Microwave-Assisted Cu-Catalyzed Protodecarboxylation of Aromatic Carboxylic Acids

Microwave-Assisted Cu-Catalyzed Protodecarboxylation of Aromatic Carboxylic Acids

Journal:

Year:

Abstract:

An effective protocol has been developed that allows the smooth protodecarboxylation of diversely functionalized aromatic carboxylic acids within 5−15 min. In the presence of at most 5 mol % of an inexpensive catalyst generated in situ from copper(I) oxide and 1,10-phenanthroline, even nonactivated benzoates were converted in high yields and with great preparative ease.

DOI:

10.1021/jo802628z

Type of document:

Language:

Microwave-Assisted Cu-Catalyzed

Protodecarboxylation of Aromatic Carboxylic

Acids

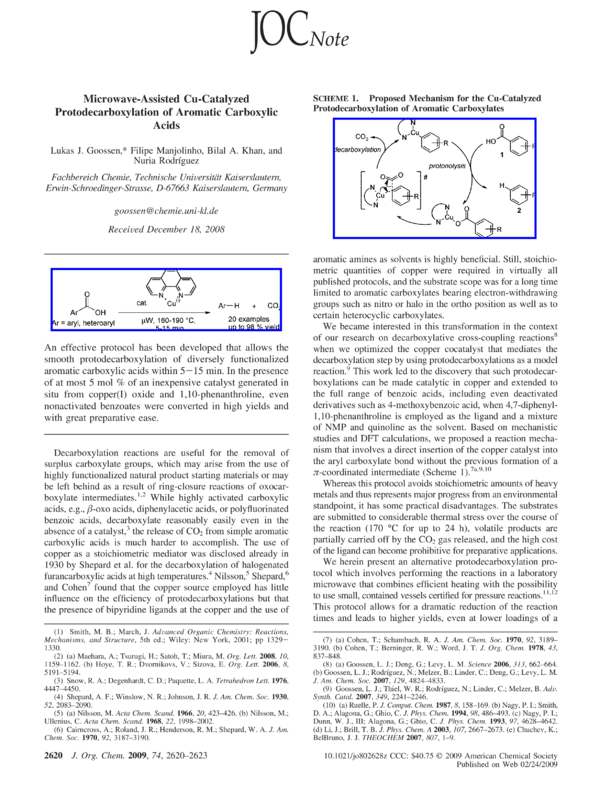

SCHEME 1. Proposed Mechanism for the Cu-Catalyzed

Protodecarboxylation of Aromatic Carboxylates

Lukas J. Goossen,* Filipe Manjolinho, Bilal A. Khan, and

Nuria Rodrıguez

´

Fachbereich Chemie, Technische UniVersitat Kaiserslautern,

¨

Erwin-Schroedinger-Strasse, D-67663 Kaiserslautern, Germany

goossen@chemie.uni-kl.de

ReceiVed December 18, 2008

An effective protocol has been developed that allows the

smooth protodecarboxylation of diversely functionalized

aromatic carboxylic acids within 5-15 min. In the presence

of at most 5 mol % of an inexpensive catalyst generated in

situ from copper(I) oxide and 1,10-phenanthroline, even

nonactivated benzoates were converted in high yields and

with great preparative ease.

Decarboxylation reactions are useful for the removal of

surplus carboxylate groups, which may arise from the use of

highly functionalized natural product starting materials or may

be left behind as a result of ring-closure reactions of oxocarboxylate intermediates.1,2 While highly activated carboxylic

acids, e.g., -oxo acids, diphenylacetic acids, or polyfluorinated

benzoic acids, decarboxylate reasonably easily even in the

absence of a catalyst,3 the release of CO2 from simple aromatic

carboxylic acids is much harder to accomplish. The use of

copper as a stoichiometric mediator was disclosed already in

1930 by Shepard et al. for the decarboxylation of halogenated

furancarboxylic acids at high temperatures.4 Nilsson,5 Shepard,6

and Cohen7 found that the copper source employed has little

influence on the efficiency of protodecarboxylations but that

the presence of bipyridine ligands at the copper and the use of

(1) Smith, M. B.; March, J. AdVanced Organic Chemistry: Reactions,

Mechanisms, and Structure, 5th ed.; Wiley: New York, 2001; pp 13291330.

(2) (a) Maehara, A.; Tsurugi, H.; Satoh, T.; Miura, M. Org. Lett. 2008, 10,

1159–1162. (b) Hoye, T. R.; Dvornikovs, V.; Sizova, E. Org. Lett. 2006, 8,

5191–5194.

(3) Snow, R. A.; Degenhardt, C. D.; Paquette, L. A. Tetrahedron Lett. 1976,

4447–4450.

(4) Shepard, A. F.; Winslow, N. R.; Johnson, J. R. J. Am. Chem. Soc. 1930,

52, 2083–2090.

(5) (a) Nilsson, M. Acta Chem. Scand. 1966, 20, 423–426. (b) Nilsson, M.;

Ullenius, C. Acta Chem. Scand. 1968, 22, 1998–2002.

(6) Cairncross, A.; Roland, J. R.; Henderson, R. M.; Shepard, W. A. J. Am.

Chem. Soc. 1970, 92, 3187–3190.

2620 J. Org. Chem. 2009, 74, 2620–2623

aromatic amines as solvents is highly beneficial. Still, stoichiometric quantities of copper were required in virtually all

published protocols, and the substrate scope was for a long time

limited to aromatic carboxylates bearing electron-withdrawing

groups such as nitro or halo in the ortho position as well as to

certain heterocyclic carboxylates.

We became interested in this transformation in the context

of our research on decarboxylative cross-coupling reactions8

when we optimized the copper cocatalyst that mediates the

decarboxylation step by using protodecarboxylations as a model

reaction.9 This work led to the discovery that such protodecarboxylations can be made catalytic in copper and extended to

the full range of benzoic acids, including even deactivated

derivatives such as 4-methoxybenzoic acid, when 4,7-diphenyl1,10-phenanthroline is employed as the ligand and a mixture

of NMP and quinoline as the solvent. Based on mechanistic

studies and DFT calculations, we proposed a reaction mechanism that involves a direct insertion of the copper catalyst into

the aryl carboxylate bond without the previous formation of a

π-coordinated intermediate (Scheme 1).7a,9,10

Whereas this protocol avoids stoichiometric amounts of heavy

metals and thus represents major progress from an environmental

standpoint, it has some practical disadvantages. The substrates

are submitted to considerable thermal stress over the course of

the reaction (170 °C for up to 24 h), volatile products are

partially carried off by the CO2 gas released, and the high cost

of the ligand can become prohibitive for preparative applications.

We herein present an alternative protodecarboxylation protocol which involves performing the reactions in a laboratory

microwave that combines efficient heating with the possibility

to use small, contained vessels certified for pressure reactions.11,12

This protocol allows for a dramatic reduction of the reaction

times and leads to higher yields, even at lower loadings of a

(7) (a) Cohen, T.; Schambach, R. A. J. Am. Chem. Soc. 1970, 92, 3189–

3190. (b) Cohen, T.; Berninger, R. W.; Word, J. T. J. Org. Chem. 1978, 43,

837–848.

(8) (a) Goossen, L. J.; Deng, G.; Levy, L. M. Science 2006, 313, 662–664.

(b) Goossen, L. J.; Rodrıguez, N.; Melzer, B.; Linder, C.; Deng, G.; Levy, L. M.

´

J. Am. Chem. Soc. 2007, 129, 4824–4833.

(9) Goossen, L. J.; Thiel, W. R.; Rodrıguez, N.; Linder, C.; Melzer, B. AdV.

´

Synth. Catal. 2007, 349, 2241–2246.

(10) (a) Ruelle, P. J. Comput. Chem. 1987, 8, 158–169. (b) Nagy, P. I.; Smith,

D. A.; Alagona, G.; Ghio, C. J. Phys. Chem. 1994, 98, 486–493. (c) Nagy, P. I.;

Dunn, W. J., III; Alagona, G.; Ghio, C. J. Phys. Chem. 1993, 97, 4628–4642.

(d) Li, J.; Brill, T. B. J. Phys. Chem. A 2003, 107, 2667–2673. (e) Chuchev, K.;

BelBruno, J. J. THEOCHEM 2007, 807, 1–9.

10.1021/jo802628z CCC: $40.75 2009 American Chemical Society

Published on Web 02/24/2009

Optimization of the Catalyst Systema

TABLE 1.

no.

substrate

Cu source

ligand

solvent

T (°C)

2 (%)

1b

2b

3b

4b

5b,c

6

7

8b

9b

10b

11b

12b

13b,d

14b

15b

16b

17b

18b

19b

20b

21b

22b

23b

24b,e

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1a

1b

1b

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

CuOAc

CuBr

CuBr

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

Cu2O

3a

3a

3a

3a

3a

3a

3a

3a

3a

3a

3a

3a

3a

3b

3c

3d

4a

4b

5a

5b

6a

6b

3a

3a

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP

quinoline

mesit/quin

DMF/quin

DMSO/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

NMP/quin

170

180

190

200

190

190

190

190

190

190

190

190

190

190

190

190

190

190

190

190

190

190

160

160

9

6

43

17

88

32

18

9

26

0

27

0

15

97

24

10

20

21

7

13

7

5

98

95

a

Reaction conditions: 1.0 mmol of carboxylic acid, 10 mol % of Cu

source (5 mol % for Cu2O), 10 mol % of ligand, 2 mL of degassed

solvent, 5 min, 190 °C/150 W. Conversions were determined by GC

analysis using n-tetradecane as the internal standard; quin ) quinoline,

mesit ) mesitylene. b 3:1 mixture of solvents. c 15 min. d 15 mol % of

K2CO3. e 1 mol % of Cu2O, 2 mol % of 1,10-phenanthroline.

less expensive catalyst. The loss of volatile products is avoided,

as the release of CO2 gas can be delayed until the end of the

reaction, after the reaction mixture has reached room temperature.

We based the search for a microwave-assisted decarboxylation

protocol on 4-methoxybenzoic acid (1a) as a test substrate

because this electron-rich benzoic acid is of particularly low

reactivity. In thermal decarboxylations, it gave only 82% yield

after 24 h at 170 °C in the presence of 10 mol % of a customized

copper(I)/4,7-diphenyl-1,10-phenanthroline complex and an

unsatisfactory 35% yield with simple 1,10-phenanthroline.9

In contrast, when 1a was heated in the presence of only 5

mol % of a copper(I) oxide/1,10-phenanthroline catalyst in a

mixture of NMP and quinoline at 170 °C using a maximum of

150 W microwave irradiation, traces of product were detected

after only 5 min (Table 1, entry 1). Increases in the reaction

temperature resulted in a steady improvement of the yields until

a turnaround point was reached at 190 °C, above which the

yield dropped again (entries 3 and 4). Further test reactions

performed at this temperature but at incomplete conversion (5

min) revealed that the protodecarboxylation is very sensitive

(11) For recent reviews, see: (a) Appukkuttan, P.; Van der Eycken, E. Eur.

J. Org. Chem. 2008, 113, 3–1155. (b) Kappe, C. O. Angew. Chem. 2004, 116,

6408–6443; Angew. Chem., Int. Ed. 2004, 43, 6250-6284. (c) Larhed, M.;

Moberg, C.; Hallberg, A. Acc. Chem. Res. 2002, 35, 717–727.

(12) For related microwave-accelerated reactions, see: (a) Forgione, P.;

Brochu, M. C.; St-Onge, M.; Thesen, K. H.; Bailey, M. D.; Bilodeau, F. J. Am.

Chem. Soc. 2006, 128, 11350–11351. (b) Voutchkova, A.; Coplin, A.; Leadbeater,

N. E.; Crabtree, R. H. Chem. Commun. 2008, 6312–6314.

FIGURE 1. Cu ligands evaluated in the protodecarboxylation reaction.

to the solvent employed. Best results were obtained with a 3:1

mixture of NMP and quinoline, which was superior to either

solvent alone or any other solvent combination tested (entries

3 and 6-10). The chosen solvent mixture strongly absorbs

microwave radiation, causing a rapid increase in temperature

and pressure during the first few seconds. Copper(I) oxide

proved to be the copper source of choice, other copper(I) or

copper(II) salts were less effective (entries 11-13).

When extending the reaction time to 15 min at optimum

reaction conditions, the yields could finally be improved up to

an excellent 88% when using simple 1,10-phenanthroline (entry

5). Again, we found 4,7-diphenyl-1,10-phenanthroline to be even

more effective, leading to almost quantitative formation of

anisole (2a) after only 5 min (entry 14). Besides phenanthrolines,

other ligands (Figure 1) can also be employed, but none of them

was of similar effectiveness to the phenanthrolines (entries

14-22).

A second test reaction with 2-nitrobenzoic acid (1b) revealed

that for such highly reactive substrates the decarboxylation

proceeds in high yields even when the reaction temperature is

reduced to 160 °C and the catalyst loading to 2 mol % (entries

23 and 24).

Encouraged by the results obtained with these two rather

extreme model substrates, we set out to systematically explore

the generality of the catalytic protocol using various aromatic

and heteroaromatic carboxylic acids. Due to its easy availability

and low price, we used Cu2O/1,10-phenanthroline as the catalyst.

We were pleased to find that even with this simple system, all

substrates tested smoothly decarboxylated within 5-15 min.

Usually, the yields were significantly in excess of those obtained

after 16-24 h of conventional heating using the expensive 4,7diphenyl-1,10-phenanthroline ligand. Selected results are summarized in Table 2.

The reactions are very easy to perform by irradiating a

suspension of the carboxylic acid (1a-t), Cu2O, and 1,10phenanthroline in NMP/quinoline (3:1) at 190 °C for 5-15 min

under inert conditions in a sealed crimp-top glass tube. After

air-jet cooling, the pressure is carefully released, and the product

is isolated by simple aqueous workup and removal of the

solvents by fractional distillation. The conditions are sufficiently

mild to be tolerated by a number of functionalities including

ether, ester, formyl, nitro, cyano, and hydroxyl groups. The

selectivity is high throughout, with at most traces of side

products arising from homocoupling or substitution reactions.

Lower yields were due only to incomplete conversion. All

J. Org. Chem. Vol. 74, No. 6, 2009 2621

TABLE 2.

Scope of the Transformationa

Ar-COOH

1a

1b

1c

1d

1e

1f

1g

1h

1i

1j

1k

1l

1m

1n

1o

1p

1q

1r

1s

1t

method

Ar-H

yield (GC) (%)

4-MeO-C6H4-COOH

2-NO2-C6H4-COOH

4-NO2-C6H4-COOH

4-CN-C6H4-COOH

4-CHO-C6H4-COOH

4-MeC(O)-C6H4-COOH

4-Et-C6H4-COOH

4-CF3-C6H4-COOH

4-Cl-C6H4-COOH

4-HO-C6H4-COOH

3-Me-C6H4-COOH

3-NO2-C6H4-COOH

2-PhNH-C6H4-COOH

2-MeC(O)-C6H4-COOH

2-MeS(O)2-C6H4-COOH

2-iPrOC(O)-C6H4-COOH

2-thienyl-COOH

2-furyl-COOH

1-naphthyl-COOH

2-NO2-5-Me-C6H3-COOH

A

B

A

A

A

A

A

A

A

A

A

B

B

B

B

B

Bc

Bc

B

B

2a

2b

2b

2c

2d

2e

2f

2g

2h

2i

2b

2j

2k

2e

2l

2m

2n

2o

2p

2q

77 (88)

85 (98)

86b (94)

81 (89)

64 (77)

79 (87)

(80)

(22)

(90)

(64)

(96)

(99)

63 (88)

84 (91)

70 (82)

85 (94)

(62)

(99)

38 (56)

80 (94)

a

Reaction conditions. Method A: 1.0 mmol of carboxylic acid, 5 mol

% of Cu2O, 10 mol % of 1,10-phenanthroline, 1.5 mL of NMP, 0.5 mL

of quinoline, 190 °C, 150 W, 15 min; isolated yields. Method B: 1.0

mmol of carboxylic acid, 1 mol % of Cu2O, 2 mol % of

1,10-phenanthroline, 1.50 mL of NMP, 0.50 mL of quinoline, 190 °C,

150 W, 5 min; isolated yields. GC yields were determined using

n-tetradecane as the internal standard and calibrated for each product. b a

yield of 80% was isolated on 3 mmol scale c 160 °C.

reactions were performed on a 1 mmol scale in 10 mL vessels.

When using these standard microwave vials, the reactions can

be scaled up to a maximum of 3 mmol with comparable yields

as shown for compound 2b. Larger scales should also be

possible but require additional equipment.

In conclusion, an efficient microwave-based protocol has been

developed for Cu-catalyzed decarboxylations of arenecarboxylates. It is ideally suited for the demands of parallel synthesis

as commonly used, for example, in drug discovery. Because

test reactions can now be completed within a few minutes rather

than an entire day, it will also serve to expedite the development

of more effective catalyst systems.

Experimental Section

Protodecarboxylation of Aromatic Carboxylic Acids.

Method A (Table 2). An oven-dried 10 mL microwave vial was

charged with the carboxylic acid (1a,c-k) (1.0 mmol), Cu2O (7.2

mg, 0.05 mmol), and 1,10-phenanthroline (18 mg, 0.10 mmol).

After the reaction mixture was made inert, a mixture of NMP (1.5

mL) and quinoline (0.5 mL) was added via syringe. The resulting

mixture was submitted to microwave irradiation at 190 °C for 15

min at a maximum power of 150 W and subsequently air-jet cooled

to room temperature. The maximum pressure detected during the

reaction was 5.5 bar. The mixture was then diluted with aqueous

HCl (5N, 10 mL) and extracted repeatedly with diethyl ether (2

mL portions). The combined organic layers were washed with water

and brine, dried over MgSO4, and filtered. The corresponding arene

2 was obtained in pure form after removal of the solvents by

distillation over a Vigreux column.

Method B (Table 2). Method B is analogous to method A but

with a lower loading of the copper/phenanthroline catalyst and

microwave irradiation at 190 °C for 5 min at a maximum power of

150 W. The following amounts were used: carboxylic acid (1b,

2622 J. Org. Chem. Vol. 74, No. 6, 2009

l-t) (1.0 mmol), Cu2O (1.5 mg, 0.01 mmol), and 1,10-phenanthroline (3.6 mg, 0.02 mmol).

Anisole (2a). Synthesized from 4-methoxybenzoic acid (1a) (152

mg, 1.00 mmol) following method A and obtained as a colorless

liquid (84 mg, 77%). The spectroscopic data (NMR, GC-MS)

matched those reported in the literature [CAS no. 100-66-3].

Nitrobenzene (2b). Synthesized from 2-nitrobenzoic acid (1b)

(167 mg, 1.00 mmol) following method B (105 mg, 85%), from

3-nitrobenzoic acid (1l) (167 mg, 1.00 mmol) following method B

(107 mg, 87%), and from 4-nitrobenzoic acid (1c) (167 mg, 1.00

mmol) following method A (105 mg, 86%), obtained each time as

a yellow liquid. The spectroscopic data (NMR, GC-MS) all

matched those reported in the literature [CAS no. 98-95-3]. A larger

scale reaction starting from 4-nitrobenzoic acid (1c) (501 mg, 3

mmol) in 6 mL of NMP gave 2b in 80% yield (293 mg).

Benzonitrile (2c). Synthesized from 4-cyanobenzoic acid (1d)

(147 mg, 1.00 mmol) following method A and obtained as a

colorless liquid (84 mg, 81%). The spectroscopic data (NMR,

GC-MS) matched those reported in the literature [CAS no. 10047-0].

Benzaldehyde (2d). Synthesized from 4-formylbenzoic acid (1e)

(150 mg, 1.00 mmol) following method A and obtained as a yellow

liquid (68 mg, 64%). The spectroscopic data (NMR, GC-MS)

matched those reported in the literature [CAS no. 100-52-7].

Acetophenone (2e). Synthesized from 4-acetylbenzoic acid (1f)

(164 mg, 1.00 mmol) following method A (95 mg, 79%) and from

2-acetylbenzoic acid (1n) (164 mg, 1.00 mmol) following method

B (101 mg, 84%), both times obtained as a yellow liquid. The

spectroscopic data (NMR, GC-MS) all matched those reported in

the literature [CAS no. 98-86-2].

Ethylbenzene (2f). Synthesized from 4-ethylbenzoic acid (1g)

(150 mg, 1.00 mmol) following method B. The identity of the

product 2f was confirmed by GC-MS and the yield determined

by quantitative GC to be 80% based on a response factor obtained

with commercial ethylbenzene [CAS no. 100-41-4] using ntetradecane (50 µL) as an internal gas chromatographic standard.

Trifluoromethylbenzene (2g). Synthesized from 4-(trifluoromethyl)benzoic acid (1h) (190 mg, 1.00 mmol) following method

B. The identity of the product 2g was confirmed by GC-MS and

the yield determined by quantitative GC to be 22%, based on a

response factor obtained with commercial trifluoromethylbenzene

[CAS no. 98-08-8] using n-tetradecane (50 µL) as an internal gas

chromatographic standard.

Chlorobenzene (2h). Synthesized from 4-chlorobenzoic acid (1i)

(156 mg, 1.00 mmol) following method A. The identity of the

product 2h was confirmed by GC-MS and the yield determined

by quantitative GC to be 90% based on a response factor obtained

with commercial chlorobenzene [CAS no. 108-90-7] using ntetradecane (50 µL) as an internal gas chromatographic standard.

Phenol (2i). Synthesized from 4-hydroxybenzoic acid (1j) (138

mg, 1.00 mmol) following method A. The identity of the product

2i was confirmed by GC-MS and the yield determined by

quantitative GC to be 64%, based on a response factor obtained

with commercial phenol [CAS no. 108-95-2] using n-tetradecane

(50 µL) as an internal gas chromatographic standard.

Toluene (2j). Synthesized from 3-methylbenzoic acid (1k) (136

mg, 1.00 mmol) following method A. The identity of the product

2j was confirmed by GC-MS and the yield determined by

quantitative GC to be 99%, based on a response factor obtained

with commercial toluene [CAS no. 108-88-3] using n-tetradecane

(50 µL) as an internal gas chromatographic standard.

Diphenylamine (2k). Synthesized from 2-(phenylamino)benzoic

acid (1m) (213 mg, 1.00 mmol) following method B and obtained

as a white solid (107 mg, 63%): mp 49-51 °C. The spectroscopic

data (NMR, GC-MS) matched those reported in the literature for

diphenylamine [CAS no. 122-39-4].

Methyl Phenyl Sulfone (2l). Synthesized from 2-(methylsulfonyl)benzoic acid (1o) (200 mg, 1.00 mmol) following method B

and obtained as a white solid (109 mg, 70%): mp. 85-87 °C. The

spectroscopic data (NMR, GC-MS) matched those reported in the

literature for methyl phenyl sulfone [CAS no. 3112-85-4].

Isopropyl Benzoate (2m). Synthesized from 2-(isopropyloxycarbonyl)benzoic acid (1p) (208 mg, 1.00 mmol) following method

B and obtained as a yellow liquid (139 mg, 85%). The spectroscopic

data (NMR, GC-MS) matched those reported in the literature for

isopropyl benzoate [CAS no. 939-48-0].

Thiophene (2n). Synthesized from thiophene-2-carboxylic acid

(1q) (128 mg, 1.00 mmol) following method B but at 160 °C

reaction temperature. The identity of the product 2n was confirmed

by GC-MS and the yield determined by quantitative GC to be

62%, based on a response factor obtained with commercial

thiophene [CAS no. 110-02-1] using n-tetradecane (50 µL) as an

internal gas chromatographic standard.

Furan (2o). Synthesized from furan-2-carboxylic acid (1r) (112

mg, 1.00 mmol) following method B but at 160 °C reaction

temperature. The identity of the product 2o was confirmed by

GC-MS and the yield determined by quantitative GC to be 99%

based on a response factor obtained with commercial furan [CAS

no. 110-00-9] using n-tetradecane (50 µL) as an internal gas

chromatographic standard.

Naphthalene (2p). Synthesized from 1-naphthoic acid (1s) (172

mg, 1.00 mmol) following method B and obtained as a white solid

(49 mg, 38%): mp.78-80 °C. The spectroscopic data (NMR,

GC-MS) matched those reported in the literature for naphthalene

[CAS no. 91-20-3].

4-Nitrotoluene (2q). Synthesized from 5-methyl-2-nitrobenzoic

acid (1t) (197 mg, 1.00 mmol) following method B and obtained

as a colorless liquid (109 mg, 80%). The spectroscopic data (NMR,

GC-MS) matched those reported in the literature for 4-nitrotoluene

[CAS no. 99-99-0].

Acknowledgment. We thank Prof. Jens Hartung for giving

us access to his microwave equipment. We also thank the DFG,

the Saltigo GmbH, and NanoKat for funding, Umicore AG for

the generous donation of catalysts, the A. v. Humboldt Foundation for a scholarship to N.R., and the HEC Pakistan for a

scholarship to B.A.K.

Supporting Information Available: NMR spectra for all

compounds. This material is available free of charge via the

Internet at http://pubs.acs.org.

JO802628Z

J. Org. Chem. Vol. 74, No. 6, 2009 2623

Coments go here:

- Log in to post comments