Carbonates carrying cyclic carbonate groups

Carbonates carrying cyclic carbonate groups

US4423235

Year:

Abstract:

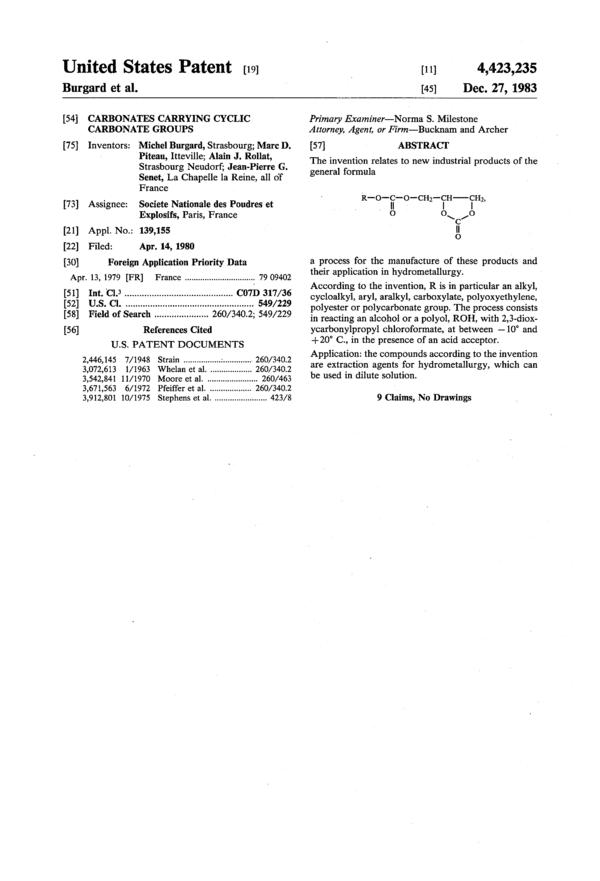

The invention relates to new industrial products of the general formula ##STR1## a process for the manufacture of these products and their application in hydrometallurgy.

Type of document:

Language:

United States Patent [19]

Burgard et al.

[54] CARBONATES CARRYING CYCLIC

CARBONATE GROUPS

Michel Burgard, Strasbourg; Marc D.

Piteau, Itteville; Alain J. Rollat,

Strasbourg Neudorf; Jean-Pierre G.

Senet, La Chapelle la Reine, all of

France

Societe Nationale des Poudres et

Explosifs, Paris, France

[21] Appl. No.: 139,155

[75] Inventors:

[73] Assignee:

[22] Filed: Apr. 14, 1980

[30] Foreign Application Priority Data

Apr. 13, 1979 [FR] France .............................. .. 79 09402

[51] Int. Cl.3 .......................................... .. C07D 317/36

[52] U.S. Cl. .................................... .. 549/229

[58] Field of Search .................... .. 260/340.2; 549/229

[56] References Cited

U.S. PATENT DOCUMENTS

2,446,145 7/1948 Strain ................ .; ........... .. 260/340.2

3,072,613 1/1963 Whelan et al. . .. 260/ 340.2

3,542,841 11/1970 Moore et al. 260/463

3,671,563 6/1972 Pfeiffer et al. .. .. 260/ 340.2

3,912,801 10/1975 Stephens et al. ...................... .. 423/8

[11] 4,423,235

[45] Dec. 27, 1983

Primary Examiner—Norma S. Milestone

Attorney, Agent, or Firm—Bucknam and Archer

[57] ABSTRACT

The invention relates to new industrial products of the

general formula

R—o—fi:—o—cH2—$H——$H2,

‘o o o

a process for the manufacture of these products and

their application in hydrometallurgy.

According to the invention, R is in particular an alkyl,

cycloalkyl, aryl, aralkyl, carboxylate, polyoxyethylene,

polyester or polycarbonate group. The process consists

in reacting an alcohol or a polyol, ROH, with 2,3-diox-

ycarbonylpropyl chloroformate, at between — 10° and

+20° C., in the presence of an acid acceptor.

Application: the compounds according to the invention

are extraction agents for hydrometallurgy, which can

be used in dilute solution.

9 Claims, No Drawings

4,423,235

1

CARBONATES CARRYING CY CLIC CARBONATE

GROUPS

The present invention relates to compounds carrying

cyclic carbonate groups, to the processes for the manu-

facture of these compounds and to their application in-

hydrometallurgy.

It is known from U.S. Pat. No. 2,446,145 to prepare

2,3-dioxycarbonylpropyl chloroforniate by reacting

phosgene with glycerol. It is also known, from the same

document, to obtain the carbamate and corresponding

urethanes by reacting this chloroformate with ammonia

or amines.

Furthermore, the value of certain organic substances

having the ability wholly or partially to extract metal

ions present in aqueous solutions is known. Such ore-

leaching solutions, from solutions resulting from attack

on recycled scrap metals or, alternatively, from indus-

trial effluents which are harmful to the environment.

Basically, these organic substances, which are re-

ferred to as extraction agents, must be capable not only

of more or less selectively extracting metal ions from

aqueous solutions, but also of returning them to a new,

pure and more concentrated aqueous solution which is

then treated in a manner which is in itself known.

However, in order to enable all the advantages pecu-

liar to hydrometallurgical techniques to be derived

from the extraction agents (versatility, production of

metals of high purity, automation, continuous operation

and, in particular, utilisation of the ores or waste), the

said extraction agents must also possess a number of

other properties, namely low solubility in the aqueous

phases (a cause of loss), low volatility (also a cause of

loss), stability (a further cause of loss), good solubility in

inexpensive organic media, good reversibility, high

extraction rate, selectivity (in the case of complex solu-

tions), high extraction capacity, high coefficient of ex-

traction, good resistance to recycling, low or zero tox-

icity and low or zero corrosive character.

In an article appearing in the review HYDRO-

METALLURGY in l976, Volume 1, pages 207-240,

and entitled “Solvent Extraction of Non-ferrous met-

als”, D. S. FLETT and D. R. SPINK focus on the main

extraction agents known and give their spectrum of

activity and their conditions of use in each case. A

distinction is thus made between solvating, acid, chelat-

ing and ionic extraction agents. The solvating extrac-

tion agents include phosphates, such as tributyl phos-

phate (TBP), ketones, such as methyl isobutyl ketone

(or MIBK) or isophorone (U .S. Pat. No. 4,008,308), and

ethers, such as glycol dibutyl ether (BUTEX). The acid

extraction agents’ include naphthenic and versatic acids

and, in particular, di-(2—ethylhexyl)—phosphoric acid (or

DZEHPA) (for example U.S. Pat. No. 3,989,607 and

French Pat. Nos. 2,342,346 and 2,367,832). The chelat-

ing extraction agents essentially include a-hydroxyox-

imes (commercially known under the name LIX),

which are described in U.S. Pat. Nos. 3,224,873 and

3,449,066. Finally, the ionic extraction agents mainly

include amines and quaternary ammonium salts, such as

those described in French Pat. No. 1,266,363.

The invention itself relates to new chemical com-

pounds which, in their application as extraction agents,

do not resemble any known type and thereby have a

particular spectrum of application, which is suitable for

providing solutions to general or specific problems in

the field of extraction.

10

15

20

25

30

35

40

45

50

55

60

65

2

The carbonates carrying cyclic carbonate groups,

according to the invention, have the general formula:

R-0--C--O—CH;_-CH——CH2 (A)

II I I

0

in which R is a linear or branched alkyl group which

contains from 1 to 20 carbon atoms and is optionally

substituted by one to three groups

—OCOO-CI-12"‘ CH— CH2,

I I

o—co——o

an alicyclic group which contains 4 to 20 carbon atoms

and is optionally substituted by one to three groups

——0—c—o—cH2-—cH—cH2,

II I I

0

an aralkyl group which contains from 7 to 20 carbon

atoms and is optionally substituted by one to three

groups

—o—c—o—cH2—cH——'-CH2,

II I I

o

a carboxylate group which contains from 2 to 20 carbon

atoms and is optionallysubstituted by a group

—O—C-0-CH2—CI-I-—CH2,

II — I I

o

a polyoxyethylene of the formula

R'—O—CH7_—CI-12),,

in which n is between 1 and 40 and in which R’ is a

hydrocarbon group containing from 1 to 10 carbon

atoms and optionally carries one or two chains

~—O—CH2——CH2),,', in which n’ is between 1 and 40,

which chains are terminated by a group

—o—c—o—cH;—cH—cH2,

II I I

o

a polyoxypropylene of the formula

R’-(-O-'CH2—?H-)5,

CH3

4,423,235

3

in which p is between 1 and 40 and in which R’ is a

hydrocarbon group containing from 1 to 10 carbon

atoms and optionally carries one or two chains

'—('0—CH2-C_—_O (chloroformate) at 1,780 30

cm*1 and v>%O (cyclic carbonate) at 1,800 cm—1

EXAMPLE 2

Preparation of 2,3-Dioxycarbonylpropyl n-Octyl

Carbonate

346 g (1.9 mols) of the chloroformate prepared above,

247 g (1.9 mols) of n-octanol and 600 ml of methylene

20

25

35

8

NMR spectrum agrees with the formula.

It should be noted that more volatile or less volatile 1

alkyl carbonates can be synthesised with the same ease;

under the same conditions and with a comparable suc-

cess to that which has just been reported.

EXAMPLE 3

Synthesis of trimethylolpropane tri-(-2,3-dioxycar-

bonylpropyl carbonate). .

93.8 g (0.7 mol) of trimethylolpropane, 400 cm3 of

acetone and 183 g (2.31 mols) of pyridine are introduced

into a 2 liter reactor. The temperature is kept at about 0°

C. and a solution of 417 g (2.31 mols) of 2,3-dioxycar-

bonylpropyl chloroformate in 400 cm3 of acetone is

added. After stirring for two hours at ambient tempera-

ture, the reaction mixture is filtered, the filtrate is con-

centrated under reduced pressure, the residue is taken

up in 1.5 liters of methylene chloride and the solution is

washed with acidified water and then with pure water.

The organic solution is dried, filtered and concentrated

under reduced pressure. 347 g (yield 88%) of trimethyl-

olpropane tri-(2,3-dioxycarbonylpropyl carbonate) are

thus obtained.

Melting point: 120° C. Residual OH level: 0%

Infra-red spectrum:

v E (linear carbonate): 1,750 cm'‘1

0

v OIIIJ (cyclic carbonate): 1,800 cm‘1

0

This spectrum is in total agreement with theory.

EXAMPLE 4

Synthesis of tetraethylene glycol di-(2,3-dioxycar-

bonylpropyl carbonate).

CH2-— CH— CH2'—O-C’-O-('CH2'— CH2--O')2;-C-0-' CH2-' CH——CH2

! I

o

chloride are introduced into a reactor equipped with a

reflux condenser, a thermometer, a stirrer and a drop-

ping funnel.

152 g (2.2 mols) of pyridine (that is to say a molar

excess of 15%) are run in over a period of about 1 hour,

whilst keeping the temperature between —5° and 5° C.

The mixture is stirred for 1 hour at 0° C. and is then

left to return to ambient temperature in the course of

about 2 hours.

The pyridine hydrochloride is removed by filtration 55

and the organic phase is washed with twice 500 ml of

water. ‘ '

After drying over magnesium sulphate and removing

the solvent by evaporation under reduced pressure, the

product is topped at 100° C. under a pressure of 1 mm

Hg for 30 minutes.

460 g of a colourless oil, which crystallises at ambient

temperature, are thus obtained. The yield is 88% rela-

tive to the chloroformate.

Analyses:

Infra-red spectrum: absorption bands

vC-:0 (linear carbonate) at 1,740 cm—1 and

vC=O (cyclic carbonate) at 1,800 cm-1

50

60

65

O\ /O

C

II

0

II II

0 0

2.888 kg (16 mols) of 2,3-dioxycarbonylpropyl chlo-

roformate and 5 liters of anhydrous methylene chloride

are introduced into a 20 liter glass reactor.

The temperature is kept between -4“ and +2° C.

and a mixture of 1.552 kg (8 mols) of tetraethylene

glycol, 1.430 kg (18.1 mols) of pyridine (that is to say an

excess of 13% relative to stoichiometry) and 1 liter of

anhydrous methylene chloride is run in slowly, whilst

stirring.

After the introduction, which takes 1 hour 45 min-

utes, the reaction mixture is heated to between +15°

and + 18° C. and this temperature is maintained for one

hour.

7 liters of salt water are added and the organic phase

is separated off. The latter is washed three times with a

mixture of 7 liters of salt water and 500 ml of concen-

trated hydrochloric acid, twice with 7 liters of salt

water and once with 7 liters of demineralised water.

The organic phase is dried over anhydrous sodium

sulphate and the solvent is removed by evaporation

under reduced pressure at 50° C. '

4,423,235

9 10

3.225 kg (yield 83.6%) of a very viscous product are

thus collected, the main characteristics of this product EXAMPLE 6

being as follows: Synthesis of poly—[(diethy1ene glycol) carbonate]

water content: 0.040% di-(2,3-dioxycarbonylpropyl carbonate)

cH2—CH-cH;o—c—o—(-CH2-—CH2-o—cH1—cH2—o-c—oa-,;—cH2——cH———cH2

I I II II I I

o 0 o o 0 o

\ C / \C./

‘ II II

0 O

m = 10

content of residual OH groups §10—2 eq/kg The procedure used is strictly identical to the above

Tetraethylene glycol di—(2,3-dioxycarbonylpropyl procedure (Example 5), using 410 g (0.33 mol) of poly-

carbonate) 15 (diethylene glycol carbonate), 58 g (0.73 mol) of pyri-

Cill-lz—-'CH"'CH2— O—C—O'f'CH2— CI-12- O‘)trC-" 0- CH2—(|3HjC|IH2

II II

o\ /o 0 o o\ /o

C

II ' II

0

Viscous liquid, slightly amber—coloured, possessing a dine (that is to say an excess of 10% relative to stoichi-

slight odour: 25 ometry), 600 ml of anhydrous methylene chloride and

Melting point: 14° C. (transition point) 132 g (0.73 mol) of 2,3-dioxycarbonylpropyl chlorofor-

Vapour pressure mate.

at 20° C.: 5 mm Hg . 435 g of product are thus collected, the infra-red

at 100° C.: 22 mm Hg spectrum of this product agrees with the formula given

Density d2525: 1.41 30 above and its number—average molecular weight is

Viscosity at 25° C.: 60,000 cP about 1,500, its content of OH groups is less than or

Refractive index at 25° C., nD25: 1.4750 equal to 0.02 eq/kg and the total chlorine level is 0.06%.

Solubility: insoluble in water, good solubility in or-

ganic solvents (60 g in 100 g of CH2C12 at 20° c.) EXAMPLE 7

Synthesis of 2,3-dioxycarbonylpropyl (ethyl

35

EXAMPLE 5 methacrylate) carbonate

Synthesis of poly-(ethy1eneglycol)di-(2,3-dioxycar-

bonylpropyl carbonate) 11.4 g (0.1 mol) of 2-hydroxyethyl methacrylate, 9 g

(0.11 mol) of pyridine and 50 ml of 2,3-dioxycarbonyyl-

Coments go here:

- Log in to post comments