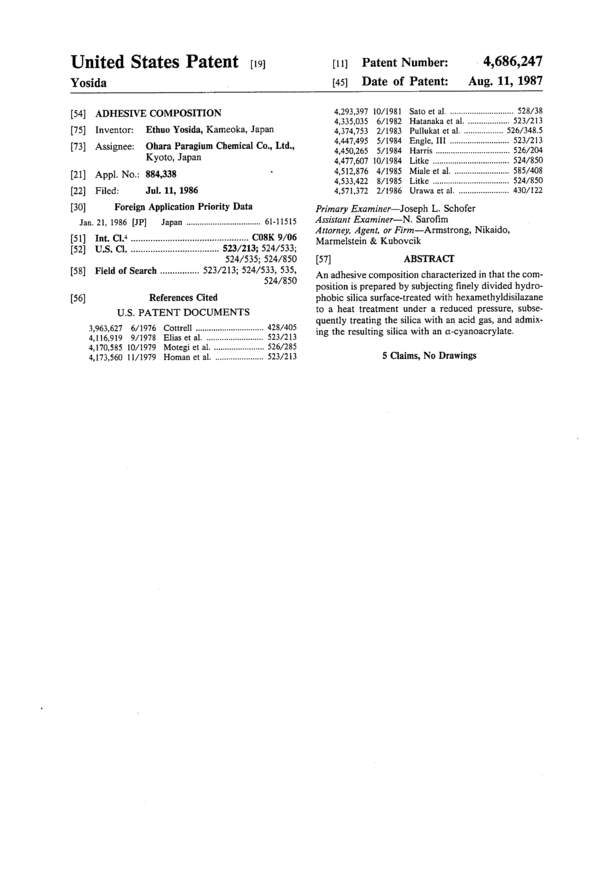

United States Patent [19]

Yosida

1 4,686,247

Aug. 11, 1987

[11] Patent Number:

[45] Date of Patent:

[54] ADHESIVE COMPOSITION

[75] Inventor:

[73] Assignee:

Ethuo Yosida, Kameoka, Japan

Ohara Paragium Chemical Co., Ltd.,

Kyoto, Japan

[21] Appl. No.: 884,338

[22] Filed: Jul. 11, 1986

[30] Foreign Application Priority Data

Jan. 21, 1986 [JP] Japan ........................ .. 61-11515

[51] Int. Cl.‘ . . . . . . . . . . . . . .. C08K 9/06

[52] U.S. C1. .................................. .. 523/213; 524/533;

524/535; 524/850

[58] Field of Search .............. .. 523/213; 524/533, 535,

524/850

[56] References Cited

U.S. PATENT DOCUMENTS

3,963,627 6/1976 Cottrell ............................. .. 428/405

4,116,919 9/1978 Elias et al. ..... .. 523/213

4,170,585 10/1979 Motegi et a1. 526/285

4,173,560 11/1979 Homan et a1. .................... .. 523/213

4,293,397 10/1981 Sato et a1. ........................... .. 528/38

4,335,035 6/1982 Hatanaka et a1. 523/213

4,374,753 2/1983 Pullukat et a1. ..... .. 526/348.5

4,447,495 5/1984 Engle, III . . . . . . . . . . . . . .. 523/213

4,450,265 5/1984 Harris ...... .. 526/204

4,477,607 10/1984 Litke ................................. .. 524/850

4,512,876 4/1985 Miale et a1. .... ................. .. 585/408

4,533,422 8/1985 Litke . . . . . . . . . . . . . . . . . . . . . .. 524/850

4,571,372 2/1986 Urawa et a1. ..................... .. 430/122

Primary Examiner—Joseph L. Schofer

Assistant Examiner—N. Sarofim

Attorney, Agent, or Firm—Armstrong, Nikaido,

Marmelstein & Kubovcik

[57] ABSTRACT

An adhesive composition characterized in that the com-

position is prepared by subjecting finely divided hydro-

phobic silica surface-treated with hexamethyldisilazane

to a heat treatment under a reduced pressure, subse-

quently treating the silica with an acid gas, and admix-

ing the resulting silica with an a-cyanoacrylate.

5 Claims, No Drawings

4,686,247

1

ADHESIVE COMPOSITION

The present invention relates to a-cyanoacrylate S

adhesive compositions, and more particularly to a-

cyanoacrylate adhesive compositions containing a

thixotropic agent.

Alpha-cyanoacrylate adhesives based on esters of

cyanoacrylic acid are well known as rapidly setting 10

adhesives. It is also known to admix thixotropic agents

with these adhesives to give them thixotropy.

Such thixotropic agents include finely divided hydro-

phobic silica prepared by rendering finely divided hy-

drophilic silica hydrophobic, for example, by treating

the hydrophilic silica with a silicon compound such as

polydimethylsiloxane, trialkoxyalkylsilane, dimethyldi-

chlorosilane or the like to substitute hydrophobic

groups for the hydrophilic hydroxyl groups covering

the surface of the silica.

It is further known that finely divided hydrophobic

silica surface-treated with hexamethyldisilazane (here-

inafter referred to as “HMDS”) is also usable as a thixo-

tropic agent for on-cyanoacrylates. The hydrophobic

silica surface-treated with HMDS is prepared basically

from hydrophilic silicon dioxide by reacting HMDS

with the hydroxyl groups covering the silica surface to

substitute trimethylsiloxyl groups for the hydroxyl

groups. The hydrophobic silica thus surface-treated

with HMDS has high affinity for a-cyanoacrylates and

can be dispersed highly uniformly when adjusted to

have specified characteristics values, making it possible

to readily provide pastes of thixotropic adhesive com-

positions.

However, a-cyanoacrylate adhesive compositions

incorporating the HMDS-treated hydrophobic silica

are not usable with satisfactory stability. For example,

the composition markedly thickens or hardens in one or

two days when tested for storage stability with heating

at 70° C. In fact, a part of compositions has the fatal

drawback of hardening within less than one day when

tested for stability at 82° C. as disclosed in U.S. Pat. No.

4,477,607’ and U.S. Pat. No. 4,533,422.

Accordingly, an object of the present invention is to

provide an on-cyanoacrylate adhesive composition

which has incorporated therein the hydrophobic silica

surfacetreated with HMDS and which is free of the

above drawback.

Another object of the present invention is to develop

an on-cyanoacrylate adhesive composition which con-

tains hydrophobic silica surface-treated with HMDS

(hereinafter referred to as “HMDS-silica”) and which is

outstanding in storage stability.

Another object of the present invention is to develop

an a-cyanoacrylate adhesive composition which con-

tains HMDS-silica and which does not thicken or

harden even when tested for stability at 70° C.‘ for a

prolonged period of time.

These objects and other features of the present inven-

tion will become apparent from the following descrip-

tion.

The above objects of the present invention can be

fulfilled by subjecting HMDS-silica to two specified

treatments, i.e., heat treatment under a reduced pressure

and subsequent treatment with an acid gas, and admix-

ing the resulting silica with an a-cyanoacrylate.

More specifically, the present invention provides an

adhesive composition which is characterized in that the

composition is prepared by subjecting finely divided

15

20

25

30

35

40

45

50

55

60

65

2

hydrophobic silica surface-treated with hexamethyldi-

silazane to a heat treatment under a reduced pressure,

subsequently treating the silica with an acid gas, and

admixing the resulting silica with an a-cyanoacrylate.

The present invention is distinctly characterized in

that HMDS-silica is heated under a reduced pressure

and then treated with an acid gas.

When thus treated specifically and admixed with an

a-cyanoacrylate, HMDS-silica affords a very stable

composition exhibiting very high stability and undergo-

ing little or no thickening or hardening over a pro-

longed period of time, for example, when tested for

stability at 70° C.

Although the reason why the specifically treated

HMDS-silica exhibits such an outstanding effect still

iemains to be fully clarified, HMDS-silica fails to show

the effect when subjected to the reduced-pressure heat

treatment only or to the acid gas treatment only. It is the

two procedures of reduced-pressure heat treatment and

acid gas treatment that enable HMDS-silica to exhibit

the outstanding effect. For instance, Examples given

below show that if HMDS-silica is merely heated at a

reduced pressure, the composition obtained markedly

thickens or hardens in one or two days when tested for

stability at 70° C. Further HMDS-silica, if merely

treated with an acid gas, provides a composition which

greatly thickens or hardens in three to four days and

which requires an especially prolonged initial setting

time.

According to the present invention, HMDS-silica is

first heated under a reduced pressure. The lower the

pressure, the better. The pressure is usually up to 10 mm

Hg, preferably up to about 1 mm Hg. The heat treat-

ment is conducted at 40° to 200° C., preferably about 60

to about 120° C., for 5 to 30 hours, preferably about 7 to

about 18 hours.

Typical of HMDS-silica to be treated according to

the present invention are Tullanox TM 500 (brand

name, product of Tulco Co., U.S.A.), Aerosil R812 and

RX-200 (brand names, sold by Nippon Aerosil Co.,

Ltd.), etc.

The heat-treated silica is then treated with an acid

gas. The acid gas is defined as “a compound which is in

the form of a gas at a pressure of 760 mm Hg and at

room temperature (15° to 25° C.) and is capable of ac-

cepting electron (or electron pair) in the gas phase.”

Examples of preferred compounds are fluorides of ele-

ments from the groups III to V, such as BF3, SiF4, PF5

and POF3, hydrogen halides such as HCI, HF, HBr and

HI, and acid oxides such as S02, CO2 and NO. The

silica is treated with the acid gas to such an extent that

when the resulting silica is dispersed in a mixture of 50

vol. % of methanol and 50 vol. % of water to a concen-

tration of 4 wt. %, the mixture exhibits a pH of 2.6 to

6.2, preferably about 3.0 to about 5.7. If the pH is lower

than 2.6, the adhesive composition obtained by admix-

ing the silica with an on-cyanoacrylate tends to require a

longer setting time although having high stability,

whereas if it is higher than 6.2, there is a tendency for

the composition to exhibit unsatisfactory storage stabil-

ity although the setting time is shorter.

The hydrophobic silica of the present invention thus

specifically treated by the two steps usually has the

following properties (characteristics values).

Specific surface area: At least 70 m2/g, ‘preferably at

least about 100 m2/g.

Bulk density: Up to 60 g/liter, preferably up to 50

g/liter.

Particle size: Up to 12 mp., preferably up to 9 mp.

4,686,247

3

Contact angle: At least 60 degrees, preferably at least

90 degrees, most preferably at least 120 degrees.

These properties are determined by the following

methods.

Specific surface area:

Measured by the BET method (nitrogen adsorption

method) using a surface area measuring device.

Bulk density:

The specimen as placed on a sheet of paper is slowly

5

placed into a 100-ml graduated cylinder to a volume of 10

100 ml without being subjected to any impact. The

weight difference of the cylinder before and after the

placement of the specimen is measured.

Bulk density (g/liter) = weight of specimen (3) X 10

Particle size:

The diameters of about 3000 primary particles are

measured from an electron microphotograph of the

specimen, and the arithmetic mean of the values is cal-

culated.

Contact angle:

The contact angle is measured by dispersing 1 wt. %

of the specimen in isopropanol, dipping a piece of filter

paper of suitable size (No. 50 for paper chromatograph,

product of Toyo Roshi Co., Ltd.) in the dispersion, then

drying the paper at room temperature (20° to 30° C.) for

3 hours, subsequently allowing a drop of water (0.1 ml)

to stand on the paper for 5 minutes and thereafter mea-

suring the contact angle of the water drop.

When the specific surface area is less than 70 m2/ g,

the adhesive composition prepared by admixing

HMDS-silica with an a-cyanoacrylate has reduced

thixotropy (is less likely to become pasty). exhibiting a

tendency for the silica to separate from the composition.

When the bulk density is greater than 60 g/liter, the

. silica, even if adjusted to a pH suited to the invention,

‘Tfresults in the tendency that the composition obtained

requires a longer setting time.

When greater than 12 mp. in particle size, the silica

‘tends to give a reduced bond strength to the adhesive

composition in which it is incorporated. If smaller than

60 degrees in contact angle, the silica is not smoothly

dispersible in at-cyanoacrylates, fails to give satisfactory

thixotropy and is likely to separate from the composi-

tion during storage.

A wide variety of a-cyanoacrylates heretofore used

for adhesive compositions of the type described are

usable in this invention. Such compounds are repre-

sented by the formula (1)

CN

I

CI-I2=C-COOR

(1)

wherein R is a straight-chain or branched alkyl having

1 to 16 carbon atoms, allyl or substituted or unsubsti-

tuted phenyl. These compounds are usable singly or in

admixture. Stated more specifically, the alkyl in the

formula (1) may have a halogen atom or alkoxy substit-

uent. The phenyl may have at least one substituent such

as a halogen atom or alkoxyl. Examples of typical alk-

oxyl groups are lower alkoxyl groups.

The adhesive composition of the present invention

comprises at least one of the a-cyanoacrylates repre-

sented by the formula (1) and HMDS-silica treated by

the above two treatments in an amount of 0.5 to 12 wt.

%, preferably 3 to 10 wt. %, based on the composition.

If the amount is less than 0.5 wt. %, the composition

15

20

25

30

35

45

50

55

60

65

4

will not have sufficient thixotropy even when contain-

ing a thickener such as an organic polymer mentioned

below, whereas if the amount exceeds 12 wt. %, the

composition is in the form of a hard paste and is incon-

venient to use.

The a-cyanoacrylate to be used as the main compo-

nent of the present adhesive composition is liable to

anionic polymerization as is well known, so that it is

desirable to add an anionic polymerization inhibitor to

the present composition. Variouspanionic polymeriza-

tion inhibitors heretofore used for adhesives of the pres-

ent type are usable. Examples of preferred inhibitors are

S02, BF3, NO, aromatic sulfonic acids, alkylsulfonic

acids, etc.

Further according to the present invention, a radical

polymerization inhibitor is usable in combination with

the anionic polymerization inhibitor when so required.

Examples of useful radical polymerization inhibitors are

those heretofore used, such as hydroquinone, pyrogal-

lol, hydroquinone monomethyl ether and the like.

While the amounts of such inhibitors to be used vary

with the kind of inhibitors, the anionic polymerization

inhibitor is used generally in an amount of 1 to 400 ppm,

preferably 5 to 100 ppm, and the radical polymerization

inhibitor in an amount of 1 to 2000 ppm, preferably 10 to

1200 ppm.

Other additives heretofore used for at-cyanoacrylate

adhesives of the type mentioned can be incorporated

into the adhesive composition of the present invention.

Such additives include organic polymers which assist in

dispersing the hydrophobic silica of the invention in

at-cyanoacrylates and serve to prevent the possible sep-

aration of the silica during storage. Typical of such

polymers are polymethyl methacrylate, methacrylic

copolymers, hydroxypropylcellulose acetate, etc.

These polymers are used in an amount of O to 7 wt. %,

preferably about 0.5 to about 2.5 wt. %, based on the

composition.

Other useful additives are plasticizers, such as dioctyl

phthalate, sebacic acid esters and phosphoric acid es-

ters, for giving improved flexibility to the polymer on

curing. According to the contemplated purpose, per-

fumes, dyes, etc. may be added to the adhesive composi-

tion suitably insofar as the stability of the composition is

not impaired.

Like the conventional on-cyanoacrylate adhesives, the

composition of the invention, which is serviceable as an

rapidly acting adhesive, is usable for metals such as iron,

stainless steel, copper, aluminum and ferrite, plastics,

wood, rubber, glass, ceramics, leather, paper, fabrics,

etc.

EXAMPLE 1

Hydrophobic silica surface-treated with HMDS was

treated according to the present invention as shown in

Table l. The hydrophobic silica thus treated was ad-

mixed with an a-cyanoacrylate to prepare an adhesive

composition, which was then tested for stability. Table

2 shows the result.

The silica material was treated according to the in-

vention as follows. The heat treatment was conducted

at a reduced pressure of 0.5 to 1.0 mm Hg at 60° to 65°

C. for 15 hours. The acid gas treatment was conducted

by holding the silica in contact with BF3 for 5 to 7

minutes at a reduced pressure of 42 to 43 mm Hg at

room temperature. The degree of the acid gas treatment

is expressed in terms of pH.

4,686,247

5

For comparison, hydrophobic silica surface-treated

with HMDS was merely heated at 205° C. for 15 min-

utes and then used as Comparative Example.

Table 2 shows the results achieved by the composi-

6

According to JIS K 6861-1977 using a test specimen

of NBR.

Accelerated degradation test:

The specimen was placed into a polyethylene tube

tions thus prepared with use of hydrophobic silica sur- 5 and an aluminum tube, both 2 to 3 g in capacity, the

face-treated with HMDS. The compositions incorpo- tubes were then allowed to stand in an oven maintaining

rating the hydrophobic silica as merely heat-treated had at 70i2“ C., and the contents were checked for stabil-

the drawback that they gelled in l to 2 days when ity.

heated at 70° C. and was not usable with good stability, TABLE 3

whereas the compositions incorporating the hydropho- 10 . p _ _

bic silica as treated according to the invention exhibited S_?""3 s'°”‘g° 5"’b']"y d°‘°""l""d

_ . , . ime by accelerated degradation

high stability even after having been heated under the PH. (Sec) .65,

Same condlnon for 16 dayS' Untreated 9.7 5 Gelled in less than 1 day.

TABLE 1

pH of hydrophobic silica

Treatments of the invention

Comparative Example lst treatment 2nd treatment

Hydrophobic Heated at 205° C. Heated in Treated with acid gas

silica Untreated for 15 minutes vacuum Adjustment 1 Adjustment 2

A 9.7 8.5 7.1 5.7-6.2 2.7-5.5

B 7.3 7.2 6.9 5.6-6.1 3.1-5.4

C 7.6 7.4 7.1 5.6-6.1 2.6-5.3

D 7.5 7.1 6.8 5.7-6.2 3.2-5.5

Note: A-D: Hyrophobic silicas surface-treated with HMDS.

A: Tullanox TM 500 (product of Tulco Co., U.S.A)

B: Aerosil R812

C: Aerosil RXl7O

D: Aerosil RX200

B-D: Sold by Nippan Aerosi Co.. Ltd

TABLE 2

Components of

adhesive

composition Accelerated degradation test with heating at 70° C.

Hydro- Comparative Example Treatments of the invention

a-Cyano- phobic Heated at 1st treatment 2nd treatment

acrylate silica 205° C. for Heated in Treated with acid gas

(wt. %) (wt. %) Untreated 15 min vacuum pH 5.7-6.2 pH 2.6-5.5

93.0 A Gelled in Gelled in Gelled in Slightly Satisfactory

7.0 less than 1 day 4-5 days thickened in for more

1 day 9-10 days than 16 days

93.0 B Gelled in Gelled in Gelled in Slightly Satisfactory

7.0 2-3 days 3-4 days 6-7 days thickened in for more

9-10 days than 16 days

93.0 C Gelled in Gelled in Gelled in Slightly Satisfactory

7.0 2-3 days 3-4 days 6-7 days thickened in for more

9-10 days than 16 days

9.3 D Gelled in Gelled in Gelled in Slightly Satisfactory

7.0 2-3 days 3-4 days 6-7 days thickened in for more

9-10 days than 16 days

Note: a-Cyanoacrylate: Ethyl ester containing 40 ppm of S03 and 1200 ppm of hydroquinone added.

50

EXAMPLE 2

Hydrophobic silica surface-treated with HMDS (Tul-

lanox TM 500) was treated by the process of the inven- Hefting at 8-5 10 Gelled in 1 day-

tion to obtain hydrophobic silicas having varying pH :35 ‘gmin

values. Seven wt. % _(based on the composition) of each 55 1-,ea,mem 7.1 10 Gelled in 4_5 days_

silica was admixed with ethyl a.-cyanoacrylate (contain- of inven- 6.6 15 Thickened in 6-7 days.

ing 40 ppm of S02 and 1200 ppm of hydroquinone) to “On 5-2 15-20 Slightly Ehi°k°"e‘§ 1“ 19 days

prepare an adhesive composition. The compositions 5'7 2° 1]? d§“;1:‘‘°" °' ”"°k°"'"g m

thus. obtained were tested for setting time and storage 55 20 No gelation or thickening in

stability. Table 3 shows the results. 60 16 days.

The setting time of the composition comprising the 4-7 2°45 N0 ECWOH 0' ”“°ke"l“S 1“

cyanoacrylate and the silica of the invention is adjust- 16 days’. . . .

, , 4.2 30 No gelation or thickening in

able according to ‘the contemplated purpose, by varying 16 dayS_

the pH of the silica in the range of from about 3.0 to 3.8 35-40 No gelation or thickening in

about 5.7. 65 3 ;\I5 d3Y1S- h k

- - .1 45 o ge ation ort ic ening in

The properties were measured by the following 16 days, Sngmy thickened

methods. I in 19 days.

Setting time: 2.7 70-80 No gelation or thickening in

7

TABLE 3-continued

Setting Storage stability determined

Time by accelerated degradation

pl-1* (sec) test

20 days.

Note: ‘pH of hydrophobic silica

EXAMPLE 3

Four hundred parts by weight of hydrophobic silica

surface-treated with HMDS and exhibiting a pH of 9.7

(brand name: Tullanox TM 500, product of Tulco Co.,

U.S.A.) was heated in a 27-liter square vacuum dryer at

a reduced pressure of up to 3 mm Hg at 60° to 65° C. for

12 to 15 hours while being allowed to stand (first treat-

ment). The hydrophobic silica thus treated was 7.1 to

7.15 in pH. The silica was then placed into a 10-liter

rotary evaporator (comprising a rotatable flask and an

inner buffer plate for thoroughly stirring the finely

divided silica), the evaporator was evacuated to 30 mm

Hg, and BF3 was then introduced into the flask to an

internal pressure of 40 to 45 mm Hg. The silica was

thereafter brought into full contact with the BF3 gas by

rotating the flask for 3 to 20 minutes. Subsequently, the

flask, as evacuated to a reduced pressure of up to 10 mm

Hg, was held in a water bath at 35° to 40° C. for 30 to

90 minutes while being rotated to expel the BF3 gas.

Adhesive composition

Component

4,686,247

5

10

15

20

25

8

C. for 15 minutes, with ethyl a-cyanoacrylate to pre-

pare compositions containing 5 wt. % of the silica.

When heated at 70° C., these compositions gelled in one

day. On the other hand, when the compositions com-

prising 0.5 to 10 wt. %, preferably 3 to 9 wt. %, of the

silica treated by the process of the invention and ethyl

a-cyanoacrylate containing an organic polymer were

similarly heated at 70° C., the compositions exhibited

satisfactory stability even after the lapse of 16 days,

while the variations in the setting time of these composi-

tions with the lapse of time were within an allowable

range for adhesive compositions of this type.

The tensile shear strength and storage stability were

determined by the following methods.

Tensile shear strength:

According to JIS K 6861, Item 6, using Autograph

S-2000, product of Shimadzu Seisakusho Ltd.

Storage stability:

The specimen was placed into a polyethylene tube

and an aluminum tube, both 2 to 3 g in capacity, allowed

to stand with the tubes held in an oven maintaining at

70:2“ C., and checked for changes with time. When

there was no difference between the specimen and a

control after the specimen had been tested for 10 to 16

days; it was speculated that the composition would

remain stable for at least one year at room temperature.

TABLE 4

Initial As heated at

adhesion 70° C. for 16 days

Set- Tensile Set-

Organic Appearence ting Shear ting

polymer of time strength time

Ethyl a- Silica

cyano of inven-

acrylate tion

(wt. %) (wt. %)

Composition of 96.0 0.5

the invention 96.0 1.0

95.5 2.0

95.5 3.0

93.3 5.0

91.5 7.0

89.8 9.0

89.0 10.0

87.5 12.0

86.5 13.0

Comparative 93.3 Untreated

Example silica

(pH 9.7)

5.0

93.3 As heated

at 205° C.

for 15 min

5.0

(wt. %) composition

(sec) (kg/cmz) (sec) Stability

3.5 Flowable liquid 5 134 15 Good

3.0 ” 5 136 15 ”

2.5 ” 5 . 144 10 "

2.0 Soft paste 10 152 25 "

1.7 Smooh paste 15 167 30 "

1.5 " 20 163 45 "

1.2 " 35 145 60 "

1.0 ” 40 130 75 Slightly thickened

0.5 Slightly hard 50 121 130 Slightly thickened

paste V

0.5 Hard paste 70 125 — Thickened

1.7 Smooth paste 5 159 — Gelled in one day

1.7 Smooth paste 5 141 — Gelled in one day

___:__.:._

Note: Organic polymer: polymethyl methacrylate 500,000-600,000 in molecular weight.

When the silica thus treated according to the inven-

tion was dispersed in a methanol-water solution (50:50

by volume), the solution had a pH of 5.2. The silica of

the invention was admixed with ethyl a-cyanoacrylate

(containing 40 ppm of S02 and 1200 ppm of hydroqui-

none) to obtain compositions containing the silica in

varying concentrations of 0.5 to 13 wt. %. The compo-

sitions were tested for properties, with the results

shown in Table 4.

Hydrophobic silica surface treated with HMDS was

admixed, as untreated or as merely heat-treated at 205°

60

65

EXAMPLE 4

Hydrophobic silica surface-treated with HMDS and

having a pH of 7.3 (brand name: Aerosil R812, sold by

Nippon Aerosil Co., Ltd.) was treated in the same man-

ner as in Example 3 with the exception of using S02 gas

in place of BF3 to obtain hydrophobic silica of the in-

vention having a pH of 3.6. Varying proportions of the

silica were admixed with various a-cyanoacrylates as

shown in Table 5 to obtain compositions, which were

then tested for properties. Table 5 shows the results.

4,686,247

9 10

TABLE 5

Initial As heated at

Adhesive composition adhesion 70“ C. for 15 days

Silica of Set- Tensile Set-

a-Cyano— invention Organic ting shear ting

acrylate (pH 3.6) polymer Stabilizer time strength time

(91.9 wt. %) (wt. %) (wt. %) (ppm) (sec) (kg/cm) (sec) Stability

Composition of Methyl ester 6.5 1.6 502: 20 20 207 35 Good

the invention MS: 30

HQ: 1200

Ethyl ester 6.5 1.6 S01: 40 20 165 45 "

HQ: 1200

2-Methoxy- 6.5 1.6 S03: 30 25 125 40 ”

isopopyl ester HQ: 500

Methyl ester Untreated l.6 S02: 20 10 196 — Gelled in

(pH 7.2) MS: 30 l day

6.5 HQ: 1200

Methyl ester (pH 6.9) S02: 20 15 210 — Gelled in

6.5 MS: 30 2 days

HQ: 1200

Comparative 2-Methoxy— Untreated 1.6 S02: 30 15 127 — Gelled in

Example isopropyl ester 6.5 HQ: 500 3 days

2-Methoxy- As heated 1.6 S03: 30 20 135 — Gelled in

isopropyl ester at 205° C. HQ: 500 3 days

for l5 min

6.5

.m..j._

Note: S0; = sulfur dioxide. MS = methanesulfonic acid. HQ = hydroquinone

I claim:

1. An adhesive composition characterized in that the

composition is prepared by subjecting finely divided

hydrophobic silica surface—treated with hexamethyldi-

silazane to a heat treatment under a reduced pressure,

subsequently treating the silica with an acid gas, and

admixing the resulting silica with an a-cyanoacrylate.

2. A composition as defined in claim 1 wherein the

heat treatment is conducted under a reduced pressure of

up to 10 mm Hg at 40° to 200° C. for 5 to 30 hours.

3. A composition as defined in claim 1 wherein the

acid gas is in the form of a gas at a pressure of 760 mm

Hg at a temperature of up to 25“ C. and is a compound

30

35

40

45

50

55

60

65

selected from the group consisting of fluorides of ele-

ments from the groups III, IV and V, hydrogen halides

and acid oxides.

4. A composition as defined in claim 1 wherein the

acid gas is at least one of S02, BF3 and HCl.

5. A composition as defined in claim 1 wherein the

acid gas treatment is so conducted that when the result-

ing silica is dispersed in an aqueous solution composed

of 50 vol. % of methanol and 50 vol. % of water to a

concentration of 4 wt. %, the solution exhibits a pH of

2.6 to 6.2.

it * * 1|! 1|!

Coments go here:

- Log in to post comments