2-Cyanoacrylate Adhesive Compositions Having Enhanced Bond Strength

2-Cyanoacrylate Adhesive Compositions Having Enhanced Bond Strength

GB2017716

Company:

Folder:

Year:

Abstract:

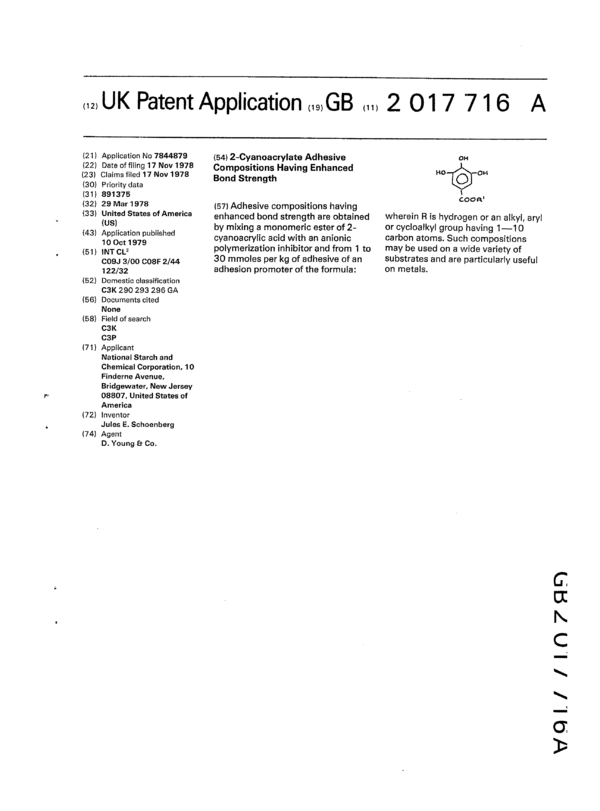

Adhesive compositions having enhanced bond strength are obtained by mixing a monomeric ester of 2-cyanoacrylic acid with an anionic polymerization inhibitor and from 1 to 30 mmoles per kg. of adhesive of an adhesion promoter of the formula: wherein R' is hydrogen or an alkyl, aryl or cycloalkyl group having 1-10 carbon atoms. Such compositions may be used on a wide variety of substrates and are particularly useful on metals.

Type of document:

Language:

(12)UK Patent Application (19)GB (11) 2 017 716 A

(21)

(22)

Application No 7844879

Date of filing 17 Nov 1978

(23) Claims filed 17 Nov 1978

(30)

(31)

(32)

(33)

(43)

(51)

(52)

(56)

(58)

(71)

(72)

(74)

Priority data

891375

29 Mar 1978

United States of America

(US)

Application published

10 Oct 1979

lNT CL2

C09J 3/00 CO8F 2/44

122/32

Domestic classification

C3K 290 293 296 GA

Documents cited

None

Field of search

C3K

C3P

Applicant

National Starch and

Chemical Corporation, 10

Finderne Avenue,

Bridgewater, New Jersey

08807. United States of

America

Inventor

Jules. E. Schoenberg

Agent

D. Young & Co.

(54) 2-Cyanoacrylate Adhesive

Compositions Having Enhanced

Bond Strength

(57) Adhesive compositions having

enhanced bond strength are obtained

by mixing a monomeric ester of 2-

cyanoacrylic acid with an anionic

polymerization inhibitor and from 1 to

30 mmoles per kg of adhesive of an

adhesion promoter of the formula:

OH

HO OFl

I

coca‘

wherein R is hydrogen or an alkyl, aryl

or cycloalkyl group having 1——1 0

carbon atoms. Such compositions

may be used on a wide variety of

substrates and are particularly useful

on metals.

‘t7'Ql-/ / lrfl7FlF3

1 GB 2 017 716 A 1

SPECIFICATION

2—Cyanoacrylate Adhesive Compositions Having Enhanced Bond Strength

This invention relates to improved 2—cyanoacrylate adhesive compositions. More particularly, this

invention is directed to 2—cyano-acrylate adhesive compositions containing an adhesion promoter

5 which compositions have enhanced bond strength. 5

Adhesive compositions based on 2—cyanoacrylate esters belong to a class of adhesives known as

reactive liquid adhesives. 2—Cyanoacrylate adhesives are single—part, low-viscosity adhesives which are T

characterized by features such as (1) their ability to polymerize at room temperature without the use of

an added catalyst when pressed between two substrates, (2) their rapid rate of cure, and (3) the

10 strength of the bonds produced with a wide variety of substrates. Conventional adhesives, on the other 10

hand, cure, for example, upon application of heat and pressure, addition of catalyst, or evaporation of a

solvent. A general review of 2—cyanoacrylate adhesives can be found in I. Skeist's "Handbook of

Adhesives”, New York; Reinhold Publishing Corporation, 1962, Chapter 31, p. 409-414.

Application of the 2—cyanoacrylate adhesive merely involves spreading a small sample thereof in a

15 thin film between two substrates, pressing the substrates together, and allowing the resultant bond to 15

cure. The adhesive develops sufficient strength after a short period of time to hold the substrates

together until the adhesive completely polymerizes and builds up to its maximum bonding strength.

Initiation of polymerization (cure) is generally believed to proceed through an anionic mechanism;

the 2—cyanoacrylate adhesives have such a great tendency to polymerize that water itself is a

20 sufficiently active initiator. Hence, when the adhesive is applied to a substrate and thereby exposed to 20

atmospheric and surface moisture, cure normally begins within a relatively short period of time,

generally less than one minute, and on many surfaces within a matter of a few seconds. The rapid cure

rate of the 2—cyanoacrylate adhesives is particularly advantageous in production line applications.

Due to their tendency to polymerize, 2—cyanoacrylate adhesive compositions normally contain

25 one or more stabilizers. To prevent anionic polymerization, an inhibitor such as an acidic gas or a 25

protonic acid is normally added to the composition. In general, as the acidity of these inhibitors

increases, the stability of the adhesive is enhanced while,. at the same time, the cure rate is reduced. It

is sometimes desirable to further add an inhibitor of free radical polymerization to the monomer. This

latter type of inhibitor is generally a phenolic type compound such as, for example, hydroquinone, 1;-

3o butyl catechol, pyrocatechol, p-methoxyphenol, and pyrogallol. Typical patents describing use of these 30

and other compounds as stabilizers for 2—cyanoacrylate adhesive compounds include U.S. Patent Nos.

2,726,332; 2,912,454: 2,926,188; and 3,993,678; as well as Japanese Patent Publication No.

9- 619.

Although adhesive compositions consisting of 2—cyanoacrylate esters and conventional

35 stabilizers inherently yield high bond strength (as commonly measured by the test of tensile shear 35

strength), improvements therein would be desirable particularly in cases where the substrate is of

greater strength than the adhesive, as in the case of many metal bonds. While many stabilizers for 2-

cyanoacrylate adhesive compositions have been investigated in the prior art, relatively little research

has been done on adhesion promoters which enhance the bond strength of the adhesive without

40 lessening the stability or cure rate thereof. In this regard, selected carboxylic acid anhydrides have been 40

used in the prior art as adhesion promoters for 2—cyanoacrylate adhesive compositions. Thus, U.S.

Patent No. 3,832,334 teaches the use of maleic anhydride to increase the bond strength of a 2-

cyanoacrylate adhesive at elevated temperatures, while U.S. Patent No. 3,948,794 teaches the use of

itaconic anhydride to improve not only the stability of the 2—cyanoacrylate adhesive composition but

45 also the tensile shear strength and other properties associated therewith. 45

It has been disclosed in German Offenlegungsschrift 26 12 546 that a wide variety of carboxylic

acids, generally known to stabilize 2—cyanoacrylate adhesives to varying degrees, exert a definite effect

on the bond strength of certain 2—cyanoacrylate adhesive compositions containing excess plasticizer.

The plasticizer is added in amounts of 20—60% by weight, based on the total composition, to make

50 the adhesive bonds readily releasable. It is suggested that one of the functions of the carboxylic acid 50

therein is to counteract the weakening effect of the plasticizer on the bond strength of the adhesive.

Nevertheless, the large number of carboxylic acids described as being applicable in the German

publication limits the use of the adhesive composition to very few types of substrates. For example,

many of the carboxylic acids listed therein, i.e., those with a high acid strength, act very effectively as

55 anionic polymerization inhibitors and hence will significantly retard the rate of cure of the adhesive, 55

particularly on non—polar substrates, within the concentration range given therein. Yet, as described '

hereinabove, the rapid rate of cure is one of the main characterizing features of 2—cyanoacrylate

adhesives in general. Furthermore, it has been demonstrated that at least some of the weaker acids

within the scope of the German publication, which acids do not significantly reduce the rate of cure of

60 the adhesive composition, have in fact very minimal effect on the bond strength of the composition on so

many__r_neta|s.

The present invention is based on the discovery that 2—cyanoacrylate adhesive composition

having enhanced bond strength can be obtained by incorporating into the adhesive 3,4,5-

trihydroxybenzoic acid or an ester thereof.

GB 2 017 716 A

2.

5

10

15

20

25

30

35

40

45

50

In accordance with this invention, therefore there is provided an adhesive composition

comprising a mixture of:

(A) a monomeric ester of 2—cyanoacry|ic acid of the general formula:

0

ll

H2C=C—C—0R

l

CN

wherein R is an alkyl or alkenyl group having from 1 to 6 carbon atoms, a cyclohexyl group or a phenyl

group; ‘

(B) an anionic polymerization inhibitor; and _

(C) from 1 to 30 mmoles per kg. of adhesive of an adhesion promoter of the general formula

OH

HO - -OH

l

coca‘

wherein R’ is hydrogen or an alkyl, aryl or cycloalkyl group having from 1 to 10 carbon atoms.

The process for preparing the improved adhesive composition of this invention comprises the

step of dissolving into the stabilized 2-cyanoacrylate adhesive from 1 to 30 mmoles per kg. of adhesive

of the adhesion promoter defined above.

The preferred 2-cyanoacrylate esters herein are those wherein the R group is an alkyl or alkenyl

group having 1 to 4 carbon atoms, with the ethyl ester being particularly preferred. The anionic

polymerization inhibitor which is most preferred in sulfur dioxide. The preferred group of adhesion

promoters for use herein are those wherein R’ is an alkyl, aryl or cycloalkyl group of 1—1 0 carbon

atoms, and most preferably an alkyl group having 1—6 carbon atoms.

If the adhesive composition is to be stored for an extended period of time, it may be desirable to

add a free radical polymerization inhibitor to the composition of this invention to impart added storaged

stability. Other optional ingredients which improve specific properties of the adhesive such as

thickeners or plasticizers also may be incorporated into the composition, if desired.

The adhesion promoter herein serves to enhance the bond strength of the adhesive composition

when applied to many substrates which are stronger than the adhesive bond, such as most metal

substrates. ltit necessary that the adhesion promoter be present in the composition within a specified

concentration range, and only the narrow range prescribed herein is effective in obtaining the high

bond strengths characteristic of this invention. To maximize bond strength while minimizing retardation

in cure rate, the adhesion promoter is preferably employed in amounts ranging from 1 to 10

mmoles/kg. of total adhesive composition.

Description of the Preferred Embodiments

The adhesive composition of the present invention is based on a monomeric ester or mixture of

esters of 2-cyanoacrylate acid as described hereinabove. For purposes of this invention, the preferred

esters are those wherein the R group is an alkyl or alkenyl group having 1 to 4 carbon atoms, and, more

particularly, a methyl, ethyl, allyl, or isa— or n—butyl group. An especially preferred ester for preparing

the adhesives of this invention is ethyl 2-cyanoacrylate due to its commercial availability.

The above-mentioned monomeric esters of 2—cyanoacry|ic acid may be prepared by methods well

known in the art such as those described in U.S. Patent Nos. 2,467,926; 2,467,927; and 3,254,1 1 1;

the disclosures of which are incorporated herein by reference.

The 2-cyanoacrylate esters herein are stabilized by adding one or more anionic polymerization

inhibitors thereto. A wide variety of anionic polymerization inhibitors known in the art to stabilize 2-

cyanoacrylate adhesive compositions such as acidic gases and protonic acids or anhydrides thereof is

applicable herein. Examples of suitable acidic gases for this purpose include sulfur dioxide, nitric oxide,

carbon dioxide, hydrogen fluoride, and the like. Suitable protonic acids include mineral acids such as

hydrochloric, sulfuric or carboxylic acids. Examples of anhydrides which may be employed as anionic

polymerization inhibitors include carboxylic acid anhydrides, phosphoric acid anhydrides such as

- phosphorus pentoxide, sulfones, acid chlorides, and the like. it is to be recognized that this invention is

not limited to any particular anionic polymerization inhibitor since adding such an inhibitor to 2-

cyanoacrylate adhesives is well known in the art. It is also to be noted that the particular anionic

polymerization inhibitor used depends on the 2-cyanoacrylate ester employed. Thus, the lower (C,—

C3) alkyl 2-cyanoacrylate esters require a relatively acidic inhibitor such as sulfur dioxide or p-

,-toluenesulfonic acid, while the butyl and higher esters of 2-cyanoacrylic acid generally require weaker

acids such as carbon dioxide. The preferred polymerization inhibitor herein is sulfur dioxide.

10

15

20

25

30

35

40

45

50

rut

I 3;,

GB2 017 716A.

3

10

15

20

25

30

35

40

45

50

055

Those anionic polymerization inhibitors which are in the gaseous form act not only to lengthen

the shelf life of the adhesive but also are used as process stabilizers. Hence, throughout several stages

in the synthesis of the 2-cyanoacrylate ester, the gaseous inhibitor, such as, for example, sulfur dioxide,

is passed through the system. The high concentration of inhibitor which is thus built up is removed by

pulling vacuum on the ester upon completion of the synthesis procedure. This process of stabilizing the

adhesive during synthesis is known and is typically described in U.S. Patent No. 2,756,251.

The amount of anionic polymerization inhibitor employed generally ranges from 0.001 to 0.05%

by weight, based on the total adhesive composition, however, because the amount of stabilizer

depends on many factors, it may be required in certain instances to use amounts outside of this range.

Furthermore, it may not always be necessary to add an anionic polymerization inhibitor if the 2-

cyanoacrylate ester used in the composition is commercially obtained because the commercially

produced esters in some cases already contain an effective amount of inhibitor for stabilization

purposes. —

In accordance with the invention herein, the adhesive properties of the 2—cyanoacrylate adhesive

composition stabilized with anionic polymerization inhibitor are improved by the addition of an

adhesion promoter of the general formula:

OH

HO oH

|

COOR'

wherein R’ is hydrogen or an alkyl, aryl or cycloalkyl group having 1 to 10 carbon atoms. The formal name

given to this class of compounds is 3,4,5—trihydroxybenzoic acid or esters thereof, while the common

name is gallic acid or esters thereof. The adhesion promoting ability of gallic acid and its esters is

observed when many substrates which are stronger than the adhesive bond, such as most metals, are

bonded. In addition to metals, other substrates generally known to be bondable by means of 2-

cyanoacrylate adhesives, such substrates including, for example, rubber, most plastics, phenolic resins,

glass, and the like, may also be bonded using the adhesive composition of this invention. However, for

certain of these substrates wherein the adhesive bond is stronger than the substrate itself,

enhancement of the bond strength will not be Observed.

Gallic acid, as well as certain of its esters such as propyl gallate, can be obtained commercially.

The esters can be readily prepared by known esterificat-ion methods. The preferred adhesion promoters

herein are the gallic acid esters because gallic acid itself is relatively acidic and has limited solubility in

the 2-cyanoacrylate esters. Particularly preferred for use herein are those esters wherein R’ in the

above formula is an alkyl group having 1—6 carbon atoms.

The amount of adhesion promoter to be used depends on the surface to which the composition is

applied, the solubility of the adhesion promotor in the particular 2-cyanoacrylate ester employed, and

the amount of inhibition incurred by the promoter at higher concentrations thereof. Generally the

amount which results in optimal bond strength values with minimal retardation in cure rate on non-

polar surfaces ranges from 1 to 30 mmoles per kg. of adhesive. Below 1 mmole, there is no significant

improvement in the adhesion, while at concentrations above 30 mmoles, the cure rate is retarded

significantly while bond strength is lessened relative to the control. The preferred amount to be

employed herein is about 1—1 0 mmoles/kg. of adhesion promoter because at this lower concentration

very little retardation in the cure rate occurs. it is to be noted that the maximum amount of adhesive

promoter employed may be limited by solubility alone. For example, gallic acid and methyl gallate have

limited solubilities in the less polar 2-cyanoacrylate esters (wherein R is an alkyl group having more

than 3 carbon atoms).

For added storage stability it may be desirable to add a free radical polymerization inhibitor to the

composition, depending on the particular 2-cyanoacrylate ester employed. For example, the addition of

a powerful free radical inhibitor such as hydroquinone to an adhesive composition based on methyl 2-

cyanoacrylate is highly preferred. With higher cyanoacrylate esters, however, the adhesion promoters,

which are themselves weak free radical scavengers, generally provide sufficient stabilization against

free radical polymerization. As a suitable inhibitor for this purpose, any one of a wide variety of

inhibitors known in the art to stabilize 2-cyanoacrylate adhesive compositions against free radical

polymerization is applicable. Such inhibitors include phenolic compounds such as hydroquinone, t-

butyl catechol, pyrocatechol, p-methoxyphenol, and the like. The conventional free radical

polymerization inhibitor, like the anionic polymerization inhibitor, is normally added during the

processing of the 2-cyanoacrylate ester. Hence, a free radical polymerization inhibitor is generally

introduced into the distillation vessel and the receiver to stabilize the ester in the synthesis thereof. As

a result, commercially available 2—cyanoacrylate esters may already contain a certain amount of a

conventional free radical polymerization inhibitor such as those mentioned hereinabove. More such

inhibitor, however, may be added thereto if greater stability is desired. The total amount of such

inhibitor which will be effective for stabilization purposes will range from 0.001 to 0.05% by weight of

60 the total composition.

5

10

15

20

25

30

35

40

45

50

55

60

4

GB 2 017 716 A

4

10

15

There may also be present in the adhesive compositions of this invention various other optional

ingredients including, for example, plasticizers and thickeners. Plasticizers improve the aging

characteristics of the cured bonds by lessening the brittleness thereof. For best performance the

amount of plasticizer to be used should not exceed 20% by weight of the total composition. Suitable

plasticizers include monofunctional and difunctional aliphatic esters of acids having 1 to 10 carbon

atoms such as, for example, dimethyl- and dioctyl—sebacate, and esters of malonic acid, difunctional

aromatic esters, and alkyl and aromatic phosphates and phosphonates. Thickeners, which may be used

in amounts of up to 25% by weight, depending in part on their thickening power at room temperature,

serve to increase the viscosity of the adhesive so that they may be more easily applied. Among the

suitable thickeners for this purpose are included, for example, polymeric alkyl 2—cyanoacrylates,

cellulose esters including cellulose acetate butyrate, acrylate resins such as poly(methyl methacylatel

and polylethyl methacrylate), and polylvinyl alkyl ethers) such as poly(vinyl methyl ether).

The adhesive compositions of the present invention are generally prepared by adding a given

amount of the adhesion promoter to the stabilized 2-cyanoacrylate ester and mixing at room

temperature until the promoter is thoroughly dissolved in the ester. The anionic polymerization inhibitor

is already present in or added to the ester before the adhesion promoter is dissolved therein. Any

optional ingredients desired, including the free radical polymerization inhibitor, may be added either

' prior to or following the addition of adhesion promoter. The resultant adhesive composition may be

20

25

30

35

40

45

50

55

used in a variety of applications, including household articles, precision instruments, optical lenses, and

the like.

The following examples will demonstrate the efficacy of the 2-cyanoacrylate adhesive

compositions of this invention. In these examples all percentages and parts are given by weight unless

otherwise specified.

The present adhesive compositions are evaluated on the basis of the following two test

procedures:

I. Set Time Test

One drop of test adhesive is placed near one edge of a 2.54 cm. by 2.54 cm. by 0.48 cm.

phenolic chip. The mating surface of a second chip of the same dimensions is quickly placed thereover

and positioned such that half of each chip overlaps the other chip. The lamination is immediately

clamped together by means of a spring clip. At 15—second intervals an attempt is made to pull the two

chips apart using a light peel force. The "set time" is related to the cure rate and is defined as the time

interval between the initial application of the adhesive and the final time at which the chips can nq

longer be pulled apart manually.

II. Tensile Shear Strength Test

Two metal bars of dimensions 1.27 cm. by 10.16 cm. by 0.32 cm. are used as the test materials

to be bonded. Prior to use, they are treated by scouring with Scotch-Brite (Registered Trademark of

3 M. Co.) scouring pads and then cleaned with acetone.

A small amount (10 microliters) of test adhesive is applied to the cleaned surface of one bar near

one edge. The second bar is then pressed against the first to form an adhesive film such that there is

1.27 cm. overlap for each bar and hence a bonding area of 1.61 cm”. The bars are clamped together

by means of a spring clip and allowed to cure for 24 hours. The bond strength, or tensile shear

strength, is determined by pulling the bars apart with an lnstron Tensile Tester at a crosshead operation

speed of 0.254 cm./min. The values given herein for the tensile shear strength are usually the average

of five determinations and are given in units of kg-/cmz.

Example I .

This example illustrates the effect of the adhesion promoters of this invention on the cure rate

and bond strength of 2-cyanoacryylate adhesive compositions.

Four samples of 2-cyanoacrylate adhesive compositions were prepared by adding approximately

equimolar amounts of the given adhesion promoter in a quantity of ethyl 2-cyanoacrylate obtained

commercially containing 0.002% sulfur dioxide and 0.001% hydroquinone as inhibitors of anionic and

free radical polymerization, respectively. The gallic acid and methyl gallate used as adhesion promoters

were stirred to effect solution in the 2-cyanoacrylate ester, while, with the propyl and hexyl gallates,

dissolution was effected only with shaking. Each resulting composition was evaluated as to set time

and tensile shear strength against a control containing no adhesion promoter. The results are

summarized in Table l.

10

15

20

25

30

35

40

45

50

55

10

15

20

25

30

35

40

45

50

55

GB 2 017 716A 5

Table I

Amount ofAdhesion Tensile Shear Strength

Adhesion Promoter Added Set Time (kg./cm’)

Promoter ppm. mmo/es/kg. (sec.) Steel Brass Aluminum

None (control) 0 0 15 171 109 114 5

Gallic Acid

Monohydrate 740 3.9 15 233 230 159

Methyl Gallate 730 4.0 15 220 220 157

Propyl Gallate 840 4.0 15 187 221 162

Hexyl Gallate 990 3.9 15 198 187 159 10

It can be seen from the table above that gallic acid and the esters thereof increase the bond_ ‘

strength of the 2—cyanoacry|ate adhesive on all three types of metal substrates. F_urthermore, addition

of these adhesion promoters does not adversely affect the cure rate of the adhesive.

Example II

This example illustrates the effect of the adhesion promoters of this invention on the cure rate 15

and bond strength of butyl 2—cyanoacry|ate. _

Four samples of 2—cyanoacry|ate adhesive composition were prepared as described in Example I

except that the 2—cyanoacry|ate ester was n—butyl 2-cyanoacrylate containing a small fixed amount of

sulfur dioxide as anionic polymerization inhibitor. Each resulting composition was evaluated as in

Example I. The results aresummarized in Table ll. 20

g Table II

Amount ofAdhesion Tensi/e Shear Strength

Adhesion Promoter Added Set Time (kg./cm.2)'

promoter ppm mmo/es/kg. (seal Steel Brass Aluminum

None (control) 0 0 60 81 103 58 25

Gallic Acid

Monohydrate 720 3.8 60 106 120 80

Methyl Gallate 700 3.8 60 1 15 101 72

Propyl Gallate 830 3.9 90* 122 1 14 70

Hexyl Gallate 1020 4.0 60 122 87 84 30

*The higher alkyl 2—cyanoacry|ate esters such as butyl 2—cyanoacry|ate have much lower cure rates in

general than lower alkyl 2—cyanoacrylates. Moreover, they are particularly susceptible to inhibition by

acidic impurities. This higher set time was caused by such an impurity present in the propyl gallate.

Purification of the propyl gallate by crystallization gave a product which had a set time comparable to

that of other adhesion promoters herein. 35

From the results it is clear that the adhesion promoters are very effective in butyl 2—cyanoacry|ate A

adhesives for bonding steel and aluminum. The results obtained on brass are somewhat anomalous

since the control yielded an unusually high value for the tensile shear strength on brass. in all cases,

with the exception noted above for the propyl gallate containing the acidic impurity, the cure rate of the

adhesive is not retarded with addition of the adhesion promoter. 40

Example Ill

This example illustrates the effect of the adhesion promoters of this invention on the cure rate

and bond strength of methyl 2—cyanoacry|ate, which gives very strong bonds with metals and is thus

frequently the recommended ester for bonding these types of substrates.

Four samples of 2—cyanoacry|ate adhesive composition were prepared as described in Example I 45

except that the 2—cyanoacry|ate ester employed was methyl 2—cyanoacry|ate containing a small fixed

amount of sulfur dioxide and 0.001% hydroquinone as stabilizers. Each resulting composition was

evaluated as in Example I. The results. are summarized in Table III.

Table III

_ Amount of Adhesion Tensile Shear Strength 50

14¢?’/768/ON Promoter Added Set Time l/60 123 1 12 79

59.2 >60 75 59 58

The above procedure was repeated using propyl gallate instead of methyl gallate as adhesion

25 promoter. The propyl gallate was obtained commercially and was recrystallized to remove any acid 25

impurities before use thereof. The results are given in Table V.

Table V

Concentration

of Propyl Gallate Set Time Tensile Shear Strength l/

Coments go here:

- Log in to post comments