The Synthesis of 2,4,6-Trinitrostyrene and Some Intermediates

The Synthesis of 2,4,6-Trinitrostyrene and Some Intermediates

Year:

DOI:

10.1021/ja01104a502

Type of document:

Language:

19%

Vol. 75

NOTES

Downloaded by HENKEL KGAA on September 2, 2009 | http://pubs.acs.org

Publication Date: April 1, 1953 | doi: 10.1021/ja01104a502

yield of crude product on distillation of the organic layer

was 11 8. (44%). P2re material was obtained on redistillation; b.p. 36.6-37.1 a t 2.5 mm., n% 1.4184.d% 0.9296.

~.

Anal. Calcd. for C~H1603:C, 56.73; H , 10.88. Found:

C, 57.55; H , 10.75.

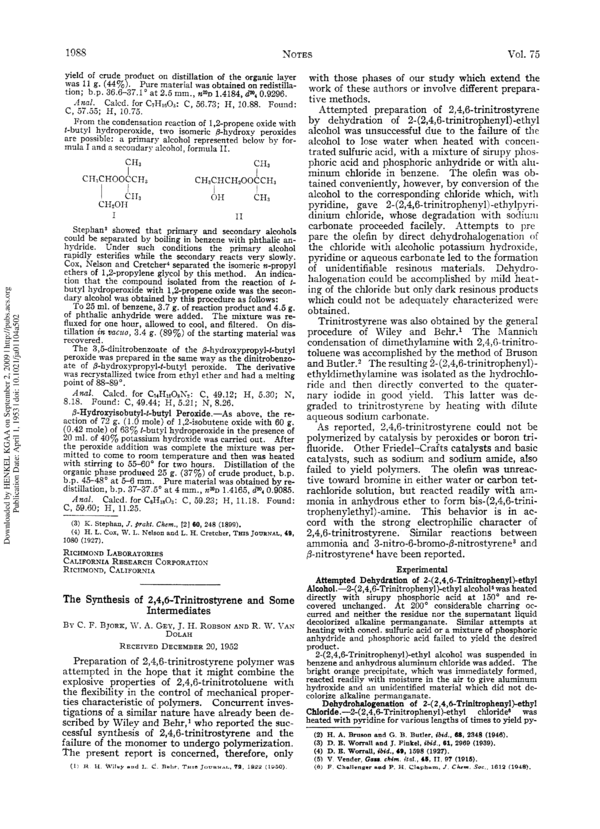

From the condensation reaction of 1,Qpropene oxide with

t-butyl hydroperoxide, two isomeric p-hydroxy peroxides

are possible: a primary alcohol represented below by formula I and a secondary alcohol, formula 11.

with those phases of our study which extend the

work of these authors or involve different preparative methods.

Attempted preparation of 2,4,6-trinitrostyrene

by dehydration of 2-(2,4,6-trinitrophenyl)-ethyl

alcohol was unsuccessful due to the failure of the

alcohol to lose water when heated with conceiitrated sulfuric acid, with a mixture of sirupy phosphoric acid and phosphoric anhydride or with aluCIIJ

CH3

minum chloride in benzene. The olefin was obCF€?CHOOCCH,

I

CHJCHCH?OO&~HJ

tained conveniently, however, by conversion of the

I

I

alcohol to the corresponding chloride which, with

O€I

Cf-I3

pyridine, gave 2-(2,4,6-trinitrophenyl)-ethylpyridinium chloride, whose degradation with sodium

I

I1

Attempts to pre

Stephan3 showed that primary and secondary alcohols carbonate proceeded facilely.

could be separated by boiling in benzene with phthalic an- pare the olefin by direct dehydrohalogenation of

hydride. Under such conditions the primary alcohol the chloride with alcoholic potassium hydroxide,

rapidly esterifies while the secondary reacts very slowly. pyridine or aqueous carbonate led to the formation

Cox, Nelson and Cretcher4 separated the isomeric n-propyl of unidentifiable resinous materials. Dehydroethers of l,2-propylene glycol by this method. An indication that the compound isolated from the reaction of t- halogenation could be accomplished by mild heatbutyl hydroperoxide with 1,2-propene oxide was the secon- ing of the chloride but only dark resinous products

dary alcohol was obtained by this procedure as follows:

which could not be adequately characterized were

To 25 ml. of benzene, 3.7 g. of reaction product and 4.5 g. obtained.

of phthalic anhydride were added. The mixture was reTrinitrostyrene was also obtained by the general

fluxed for one hour, allowed to cool, and filtered. On distillation kn vacuo, 3.4 g. (89%) of the starting material was procedure of Wiley and Behr.' The RZannich

recovered.

condensation of dimethylamine with 2,4,G-trinitroThe 3,5-dinitrobenzoate of the 8-hydroxypropyl-t-butyl

toluene was accomplished by the method of Bruson

peroxide was prepared in the same way as the dinitrobenzoate of Bhydroxypropyl-t-butyl peroxide. The derivative and Butler.* The resulting 2-(2,4,6-trinitrophenyl)was recrystallized twice from ethyl ether and had a melting ethyldimethylamine was isolated as the hydrochlopoint of 88-89 '.

ride and then directly converted to the quaterAnal. Calcd. for Cj,H180&2: C, 49.12; H, 5.30; N, nary iodide in good yield. This latter was de8.18. Found: C, 49.44; H, 5.21; N, 8.26.

graded to trinitrostyrene by heating with dilute

8-Hydroxyisobutyl-t-butyl Peroxide.-As above, the re- aqueous sodium carbonate.

action of 72 g. (1.0 mole) of 1,2-isobutene oxide with 60 g.

As reported, 2,4,6-trinitrostyrene could not be

(0.42 mole) of 63% t-butyl hydroperoxide in the presence of

20 ml. of 40% potassium hydroxide was carried out. After polymerized by catalysis by peroxides or boron trithe peroxide addition was complete the mixture was per- fluoride. Other Friedel-Crafts catalysts and basic

mitted to come to room temperature and then was heated catalysts, such as sodium and sodium amide, also

with stirring to 55-60' for two hours. Distillation of the

organic phase produced 25 g. (37%) of crude product, b.p. failed to yield polymers. The olefin was unreacb.p. 45-48' at 5-6 mm. Pure material was obtained by re- tive toward bromine in either water or carbon tetdistillation, b.p. 37-37.5' a t 4 mm., n% 1.4165, d", 0.9085. rachloride solution, but reacted readily with amAnal. Calcd. for C$H&: C, 59.23; H, 11.18. Found: monia in anhydrous ether to form bis-(2,4,6-triniC, 59.60; H, 11.25.

trophenylethy1)-amine. This behavior is in accord with the strong electrophilic character of

(3) K. Stephan, J. p r a k f . Chem., 121 60, 248 (1899).

(4) H.L.Cox, W.L. Nelson and L. H. Cretcher, THIS

JOURNAL, 49,

2,4,6-trinitrostyrene. Similar reactions between

1080 (1927).

ammonia and 3-nitro-6-bromo-/3-nitrostyrene3 and

RICHMOND

LABORATORIES

P-nitr~styrene~ been reported.

have

CALIFORNIA

RESEARCH

CORPORATION

RICHMOND,

CALIFORNIA

The Synthesis of 2,4,6-Trinitrostyrene and Some

Intermediates

Experimental

Attempted Dehydration of 2-(2,4,6-Trinitrophenyl)-ethyl

Alcohol.-Z-( 2,4,6-Trinitrophenyl)-ethylalcohol6was heated

directly with sirupy phosphoric acid at 150' and re-

covered unchanged. At 200' considerable charring occurred and neither the residue nor the supernatant liquid

permanganate. Similar attempts at

BY C. F. BJORK, A. GEY,J. 1%.ROBSON R. 1 VAN decolorized alkalinesulfuric acid or a mixture of phosphoric

W.

AND

%

'

.

heating with concd.

DOLAH

anhydride and phosphoric acid failed to yield the desired

product.

RECEIVED

DECEMBER 1952

20,

2-(

2,4,6-Trinitrophenyl)-ethyl alcohol was suspended in

Preparation of 2,4,6-trinitrostyrene polymer was benzene and anhydrous aluminum chloride was added. The

attempted in the hope that it might combine the bright orange precipitate, which was immediately formed,

with moisture

t o give aluminum

explosive properties of 2,4,6-trinitrotoluene with reacted readily an unidentified in the air which did not dehydroxide and

material

the flexibility in the control of mechanical proper- colorize alkaline permanganate.

ties characteristic of polymers. Concurrent invesDehydrohalogenation of 2-(2,4,6-Trinitrophenyl)-ethyl

tigations of a similar nature have already been de- Chloride.-2-(2,4,6Trinitrophenyl)-ethyl chloride6 was

scribed by Wiley and Behr,' who reported the SUC- heated with pyridine for various lengths of times to yield py-

cessful synthesis of 2,4,6-trinitrostyreae and the

failure of the monomer to undergo polymerization.

The present report is concerned, therefore, only

( 1 ) 11. I€ Wrlr). mnd L C neht.. T>xm J O U O N A L . 79. !a22 (1050)

H.A. Bruson and G . B. Butler, ibid., 68, 2348 (1946).

(3) D. E Worrall and J. Pinkel, ibid.. 61,2969 (1939).

.

.

(4) D E.Worrall, ibid., 40, 1598 (1927).

(5) V Vender, Gam chfm i t n l , 45, 11. 97 (1915).

( 8 ) F Chdlonscr sed P. H Clapbum. J C h c m . Soc 1812

(2)

(1948).

Downloaded by HENKEL KGAA on September 2, 2009 | http://pubs.acs.org

Publication Date: April 1, 1953 | doi: 10.1021/ja01104a502

April 20, 1053

NOTES

ridine hydrochloride and products varying from dark resins

to brown, infusible materials, depending on length of heating. One such resin analyzed correctly (17.48%) for nitrogen (theory for trinitrostyrene, 17.58%) but was not otherwise characterized.

Dehydrohalogenation could be accomplished by heating

the chloride a t 85-90' until the evolution of HC1 was completed as evidenced by testing with moist litmus paper.

The products werc brittle, resinous substances with a softening temperature of 50-60" which did not change on further heating.

2-( 2,4,6-Trinitrophenyl)-ethylpyridmium Chloride .-2(2,4,6-Trinitrophenyl)-ethyl chloride, 27.6 g. (0.1 mole),

was added to 23.7 g. (0.3 mole) of pyridine. After the entire mass had solidified (about 20 minutes) the excess pyridine

was extracted with low-boiling petroleum ether. Recrystallization of the residue from a methanol-methyl ethyl

ketone mixture gave 17.7 g. (50%) of light yellow to colorless 2-(2,4,6-trinitrophenyl)-ethylpyridinium chloride, m.p.

132.0-134.2'.

Anal. Calcd. for ClsHllOeNdCl: N, 15.80; C1, 10.00.

Found: N, 15.90; C1, 9.94.

On dilution of the pyridine extract with water, colorless

platelets were deposited which on recrystallization from

carbon tetrachloride melted a t 63-64'. These were shown,

by mixed melting point with an authentic sample, to be

2,4,6-trinitrostyrene.

Preparation of 2,4,6-Trinitrostyrene from 2 4 2,4,6-Trinitropheny1)-ethylpyridmium Chloride.-To a mixture of 5

g. (0.014 mole) of 2-(2,4,&trinitrophenyl)-ethylpyridinium

chloride and 100 ml. of water, 0.75 g. (0.007 mole) of sodium

carbonate was added with shaking, forming a cherry-red

solution, which gradually turned darker. Pyridine was

evolved and a brown precipitate settled. After 20 minutes,

the solution was neutralized with dilute hydrochloric acid.

Extractions of the precipitate with carbon tetrachloride

yielded a solution from whi2h was isolated 1.0 g. (29%).of

trinitrostyrene, m.p. 63-64 , which failed to add bromine

but did decolorize alkaline permanganate.

Anal. Calcd. for CsHsNs06: C, 40.18; H , 2.11; N,

17.57. Found: C, 40.44; H, 2.22; N, 17.54.

2-( 2,4,6-Trinitrophenyl)-ethyltrimethylammonium Iodide.

-To a warm solution of 12.8 g. (0.04 mole) of 2-(2,4,6-trinitropheny1)-ethyldimethylamine hydrochloride' in 80 g.

(2.5 moles) of methanol, 9.9 g. (0.07 mole) of methyl iodide

and 2.7 g. (0.048) mole of potassium hydroxide pellets were

added with vigorous shaking. The brick-red precipitate

which began to form in about 20 minutes was promptly

separated by decanting and was recrystallized from methanol

t o give 12.7 g. (75%) of 2-(2,4,6-trinitrophenyl)-ethyltrimethylammonium iodide, m.p. 139-141'.

Addition of Ammonia to 2,4,6-Trinitrostyrene.-To a

solution of 0.69 g. of the olefin in 25 ml. of anhydrous ether,

0.5 ml. of anhydrous ammonia was added. On partial

evaporation of the solvent, 0.5 g. (70%) of yellow bis(2,4,6-trinitrophenylethyl)-amine,m.p. 129.5-130.5' after

repeated washing with dry ether, separated.

Anal. Calcd. for C L ~ H L ~ O I ~ N ,19.80. Found: N,

N, :

19.61.

ORGANIC

CHEMISTRY

BRANCH

U. S. NAVAL

ORDNANCE

TEST

STATION

INYOKERN,

CHINALAKE,CALIF.

xylene with chlorine gas yielded only the 4,5- and

3,4-dichloro-isomers. The absence of substantial

quantities of 3,5-dichloro-o-xylene would, of course,

be expected because of the ortho-para directive

power of the chlorine atom, but the failure of these

workers to obtain 3,G-dichloro-o-xylene is puzzling

in view of the tendency of catalyzed chlorination to

occur predominantly in the position para to chlorine

already present .6 In addition, White, Biggs and

Morgan6 reported that 5-nitro-3,4-dichloro-o-xylene which was prepared according to the method of

Hinkel and co-workers had a melting point higher

than the one given by the original authors. White

and co-workers attributed the higher melting point

to contamination of their product with 3-nitro-4,5dichloro-o-xylene in solid solution.

In the present work a low temperature, iron-catalvzed dichlorination of o-xylene was carried out and

the products fractionated, 4,5-Dichloro-o-xylene

was identified by its melting point and the melting

point of the mononitro derivative. The distillation

fractions in which 3,4-dichloro-o-xylene would be

expected on the basis of the previous work were

found to have melting points substantially higher

than that of the pure compound (8-9°3,4).

Recrystallization of these fractions yielded a compound which melted a t the same temperature as

that recorded for 3,G-dichloro-o-xylene (%Io4).

The infrared spectrum of the compound shows a

strong absorption band at 8.03 cm.-', a frequency

which is characteristic of 1,2,3,4-tetrasubstituted

benzenes.' The mononitro derivative prepared

from these fractions was found, after purification,

to have the melting point recorded for 4-nitro-3,6dichloro-o-xylene (8404) rather than that for 5nitro-3,4-dichloro-o-xylene 9 . To confirm the

(78"

conclusion that 3,G-dichloro-o-xylenewas formed in

the chlorination, a dinitro-derivative was prepared

from one of these fractions. This compound had a

melting point closer to the recorded value for 4,5dinitro-3,G-dichloro-o-xylene

(174" 4, than that for

5,G-dinitro-3,4-dichloro-o-xylene 3 , 4 ) .

(173"

No attempt was made to isolate 3,4-dichloro-oxylene which was probably present as a minor constituent in the fractions containing 3,G-dichloro-oxylene. These two isomers have the same boiling

point (2340as4). The melting points of the distillation fractions (Table I, below) indicate that the

major constituent of fractions G, 7 and 8 is the 3,6dichloro-isomer. The decreasing melting points of

the later fractions are probably due to the presence

of increasing amounts of 4,5-dichloro-o-xylene as a

contaminant.

The Dichlorination of o-Xylene'

BY CARLB O Y A R ~

RECEIVED

NOVEMBER 1952

3,

Hinkel and c o - ~ o r k e r s ~ ~ ~ that the low

reported

temperature, iron-catalyzed dichlorination of o(1) Abstracted mainly from a portion of a thesis on "The Dielectric

Properties o Solid Nitrodichloro-o-xylenes"directed by Dr. Reuben E.

f

Wood and submitted in partial fulfillment of the requirements for the

M.S.degree at The George Washington University, May, 1952.

(2) Research and Development Department, Naval Powder Factory,

Indian Head, M d .

(8) L. E. Hinkel, E. E. Ayling and L. C. Bevnn. J . Chm. Soc., 1874

(19!28).

(4) L E Riakd. E E Ayling and T M.W d t m , iW., 1946 (1984).

. .

. .

.

1989

Experimental

Five moles of o-xylene (City Chemical Corporation, b.p.

143.5-144.5', nmD 1.5047) with 5.5 g. of iron filings was

chlorinated at -10 to 0' using chlorine dried with concentrated sulfuric acid. A total of 32 hours was required for

the reaction mixture t o gain the weight corresponding to dichlorination. This weight increase was determined after

aspirating the reaction product. The chlorinated product

was washed with water, refluxed one hour with 10% sodium

(5) H. J. Lucas, "Organic Chemistry," American Book Company,

New York, N. Y., 1935, p. 360.

(6) A. H. White, B. S Biggs and S. 0. Morgan, THIS

.

JOURNAL, 68,

16 (1940). 3.4-Dichloro-o-xylene ii erroneously referred to aa 4.5diehl-xylene

on p. 17 of thii article.

(7) P.J. Lnunamd D. A. MeCaulay. Asd.'Ckm., II. 1876(19S1).

Coments go here:

- Log in to post comments