Methyl Alpha-Cyanoacrylate I. Free-Radical Homopolymerization

Methyl Alpha-Cyanoacrylate I. Free-Radical Homopolymerization

Folder:

Journal:

Year:

Abstract:

Methyl α-cyanoacrylate, when suitably inhibited by Lewis acids against anionic polymerization, can be polymerized readily with free-radical initiators to form hard, clear, high molecular weight polymers. The ratio of kp2/kt is approximately 0.021 at 60°C. if 100% efficiency of initiation by azobisisobutyronitrile is assumed. Acceleration occurs at very low conversion to polymer during bulk polymerizations. The homopolymer is thermally unstable at temperatures only slightly above the glass temperature (estimated to be 165–170°C.). Degradation of the polymer under gamma irradiation is pronounced, only 18 e.v. being required per main-chain scission.

DOI:

10.1002/app.1960.070041116

Type of document:

Language:

VOL. IV, ISSUE NO. 11, PAGES 231-236 (1960)

JOURNAL OF APPLIED POLYMER SCIENCE

Methyl a-Cyanoacrylate. I. Free-Radical Homopolymerization*

A. J. CANALE, E. GOODE, €3. KlNSINGER,t J. R. PANCHAK, KELSO, R. K. GRAHAM$

W.

J.

R. L.

and

Research Division, Rohm & Haas Company, Bristol, Pennsylvania

The preparation of high polymers of methyl

When the monomer is suitably inhibited with a

a-cyanoacrylate by free-radical initiation does not

Lewis acid against anionic polymerization and when

seem to have been adequately described in the

precautions are taken against extraneous moisture

literature. Procedures for the preparation of the

(such as using acid-washed and carefully dried

monomer,'S2 stabilization against anionic polymerequipment and conducting all handling operations

ization,2 and some properties of the bulk polymer'

in a dry box), reproducible results can be obtained

have appeared in the patent literature. A discusin free-radical polymerizations.

sion of the chemistry of cyanoacrylate monomers

as adhesives has a ~ p e a r e d . ~

With the exception of

Bulk Free-Radical Polymerization

a recent study by Mihail, Lupu, and D a ~ c a l u , ~

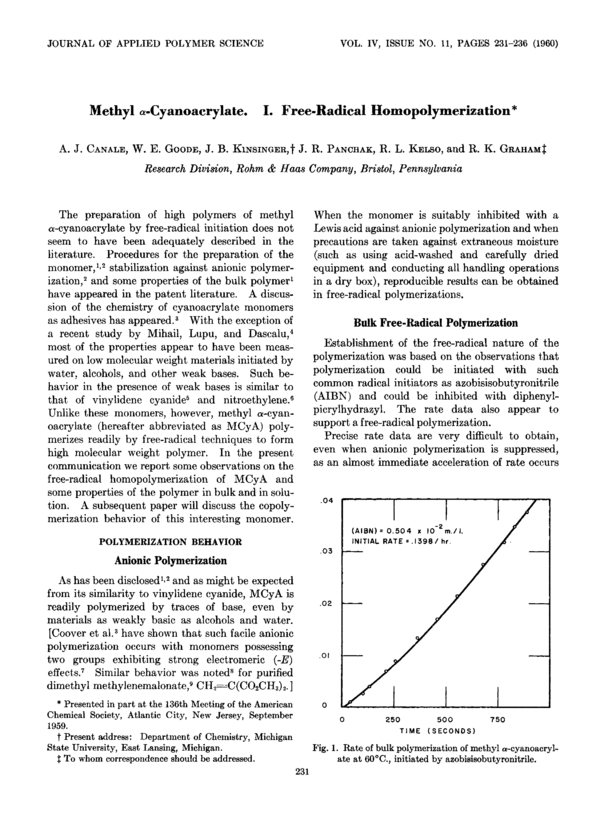

Establishment of the free-radical nature of the

most of the properties appear to have been measpolymerization was based on the observations that

ured on low molecular weight materials initiated by

polymerization could be initiated with such

water, alcohols, and other weak bases. Such becommon radical initiators as azobisisobutyronitrile

havior in the presence of weak bases is similar to

(AIBN) and could be inhibited with diphenylthat of vinylidene cyanide5 and nitroethylene.6

picrylhydrazyl. The rate data also appear to

Unlike these monomers, however, methyl a-cyansupport a free-radical polymerization.

oacrylate (hereafter abbreviated as MCyA) polyPrecise rate data are very difficult to obtain,

merizes readily by free-radical techniques to form

even when anionic polymerization is suppressed,

high molecular weight polymer. In the present

as an almost immediate acceleration of rate occurs

communication we report some observations on the

free-radical homopolymerization of MCyA and

some properties of the polymer in bulk and in solu.04

tion. A subsequent paper will discuss the copolymerization behavior of this interesting monomer.

TlAL RATE

POLYMERIZATION BEHAVIOR

= .I398 / h

.03

Anionic Polymerization

As has been disclosed1v2 as might be expected

and

from its similarity to vinylidene cyanide, MCyA is

readily polymerized by traces of base, even by

materials as weakly basic as alcohols and water.

[Coover et al.3 have shown that such facile anionic

polymerization occurs with monomers possessing

two groups exhibiting strong electromeric (-E)

effect,~.' Similar behavior was noted8 for purified

dimethyl met hylenemalonate , CH,=C (COzC *.]

H3)

* Presented in part a t the 136th Meeting of the American

Chemical Society, Atlantic City, New Jersey, September

1959.

t Present address: Department of Chemistry, Michigan

State University, East Lansing, Michigan.

$ To whom correspondence should be addressed.

.02

.01

0

0

250

TIME

500

750

(SECONDS)

Fig. 1. Rate of bulk polymerization of methyl a-cyanoacrylate at 6OoC., initiated by azobisisobutyronitrile.

231

232

CANALE, GOODE, KINSINGER, PANCHAK, KELSO, AND GRAHAM

at low conversion. This effect is similar to that

found for methyl acrylate,*O although the autoacceleration is detected here at even lower conversions. Some turbidity is noticed throughout the

polymerization, but no settling out of polymer was

found; the polymer formed at high conversions

is optically clear. This behavior is somewhat

similar to that of methacrylonitrile in bulk.”

TABLE I

Comparison of kps/kl Values of Various Vinyl Monomers at

6OOC.

kp2/kt x 104,

1./mole/see.

Vinylidene cyanide

Styrene

Acrylonitrile

Methacrylonitrile

Methyl methacrylate

Methyl a-cyanoacrylate

Vinyl acetate

Methyl acrylate

.20

-

(Table I) of this value with those for severaI other

common monomers.

.I 5

.

r

9

0.116

0.491b

0. 697b

1.44

2.10

18.5

106.0

Reference

5

14

15

15

16

This work

16

16

a Does not appear to form homopolymer with free-radical

initiation.

Measured in dimethylformamide solution.

e Assumes 100% efficiency of initiation.

.05

0

0

02

04

06

(AIBN,

oe

m l l

1

0

1

2

Io5

Fig. 2. Rate of bulk polymerization of methyl a-cyanoacrylate at 60°C. as a function of initiator concentration.

The data from a typical dilatometric polymerization are shown in Figure 1; extrapolation to initial

rate was made from times of less than 200 sec.

A duplicate polymerization was performed at the

same time with no AIBN present, and the rate of

this control was subtracted from the overall rate

to obtain the AIBN-initiated rate to compensate

for any spurious anionic or free-radical reactions.

It is realized that error could be introduced because of expansion of the confining liquid under

nonsteady-state conditions12 and also because the

rate of the “control” is competitive with the AIBNinitiated reaction, so that the corrected rate is a

relatively small difference between relatively large

numbers. A series of these measurements was

applied to the determination of the rate-initiator

concentration relationship, which is shown in

Figure 2 to be: rate (yo/hour) = 175 [AIBNIOJ;

rate (fraction/sec.) = 4.86 X 10-4[AIBN]o.5 =

R , / [ M ] . From this relationship, from the known

valuesI3 for the decomposition of AIBN at 60°C.

(1.1 X

sec.-l> and arbitrarily assuming 1 0 0 ~ o

efficiency of initiation, k P 2 / k ,is calculated as 0.021

l./mole/sec. Although this calculation requires

several approximations, it allows a comparison

It can be seen that MCyA is quite unlike vinylidene cyanide in its free-radical homopolymerization

behavior. Examination of models suggests a

lower degree of electrostatic hindrance for addition

of MCyA to its own polymeric radical relative to

vinylidene cyanide, but the striking difference in

behavior is not obviously explained.

The relatively high value of k P 2 / k ,may be related

to a low value of k,. Mutual electrostatic and

steric repulsion would make mutual combination of

radicals relatively unlikely. Termination by disproportioiiation would involve abstraction of a

hydrogen atom from the ester methyl group (unlikely) or from a p-carbon; examination of models

suggests that abstraction of hydrogen from the pcarbon is much more hindered than that, from a

methyl group such as that in methyl methacrylate.

Inhibition, Branching, and Chain Transfer

No detailed study of the inhibition of free-radical

polymerization of MCyA has been made. Many

of the common inhibitors, especially those which

function as antioxidants, contain basic functional

groups which initiate anionic polymerization of

MCyA.

Diphenylpicryhydrazyl and benzoquinone are relatively effective inhibitors. Furfurylidene malononitrile, a very effective inhibitor

for styrene” and a relatively effective inhibitor

for methyl methacrylateX8

and methyl acrylate, l 9

acts only as a ret,arder of polymerization in this

system. An effective inhibitor of MCyA would

be expected to act as an electron donor, so t.hat a

METHYL or-CYANOACRYLATE. I

contribution to the transition state could be made

by resonance forms of the type

233

strongly suggests that these polymerizations were

not free-radical, but anionic in nature.

CN

-CH2-

L

:a--

SOLUTION PROPERTIES

- -(Inhibitor)a'

AOOCHJ

with a consequent lowering of the activation

energy. 2o Furfurylidene malononitrile would be expected to act as an electron acceptor in such

systemsls and so would be much less effective.

Branching by chain transfer with polymer is

unlikely with MCyA, since there are no labile hydrogen atoms in the polymer. No crosslinked

polymer has ever been detected, even in high conversion polymerizations, but no attempt has been

made to detect low degrees of branching. Synthesis

of pure model compounds for chain transfer studies

has proved difficult.

Attempts to regulate the molecular weight of

bulk or solution polymerizations with dodecyl

mercaptan indicated that little change was effected.

Also, conversions seemed to be somewhat higher

in the presence of mercaptan. It is conceivable

that the mercaptan is capable of acting as a weak

anionic initiator. Mercaptans would not be expected to be very effective transfer agents in the

radical polymerization of MCyA, since polar contributions to the transition state are less favored

than in the case of styrene;21 however, it was unexpected that essentially no control could be

achieved.

Solution Polymerization

An attempt to study polymerization in solution

to minimize the autoacceleration effect found in

bulk was unsuccessful when benzene was used as

a solvent, since the polymer precipitated as a highly

swollen gel. Many of the solvents in which homogeneous polymerizations could be conducted are

extremely difficult t,o obtain completely free of

water or other ionic initiators. Near the completion of this study, it was found that AIBNinitiated solution polymerizations could be conducted in carefully purified isobutyronitrile or

nitromethane, but no kinetic data were obtained

in these solvents.

Mihail et al.4 have described the emulsion polymerization of cyanoacrylate esters initiated with

hydrogen peroxide in the absence of emulsifying

agent. The molecular weight was reported to

decrease with increasing temperature. The extreme sensitivity of MCyA to even traces of water

Solvents for the homopolymer include propionitrile, pyridine, nitroethane, nitromethane, acetonitrile, dimethylformamide, ethylene carbonate,

succinonitrile, and butyrolactone. Swelling ratios

in these solvents were measured on polymer crosslinked with a small amount of ethylene glycol

dimethacrylate; a rough estimate of the square

root of the cohesive energy density from these

data gives a value of ca. 14.5, relatively close to

that for polyacrylonitrile. Many of the above

solvents are also solvents for polyacrylonitrile.

Polymers of MCyA are insoluble in alcohols, which

indicates the absence of strong hydrogen bonding.

The homopolymer is also insoluble5 in common

aromatic solvents (benzene, toluene), ketones

(acetone, methyl ethyl ketone), and chlorinated

solvents (chloroform, ethylene dichloride).

Polymers were purified for analysis by dilution

with purified nitromethane and precipitation in

the nonsolvent, diethyl ether. Anhydrous ether

was used to prevent inadvertant polymerization

of remaining monomer. After thorough washing

with ether to remove monomer, the polymer was

redissolved in nitromethane and reprecipitated

into ether or methanol containing a little hydkochloric acid.

Preliminary data have been obtained on the

intrinsic viscosity-molecular weight relationships

for MCyA homopolymer in acetonitrile (a poor

solvent) and nitromethane (a good solvent).

Measurements were carried out a t 30°, which is

below the theta temperature for this polymer in

acetonitrile. The data for four whole polymers

give the relationships:

[q] =

6.43 X 10-5M,0-77

(nitromethane, 30°,

~ w - r a n g 106 to 5

e

[TI

=

x

106)

8.45 X 10-4M,0-45

(acetonitrile, 30°,

MW range 5 X lo3 to 3 X lo5)

It is hoped to publish more details on the dilute

solution behavior at a later date. The present

relationships are useful in showing that high molecular weight polymer is formed with radical

initiators.

Solutions of MCyA polymer in dimethylformamide or dimethyl sulfoxide exhibited a decrease in

intrinsic viscosity on long standing at room tem-

234

CANALE, GOODE, KINSINGER, PANCHAK, KELSO, AND GRAHAM

perahre or on heating. This behavior is reminiscent of that observed for poly(vinylidene cyanide) in the presence of water and bases.6

BULK PROPERTIES

The homopolymer must be prepared from very

pure monomer to give clear, transparent sheet

castings; traces of impurities can lead to yellowing

of the material. Molding of samples for physical

testing is difficult because of the thermal degradation discussed below.

Dilatometric measurement of the glass temperature could not be accomplished because of

degradation at temperatures only slightly above

the glass temperature. From the Vicat softening

point and A.S.T.M. heat distortion measurements,

the glass temperature was estimated to be

165OC. < T o < 17OoC., which agrees well with

earlier results.22

TABLE I1

Physical Properties of High Molecular Weight

Poly(methy1 a-Cyanoacrylate)

No. 1

No. 2

No. 3

~~

Plex 1 8

1

~~~

Heat distortion

temp., "C., at

264 psi (ASTMD-648-56)

163b

157b

160b

96bo

Impact strength,

Izod, unnotched,

X 1 in. section (ASTM-D256-56)

5.8

6.3

5.6

7.0d

Flexural strength,

psi (ASTM-D790-49-T)

16,500 15,100 17,700 16,000

Modulus in flex554,000 557,000 530,Ooo 450,000

we, psi

Deflection at

break, in.

0.46

0.45

0.49

0.6

Reduced specific

viscosity, dl./g."

1.8

2.5

2.0

Average values not intended for specification purposes.

b Conditioned 48 hr. at 50°C.

Not annealed; value increased ca. 15" on annealing.

in. secd Estimated from Charpy unnotched on 1/p X

tion.

0 In nitromethane at 25°C. at 2 gJ1.

a

The cast sheet exhibits physical properties comparable with other high molecular weight thermoplastic materials such as poly(methy1 methacrylate). Some typical properties of our best preparations are shown in Table 11, where they are compared with typical data for Plexiglas 11.

THERMAL AND IRRADIATION DEGRADATION

On heating in air above 18OoC., the homopolymer of MCyA yellows and bubbles. Some monomer is liberated, and the intrinsic viscosity of the

residue drops sharply. Under these conditions,

most of the relatively nonvolatile monomer cannot

escape and is repolymerized to low molecular weight

material. The actual weight loss is low. A few

i vacuo experiments indicated the decrease in

n

molecular weight to be less pronounced, but the

amount of volatile material increased sharply.

The relative ease of thermal depolymerization

has been utilized in the synthesis of MCyA monomer from low polymer.'S2 Attempts to add stabilizers or to vary the nature of the end groups have

been unsuccessful in preventing this degradation.

Whether initiation of depolymerization occurs

randomly or preferentially a t weak links has not

been determined; possible sources of weak links

might be tail-to-tail placement caused by termination of polymerization by combination or ketimine

links from polymerization t,hrough the nitrile

group. Such ketimine links, previously reported

for polymethacrylonitrile,28 could not be detected

by ultraviolet spectroscopy.

Gamma irradiation in vacua of MCyA homopolymer causes a decrease in molecular weight

which appears to be proportional to dose. In

Figure 3 are plotted reciprocal viscosity-average

molecular weights for MCyA and MMA homopolymers as a function of irradiation time. From

the relative slopes of these lines and the known

energy requirements for irradiation degradation

12

POLY-(METHYL S - C Y A N O A C R Y L A T E )

9

_

I

(D

I

2

.

_

.

x

>

I I

-

3

POLY-(METHYL

METHACRYLATEI

-

0

0

4

S

1

2

T I M E OF I R R A D I A T I O N

1

6

20

(HOURS)

Fig. 3. Reciprocal viscosity-average molecular weight,

l/MwJplotted against time of irradiation for poly(methy1

a-cyanaoacrylate)and poly(methy1 methacrylate).

METHYL a-CYANOACRYLATE. I

of poly(methy1 methacrylate) (60 e.v. per mainchain scission)124 poly-MCyA appears to require

only ca. 18 e.v. per main-chain scission. Not

enough data are available to show that some concurrent crosslinking is not occurring; as Shultz

has pointed

it is possible that such a decrease

in apparent viscosity-average molecular weight

can be found with some crosslinking also occurring.

This behavior would be unexpected, however, in

view of the rather general rule that polymers of

backbone structure -CHz-CXYonly degrade.25

EXPERIMENTAL

Monomer of high purity was prepared by the

method of McKeeverlZ8 which the condensate of

in

formaldehyde and methyl cyanoacetate is treated

with acetic anhydride to remove water liberated

in the cracking of the condensate. The monomer

had the following properties: m.p. l°C., b.p. 46OC.

(1.5 mm.), ng 1.4431, dy 1.100 g./ml., dm 1.067

g./ml. The monomer was inhibited against anionic polymerization with boron trifluoride-acet.ic

acid complex and stored in a refrigerator in polyethylene bottles .

Rates of polymerization were followed at 6OoC.

dilatometrically, mercury being used as the confining liquid. The density of the polymer was 1.304

g./ml. at 25O and 1.289 g./ml. at 60°, and the contraction on polymerization was 18.7 ml./mole.

In many of the polymerizations, a second dilatometer containing no initiator was filled and degassed at the same time. Rates of both polymeritions were measured and the rate of polymerization

of the control subtracted from the overall rate.

Reagent grade nitromethane and anhydrous

diethyl et.her were used as diluents and precipitants.

Dodecyl mercaptan was redistilled before use.

Diphenylpicrylhydrazyl and furfurylidene malononitrile were supplied by Dr. J. L. Kice.

The intrinsic viscosity measurements were determined with a Ubbelohde-type viscometer at

3OOC. Light-scattering measurements were determined with a Brice-Phoenix light scattering

photometer at 3OOC.

Many members of the Research Division have contributed

t phases of this work. We wish especially to thank Dr.

o

C. H. McKeever, Dr. H. R. Raterink and Mr. S. Wise for

monomer preparations and W. H. Snyder, J. Dzomba and

L. Foell for polymerieatlon studies. Irradiation studies

were performed using the cobalt-60 source of the University

of Pennsylvania; we are grateful to Dr. R. E. Hughes for his

assistance.

235

References

1. Ardis, A. E., U. S. Pat. 2,467,926-7 (1949).

2. Joyner, F. B., and G. F. Hawkins, U. S. Pat. 2,721,858 (1955).

3. Coover, H. W., Jr., F. B. Joyner, N. H. Shearer, Jr.,

and T. H. Wicker, Jr., SPE Journal, 15,413 (1959).

4. Mihail, R., A. Lupu, and L. Dascalu, Rev. chim.

(Bucharest), 9, 606 (1958).

5. Gilbert, H., F. F. Miller, S. J. Averill, R. F. Schmidt,

F. D. Stewart, and H. L. Trumbull, J . Am. Chem. Soc., 76,

1074 (1954).

6. Weiland, H., and E. Sakellarois, Ber., 52, 898 (1919).

7. Ingold, C. K., Structure and Mechanism in Organic

Chemistry, Cornell Univ. Press, Ithaca, N. Y., 1953, pp. 64 ff.

8. McKeever, C. E., and H. R. Raterink, private com-

munication.

9. Schildknecht, C. E., Vinyl and Related Polymers,

Wiley, New York, 1952, p. 307.

10. Walling, C., J. Am. Chem. Soc., 70, 2561 (1948).

11. Schildknecht, C. E., op. cit., pp. 294-95.

12. Burnett, G. M., Trans. Furaday Soc., 46, 772 (1950).

13. Results compiled by C. Walling, J . Polymer Sci., 14,

214 (1954).

14. Tobolsky, A. V., and J. Offenbach, J . Polymer Sci., 16,

312 (1955).

15. Bamford, C. H., A. D. Jenkins, and R. Johnston,

Proc. Royal SOC.(London), 2398, 214 (1957).

16. Matheson, M. S., E. E. Auer, E. B. Bevilacqua, and

E. J. Hart, J . Am. Chem. Soc., 71, 497, 2610 (1949); ibid.,

73, 5395 (1951).

17. Haward, R. N., and E. T. Borrows, U. S. Pat. 2,650,899 (1953).

,

18. Kice, J. L., J . Am. Chem. ~ o c .76,6274 (1954).

19. Kice, J. L., J. Polymer Sci., 19, 123 (1956).

20. Mayo, F. R., and C. Walling, Chem. Revs., 46, 191

(1950).

21. Walling, C., J. Am. Chem. Sac., 70, 2561 (1948).

22. Deutsch, K., E. A. W. Hoff, and W. Reddish, J

Polymer Sci., 13, 565 (1954).

23. Talat-Erben, M., and S. Bywater, J . Am. Chem. Soc.,

77,3710, 3712 (1955).

24. Shultz, A. R., P. I. Roth, and G. B. Rathmann, J.

Polymer Sci., 22, 495 (1956).

25. Miller, A. A., E. J. Lawton, and J. S. Balwit, J . Polymer Sci., 14, 503 (1954).

26. McKeever, C . H., U. S. Pat. 2,912,454 (1959).

synopsis

Methyl a-cyanoacrylate, when suitably inhibited by Lewis

acids against anionic polymerization, can be polymerized

readily with free-radical initiators to form hard, clear, high

molecular weight polymers. The ratio of k,a/k, is approximately 0.021 a t 6OOC. if 100% efficiency of initiation by

azobisisobutyronitrile is assumed. Acceleration occurs a t

very low conversion to polymer during bulk polymerizations.

The homopolymer is thermally unstable a t temperatures

only slightly above the glass temperature (estimated to be

165-170°C.). Degradation of the polymer under gamma

irradiation is pronounced, only 18 e.v. being required per

main-chain scission.

236

CANALE, GOODE, KINSINGER, PANCHAK, KELSO, AND GRAHAM

R6sum6

Zusammenfassung

L’a-cyanoacrylate de mkthyle, lorsqu’il est convenablement inhibe par les acides de Lewis vis-his de la polymerisation anionique, peut &re rapidement polym6ris6 par

des initiateurs radicalaires pour donner un polymbre dur,

clair et de haut poids mol6culaire. Le rapport kp2/k,est

approximativement de 0,021 B 60°C si I’on admet 100%

d’efficacit6 d’initiation par l’azobis(isobutyronitri1e).

L’acc616ration a lieu a des tres faibles degres de conversion

durant la polymerisation en bloc. L’homopolymbre n’est

thermiquement instable qu’B partir d’une temperature

Iegbrement superieure B la temperature de transition vitreuse (estim6e 165-170°C). La dhgradation du polymbre par

irradiation gamma est prononc6e e t elle ne nCcessite que 18

6lectron-volts par scission de chaSne.

Methyl-a-cyanoacrylat, das durch die Anwesenheit von

Lewis-Sauren gegen anionische Polymerisation entsprechend

geschutet ist, kann mit radikalischen Startern leicht zu

harten, klaren, hochmolekularen Polymeren polymerisiert

werden. Das Verhaltnis kp2/k,

betragt unter Annahme einer

100% Starterausbeute mit Aeo-bis-isobutyronitril bei 60°C

etwa 0,021. Bei der Polymerisation in Substane tritt bei

sehr niedrigem Umsatz eine Reaktionsbeschleunigung ein.

Das Homopolymere ist bei Temperaturen, die nur schwach

oberhalb der Glasumwandlungstemperatur (zu 165-170°C

bestimmt) liegen, thermisch instabil. Der Abbau des Polymeren unter Gammabestrahlung ist erheblich; es sind nur

18 Elektronvolt zur Spaltung der Hauptkette erforderlich.

Received March 17, 1960

Revised June 14, 1960

Coments go here:

- Log in to post comments