Synthesis of End Use Evaluation of Pinene-based Alicyclic Acrylates

Synthesis of End Use Evaluation of Pinene-based Alicyclic Acrylates

Journal:

Year:

Abstract:

Alicyclic mono and diacrylates from alpha-pinene and beta-pinene were synthesised and characterized spectroscopically. They were compounded in alkyl 2-cyanoacrylate adhesives as crosslinkers. Their effect on the adhesive bond strengths after exposing the adhesive bonds to various temperatures, was studied.

Type of document:

Language:

__ _._, ,,,..,.....,,..,,._;,_,‘.,,.,,._._-._.,:_s,...., .. . .. W

Synthesis and End Use Evaluation of Pinene-based Alicyclic Acrylates

V. VIJAYALAKSHMI, J.N. RUPAVANI and N. KHISHNAMURTF

Organic Coatings and Polymers, Indian Institute of Chemical Technology,

Hyderabad 500 007, India

ABSTRACT

Alicyclic mono "and diacrylates from or-pinene and B-pinene derivatives were synthesised and

characterized spectroscopically. They were then compounded in alkyl 2-cyanoacrylate adhesives

as crosslinkers. Their effect on the adhesive bond strengths after exposing the adhesive bonds

to various ‘temperatures, was studied. _

Kev Wono: Acrylate '

INTRODUCTION

Poor heat resistance of alkyl 2-cyanoacry-

late adhesives especially on metal surfaces has

prompted a number of attempts to improve this

limitation. Various non-cyanoacrylate modifiers

were proposed over thelast two decades; they

were dialkenyl phthalates, acrylic and

methacrylic esters“ 2. * t

The improvement in heat resistance ofthe

adhesive bonds at

depended on the formation of _a't_hree-dimen-

sional networkot the additive,‘ which may aiso

co-react radically with the 2-cyanoacrylatei

Therefore new acrylic esters irom pinenes

(Scheme 1) were prepared to study their effects

on the heat resistance of 2-cyanoacryiate ad-

hesive bonds. ’

EXPERIMENTAL

Materials

Propyl cyanoacrylate was prepared in our laboratory.

The details of the synthesis and its properties are already

' Correspondence author.

J. Polym. Mater. 13- (1996) 127-131

© Oxford & IBH Publishing Co. Pvt. Ltd.

Journal of Polymer Materials June 1996

elevated temperature.

reporteds. . _

Polyethylene glycol 200 dimethacrylate was also

prepared by us and its synthesis and properties are

reported earlier‘. '

All the rest of the chemicals used in this investigation

are of 95 per cent pure.

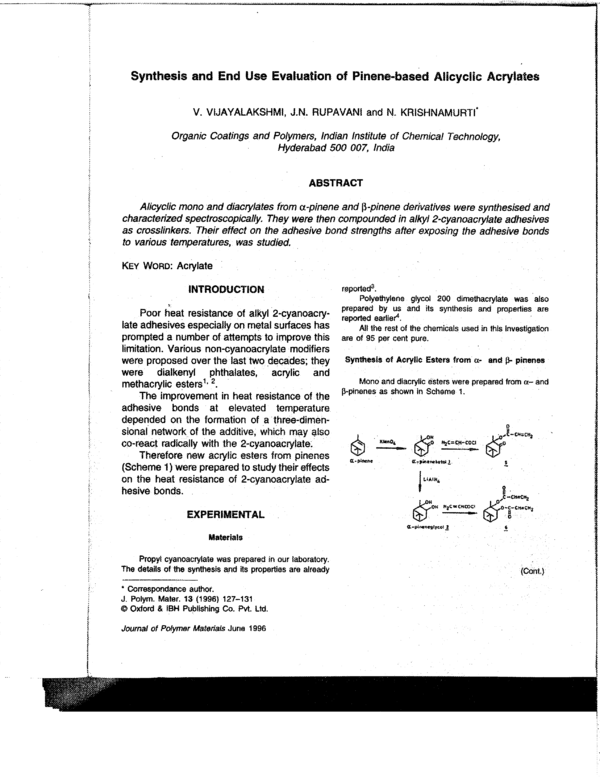

Synthesis of Acrylic Esters from a- and 13- pinenes

Mono and diacrylic esters were prepared from u~ and

it-pinenes as shown in Scheme 1. '

D

_. N _ - ,3-I-Cl-t:CH3

HOMO‘ ‘ o n;c=c_H—c-ncl o

'-'--=—C—a _ -—-.—-........y..

(I.-pincne I

t‘£._-aénnnarlwtot _l_. 5

£Luur¢,_

8 A .

C-‘CREE

N 0’ N2

on PQCIECKCOCE '.E..¢p¢.cNz

_.._......_... _

. . ‘ 9 . _ K

K-pincnzgtyaohg _§_

’(Coht.)

128 V. Vijayalakshmi, J.N. Fiupavani and N. Krishnamurti

0

$0" mcncuoocr $/°‘E"¢"=€"1

'----:-1-

S5 "°’

it-plume FR‘-oearuol 3 1

new

amen);

0

onion C1505-cH=cNz

' 0" 11,c=cn—ooc1 0-¢'¢""¢*'2

__.—-—n-

2,10 ll-r1inone_uiol _L_ I

Preparation of ketol (1). Pulverized potassium per-

manganate (100 g, 0.63 mol) was added over a period of

10 h to a ice cold stirred solution of a-pinene (50 g. 0.36

mol) in 90% aq. acetone (440 mL). The reaction mixture

was stirred at 0-5°C. for an additional 24 h. It was then

filtered, distilled to remove acetone and extracted with

ether. The combined ethereal extracts were washed with

water and saturated aqueous sodium bicarbonate. dried

and concentrated to give an oily product, which was then

distilled-to give ketol boiling point: 113—115°C (17 mm Hg).

Yield (%): 33.5 g (55); lR (neat) (cm“): 3610, 3500.

1720; ‘H-NMR (CDCl;;) 5 (ppm): 2.60-1.65 (m, 7H), 1.38

(s, 3H), 1.32 (s, 3H), 0.88 (s. SH).

Preparation of glycol (2). To a solution- of powdered

lithium aluminium hydride (1.6 g, 0.042 mol) in ether (90

mL) was added dropwise under nitrogen blanket with stir-

ring, a solution of ketol (1). (5.9 g, 0.31 mol) in ether (50

mL) at such a rate so as to maintain a gentle rell_u_x. Alter

complete addition, the mixture was heated to reflux for 0.5

h and was allowed to cool. Next, water (5 _mL). and_

aqueous 15 percent Na0H (1.5 mL) solution were added

to the mixture and stirred for one hour to ensure decom

position of the reduction complex. The mixture was filtered

and the granular precipitate was washed with several por-

tions of ether. Thecombined extracts were waslfied-with

water, dried and concentrated togive a colorless solid.

which was purified by eluting with hexane : ethylacetate

mixture (75 : 25 v/v) through a silica gel packed column.

Yield (%): 2.31 g (43); IR (neat), cm"‘: 3610, 3420;

NMR (CDCl3) 5 (ppm): 3.96 (d, 1H), 2.65-1.33 (n1. 6H),

1.29 (s, 3H), 1.26 (s. 3H), 0.93 (s, 3H),

Preparation of pinocarveol (3). A solution of selenium

dioxide (0.74 g, 0.007 mol) in tart. butane! (150 mL) was

taken into a- flask fitted with a mechanical stirrer, ther-

mometer, dropping tunnei and retiux condenser. (3-pinene

(68 g, 0.5 mol) was then introduced. The resulting mixture

was warmed to 40°C. Then aqueous 50% H202 (35 mL,

0.52 mol) was added dropwise over a period of 30 minutes

while the mixture was maintained at 40—50°C. After stirring

for a period of 2 h, the reaction mixture was diluted with

benzene (50 mL), washed with aqueous saturated am-

monium sulfate and dried over anhydrous sodium sulfate.

A small amount of hydroquinone was added and the sol-

Journal of Polymer Materials June 1996

‘ _ vents were stripped off. The product was then purified by

distillation under reduced pressure.

Boilling point: 60-70°C (1.5 mm Hg): Yield M): 35 g

(46), IR (neat), cm“: 3360, 1650, 1380, 1360, 897; NMR

(CDCI3) 5 (ppm): 4.93 (d, 2H), 2.50-2.12 (m, 7H), 1.35 (s,

3H), 0.687 (s, 3H)

Preparation of dial (4).. Sodium borohydride (1.014 g,

0.026 mol), diglyme (30 mL) and pinocarveol (10 g. 0.065

mol) diluted with 5 mL or diglyme were placed in a flask

equipped with a condenser and titled with a CaCl2 guard

tube, a pressure equalizing dropping funnel, a thermometer

and a magnetic stirring bar were placed. The flask was

immersed in a water bath at 20-25°C. Diborane was

generated by dropwise addition ol boron triliuoride

ethereate (4_.59 mL, 0.036 mol) to the well stirred reaction

mixture over a period of 15 min. The‘ mixture was stirred

for an additional hour at 30°C. The excess . sodium

borohydride was decomposedby the addition of 8 mL

water. "The organoborane thus formed was oxidized at

30°C by adding 3 M aqueous NaOH solution (8 ml.) fol— .

lowed by dropwise addition of 30% hydrogen peroxide (7.5

mL) to the well stirred reaction mixture. The reaction mix-‘

ture was stirred for an .additional.h_our and extracted with

70 mL of ether and washed with ice water to remove

diglyme. The “ether extract was dried over anhydrous mag-

nesium sulfate and the solvent was removed by distillation.

The crude product was purified through a silica gel packed

column using hexane. ethyl acetate (75:25 v/v) mixture as

eluent. 1 . . T

Yield (°/..): 8 g (59.2); lR_(n_eat), cm“: 3350, 1330,

1370; ‘H-NMR (CDCl;,). 5 (ppm): 4.87 (d, 2H), 2.5—1.62 (m,

7H), 1.31 (s, 3H), 0.667 (s, 3H), -

Preparation of monoacrylates (5, 7). Acryloyl chloride

(0.03 mol) ‘was addedgradually to an ice cooled mixture

of alcohol (0.03 mol), . triethylamine (0.06 mol), hydro:

quinone, and chlorolorm (160 mL). The solution was

heated to reflux for 2 h. After cooling, the mixture was

poured into cone. l-iCi_ (4.9lml_)_and water (65 mL)_ and

extracted three times with petroleum ether (b.pL: 4l}—60°C).

The crude product was purified over a column of silica gel

(finer than 200 mesh) and oluting with hexane to give the

purified product. 7

Preparation of diacryiates (6, 8). Two rhcrylates (6, 8)

from diols (2, 4) were prepared by taking alcoholand

acryloyl chloride in 1:2 mole ratio and following the prose

dure described lor monoacrylates5'7. 6

These alicyclic acrylates were characterized by lFt,

NMR and mass spectroscopy.

infrared Spectroscopy (ER)

The lR spectra were recorded using Perkin-Elmer

(Model 221) spectrophotometer. The absorption bands for

C=O stretching vibrations at 1725 cm“ and for 0-0

hen purified by

Yield (Va): 35 g

360. 897: NMR

n, 7H). 1.35 (s,

'dride (1.014 g,

ol (10 g. 0.065

aced in a flask

a CaCl2 guard

a thermometer

The flask was

Diborane was

Jron tritluoride

stirred reaction

ure was stirred

excess sodium

dition of 8 mL

‘as oxidized at

lion (8 mL) fol- .

in peroxide (7.5

:e reaction mix-

! extracted with

ater to remove

inltydrous mag-

d by distillation.

llica gel packed

vlv) mixture as

": 3350. 1330,

_i)_, 2.5—1.s2 (m,

lcryloyl chloride

cooled mixture

6 mol), hydro-

a_ solution was

re mixture was

ar (65 mt.) "and

(b.p.: 40—60°C).

imn of silica gel

zane to give the

«ciacrylabs (6. 8)

ng alcohol and

wing the proce-

tcterized by lR,

)

lg Perkin-Elmer

rption bands for

‘ and for 0-0

;.-.-».-;.-.—/9.x.»-t-.-.-.-.t,..-aw.-.-4-.«..~.-.... ... . . . .

. Acrylates

Synthesis and End Use Evaluation of Pinene-based Alicyclic Acrylares 129

TABLE 1. ‘H—NMR (5 ppm) Values of Acrylates from Pinenes

8 ppm values. of alkyl protons

3-Keto pinyl acrylate (5)

0.37 (s, 3H). 1.37 (5, 31-1), 1.62

(s, 3H), 1.95-3.02 (in, 6H)

Pinocarveyl acrylate (7)

0.75 (5, 3H), 1.33 (s. 3H). 4.75 (

Coments go here:

- Log in to post comments