Cyanoacrylate Esters

Year:

Abstract:

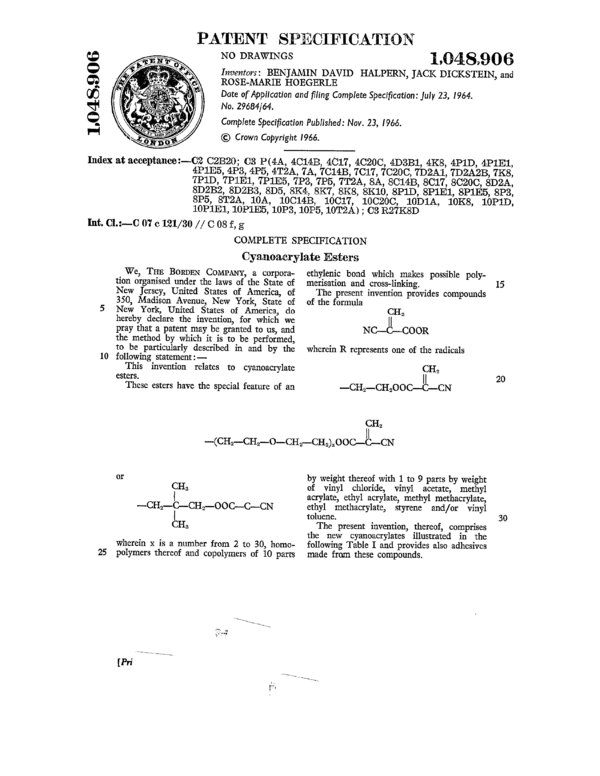

The invention comprises compounds of the formula <1048906><1048906><1048906><1048906><1048906><1048906><1048906>

Type of document:

Language:

PATENT SPECIFICATION

NO DRAWINGS 1,048,906

Inventors: BENJAMIN DAVID HALPERN, JACK DICKSTEIN, and

ROSE-MARIE HOEGERLE

Date of Application and filing Complete Specification: july 23, I 964.

No. Z9684/64.

Complete Specification Published: Nov. 23, I966.

© Crown Copyright I966.

1.0-48,906

Index at acceptance :—C2 021320; 03 P(4A, 4014B, 4C17, 4C20C‘, 4D3B1, 4K8, 4P1D, 4P1E1,

4P1E5, 4P3, 4P5, 4T2A, 7A, 7C14B, 7C17, 7C20C, 7D2-‘A1, 7D21A2B, 7K8,

7P1D, 7P1E1, 7P1E5, 7P3, 7P5, 7T2A., 8A, 8C14B, 8C17, 8C20C, 8D2A,

8D2B2, 8D2B3, SD5, 8K4, 8K7, 8K8, 8K10, 8P1D, 8P1E1, 8P1E5, SP3,

SP5, 8T2A, 10A, 10C14B, ZLOC17, 10C20C, 10D1A, 10K8, 10P1D,

10P1E1, 10PlE5, 10P3, 1OP5, 10T2A) ; C3 R27K8D

Int. o1.:_0 07 c 121/30 // C 08 f, g

COMPLETE SPECIFICATION

Cyanoaerylate Esters

_We, THE BORDEN COMPANY, a corpora- ethylenic bond which makes possible poly-

tion organised under the laws of the State of merisation and cross-linking. 15

New Jersey, United States of America, of The present invention provides compounds

350, Madison Avenue, New York, State of of the formula

5 New York, United States of America, do CH2

hereby declare the invention, for which we

pray that a patent may be granted to us, and NC—C-—COOR

the method by which it is to be performed,

to be particularly described in and by the wherein R represents one of the radicals

10 following statement : —

This invention relates to cyanoacrylate CH2

esters. H 20

These esters have the special feature of an —CH2—CH2OOC—G—CN

CH2

ll

—-(CH2—CI-I._.—O—CH2—CH2)xOOC—C-—CN

or by weight thereof with 1 to 9 parts by weight

CH3 of vinyl chloride, vinyl acetate, methyl

acrylate, ethyl acrylate, methyl methacrylate,

—CH2—C—CH-_»—OOC—C—CN ethyl methacrylate, styrene and/or vinyl

I toluene. 30

CH3 The present invention, thereof, comprises

the new cyanoacrylates illustrated in the

wherein X is a number from 2 to 30, homo- following Table I and provides also adhesives

25 polymers thereof and copolymers of 10 parts made from these compounds.

10

15

20

45

50

55

1,048,906

TABLE I

Compound Name

Ethylene glycol 2,2 '-

dicyanoacrylate

Dicyanoacrylates of

polyethylene glycol

Formula

CH. CH..

H H

NC—C—-COOCH2CH2OOC—C—CN

cH._.

ll

NC--C-COO(C2H,,—O—-C._.H.,)::c—

CH2

:1

OO C—C—CN

Neopentyl glycol

2,2-dicyanoacrylate

CH2 Ion, CH,

H {I

NC—C——COOCH2-C-CH20OC—C—CN

I

CH3

Here x is a number from 2 to 30.

The invention provides also adhesive com-

positions comprising a solution of one part

by weight of any of the materials set out

above in 2 to 10 parts by weight of a volatile,

chemically inert solvent.

These compounds are made as shown in

the following Examples. Except where

specifically stated to the contrary, all dryings

are carried out over anhydrous magnesium

sulphate at room temperature and all pro-

portions are expressed by weight.

EXAMPLE 1.

Ethylene Glycol Dicyanoacrylate.

Ethylene glycol dicyanoacetate was first made

as follows:

A mixture of 190 g. of cyanoacetic acid,

62 g. of ethylene glycol, 5 g. of p-toluene-

sulphonic acid and 440 g, of anhydrous

benzene were boiled under reflux with con-

Analysis, 7, calcd. for C,H,.N;.0,,: C, 4 .

4

Found.

1 mole of the ethylene glycol dicyanoacetate

so made was then mixed with 2 moles of

formaldehyde and condensed, in benzene solu-

tion in contact with 0.2 mole of zinc acetate

dihydrate as condensing agent and boiled for

1 hour. The water formed in the condensa-

tion was distilled ofl and collected in a water

trap.

The benzene was removed by boiling under

atmospheric pressure. The residue remaining

was then washed with three separate portions

of dioxane and thus separated from impuri-

ties preferentially soluble in the dioxane.

tinuous stirring for 10 hours. During this

period, the theoretical amount of water was

formed, distilled away and collected in a

water trap. As the dicyanoacetate ester

formed, the benzene separated. The benzene

was removed by distillation under reduced

pressure and replaced by 1,000 g. of

methylene dichloride. The resulting solution

was washed with saturated aqueous potassium

bicarbonate solution and then with water.

The washed liquid that remained was dried

and filtered and the volatile material was

distilled off. The oily residue that remained

was first dried under 12 mm. pressure and

subsequently for 4 hrs. under 0.5 mm. pres-

sure, yielding 170 g. of colourless crystals of

ethylene glycol dicyanoacetate of m.p. 37°——

40° C. Recrystallisation from methanol gave

thin needles of m.p. 41°—45° C_ and b.p.

210° C. at 2 mm.

.0

The residue so washed was dried as above.

The residue was ethylene glycol 2,2’-dicyano-

acrylate.

For use as an adhesive, the ethylene glycol

dicyanoacrylate is dissolved in a solvent

therefor, e.g., a volatile ketone such as

acetone, methyl ethyl ketone or mixtures

thereof, as in the proportion of 1 to 10 parts

of the ketone for 1 part of the cyanoacrylate.

EXAMPLE 2.

Polyethylene glycol dicyanoacrylate.

The composition and procedure of Ex-

ample 1 were followed except that the

25

30

35

40

60

65

1,048,906

l0

l5

ethylene glycol there used was replaced, first,

by an equimolecular proportion of diethylene

glycol, so that the intermediate compound

first formed was diethylene glycol dicyano-

acetate. This was then condensed with form-

aldehyde and processed as described in Ex-

ample 1.

In a modification of this Example, the di-

ethylene glycol was replaced by an equimolar

weight of another polyethylene glycol, as for

example by glycol 400 and glycol 1000, used

separately and in turn. The products are

alpha-acrylates of the polyglycols, and have

cross-linking properties because of their di-

functional nature.

cesses of Examples 1 and 2, of using dilferent

inhibitors of polymerisation of ethylenic

bonds added during the formation of the di-

cyanoacrylate esters and of different

atmospheres under which the mixture was

maintained during the condensation. It shows

also the amount of water separated from the

trap during the condensation, as a percentage

of the theoretical maximum for a perfect

yield of condensed product, the reaction time

in hours, and the physical nature of the

finished glycol 2,2’-dicyanoacrylate which

undergoes, to some extent, polymerisation of

the carbon-to-carbon double bonds. In this

table the zinc acetate, when used, was the di-

hydrate. In two instances the zinc acetate was

20

25

30

35

EXAMPLE 3. used in combination with acetic acid (ACOH)

Condensing Agents. as shown. The abbreviations “DEG” and

The following Table II shows the effect “EG” represent diethylene glycol and

of using various condensing agents in the pro— ethylene glycol, respectively.

TABLE II

Atmosphere Water Reaction Nature

Glycol Condensing During Sep. % Time, of End

used Agent Inhibitor Condensation of theory Hours Product

DEG — t—butyl N2 67 5 Rubbery mass

catechol

,, Zn(0Ac)2—Ac0H — air 87 0.75 Highly viscous

oil

,, Piperidine S02 S02 24 2.0 Hard, White

Solid

precipitate

,, Piperidine — air 48 2.0 Polymeric gel

acetate

EG Zn(OAc) 2 — air 72 0 .75 Orange red gel

,, Zn(OAc)2—AcOH — air 25 1.30 Hard, rubbery

,, Piperidine —- air 0.5 0.10 Hard, white

acetate polymeric

:_:.

45

50

55

These esters of the glycols are adhesives.

They are suitable for application to glass,

paper or aluminium foil, for example in a

solution of 20 parts of the esters for 100 of

a volatile ketone solvent.

EXAMPLE 4.

Neopentyl glycol 2,2’—dicyanoacrylate.

A mixture of 52 g. of neopentyl glycol, 94

g. of cyanoacetic acid, 2 g. of p-toluene-

sulphonic acid and 265 g. of benzene were

heated under reflux for 17 hours, during

which the theoretical amount of water was

distilled off azeotropically. The remaining

mixture had only one phase. It was washed

with aqueous potassium carbonate solution,

dried, and filtered. On distilling ofi the

solvent, a colourless oily residue was obtained

which did not crystallise after several hours

of further drying under 0.5 mm. pressure at

room temperature. 113 g. of neopentyl glycol

dicyanoacetate were isolated.

The infrared absorption spectrum showed

that there was no cyanoacetic acid remaining

in the product.

11.9 g. of this neopentyl glycol dicyano-

acetate was added gradually to 3.5 g. of para-

formaldehyde in 44 g. of benzene, contain-

ing 3 drops of piperidine, at 75° C. A colour-

less precipitate separated immediately. After

boiling for 6.5 hr., 1.9 g. of water (100% of

theory) had separated in the water trap. The

60

65

70

10

I5

20

25

30

60

4 1,048,906

residue of the reaction mixture was filtered,

washed several times with benzene and dried,

yielding 13.0 g. of neopentyl glycol 2,2’-di-

cyanoacrylate with a decomposition range of

240°,—295° C. and of only very slight solu-

bility in chloroform, benzene, acetone,

methyl ethyl ketone and ethyl acetate.

Infrared absorption spectrum: 22[50 cm“‘

(C=N); 1620, 940, 865 cm"1

The neopentyl 2,2’-dicyanoacrylate is un-

usually resistant to decomposition by heat.

EXAMPLE 5.

Cross—Linking,

The cyanoacrylate esters described herein

undergo cross-linking more rapidly at elevated

temperatures, for example, 80 to 150° C. to

accelerate the rate of cross-linking or to lower

the temperature used, an initiator, such as

any of the percompounds commonly used to

initiate polymerisation of ethylenic double

bonds, e.g., sodium or potassium per-

sulphate, benzoyl peroxide and azobisiso-

butyronitrile, may be incorporated, advan-

tageously from 0.5% to 1% of the percom—

pound based on the dry weight of the di-

- cyanoacrylate.

In a modification of this Example, the

cyanoacrylate esters that are the final products

' of each of the Examples 2, 3 and 5 are co-

polymerised with an comonomer containing

an ethylemc double bond, e.g., vinyl chloride,

vinyl acetate, methyl or ethyl acrylate or

methacrylate, styrene, or vinyl toluene, in the

proportion of 1 to 9 parts by weight of the

combined cyanoacrylate and the comonomer,

and with 10°/,, of any of the initiators set out

above, on the total weight, at 100° C.

To make an adhesive, the final product of

any of the Examples 1 to 5 is dissolved in any

anhydrous and chemically inert solvent

therefor, of which N,N-dimethylformamide is

an example. Proportions of the solvent that

are suitable are 2 to 10 parts by weight for

1 part by weight of the final product.

The adhesives made as described herein are

applied to the surface to be bonded and main-

tained at a such a temperature as will give

setting of the adhesive at the desired rate.

For most purposes either no warming or only

moderate warming is required.

WHAT WE CLAIM IS:—

1. Compounds of the formula

tea

I

NC—C—COOR

wherein R represents one of the radicals

CI-I2

ll

—CH2—CH2OOC—C—-CN

CH.

H

or

CH3

I H

—CHg—C-—CH2—O0C—C—CN

I

CH3

CH2

wherein x is a number from 2 to 30, homo-

polymers thereof and copolymers of 10 parts

by weight thereof with 1 to 9 parts by weight

of vinyl chloride, vinyl acetate, methyl

acrylate, ethyl acrylate, methyl methacrylate,

ethyl methacrylate, styrene and/or vinyl

toluene.

2. Ethylene glycol 2,2’-dicyanoacrylate.

-3. Polyethylene glycol 2,2’-dicyanoacrylate

containing 2 to 30 polyethylene glycol units

per molecule.

4. Neopentyl glycol 2,2’-dicyanoacrylate.

5. Compounds as claimed in claim 1 sub-

stantially as described with reference to any

of the Examples.

6. An adhesive composition comprising 1

part by weight of a compound or compounds

as claimed in any of the preceding claims in

Z to 10 parts by weight of a volatile,

chemically inert solvent.

ELKINGTON & FIFE,

Chartered Patent Agents,

High Holbom House, 52-54, High Holbom,

London, W.C.1,

Agents for the Applicants.

Leamington Spa: Printed for Her Majesty's Stationery Office, by the Courier Press

(Leamington) Ltd.—1966. Published by The Patent Ofi'ice, 25 Southampton Buildings,

London, W.C.2, from which copies may be obtained.

...u

35

40

45

50

55

70

75

Coments go here:

- Log in to post comments