Method of Obtaining a Tack-Free Artificial Nail Surface Using Odorless Monomers

Method of Obtaining a Tack-Free Artificial Nail Surface Using Odorless Monomers

US7622511

Company:

Folder:

Year:

Abstract:

A method and kit for providing a tack-free artificial nail surface. The tack-free artificial nail surface may include an acrylic layer and a barrier layer. The acrylic layer may comprise an odorless monomer. The barrier layer may be of any material impervious to oxygen. The tack-free nail surface may be formed by application of the acrylic layer to a fingernail nail bed. The barrier layer may then be applied over the acrylic layer. The barrier layer blocks oxygen from the acrylic layer so that the acrylic layer may polymerize in the absence of oxygen.

Type of document:

Language:

US007622511B1

(12) Ulllted States Patent (10) Patent No.: US 7,622,511 B1

Sirdesai et al. (45) Date of Patent: Nov. 24, 2009

(54) METHOD OF OBTAININGA TACK-FREE (56) References Cited

ARTIFICIAL NAIL SURFACE USING

ODORLESS MONOMERS U.S. PATENT DOCUMENTS

. 4,085,442 A * 4/1978 Liaukusetal. ............ .. 345/556

(75) lrlyerltersi SrrrrllJ-SlreleSalslrVrr1esCA (US); 4,495,172 A * 1/1985 Orlowskietal. .. 424/61

Lauren M- Breese, Sarita Barbara, CA 4,871,534 A * 10/1989 Montgomery .............. .. 424/61

(US); George W- Sehaeffer, Beverly 5,127,414 A * 7/1992 Mast et al. .................. .. 132/73

Hills; CA (US) 6,060,073 A * 5/2000 Keller ...................... .. 424/401

(73) Asslgneez OPI Products, Inc.; North Hollywood, FOREIGN PATENT DOCUMENTS

CA (U S)

JP 54-046240 * 4/1979

* N ' S bj yd’ l ' h f hi

ot1ce: u ect to an 1sc a1mer;t etermo t s

patent is extended or adjusted under 35 . .

U.S.C. 154(b) by 606 days. * Cited by exammer

Primary Examiner—Sanza L McClendon

(21) Appl' No’: 11/211053 (74) Attorney, Agent, or Firm—Blakely Sokoloff Taylor &

(22) Filed: Aug. 30, 2005 Zafma“

(51) Int CL (57) ABSTRACT

C08J 3/28 (2006.01)

C08F 2/46 (2006.01) A method and kit for providing a tack-free artificial nail

A61K 8/00 (2006.01) surface. The tack-free artificial nail surface may include an

A61K 8/18 (2006.01) acrylic layer and a barrier layer. The acrylic layer may com-

A61K 8/37 (2006.01) prise an odorless monomer. The barrier layer may be of any

(52) U.s. Cl. ..................... .. 523/105; 523/137; 523/300; material impervious to Oxygen. The tack-free riail surface

522/104; 522/107; 522/113; 522/114; 522/120; may be formed by application ofthe aerylie layer to a finger-

522/121; 522/178; 522/182; 522/902; 424/61; nail nail bed. The barrier layer may then be applied over the

4 24 /401 acrylic layer. The barrier layer blocks oxygen from the acrylic

(58) Field of Classification Search ............... .. 424/401; layer 50 that the aeryhe layer may Pelyrrrerrze rrr the ahserree

424/61; 522/104; 107; 113; 114; 120; 121; °f°Xygen'

522/178; 182; 902; 523/137; 105,300

See application file for complete search history. 27 Claims, 1 Drawing Sheet

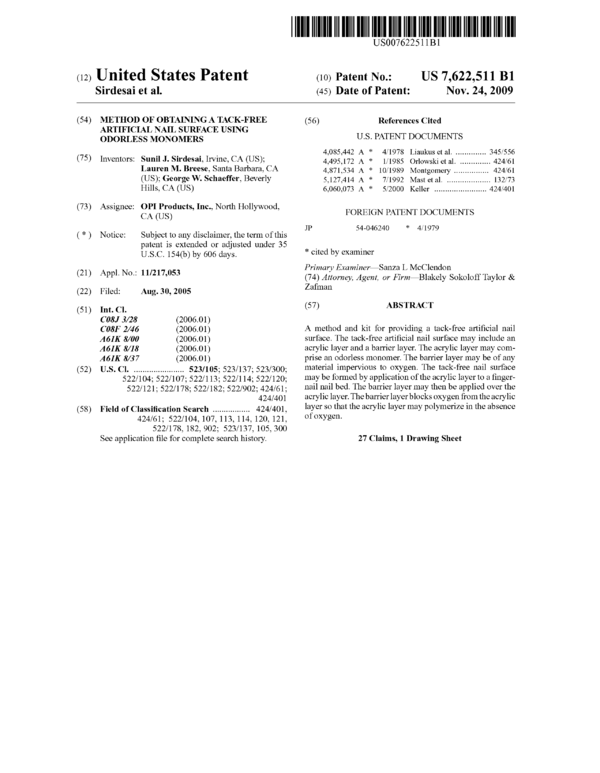

U.S. Patent Nov. 24,2009 US 7,622,511 B1

100

PREPARE FINGERNAIL /

FOR NAIL

ENHANCEMENT.

FORM AN ACRYLIC LAYER

ON THE FINGERN AIL NAIL

BED.

APPLY A BARRIER LAYER

TO THE ACRYLIC LAYER.

FIGURE 1

US 7,622,511 B1

1

METHOD OF OBTAINING A TACK-FREE

ARTIFICIAL NAIL SURFACE USING

ODORLESS MONOMERS

BACKGROUND

1. Field

A tack-free artificial nail surface formed using odorless

monomers.

2. Background

Free Radical Polymerization is usually carried out in

vacuum or inert atmosphere like argon or nitrogen. If carried

out in atmosphere, oxygen present in air, acts as a radical

scavenger and inhibits polymerization. The resulting polymer

may or may not achieve the molecular weight to yield desired

properties.

Some monomers like ethyl methacrylate (“EMA”) or

methyl methacrylate (“MMA”) are exceptions because grow-

ing EMA radicals prefer reacting with another EMA mono-

mer instead of reacting with oxygen or kMM>>>>>kMMO2

where k:rate of propagation of polymer, MM:reaction of

growing polymer radical with another monomer and

MO2:reaction of growing polymer radical with oxygen. The

above equation reveals that the growing polymer radicals are

very selective and almost exclusively react with another EMA

monomer. Thus, in spite of EMA emitting a strong odor, this

system is consistently used in the artificial nail industry.

In case of odorless monomers such as methoxyethoxy

ethyl methacrylate (“MOEOEMA”) and tetrahydrofurfuryl

methacrylate (“THFMA”), the growing polymer radical is

not very selective and it reacts with atmospheric oxygen

almost as well as with another monomer. In this case the

equation happens to be kMM>kMMO2. The growing polymer

near the surface reacts with atmospheric oxygen resulting in

a tacky surface. Thus, polymerization results in a high

molecular weight polymer formed under a low molecular

weight polymer, which is the tacky surface. The manicurist

must then remove this tacky layer from the surface to reveal a

hard plastic coating.

The resultant tacky layer is undesirable because the mani-

curist has to put a very thick coat on the nail bed for nail

enhancement. The thickness of the finished product gives it a

very plastic look and not the natural look of EMA. The mam-

curist also incorrectly assumes that the bottom layers are not

fully cured. Thus, this tacky layer prevents these odorless

systems from capturing a significant share of the artificial nail

market.

Efforts have been made to eliminate the tacky layer. In

other systems, adding wax to the system has helped eliminate

the tacky surface. The wax rises to the surface and shields the

growing polymer from oxygen and polymerization proceeds

to completion. The wax then flakes off. For some unknown

reason, the addition of wax to the system disclosed in the

present application does not eliminate the tacky surface.

Efforts to eliminate the tacky surface have also included

carrying out polymerization in a nitrogen or argon atmo-

sphere. Although this procedure has been successful, it is not

a practical solution. A further option is immersion of the

polymerizing nails in warm water (which excludes oxygen

and speeds the cure). This once popular method is no longer

considered good practice because it creates a substantial risk

of skin sensitization due to traces of uncured monomer in the

water. Significant positive attributes of these systems, like

non-crystallizing and non-lifting phenomena, are overlooked

in the face of this tackiness. Tackiness has become a big

hurdle to commercial success of these odorless systems.

l0

15

20

25

30

35

40

45

50

55

60

65

2

Thus, an odorless artificial nail system that results in a

non-tacky nail surface remains desirable.

BRIEF DESCRIPTION OF THE DRAWINGS

Various embodiments are illustrated by way of example

and not by way of limitation in the figures of the accompa-

nying drawings in which like references indicate similar ele-

ments. It should be noted that different references to “an,”

“one,” or “various” embodiments in this disclosure are not

necessarily to the same embodiment, and such references

mean at least one.

FIG. 1 is a flow chart of one embodiment for formation of

a tack-free artificial nail surface.

DETAILED DESCRIPTION

FIG. 1 is an illustration of one embodiment of a method for

forming a tack-free artificial nail surface. In one embodiment,

the artificial nail may be made of an acrylic material. In

another embodiment, the artificial nail may be made of any

material capable of forming a hard plastic coating.

In one embodiment, the tack-free artificial nail may be

formed by applying an acrylic layer and a barrier layer, or

barrier coating, to a fingemail bed. The barrier layer may be

applied over the acrylic layer. The barrier layer is impervious

to atmospheric oxygen thereby allowing the acrylic layer to

polymerize in the absence of atmospheric oxygen into a non-

tacky nail surface. The acrylic layer may be made of a meth-

acrylate monomer. The methacrylate monomer may be odor-

less. The monomer may be capable of polymerizing to form a

durable plastic coating over the fingemail bed. The monomer

may be a methoxyethoxy ethyl methacrylate or a tetrahydro-

furfuryl methacrylate. The monomer may be in a liquid form.

The acrylic layer, in the form of a plastic coating, may be

made of a monomer/polymer mixture.

In one embodiment, the acrylic layer may be made of a

mixture of the monomer in liquid form having a co-initiator

and a polymer powder having an initiator. The co-initiator

may include, but is not limited to, for example a dimethyl

p-toluidine and a dihydroxyethyl p-toluidine. The initiator

may be, but is not limited to, for example a benzoyl peroxide.

The mixture may further include additives to prevent yellow-

ing of the nail surface. For example, the additive may be

selected from the group including, but not limited to, a sun-

screen such as drometriazole (triazole family) and benzophe-

none. Additionally, the additive may be a blue dye such as

Violet 2 and Violet 34.

In an altemative embodiment, the acrylic layer may be

made of a mixture of a liquid monomer having an Ultra-violet

(UV) light initiator (i.e., photoimtiator) and a polymer pow-

der with or without benzoyl peroxide. The UV light initiator

may include, but is not limited to, for example a hydroxym-

ethylphenyl propanone and a phenyl phosphinate. The mix-

ture may further include additives to prevent yellowing of the

nail surface.

The barrier layer is any material impervious to oxygen. In

one embodiment, a suitable barrier layer may be a cyanoacry-

late glue. A suitable barrier layer may also include, but is not

limited to, a urethane, an epoxy or an acrylic. The barrier layer

may be formed by, for example, applying a coat of cyanoacry-

late glue over the acrylic layer. The barrier layer experiences

an anionic cure that is not inhibited by oxygen. Thus, provid-

ing a smooth, hard, non-tacky surface over the acrylic layer.

In one embodiment, the fingernail bed (i.e., nail bed) is

prepared for nail enhancement (110). The nail bed may be

prepared by cleaning and shaping the nail bed. Preparation of

US 7,622,511 B1

3

the nail bed may further include applying a fingernail dehy-

drator to the fingernail bed. The fingernail dehydrator may be,

but is not limited to, for example a volatile solvent like ethyl

acetate. A nail tip may be applied to the nail bed. Once the nail

bed is prepared, a liquid/powder mixture such as the meth-

acrylate monomer and polymer described above may be

applied to the nail bed to form the acrylic layer (120). Where

a nail tip is applied to the nail bed, the mixture may be applied

to both the exposed nail bed and nail tip. The acrylic layer

may be sculpted and shaped as desired. Once the manicurist is

done sculpting the acrylic layer, the barrier layer may be

applied over the acrylic layer (130). This method blocks

oxygen and allows the monomers beneath the barrier layer to

polymerize resulting in a higher molecular weight tack-free

polymer. The barrier layer experiences an anionic cure that is

not inhibited by oxygen. Thus, providing a smooth, hard,

non-tacky surface over the acrylic layer. Other oxygen barrier

coatings such as urethanes, epoxies and acrylics will be

equally effective.

Polymerization of the acrylic layer may occur by one of an

amine promoted decomposition of peroxide reaction and

photopolymerization. For example, where the acrylic layer

includes the liquid monomer with dimethyl p-toluidine and

the polymer powder with benzoyl peroxide, the dimethyl

p-toluidine in liquid monomer facilitates decomposition of

the benzoyl peroxide in polymer powder to form benzoyloxy

radicals which then polymerize the methacrylate monomer.

In an altemative embodiment, where the acrylic layer

includes a liquid monomer having a photoinitiator and a

polymer powder, UVA light may be applied to decompose the

photoinitiator to form radicals which will then start polymer-

ization of the methacrylate monomer.

The following specific examples are set forth to illustrate

the various methods for forming the non-tacky artificial nail.

Example I

In one embodiment, after preparing the fingernail for nail

enhancement, the nail bed may be dehydrated by applying a

nail dehydrator such as ethyl acetate. Once the nail bed is

dehydrated, a coat of nail primer may be applied. The acrylic

layer in the form of the liquid/powder (i.e., monomer/poly-

mer) mixture is applied over the primer. The manicurist may

sculpt the nail into a desirable shape. Once the nail is sculpted,

cyanoacrylate glue may be applied to the sculpted nail. The

cyanoacrylate glue must be applied before polymerization of

the acrylic layer has progressed to a significant degree, i.e.

usually within approximately thirty seconds of applying the

liquid/powder mixture. The cyanoacrylate glue experiences

an anionic cure over the acrylic layer to produce a smooth,

hard, non-tacky surface. The shape of the sculpted nail may

then be refined by filing. This method may be repeated on

each nail.

Example II

In another embodiment, the fingemail may be prepared for

nail enhancement. Once prepared, the nail bed may be dehy-

drated. Instead of primer, one can coat the nail bed with

cyanoacrylate glue. The liquid/powder mixture may be

applied on top of the cyanoacrylate glue to form the acrylic

layer. The nail may then be sculpted to achieve the desired

shape. As soon as sculpting is complete, i.e. before curing has

progressed significantly, a barrier layer or coating (e.g.,

cyanoacrylate glue) may be applied to the sculpted nail. The

shape of the sculpted nail may then be refined by filing. This

process should be repeated on each nail.

10

15

20

25

30

35

40

45

50

55

60

65

4

Example III

In still another embodiment, the non-tacky artificial nail

may be formed by a primer less technique. In this embodi-

ment, the fingemail may be prepared for nail enhancement.

The fingernail may be dehydrated and the liquid/ powder mix-

ture applied to the nail bed to form the acrylic layer. The

barrier layer may then be formed by coating the nail bed with

cyanoacrylate glue. The shape of the sculpted nail may then

be refined by filing. This process should be repeated on each

nail.

Example IV

In one embodiment, after preparing the fingernail for nail

enhancement, the nail bed may be dehydrated. Once the nail

bed is dehydrated, a coat of nail primer may be applied. The

acrylic layer in the form of the liquid monomer having a UV

light initiator and polymer powder with or without benzoyl

peroxide is applied over the primer. The manicurist may

sculpt the nail into a desirable shape. In this method, poly-

merization commences only when the nails are exposed to

UVA light. Hence depending on the configuration of the

lamp, all 5 or 10 nails may be sculpted before application of

cyanoacrylate glue. The nail is then cured under a UVA light.

The shape of the sculpted nail may then be refined by filing.

In the foregoing specification, the invention has been

described with reference to specific embodiments thereof. It

will, however, be evident that various modifications and

changes can be made thereto without departing from the

broader spirit and scope of the invention as set forth in the

appended claims. The specification and drawings are, accord-

ingly, to be regarded in an illustrative rather than a restrictive

sense.

What is claimed is:

1. A method comprising:

applying an acrylic layer to a fingernail bed, the acrylic

layer having an odorless methacrylate monomer that,

when applied, polymerizes to form a durable plastic

coating; and

applying a barrier layer to the acrylic layer before poly-

merization of the acrylic layer is complete, the barrier

layer being impervious to atmospheric oxygen allowing

for polymerization of the acrylic layer in the absence of

oxygen to yield a non-tacky surface; and

curing and hardening the barrier layer.

2. The method of claim 1, wherein the methacrylate mono-

mer comprises at least one of a methoxyethoxy ethyl meth-

acrylate and a tetrahydrofurfuryl methacrylate.

3. The method of claim 1, wherein the barrier layer com-

prises a cyanoacrylate glue.

4. The method of claim 1, wherein the barrier layer is

selected from a urethane, an epoxy and an acrylic.

5. The method of claim 1, wherein the acrylic layer further

comprises an additive to prevent yellowing.

6. The method of claim 1, further comprising:

a co-initiator, the co-initiator combined with the methacry-

late monomer, the methacrylate monomer in liquid

form; and

a polymer powder, the polymer powder comprising an

initiator such that the acrylic layer may be cured by an

amine promoted decomposition of peroxide reaction.

7. The method of claim 1, further comprising:

a photoinitiator, the photoinitiator combined with the

methacrylate monomer in liquid form; and

US 7,622,511 B1

5

a polymer powder, the polymer powder comprising an

initiator such that the acrylic layer may be cured under

UVA light by a photopolymerization process.

8. A method comprising:

applying a cyanoacrylate glue to a fingernail bed;

applying an acrylic layer to the cyanoacrylate glue, the

acrylic layer having an odorless methacrylate monomer

capable of polymerizing to form a durable plastic coat-

ing; and

applying a barrier layer to the acrylic layer before poly-

merization of the acrylic layer is complete, the barrier

layer being impervious to atmospheric oxygen allowing

for polymerization of the acrylic layer in the absence of

oxygen to yield a non-tacky surface, provided that the

barrier layer does not consist essentially of a wax.

9. The method of claim 8, wherein the methacrylate mono-

mer comprises at least one of a methoxyethoxy ethyl meth-

acrylate and a tetrahydrofurfuryl methacrylate.

10. The method of claim 8, wherein the cyanoacrylate glue

is used instead of a primer.

11. The method of claim 8, wherein the barrier layer is

applied over a final acrylic layer.

12. The method of claim 8, wherein the barrier layer is

selected from a cyanoacrylate glue, a urethane, an epoxy and

an acrylic.

13. A kit comprising:

an odorless methacrylate monomer with a co-initiator;

an additive to prevent yellowing;

a polymer powder with an initiator; and

a barrier coating material impervious to oxygen, the barrier

coating material to facilitate polymerization of the meth-

acrylate monomer in the absence of atmospheric oxy-

gen, wherein the barrier coating material cures and hard-

ens when applied.

14. The kit of claim 13, wherein the methacrylate monomer

comprises at least one of a methoxyethoxy ethyl methacrylate

and a tetrahydrofurfuryl methacrylate.

15. The kit of claim 13, wherein the barrier coating material

experiences an anionic cure uninhibited by oxygen when

applied to the methacrylate monomer.

16. The kit of claim 13, wherein the barrier coating material

is selected from a cyanoacrylate glue, a urethane, an epoxy

and an acrylic.

6

17. The kit of claim 13, further comprising at least one of a

fingemail primer and a fingemail dehydrator.

18. The kit of claim 13, wherein the initiator comprises a

benzoyl peroxide.

5 19. A kit comprising:

an odorless methacrylate monomer with a photoinitiator;

an additive to prevent yellowing;

a polymer powder; and

a barrier coating material impervious to oxygen, the barrier

coating material to facilitate polymerization of the meth-

acrylate monomer in the absence of atmospheric oxy-

gen, provided that the barrier coating material does not

consist essentially of a wax.

20. The kit of claim 19, wherein the methacrylate monomer

15 comprises at least one of a methoxyethoxy ethyl methacrylate

and a tetrahydrofurfuryl methacrylate.

21. The kit of claim 19, wherein the barrier coating material

experiences an anionic cure uninhibited by oxygen when

applied to the methacrylate monomer.

22. The kit of claim 19, wherein the barrier coating material

is selected from a cyanoacrylate glue, a urethane, an epoxy

and an acrylic.

23. The kit of claim 19, further comprising at least one of a

fingemail primer and a fingemail dehydrator.

24. The kit of claim 19, wherein the photoinitiator com-

prises at least one of a hydroxymethylphenyl propanone and

phenyl phosphinate.

25. The kit of claim 19, wherein the polymeric powder

includes benzoyl peroxide.

26. A method comprising:

applying a first layer over a fingernail, wherein polymer-

ization of the first layer is susceptible to atmospheric

oxygen;

applying a barrier layer over the first layer before polymer-

ization of the first layer is complete, the barrier layer to

shield the first layer from the atmospheric oxygen;

curing the first layer; and

curing the barrier layer by a cure that is not inhibited by

oxygen.

27. The method of claim 26, wherein the first layer is cured

by free radical polymerization and the barrier layer is cured

through an anionic cure.

10

20

25

30

35

40

* * * * *

Coments go here: